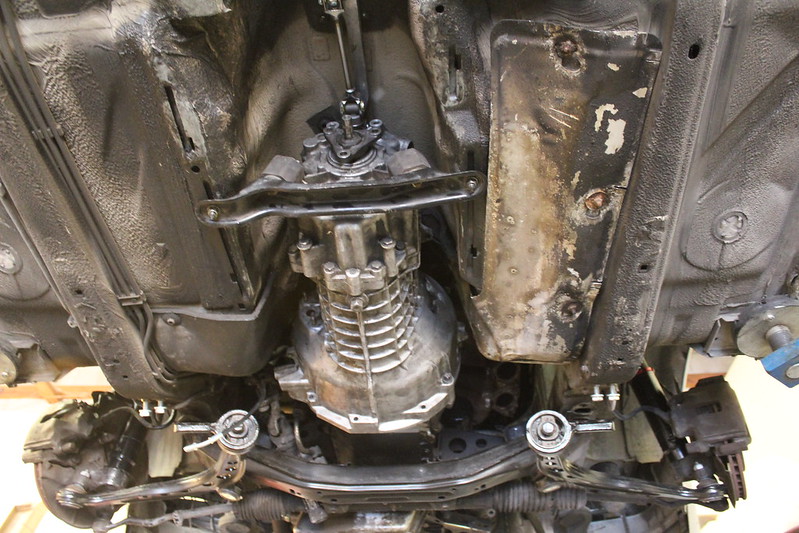

After a lot of anticipation, I finally got the E30 up on the lift and started working on it today:

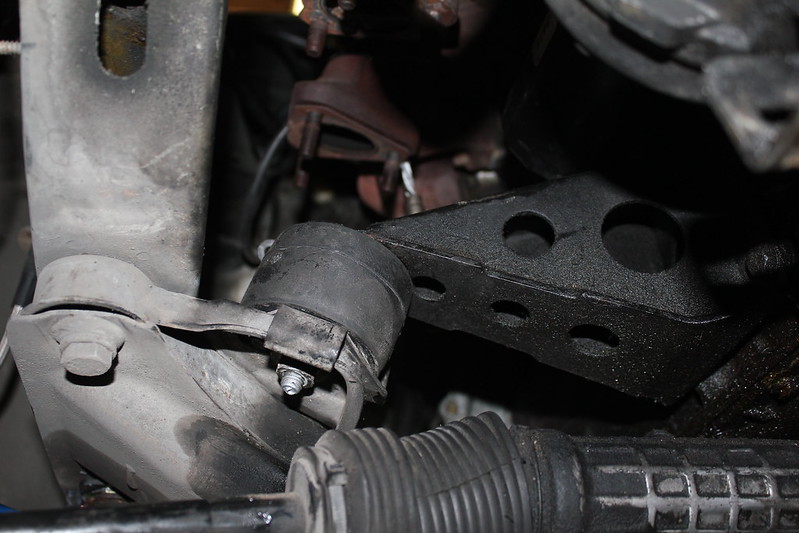

I attacked the front suspension first since I'm still waiting on a few parts for the rear subframe. Got the strut assemblies, sway bar and control arms off in prep for the CAtuned coilovers and IE sways:

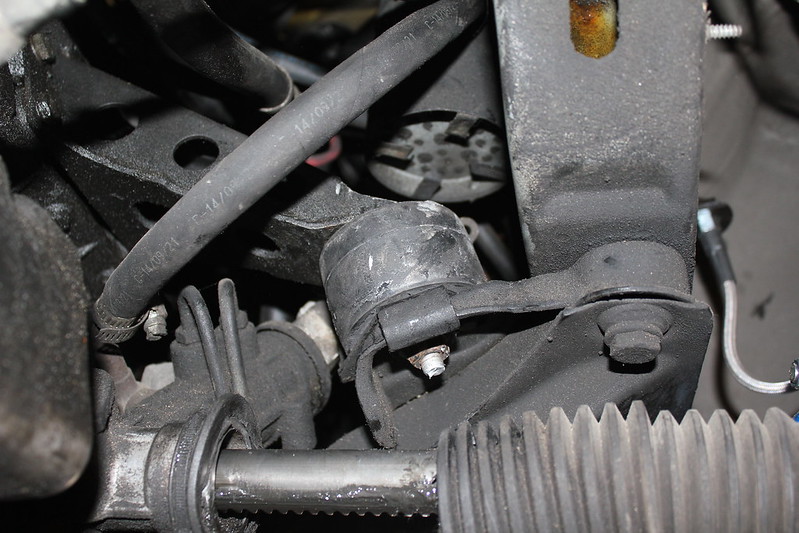

I also decided to take the exhaust off, which was a bitch because the downpipe was hitting a heat shield tab coming off the motor mount, so I pulled the sawzall out since I have another downpipe in better condition anyways:

Tomorrow I'm renting a spring compressor so I can get those strut housings disassembled and chopped up.

I attacked the front suspension first since I'm still waiting on a few parts for the rear subframe. Got the strut assemblies, sway bar and control arms off in prep for the CAtuned coilovers and IE sways:

I also decided to take the exhaust off, which was a bitch because the downpipe was hitting a heat shield tab coming off the motor mount, so I pulled the sawzall out since I have another downpipe in better condition anyways:

Tomorrow I'm renting a spring compressor so I can get those strut housings disassembled and chopped up.

Comment