Chapter 3 - 84 318i m-tech - M60 powered.

Collapse

X

-

Still need to figure out the coolant flow direction and smaller charcoal canister, anyone got any ideas on this?Leave a comment:

-

Made some progress - bracket for the clutch/brake res done. Probably will either shorten the lines or make a bracket to hold them closer to the firewall and away from the driver side head.

Got a z3 2.8 shifter (used the 1.9 before and loved it) and favorite zhp weighted shift knob and all new shifter bushings from Blunt. Got the shift rod cut and extended/welded after finding optimal position for it and ensuring R and 5th don't hit the console.

early console cut/modified, new shift bushings, shifter and knob.

It felt good to see some progress by putting some interior parts back in the car .

Replaced the driveshaft CSB and need to install the driveshaft guide bushing tomorrow, and get the right size flex disc and test fit the whole thing.

Then, oil filter housing test fitting for it's permanent location to ensure clearance against z3m radiator and making a bracket for it and expansion tank.Leave a comment:

-

Tomorrow plan is to make a bracket to hold 3 wilwood reservoirs and double check the clutch and brakes to make sure they are indeed working 100% before I re-install the steering column and dashboard and all the crap that goes with it. And also need to add a return spring for the gas pedal.

I am going to finish re-wrapping rest of the wiring under the dash with cloth tape as well, since I am in there, and re-run a couple of wires in a loom through the firewall to the cluster from the c101/x25 side (check engine light/speed sensor wires that don't exist on my main chassis/harness side).Last edited by Jean; 10-06-2017, 08:39 PM.Leave a comment:

-

Update - Got the issue resolved, I think. Removed the pedals again, played with the location and quantity of spacers on the balance bar, shorted the right side end of the balance bar (did not want to risk it touching the Garagistic bracket in it's movement, filed the corner of Garagistic bracket where you can see it was making contact with the clevis. This was causing the interference.

Pedal now returns fully, and got the clutch bled and pedals aligned to be on the same plane.

I am concerned with the rubber boot on the MC as it's rubbing against the Garagistic bracket as seen in the photo, this will cause a premature failure of the rubber boot. This is why I think Garagistic should re-design the mount, it should wrap below the wilwood pedal and not sit on the top and interfere with the moving parts.

Also, wrapping the harness under the column is an absolute must....really tight fit against the bracket on the top left corner under the column. This is even with removing the oem harness holders to try and move/push the wiring as much to the left as possible.

Leave a comment:

-

I am using the pedal box and masters that Garagistic recommends using -

Wilwood 340-11299 Brake and Clutch Pedal Assembly

and the compact masters.

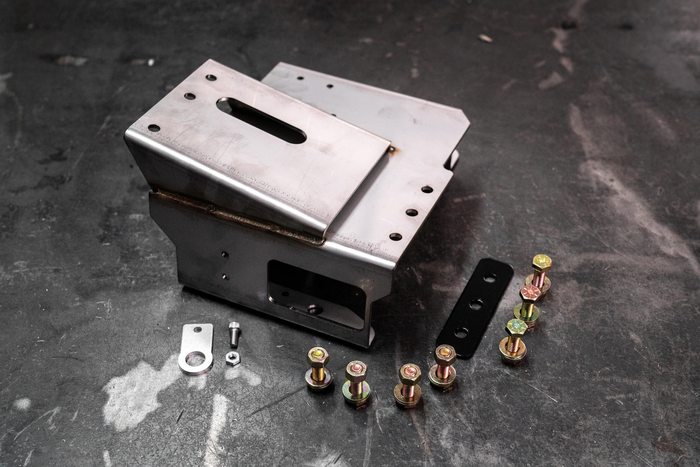

E30 BRAKE BOOSTER DELETE BRACKET (FOR WILWOOD AND TILTON PEDAL BOX) It's no secret. The brake booster relocation is the hardest part of the V8 into E30 swap! The factory booster is in the way. Some choose to use E32/E34 booster setup and relocate behind the headlight. This is costly,

E30 BRAKE BOOSTER DELETE BRACKET (FOR WILWOOD AND TILTON PEDAL BOX) It's no secret. The brake booster relocation is the hardest part of the V8 into E30 swap! The factory booster is in the way. Some choose to use E32/E34 booster setup and relocate behind the headlight. This is costly,

I just looked at the photos you've posted and it looks like your pushrods might be pinched, the rod going to the balance bar should be Parallel otherwise you'll have a failure. I've looked at the installation guides from Wilwood, Tilton and Stoptech to make sure it's not something I was doing wrong,

Example - http://www.wilwood.com/Pedals/PedalP...emno=340-11299

Guide - http://www.wilwood.com/PDF/DataSheets/ds252.pdfLast edited by Jean; 10-04-2017, 09:05 PM.Leave a comment:

-

Leave a comment:

-

Clutch line made, connected and bled. Unlike the brake pedals, this one works as you'd expect. Press it, release it and it comes right back w/o any return spring (Summit Racing was telling me I could add a return spring to the brake pedal ).

Adjusted the push rods today on all 3 masters, to make sure there weren't preloaded and nothing binding.. bolted the thing back up and brakes aren't perfect still. I am now thinking about selling it and going with Tilton, I'll monkey with it one last time this weekend and then decide. I got an idea on what else it might be, will report back if my thinking was correct.

Test fitted m62 740i oil filter lines, they are a bit longer than the m60 lines and will allow me to mount the oil filter housing behind the driver side headlight.

Ordering z3m s54 radiator next, as I want to install the radiator in place and then get the bracket for the oil filter housing fabricated to ensure clearance around it is good. If the lines turn out to be too short, I am thinking about getting AN fittings welded to the x5 block plate and oil filter housing and get custom lines made (my plan B).

Some pics from progress. Clutch line, and pedal stuff.

For guys using the Garagistic bracket , I highly recommend re-wrapping the main harness in there as it will be very close/against the metal bracket and you don't want the wiring to get damaged over time and cause a short or a fire.

I bought a roll of cloth tape , and went to town with it :)

See below -

Overview after adjusting push rods

Not sure if I got a bad bracket here, but the clevis of the wilwood pedal assembly IS touching the mounting bolt of the bracket.

I'll need to run this by Garagistic to see if this was a bad batch or what, but it's too close to my liking. You can see I actually had to file a corner

a little bit to make room for the corner of the clevis here. I had to also move the nut that goes on the balance by to the other side, it usually would be on the right most side of the balance bar as thats where you'd connect a remote bias bar cable (can't do it here, as the design of the mounting bracket does not allow it).

Garagistic - can you guys compare your latest batch of brackets and check for clearance there?

If there is one recommendation I can make to make this bracket better, and not have interference with the moving parts of the pedal assembly it would be to re-design the side of the bracket or at least that one corner to go UNDER the wilwood assembly and not OVER. This would prevent the clearance issue with the clevis that in the resting position is touching the bracket itself.Last edited by Jean; 10-04-2017, 08:00 PM.Leave a comment:

-

Has anyone found a SMALLER charcoal canister? The one in the e30 is HUGE, wondering if there is something smaller in size that was available maybe on another model chassis that would still work. I've looked at some late model ones, but don't think they'd work.Leave a comment:

-

Took a break from the pedal box stuff, replaced the pivot ball and installed the trans on the engine. Went to auto zone and looked at all the fuel filters they had to find something small that I could install in the back of the car near the external fuel pump.

I really don't get why people are cutting the radiator support on e30s to drop the m6x in, it is completely unnecessary. It just takes two people to get the right angle, and it easily fits w/o any issues. Key is to not have the alternator/power steering pump on there to get the needed room and you can install those once engine is in the car.

I went ahead and weighted the long block with the flywheel/clutch kit/trans mounted and it came out to about 470lbs. I'll need to find my previous post from years back when I weighted my M30B35 swap to compare.

Found it - https://www.r3vlimited.com/board/sho...&postcount=213

My M10 with trans on the same scale was 395lbs

My M30 with g260 / 533 flywheel w/o exhaust manifolds was 540lbs.

Engine is using Garagistic arms, with their poly mounts. Trans is on my old poly mount from m30 swap, seem to fit fine here as well. Replaced the CSB on the e36 328i driveshaft today and test fitted it, looks like length might just work w/o any modifications but I need to get a guibo/flex disc in there first.

With the engine and trans mounted I was able to get the exhaust manifolds in and out w/o any issues also, just have to rotate them a bit but you can get them in and out as long as you don't have power steering shaft in there.

Pics below

Couple things I need to figure out/ confirm is the coolant flow direction, to ensure the heater core lines / hoses are connected correctly to the rear water accumulator pipe.

Clutch line angle is worrying me a bit, so I'll need to think about that one. Perhaps add a hard line in there ?Last edited by Jean; 10-03-2017, 08:19 PM.Leave a comment:

-

Thanks man!

So, after spending about an hour on the phone with Summit Racing (was not impressed with their tech line at all), then Wilwood (better tech support, and they actually laughed when I mentioned Summit Racing techline so I guess it's not the first time) they've confirmed that dual 5/8 should be OK, but they actually recommended 3/4" size in order to get rid of the initial slop or dead play I am experiencing in the brake pedal.

I've called Garagistic and ran the whole thing by them as well, since after all they recommend dual 5/8 in their guide. After some in depth discussion, they've confirmed that they have also experienced the slop or dead play I am running it and were able to dial some that out by adjusting the MC rod lengths.

So, today I've removed the steering column tube after welding nuts to the sheer bolts, and of course in turn melting the plastic bushings there in the process.

Parts #15/17 - http://www.realoem.com/bmw/enUS/show...diagId=32_0427

This was done to get more room as I did not want to disconnect the brake lines, and wanted to lower the pedal box as ONE unit and get to the rods in order to adjust their length. I swear, after dealing with this now for the 3rd time if I was going to do it again I would totally go with the floor mounted 3 pedal box OR relocate the booster behind the driver side headlight (Aka 540i/740i config). Going to remount the pedal box this week and see if it's any better.

Good news, found and e36 328i manual driveshaft with 4 bolt rear u-joint, apparently it's the same as 96+ m3 from what the local recycler told me. U joints seem in good condition, CSB is OK but I have a spare new one I've never used before.

Also got the early shifter carrier console modified today, to fit on top of the trans tunnel (aka DTM style). In the process of mounting it I recognized that the Reverse Light switch wires are in the trans tunnel and are part of the chassis harness (good right?) but the 540i engine harness ALSO has reverse light wires? I am thinking I can ignore the wiring harness reverse light wires since they are probably routed via X25 pin into the chassis VS. e30 being separate.

Note to self - get some hockey tape, rewrap some of the wiring under the dash near the pedal box while I am in there.

Ordered new shifter bushings, went with 740i pump, and 325e style expansion tank. I want to have as little water hoses behind the engine / at the firewall as possible.

New spark plugs/boots installed, ignition coils done. I went ahead and ordered new knock sensors and grabbed my 540i manifold with trumpets with the new PCV and gaskets.

Down to radiator, cats/exhaust work next. Oh, and re-locating the fuel filter from the engine bay towards to the back of the car, I've been looking at smaller filters and I think I found something that will fit near the rear subframe by the external fuel pump.Last edited by Jean; 10-02-2017, 07:49 PM.Leave a comment:

-

Engine looks good in there mate. Yours is coming along in leaps and bounds now. Won't be too long and you'll be firing it up.Leave a comment:

-

Thanks!

Just noticed there are Ventus RS-4 245/40/15 tires out there now, will need to check out reviews and see if they are worth getting until next season of SCCA solo2 starts.

And there is also Hoosier A7 in 245/45/15 as well WOW! Maybe I'll stick with current 15x8s for now to save some cash and not go with 15x9-15x10 wheels just yet.Leave a comment:

Leave a comment: