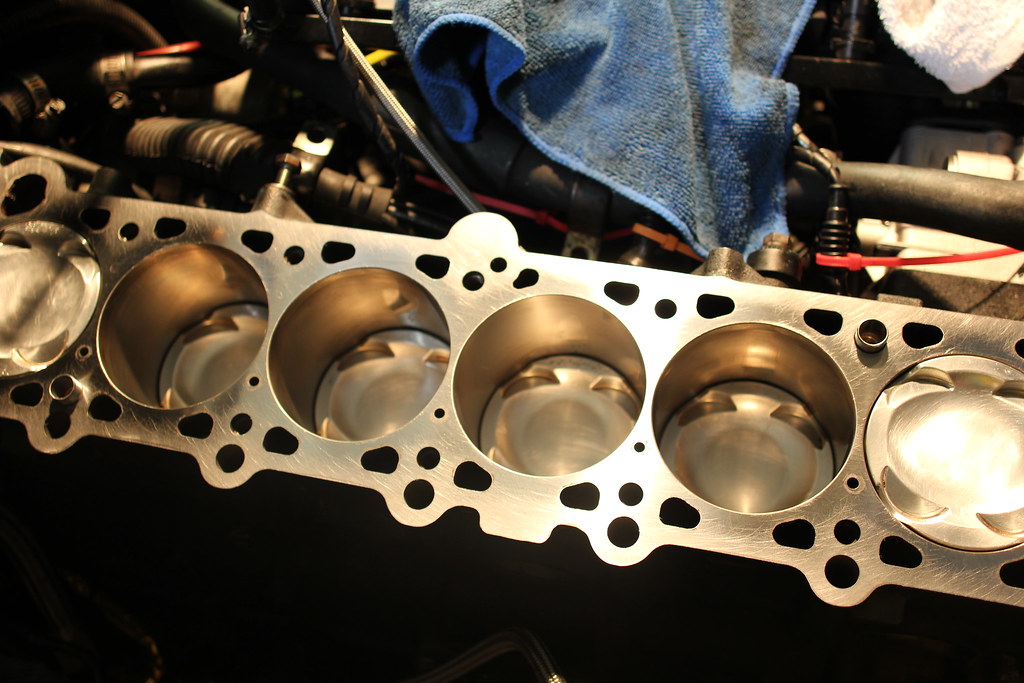

Ready for the strut tower!

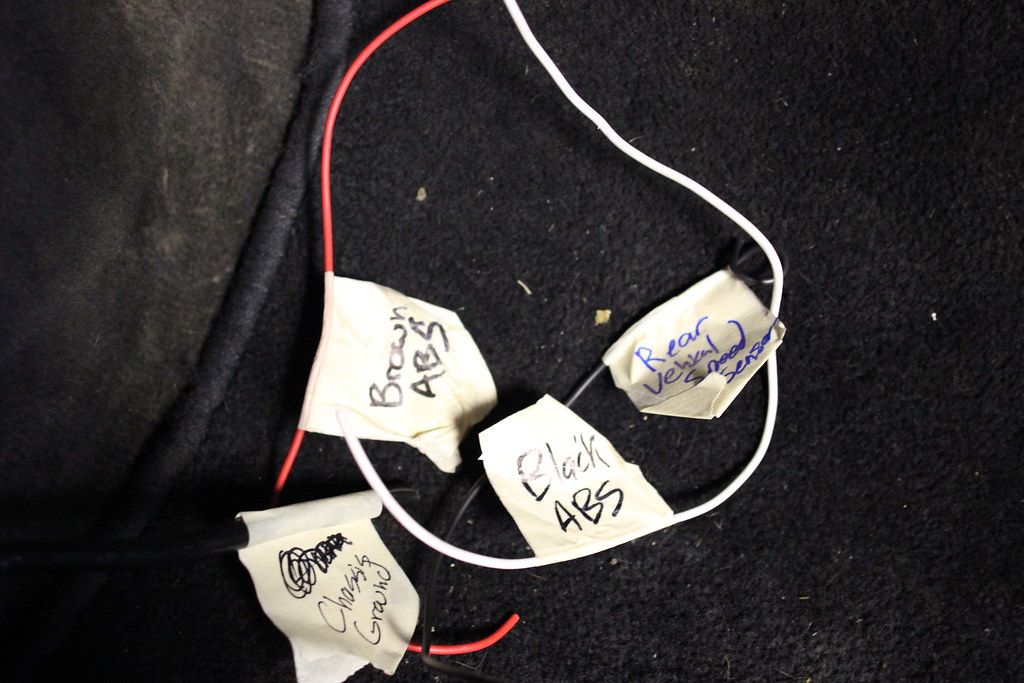

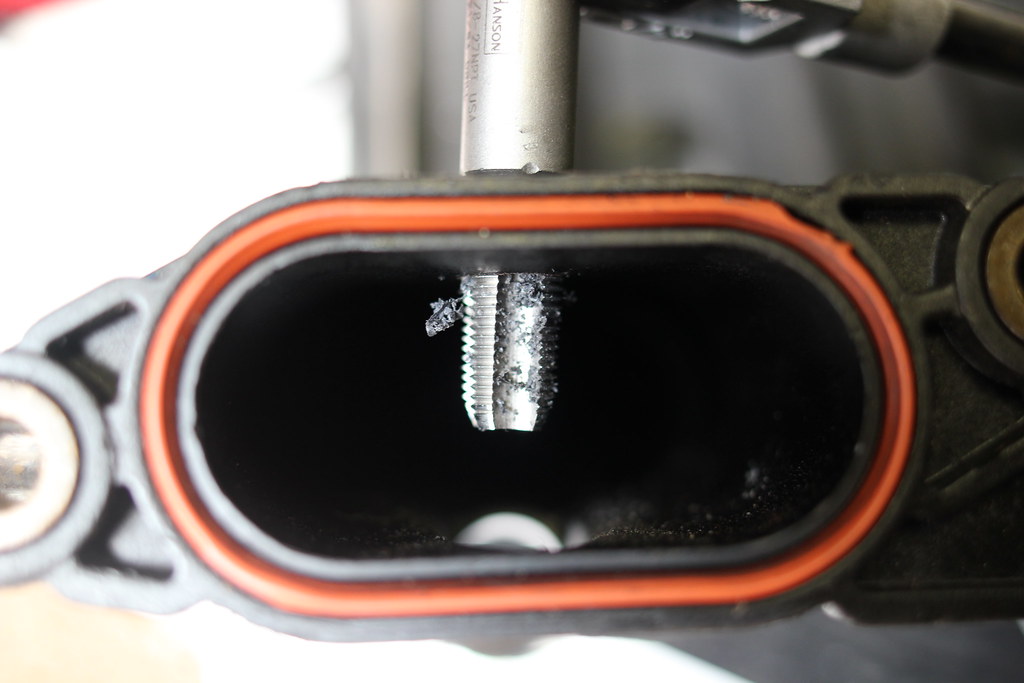

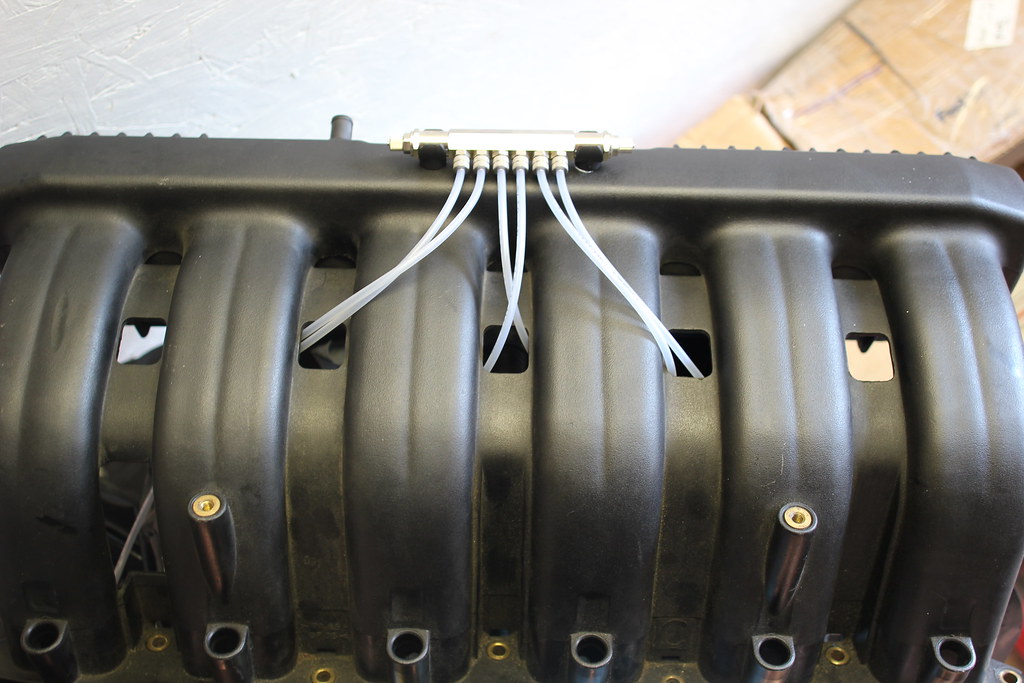

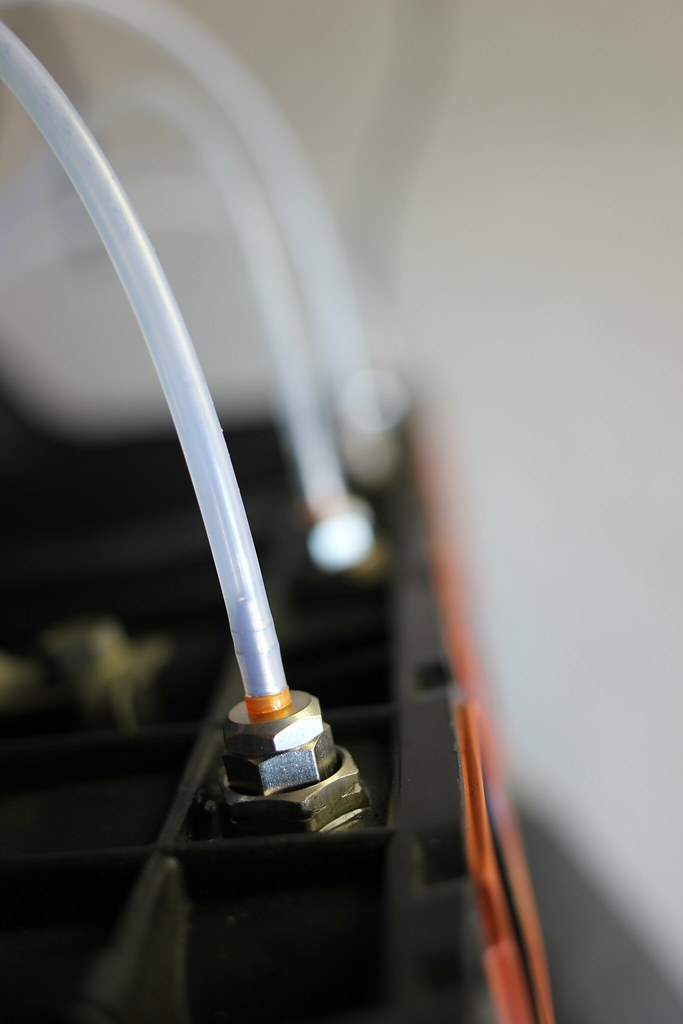

Getting ready for wiring up the traction control. The brown ABS wire is the ground for the sensor??

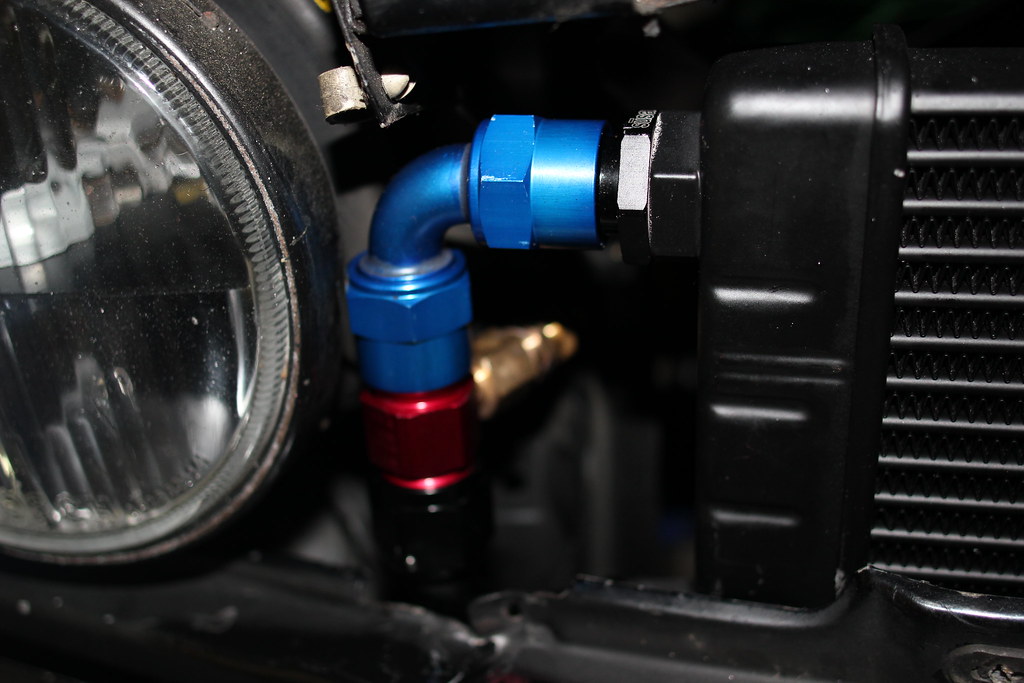

Don't mind the bent valance.

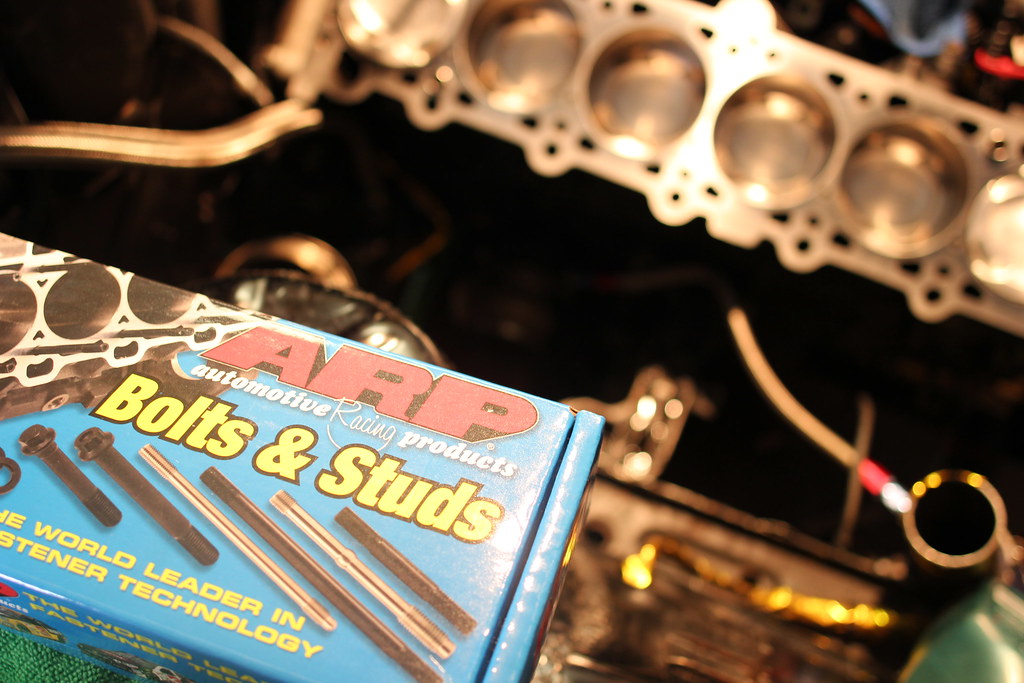

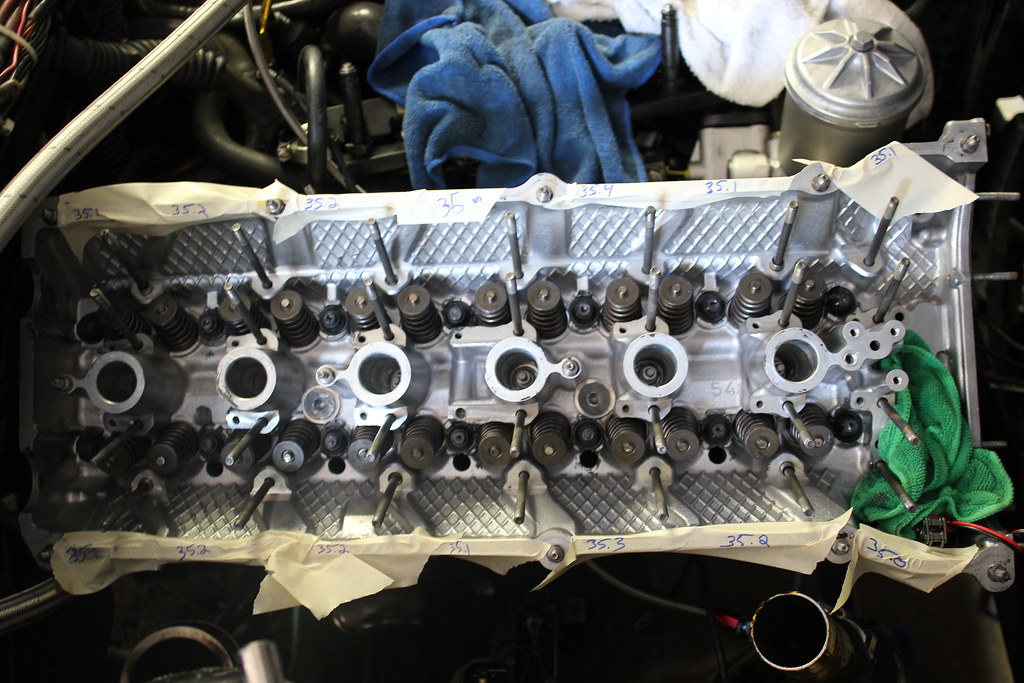

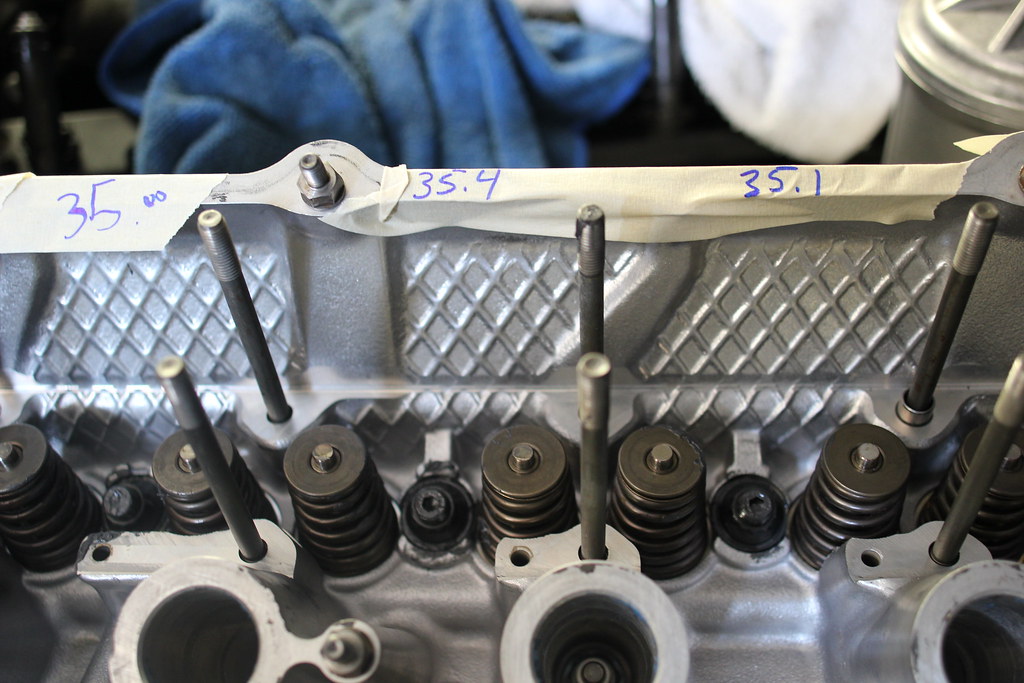

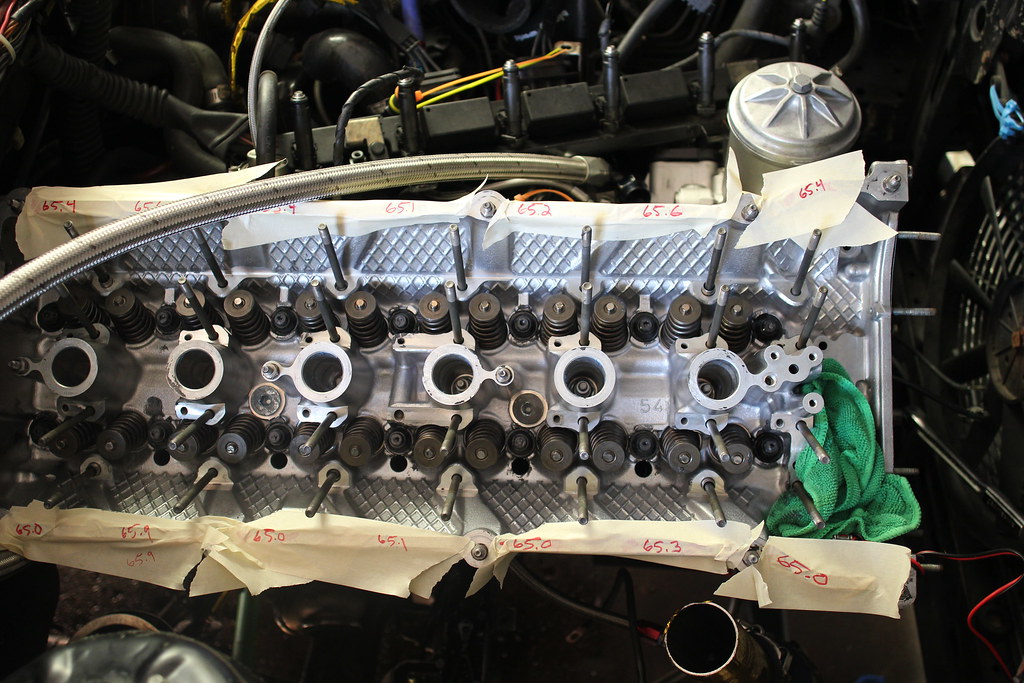

Torque Update: There are 4 studs that have a slight creep in them. I'll re-torque tonight. Getting close!

Leave a comment: