Sure, makes sense. Brake caliper acting at a larger radius can generate a larger moment than the same caliper at a smaller radius.

I was also thinking the larger diameter and thicker rotor would probably last longer. Like you say bigger heat sink more wear surface area.

With the different offset for the 1er/z4 hubs his kit wouldn't be bolt on. At the very least I would need a custom hat to make up for the offset. Does Lee's front Monster E30 kit fit the front of the stock ix? I don't have any RWD front struts to compare but I would think the location of the caliper mount, strut tube, and hub face are different than the ix. But maybe not, do the front brakes off an ix fit a rwd? I thought there was a difference between Grilling and ATE calipers.

Anyway, I'm an engineer, I should be able to figure it out lol. Built not bought, right?

TehRaydarlover's AWD Lover

Collapse

X

-

It's really the mass, not the diameter - you get more leverage with a bigger rotor, but really, the E30 is small and light, you'll be more limited by tires I think than brakes. You could go with thicker rotors for more thermal capacity (bigger heat sink) and if it saves a lot of money on consumables I think that is worth the trade off.

But why reinvent the wheel? Doesn't massive carry all of this stuff already? His kits seemed affordable when I looked at them last.Leave a comment:

-

-

I've got the hats roughly drawn in Autocad and I'm working on the adapters getting the clearances correct. Talking with Wilwood they suggest 0.080" clearance everywhere to give room for thermal growth. I'll probably give myself a little more even for the face and ball joint.Interested to see how it all comes together. I definitely want pics of your radial mounts and hats when you do them.

Those rotors are hella expensive! I'm hoping I can use the the 8x7.00" blank rotors when I eventually make a setup, the blanks are like $40 a piece that way.

Edit: I'm talking 160-0483 (11.75"d x 1.25"t) or 160-0471 (11.75"d x 0.81"t) I think there are smaller diameter ones too, but I'm planning on ditching all the 14/15/16" stuff I have now for 17's anyway (tire selection is the main reason)

I've been on the road for work for almost a month now but when I'm home next I want to get the hubs and bearings pressed into the coilovers and test fit the wheels (still not 100% sure they will fit) If I need more clearance to the strut I can adjust the hat thickness to shim the wheel away from the strut. Wilwood suggested making the hats out of 6061 aluminum with a minimum hat thickness on 0.25".

As for mounting the rotor to the hat I'm kind of spinning my wheels. I'd like to do a floating rotor setup but I'm finding it hard to get any details on the clearances for the slots and to t-nuts. It seems like everyone has their own design. You can buy the hardware from wilwood or other sources but again shits expensive :/ Even then I don't know what the slot dimensions in the hat are supposed to be. I don’t want to but I've been thinking of just hard bolt the rotor to the hat. A lot of OEM two piece rotors are like that.

Ya the rotors aren't cheap. 13" is probably the biggest rotor I can fit. I was just running off the assumption that bigger is better as far as rotor diameter. Looks like you have to go down to 12.19 or 11.75" before they are under $200 a pop. Idk, is the inch or so larger diameter worth the extra cost?Leave a comment:

-

Your coilovers look incredible. Did you source those tabs/flanges with GC cut into them from GC or in house? Looks so good.

Sent from my Nexus 5 using TapatalkLeave a comment:

-

Interested to see how it all comes together. I definitely want pics of your radial mounts and hats when you do them.

Those rotors are hella expensive! I'm hoping I can use the the 8x7.00" blank rotors when I eventually make a setup, the blanks are like $40 a piece that way.

Edit: I'm talking 160-0483 (11.75"d x 1.25"t) or 160-0471 (11.75"d x 0.81"t) I think there are smaller diameter ones too, but I'm planning on ditching all the 14/15/16" stuff I have now for 17's anyway (tire selection is the main reason)Leave a comment:

-

-

Thanks! The turbo came earlier this summer too. Just starting to build the manifold now.Leave a comment:

-

As for the car I'm still working on the body. I rented a bigger garage to work in and bought a welder. I've been cutting out a lot of cancer and getting ready for new sheet metal.

The go fast parts have been coming in also :)

Leave a comment:

-

Time for the reassembly!!

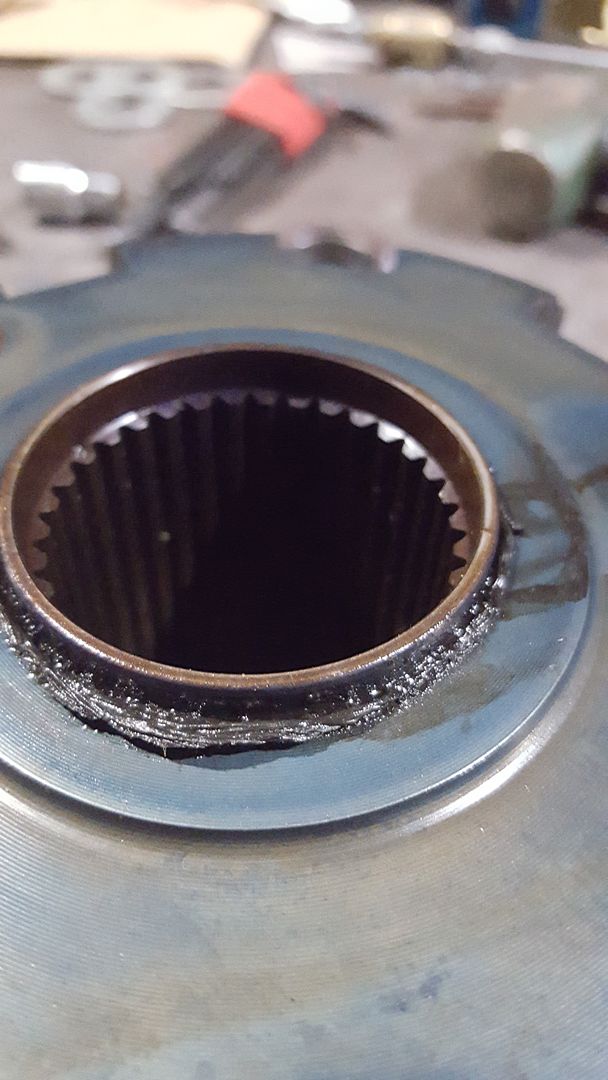

First things first, install the shaft seals into the front half of the casing. As I'm sure you noticed there are two seals installed face to face on the front output sprocket. It's kind of a pain in the a$$ to get the second seal, I think I found a socket or something with a slightly smaller diameter to knock it in with. Make sure they go in straight, and preferably on the first try! I like to lay a very thin coat of RTV in the receiving bore while installing the seals. The RTV lubricates the seal as it goes in and also helps fill any leak causing imperfections in the receiving bore, do as you wish. With both seals installed to the correct depth we can lubricate them with some o-ring grease.

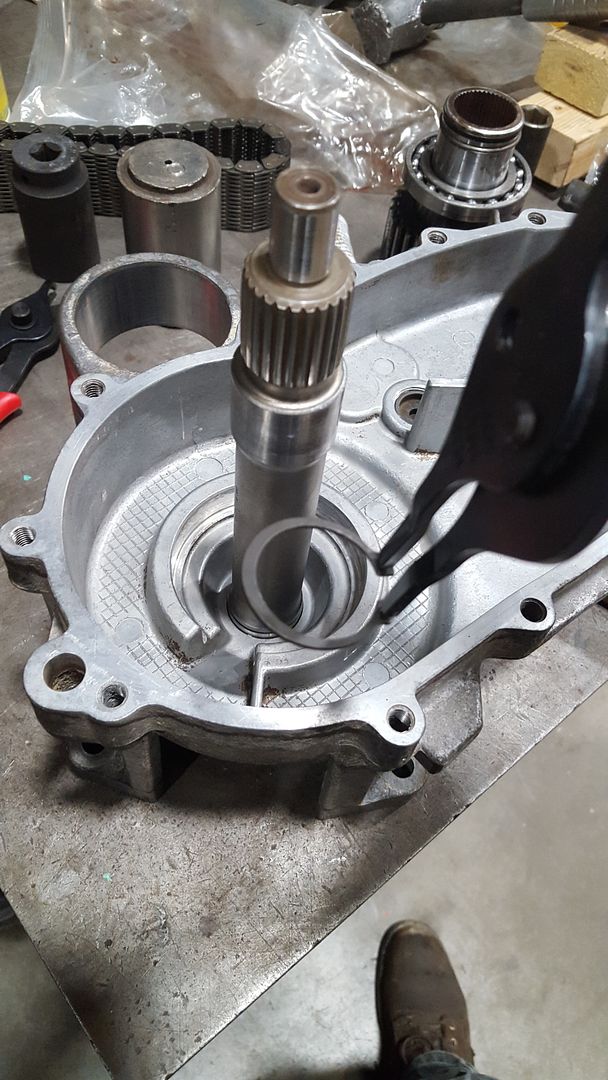

Next we can install the input shaft and retaining ring. The shaft just slides right in and fits loose to the casing for now. Install the retaining ring to keep it from sliding back out.

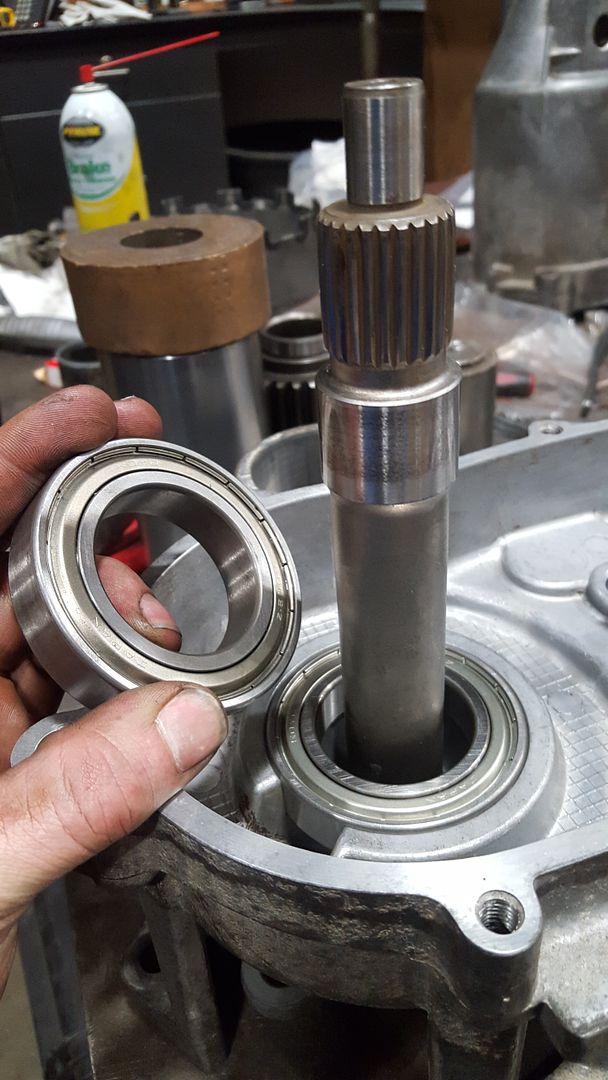

Next we can install the new bearing for the front output sprocket. Find something with a slightly smaller diameter and knock the bearing into place. Make sure it starts in straight.

Install the new bearing for the input sprocket, same method as above.

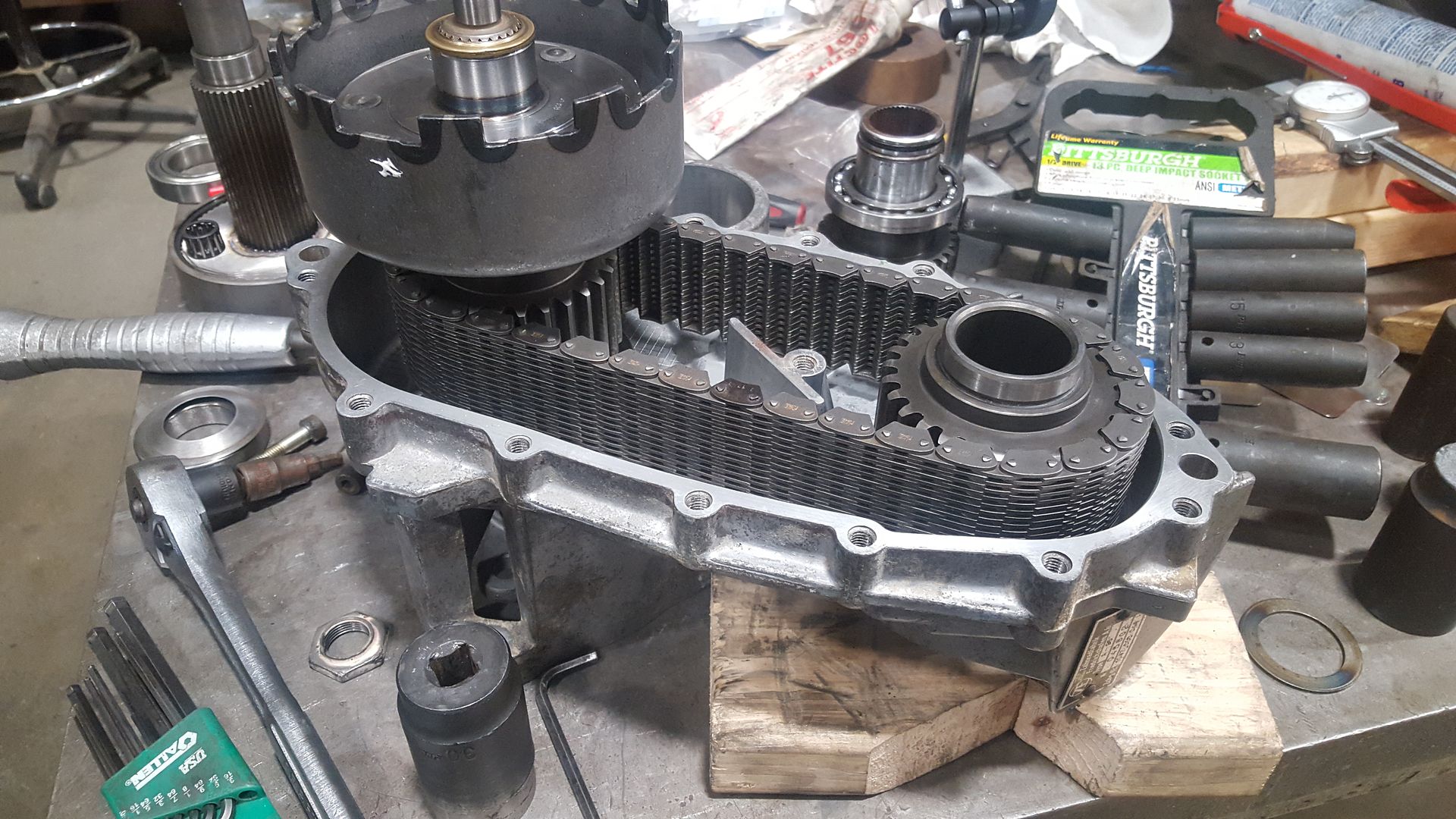

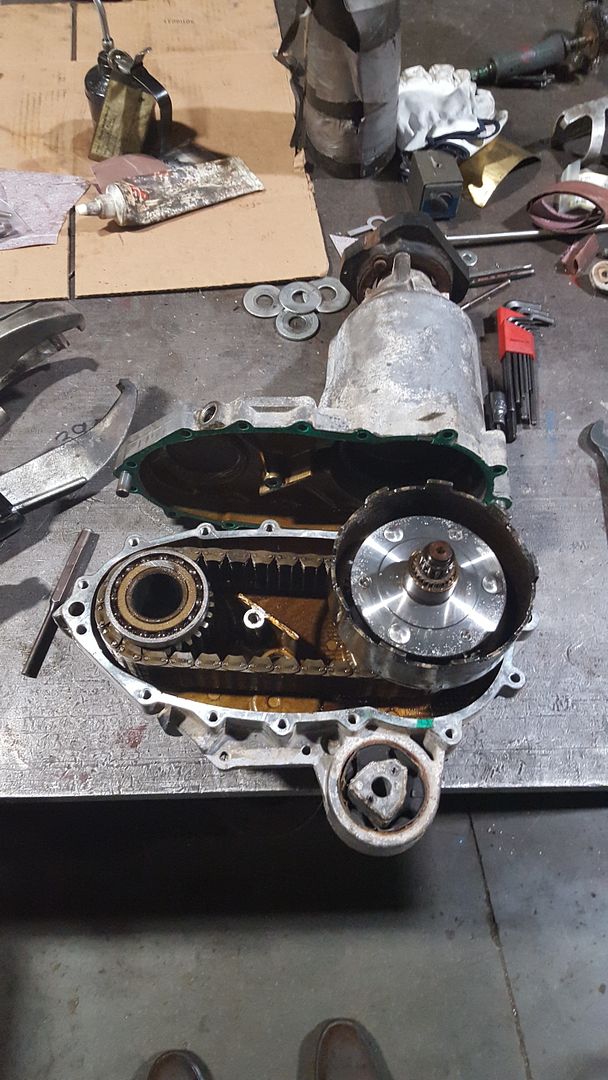

Now comes the tricky part, installing the input sprocket, chain, and front output sprocket. You have to first slide on the input sprocket onto the input shaft, with the chain on and front output sprocket loose in the chain. Then the sprockets need to be seated into the bearings at the same time. This is a pain in the a$$ because you have to get the front output sprocket through the two seals without it getting caught and damaging a seal. After my first failed attempt, I actually put some packing tape over the grooves to keep them from catching the seals.

When you get everything started and looking good you can seat the sprockets into the bearings with a dead blow hammer. Now you can also install the planetary gears.

You can also install the little brass or bronze crush ring. I think this little guy just keeps input and rear output shafts from being sloppy in the casing, crushing as needed to fill up the space. They are NLA from BMW so I was forced to reuse.

Now you can install the rear output shaft and your replacement or rebuilt VC onto the input sprocket. The gasket can also be set into place. When you order a t-case gasket from BMW it doesn't come with a gasket for the center hole. I just made one out of 0.015" gasket paper. I stuck a round file in the bolt hole to keep the gasket centered with installing the rear casing.

At this point apparently it was getting late and I stopped taking pictures, but its really pretty much done. The bearing shim, bearing, and shield thing can be installed on the rear output shaft, on top of the VC. Now we can install the new bearings for the front output sprocket and the end of the rear output shaft into the rear half of the casing. With the bearings installed the rear half can be installed. It may take a few tries to get the bearing and shield thing to align properly with the receiving bore but you'll get it eventually. Then all you have to do is torque the 6mm SHCS, install the rear output flange w/sealant on the splines, and torque the rear output nut.

Cheers!Leave a comment:

-

Time for some inspection!

Take some time to clean all of the parts you will be reusing. Clean the casing inside and out, I pulled the breather and replaced it even.

If your doing this its pretty safe to say your VC probably looks like this, o-rings blown out and nasty crap all over the inside of the t-case. Time to rebuild or source a replacement.

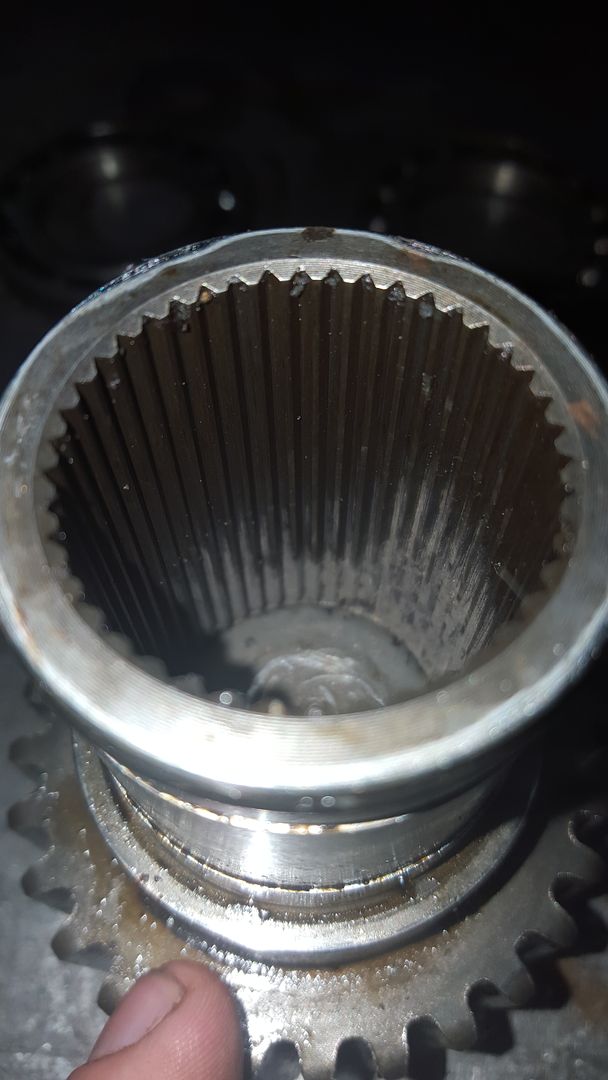

Hopefully you and your POs greased your front driveshaft splines like you should be doing. If your splines don't look like this its time to try and source a replacement :[

Check your chain for any excessive amounts of wear. Of the three I had to choose from, they all looked the same maybe I'm just lucky, maybe they're all junk. Maybe someone else can comment on what a junk chain looks like.

maybe I'm just lucky, maybe they're all junk. Maybe someone else can comment on what a junk chain looks like.

Check all of the sprockets, planetary gears, splines, and bearing fits for wear and damage. Replace as necessary.Leave a comment:

-

So here is the T-case rebuild, I actually rebuild it back in January so the details are kind of foggy. If I missed something let me know! Thanks :)

Here is the list of parts I used:

27111224629 Qty(1) Transfer Case Breather Valve

27111224677 Qty(1) Transfer Case Gasket

07119981063 Qty(1) 8-BEARING-IX

27211224637 Qty(1) 8-NEEDLE CAGE

07119981047 Qty(1) Transfer Case Bearing

07119981047 Qty(1) Transfer Case Bearing

27211224636 Qty(1) Transfer Case Seal

27241224660 Qty(2) Front Transfer Case Output Seal

07119981724 Qty(2) 8-BEARING-IX

27211224632 Qty(1) Drive Shaft Seal

27211224634 Qty(1) Collar Nut

27241224662 Qty(1) Snap Ring

23711130502 Qty(1) Rubber Mount

07119963308 Qty(1) Gasket Ring

27111226467 Qty(1) Screw Plug

A few of these items are NLA from BMW, such as some of the bearings, but you can still order them online from companies like Motion Industries.

You will also need a new or good used viscous coupling, see my rebuild a few pages back.

So first things first: Disassembly

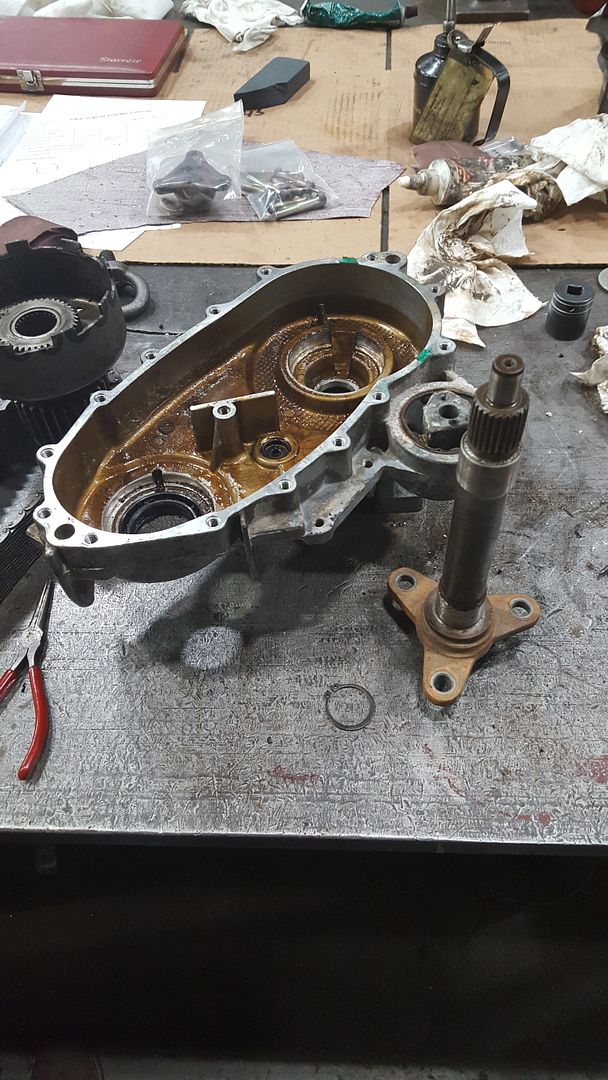

I removed the rear output shaft nut, then used a large 3 jaw puller to pull off the output flange. There's a sealant used between the shaft and output flange that can make removal a little difficult.

Next your going to remove all of the 6mm socket head cap screws.

Separate the casing halves. There are two locating dowel pins in the casing. If the casing doesn't separate easily use flat face punch to tap out the dowel pins.

Now pretty much everything just slides apart. To avoid headaches during reassembly, be sure to take pictures and tag/bag all of the small shims, needle bearings, etc.

Use a pry bar to pull the input sprocket, chain, and front output assembly out of the casing.

There is a small snap ring on the input shaft that holds the input shaft in the casing that must be removed. If I remember correctly you have to remove the bearing first before you can reach it, mine came out with the input sprocket.

Its a good idea to measure and record the location of all of your shaft seals at this point.

To remove the VC from the rear output shaft you have to remove this bearing. I had to heat mine to get it to come off. DO NOT loose the shim under the bearing, you need this lol. The thickness is likely going to be different between different transfer cases. As I understand it, the shim basically makes up for any differences in lengths between the rotor assembly and the casing stop faces, similar to the shim found in the rear diff for the pinion depth.

Everything should be disassembled by now, remove all of the bearings left in the casing or on the shafts, also remove all of the old shaft seals, be careful not to scratch the receiving bore. (I left the larger needle bearing in the input sprocket installed, couldn't source a new one)Leave a comment:

-

So I'm trying to work out my brakes... and could use some advice

Things I'm trying to decide on:

- How far away the caliper should be from the wheel. Leave more room for different wheel options?

- How far can I move the caliper before the rotor hat and adapter bracket offset is enough to cause an undesirable torque during braking?

- Do I even need to be worried about this torque?

The two calipers I have modeled are the Wilwood Forged SL6R (left) and the Wilwood Forged Narrow SL6R (right)

The narrow version is about $75 more a corner, not sure if its worth the price difference, but if the offsets and clearance are an issue the narrow version should be better.

Any help would be greatly appreciated!! :)

EDIT: I'll get back to this later, but thanks to Northern for the help!!! http://www.r3vlimited.com/board/showthread.php?t=391821Leave a comment:

Leave a comment: