Thank you sir! This is exactly what I wanted to know. Thought the raised part might get in the way. had hoped to have this done already but too many other projects.

Good work, keep it up, you'll be done soon!

Northern's Sterlingsilber M52 Turbo 325is

Collapse

X

-

Vibrant 1047 muffler cancelled, new one ordered from autopartsway.ca via amazon for another $20.

Vbands and resonator shipped this morning, and will be here friday. New muffler may ship out tomorrow morning, probably will show up after the misleadingly nicknamed "May 24" long weekend that is actually a week earlier this year.

After buying, messing around, and breaking a lot of cheap switches, I think my MS41 bench flashing setup and power supply are ready to go. I'm just waiting on a time to sit down for a final test and cross my fingers that it all works.Leave a comment:

-

Ugh Amazon still hasn't even prepped any of my exhaust bits for shipment and it's been two weeks now...

I started messing with their shipping options and now it somehow split the order into two, so apparently I'm getting my vbands and resonator friday, and the muffler does not have an expected delivery date at all.

It now says they're out of stock for the muffler, so I might just cancel the muffler and buy one somewhere else.Leave a comment:

-

Test fitted it and the raised base part of the bracket interfered with the tray, so I ended up slotting that too:

I now have too many tires:

Aforementioned driveshaft ready to go on. Still need 3 more guibo bolts though.

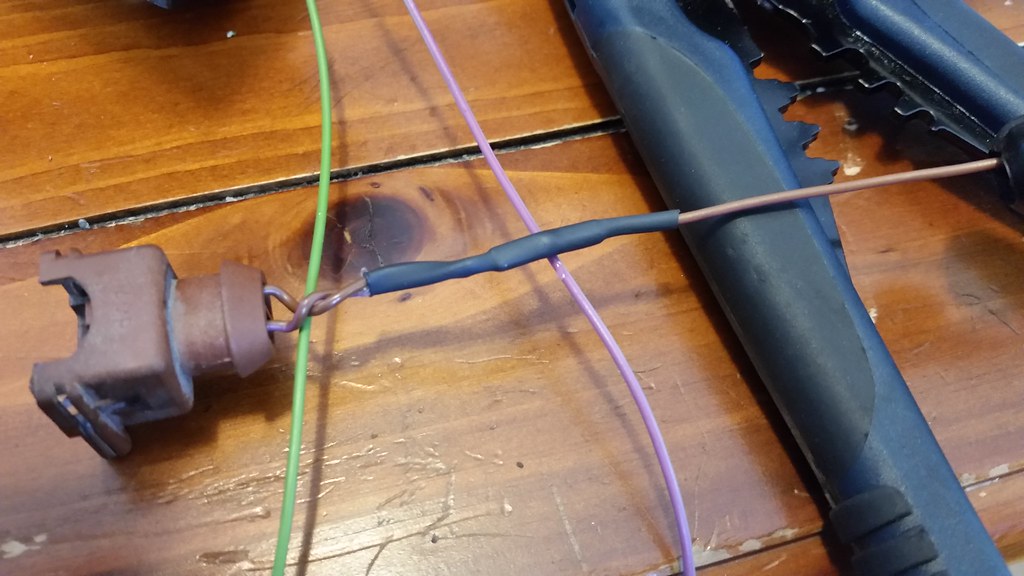

I decided to finish the harness on Monday. Found an M20 harness in a box out in the shed, and snipped C101 + the coolant temp sensor off it.

Early on:

Example of crimps this tool makes with these butt splices.

One example Heat shrunk. Slapped some dielectric grease on each one before sliding the heatshrink over. Trying to omit as much oxygen as possible...

Finished Coolant temp senders(except for taping up the Y in the harness)

C101 done:

Note the two wires poking out from under the rubber backshell are for the oil level sender that the E36 pans don't have. I'm told one of them needs to see ground, but I'm not sure if it is the one labelled "Dynamic" or the "Static" one.

Also the two pins taped up are from X6031, and are switched +12v power, and datalink for the in-cabin OBD2 port that I'll add on later. I'll probably connect them to some 2-connector plug and run it into the glovebox.

Planning on using either Torque Pro or Romraider logger via this OBD2 port.

Even the animals are curious about what's in the box:

This guy:

TinyT from The Arc Asylum sent me this Xbrace along with a Hoodie/shirt. I was just waiting for the hoodies to be ready to throw in the same box.

I'm pretty pumped about everything he's sent me so far. Maybe I'll have the opportunity to buy some slick LSx or S54 swap bits from him in the future.

Flickr is being a massive POS right now. Nothing loads anymore, so I'm going to call this good enough for tonight.Leave a comment:

-

Wish there was a picture of the finished product on this windage tray.

I am doing the same thing on mine, wanted to know how yours turned out?Last edited by wilholl; 05-06-2015, 06:30 PM.Leave a comment:

-

^ Thanks! :o

I spent most of yesterday cleaning the yard and prepping for a BBQ, but I did manage to cut off the old seized center support bearing from the E36 ZF driveshaft and install the new e30 one backwards.

The bearing dust shields didn't really work out though, I tried to put the E36 ones on backwards to suit the bearing, but then I was left with no way to mount the larger one. That was probably a mistake, but worst case it wears out prematurely, and I have to buy a new CSB + dust shields and mount them.

I cleaned the old grease off the splines (I think it's Molykote Longterm 2 Plus) and regreased with some Aeroshell Grease 33MS that T/X'd and was getting binned at work.

<Picture to come>

I'm off work today, maybe I'll get some wiring finished.Leave a comment:

-

much respect for showing your face!!! not too many have the balls to show the public who they are with their car.:up:Leave a comment:

-

Up until january we didn't see any snow or cold weather at all. I thought it was going to last all winter like that. After the new year it was obnoxious though, 1-2 times a week and never less than 4", usually closer to a foot. That one storm was probably the worst storm I've ever experienced here, and I'd managed to just leave the snowblower packed away in the shed all winter up to that point, when it suddenly became easier to dig it out of the shed and get it running than shoveling it all by hand.

I think there was only one storm here since the '70s that was even close to this, so hopefully we're good for another decade or so at least.Leave a comment:

-

Great to see people who are actually doing stuff rather than just bolting parts on

p.s. that snow further up the page is mentalLeave a comment:

-

Lazy sunday, no real pictures, just blurry instacrap.

Work is slow, only one A/C in and it's almost at flightline so I brought my windage tray in to modify to clear the pickup bracket.

Wire wheel coolant pipe/paint.

Arc Asylum pan on.

Drunk old dudes in buicks, smashing into people's shit and running from the cops.

Also started messing around with intake manifolds, making the M52 stuff fit M50:

M50 mani, M50 TB, M50 ICV hose+ICV mounted to the bottom of the intake,

New orings on pinktops, but I lost my M50 fuel rail...

Picked a spot to mount the cyclone/PCV unit and flipped/modified the bracket to mount it to the block and found a random coolant hose that fits to adapt it to the OBD2 non ASC-T TB (Which I don't know how I acquired?)

Work I need to do to the shell:

I need to attach the new ZF clutch slave/IE stainless line /iX booster soon. I'm also just finding out now that I need some sort of remote reservoir with the iX booster, even though everyone says it's plug and play...

I snipped the Aux Fan wires at the fan, keeping the connector. Need to wire in the Mishimoto fan and the new fan switch somehow. I need to read dave's fan thread again.

I need to cut off some brackets and take care of a few rust spots while I can get to them, and clean the bay out a lot.

Oh. I also need to swap out the front subframe. That's always loads of fun...

Biggest dread is finishing off the M52 harness... I've removed 25+ wires so far for SAP, Rear O2, EWS, etc. Still 5-10 more to go. Still need to find & splice up C101, loop the oil level check (or just snip the bulb?) splice a coolant temp connector, use X6031 to run an OBD2 port into the car, seal everything up that I snipped, and put it all back together.Leave a comment:

-

I still need to figure out an exhaust plan. I have like 10ft and 360 degrees worth of bends in 3" 316 Stainless, e36 OBD2 headers, E36 downpipes/midsection(I think) and nothing else.

EDIT:

No time like the present I guess.

Also ordered some ER316L MIG wire for the pipe, I'm under the impression I can use ER308L on the 304 to 316 joints. We'll see how it goes.Last edited by Northern; 04-28-2015, 05:44 PM.Leave a comment:

-

Picked up some new Crank main cap bolts from BMW. First time I've set foot in the dealership in 3+ years. New ownership and a completely different building, plus much nicer staff than I remember. I found an old highschool friend working on the Mini side who led me through the maze of dealerships to the parts counter.

Total damage: $45 for 4 bolts. It wasn't actually as bad as I was expecting, considering they wanted $65 for a hood roundel last time I was in.

I then realized I wasn't comfortable eyeballing 50 degrees, so I stopped by Princess Auto (AKA Canadian harbor freight) to get a torque angle gauge. As usual, I spent 10x as much as I planned and in addition to the gauge, I left with: 2 inline air filters (for HVLP guns), another large jug of anti-seize, a metric bubble flare kit (lost the last one) and a bunch of brake kleen.

I thought I'd be able to swing some S5x cams before the engine goes in, but instead I spent $650 on summer tires for the mazda... and they're not even installed yet, so there goes the cam money twice over.Leave a comment:

-

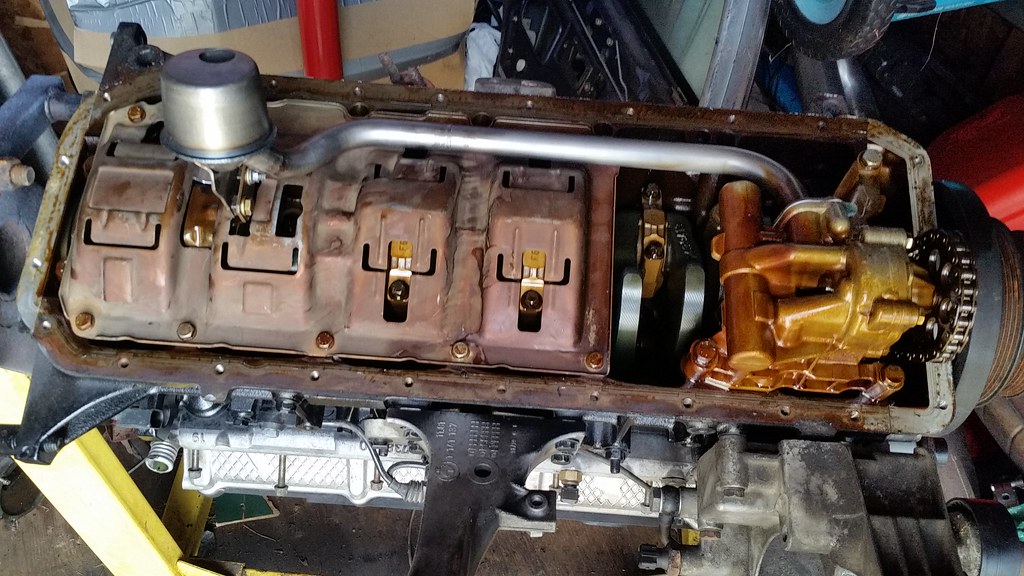

This weekend I decided to try to get the oilpan all mounted up to feel like I made progress.

welded the oilpump nut, because I don't have a jig for drilling nuts for lockwire, and I'm not willing to pay and wait for a predrilled one.

Went to fit the modified pickup for the Arc Asylum pan, and found out the modded pickup tube hits the pickup bracket, and isn't remotely close to fitting:

Quick email to TinyT and he explains that the bracket needs to be flipped 180deg and installed on the next main cap over, then the windage tray needs to be slotted to fit. He says that from now on he's going to slot trays as part of the modification service.

Now I need to wait for the dealer to be open on monday to buy 4 main cap

bolts... I'm scared to find out how much they're going to come to.

While the main bolts were undone, I decided to take a peek at the bearings:

I can't feel that scratch in the first one. I think it looks pretty good.

Trial fit with the bracket flipped:

I'm halfway through slotting the windage tray. It's easy to measure off the old hole vs tray mounting bolts and flip them to find the new spot, I just don't have any more small cutting discs.

There's a cruise late may I'm hoping to make it to, so there's my deadline.

Leave a comment:

-

Few little updates

Cut this off, flattened it, and welded for TB heater circuit delete:

Bought these plates (PN: 11121438086) for SAP blockoff... apparently not plug and play like I was told.

Cracked open the valve cover for the first time

Replaced plug gaskets and VC gasket. I thought the rubber plugs came in the upper gasket kit (Elring) but they're not there.

Looks pretty great, intake cam too.

removed all the plugs, installed new NGK coppers after noticing how much crud was built up in the intake ports:

Flipped the engine upside down, Hit it with a brass brush, then brake kleen and towel until it wasn't getting any cleaner. Spark plugs were still out, so I blew some air down in the combustion chambers to try to blow any debris I dropped in while doing this.

New N54 Exhaust studs. 3mm shorter than the E36 ones, but like 1/4 the price, and have nice little torx ends to help install/remove.

On my iX, instead of tapping the pan for an oil return, I tapped the block on the flat spot behind the A/C bracket to accept a -10AN union. I like this option much more than tapping the pan, and doing it on the car last time was a complete shitshow, so I may as well do some future proofing while it is convenient:

Mark the hole on a nice flat spot, make sure there's no reinforcement inside the block:

Grab some lube, drill and tap the hole to 7/8-14 to accept the -10 fitting. If you could mount a drill guide or use a drill press somehow it would go a long way, but a shitty cordless drill and eye of man were my tools of choice(or desperation):

I cut down the backside of a steel -10AN union so it didn't protrude into the block, chamfered the inner radius to smooth the transition of the dump into the block. Installed with loctite and capped it:

Leave a comment:

-

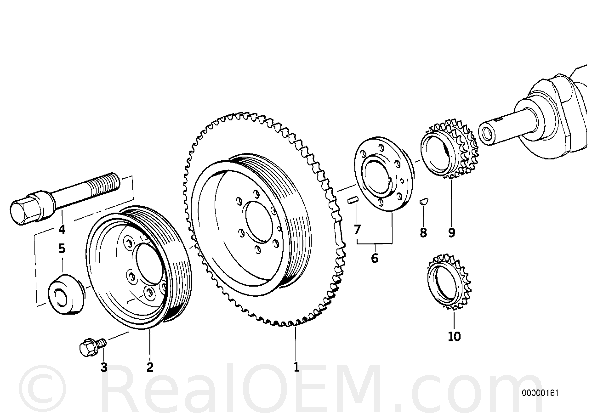

Made a little progress last weekend as the snow barely began to melt. Car was still completely covered, but I found motivation anyway.

Block was pretty much stripped already, but covered in a load of grease. I'd cleaned the timing cover off and spent almost a full day trying to separate the A/C pulley from the crank pulley/harmonic balancer before I started to hit it with a hammer. Funny story is, it's actually one piece, despite what the RealOEM diagram I was going by showed...

But since it was off, I had a chance to clean behind it (note, the engine is from a '99 vert, so it has the late harmonic balancer with no trigger wheel, and that's a different diagram)

a few cans of brake kleen later, I had this:

Not bad, compared to any other engine I've ever pulled out of a car around here.

Next, I hit it with a wire wheel on the grinder to get most of the rust off.

Didn't care to spend a huge amount of time on this, I just want to get the engine in the car, and hopefully in the next 5 years I'll have a built bottom end anyway. Sprayed with some VHT flame proof primer, then hit it with some matte BBQ paint (lol) It turned out alright though:

Next I decided to "turn down" the M20 coolant temp sender to thread into the M52 TB heater port... "turn down" because I don't actually have a lathe:

ghettolathe wooooo

Next I tried to do the same with the M52 IAT to thread into the M50 manifold sensor location, but I felt like I would break it if I cranked the chuck tight, so I ended up filing it by hand...

After threading it to M12x1.5 (seriously thought I was going to snap it in half):

I put some plumber's tape on it and threaded it into the M50 manifold until it was very hand tight... I've heard people say to JBweld it in, but if I messed it up by doing this, I want to be able to replace it.

Today I sold my IE catback and newish mounting kit for $200 locally, so I may be able to throw some money at this thing to get the last few parts I need to assemble the engine and wiring harness. Money has been tight with shitty paycheques from snow days and no overtime, plus most disposable income going toward paying off our debt.

Who knows, today I may actually go outside and enjoy this 10°C+ weather we're finally getting...Leave a comment:

Leave a comment: