Announcement

Collapse

No announcement yet.

Turbo Inka 4 Door: Stripped & street legal rotisserie build + Powdercoating Pr0n

Collapse

X

-

Just read through your entire build so far. Impressive work. The rotisserie looks awesome, and I'm super jealous of the "fridge". I'm excited to watch this car come together.

-

Right before the family packed up and went to St. George, UT for some sweet mtn biking, I finished blasting Mitchlikesbikes' subframe. He's got a press, I've got a blasting & coating setup now. Was a lil B to figure out the blasting but after hooking up dos compressors (BILs (brothers in law) are awesome for the extra compressor and 3-to-1 coupler & fittings!) the pressure came back up super fast. Blasted between 50 & 90 psi with 80 grit silica blasting media.

After blasting I had to touch up some areas with a DA sander and dremel because of all the little details and shapes on these things. You can see where the metal looks different from this.

Test piece from the M50 that was super dirty. Degreased, wire wheeled, & outgassed at 500 for 45 minutes. Wish I would have blasted this with walnut but blasting is a srs PITA.

After blasting I wiped it down with wax & grease remover, did a once over with a dry towel, preheated to 400 for a while then when it came back down to 100 I hung it outside and coated it. Carrying a 40#ish subframe 30 feet to the oven and hanging it in there was pretty frightening. Came out fantastic. After I get my reinforcements welded in I'm stoked to do a ton of my parts.

Leave a comment:

-

Thanks. There will be more!Originally posted by stonea View PostWow, love this build, can't wait to see more!!!!

Leave a comment:

-

Set up the blasting tent tonight. I opened the garage door enough to fit a box fan underneath and I didn't have any dust inside the tent whatsoever.

Always wear protection kiddos

Started blasting. Probably got through 15-20lbs of coal slag (80 grit) before getting one side of the front cross member done. Compressor kept up a little worse than I thougt @ 7.5cfm @ 90psi. I'm using the biggest nozzle though.

Before

After

Vacuumed all that stuff up and it's ready to go again tonight.

Leave a comment:

-

Oven is about done.

Added the oven seal/rope with RTV sealant

Used the oven cover to protect the 'lectronics. The fixture hanging out up top is the light. I plan on making a place for the light soon.

I didn't see the point to mounting the controls somewhere pretty, so in the side they go so I don't have to lengthen everything just to have them on the front/top of the "fridge."

Ran it up to 575 degrees on broil and stopped since a bit of the clear silicone was smoking. I'll be redoing the window with RTV instead of the cheap, clear stuff. I can't believe I didn't just grab one of two tubes of the stuff I had lying around...

However, it did hold a steady 400 degrees for 20 minutes and the thermometer synchd up with the controls so I'm stoked, just need to make the rack at the top and I'll be ready to coat.

Leave a comment:

-

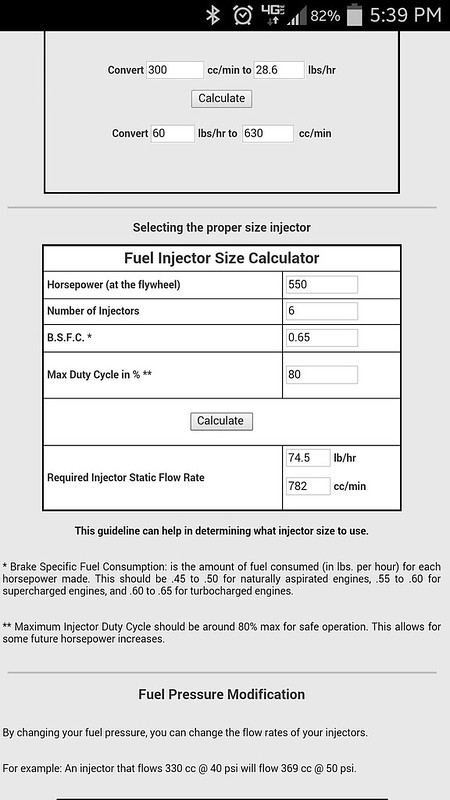

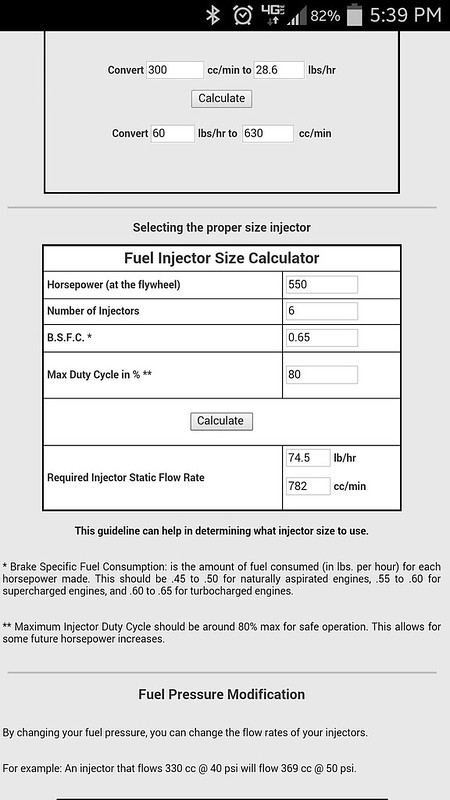

Good deal. Yeah I'd like for the whole system to come apart quickly and run a 2 to 3-section exhaust as well.Originally posted by Good & Tight View PostIf you plan on a dedicated E85 setup, 1000cc for sure.

You looking to get a V-banded turbine housing?

Leave a comment:

-

If you plan on a dedicated E85 setup, 1000cc for sure.Originally posted by eduTechnic View PostThanks I didnt know about lines and filter Otis. I meant the outside though--be rather difficult to paint the inside! Looking at a few fuel load calculators it seems 730cc/min would be the min for ~550bhp even with reg gas. Might want to get 1000cc injectors i suppose. Not sure if that's the goal yet, maybe less. You ever roll v - band flanges on your manifolds? I plan on picking one up in a few months.

You looking to get a V-banded turbine housing?

Leave a comment:

-

Got the tub built and put in with my bro-in-law (pictured). Many many rivets and one HF gun were sacrificed to the powder gods. It was a bit too wide so I had to take one side's fiberglass out. Because I'm cheap the tub's sheet metal is super thin flashing and does whateva it wants.

I didn't have the wiring lengthened or the controls/temp probe mounted on top/side/dunno yet, or even the door-to-fridge gap sealed off with some oven door gasket rope yet (incoming from Amazon), but it went up to 450 degrees in about 10 minutes, and the only place you could feel any heat on the outside was the window. Cool to the touch everywhere. I'm pretty satisfied with that. Left it on for like 20 minutes, no fire. Winning

I totally forgot that both elements don't run at the same time so the bottom-right element was red hot while the other was off? I've heard only one element stays on for heat maintenance. I'd like to build a heat shield over the one element so there's no temp spikes on the bottom right of everything that goes in.

Now on to the media blasting cabinet from the smaller fridge...

Leave a comment:

-

Exactly! Pay over a grand powder coating everything on the car or learn something new, troll local craigslist for old ovens & fridges, and build it yourself.Originally posted by TimeMachinE30 View PostI like projects that lead to projects.

Leave a comment:

-

Some supr srs fabrication going on here, hope you can handle it. Made a little progress last night. Would have made more if my jerk 4-year-old son wouldn't have barfed 3 times after midnight. Poor little dude ;)

I bought all this kind of pricey aluminum angle and then went back to the roofing section in Lowes, and found these 118" flashing bits for tree fiddy each. Done deal.

Measured once, cut twice (made one 10" too short by accident, derpaderp)

Then used a punch with some wood underneath to mark where to drill. This actually made fitting the pieces together easy since the top piece's divot fit right on the other's.

I was going to rivet, and I probably will, but I wanted to lay the frame out quickly so I just used self-tapping screws, which are the bomb

Getting it together was a lil b getting things square, not having it fall over, then getting a screw in with my impact wrench...

Made a little test fit and it should compress the insulation only slightly. Time to get it sheeted tonight with the 20"x50' roll of flashing.

Leave a comment:

-

Thanks I didnt know about lines and filter Otis. I meant the outside though--be rather difficult to paint the inside! Looking at a few fuel load calculators it seems 730cc/min would be the min for ~550bhp even with reg gas. Might want to get 1000cc injectors i suppose. Not sure if that's the goal yet, maybe less. You ever roll v - band flanges on your manifolds? I plan on picking one up in a few months.

Last edited by eduTechnic; 12-04-2014, 10:08 PM.

Last edited by eduTechnic; 12-04-2014, 10:08 PM.

Leave a comment:

-

I would not paint the inside of the gas tank, the E85 will eat through it. Just clean it real good and it will be fine. I ran E85 in my stock tank for 2 years with no issues.

The fuel lines will need to be changed to neoprene or some type that is E85 compatible.

Along with stainless fuel filters.

600cc injectors will limit your HP with E85 as you will burn 30% more fuel.

Not sure what the walbro 255 is rated for with E85.

Leave a comment:

Leave a comment: