Wouldn't that make intake temps super high?

Sent from my Pixel 2 using Tapatalk

A 50 year old Japanesse lady: SRL311 01228

Collapse

X

-

-

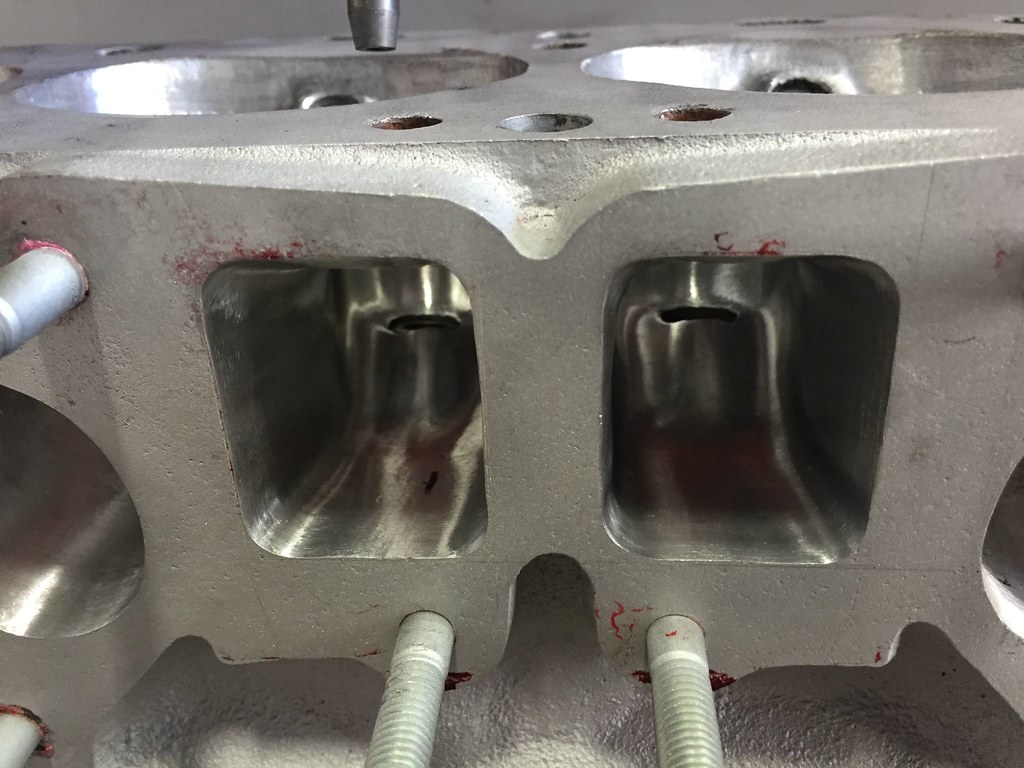

so is the intake and exhaust on the same side of the head? square inlets is new to me too. very cool stuff.Leave a comment:

-

Good things are happening, and I got some pics to prove it.

.... Im speechless.... and giddy...Leave a comment:

-

I own two cars, and once I have this one as a solid runner I can explore some of the ideas I have for the daily...

I have a wonderful and fresh WOT-tech cylinderhead in my garage though ;)Leave a comment:

-

Just stopping by to say that I love this thread.

So since cylinder head work is happening on this, the E30 is obviously next, right?Leave a comment:

-

This wasn't just a crack repair, this whole part was broken off. It was a complete separate piece. There were two other pieces that had completely broken free as well.

Why did I braze it rather than weld it? Simple really, someone threw my mild steel filler rod out

My original plan was to weld it, but when I had nothing else to work with, brazing rod was it. That said, I brazed my tray nearly 20 years ago and it hasn't broken, and it was in far worse shape than this one, so I'm confident that this won't have any issues in the future. Unlike on mine, I brazed both sides of each crack this time around.

My original plan was to weld it, but when I had nothing else to work with, brazing rod was it. That said, I brazed my tray nearly 20 years ago and it hasn't broken, and it was in far worse shape than this one, so I'm confident that this won't have any issues in the future. Unlike on mine, I brazed both sides of each crack this time around.

WillLeave a comment:

-

Update time:

- Found the missing LSD gears on 311s.org and had those shipped to Hoopers to complete the 4.38 with LSD. Love the help and support from the members there, I truly couldnt do it without their help. I hope thats ready by next Friday.

- Schneider Cams has all the numbers they need and will cut my custom cam next Wednesday. Hope that TEM Machine has it by next Friday also. Kevin @ Schneider Cams decided to make a custom cam thats basically a B-cam on the intake side with the same lift and duration, but more duration and a tad more lift on the exhaust to help scavenging and to carry the power band. Should be pretty fun from 3-7k rpms

-Rich @ TEM Machine is just about done and once he has the cam will likely have it all ready to send out, so I should have some serious work waiting for me in the near future...

For now the plan is to get the diff back and installed so I can be done with the rear and have the front assembly left. I have some interior changes coming but not sure what that timeline looks like because I want to get the car running.

One update I can report on was my Windage Tray and the cracks it had. Will (BlackbirdM3) was able to take care of it for me as I didnt feel confident with anyone in my area to handle it properly. You can see his hard work below...

Some Before / In Process shots he took...

in progress of the repair

repaired / brazed crack

Repaired Windage Tray

and heres the pan ready to go, pretty much. Will said he will clean up and chase the threads before calling it done

Leave a comment:

-

yes. every single bit...

Tonight I had a little bit of time in the garage and got some quick things crossed off the To-DO list. First was to carefully take the cutting wheel to the insulator with the stripped threads... destroyed the nut and part of the stud, but no damage or metal shreds near the carb.

Took a pic of the other side of the stud and ... yup... stripped all right

The other major news is that after a week of on and off evaporust baths, MOST of the LSD is totally clean of any rust. I couldnt totally submerge the main case so theres a stripe in the middle of it

Eagle eye viewers will notice that theres a few important pieces missing from the parts laid out, but I hope to have a solution soon. If you have an idea, Im all ears because its going to the rear end shop on monday along with the 4.38Leave a comment:

-

That’s the after, and this is the before? Would you have known the difference?

Carefully measured and bought a 24mm hole saw which is the same size as the existing OEM holes were.

Look at all the weight I saved! Lol

Leave a comment:

-

Barnfinds.com - looks like what BaT used to be.

As temperatures climb and summertime quickly approaches, it’s easy to imagine yourself behind the wheel of a fun-to-drive convertible. This 1967 Datsun 1600 Fairlady is available here on eBay with no reserve, and it certainly serves as a tempting example of this increasingly rare roadster. This Datsun is available in Dade City, Florida with a...

As temperatures climb and summertime quickly approaches, it’s easy to imagine yourself behind the wheel of a fun-to-drive convertible. This 1967 Datsun 1600 Fairlady is available here on eBay with no reserve, and it certainly serves as a tempting example of this increasingly rare roadster. This Datsun is available in Dade City, Florida with a...Leave a comment:

-

-

Leave a comment: