nice work so far

Dang, what has matt325is been up to???

Collapse

X

-

BBY1104

BBY1104 -

Well, wherever it came from, it's not typ210 E28 535 big diff. typ210 can't be bolted to E30 rear subframe, it's way too big for that. Also the typ188 back plate won't fit typ210. Driveshafts had to be shortened etc etc, it just can't be done "plug'n'play".Jonsku, it was actually from a 535, but I swapped the diff cover and output flanges, which is why it looks like an e30 diff. I wish i could understand Finnish, it is one of my goals in the next year or so. Yes, I am 1/2 Finnish, my dad's mother came from Finland to the US. And I really want to visit there!

Here's typ210 big diff and some E28 stuff

And welcome to Finland, i recommend coming in the summer or mid-winter :)Last edited by Jonsku; 06-05-2008, 03:58 AM.- E34 M5 (x 2) -

- E30 V8 Cabrio "Kylpyamme" -

- Alpina D10 Touring #33/94 -

+

- E46 318i Touring -

- Toyota Hiace 4wd -Comment

-

dude, that looks like melted american cheese...what kind of sealant is that?IG: deniso_nsi Leave me feedback here

Comment

-

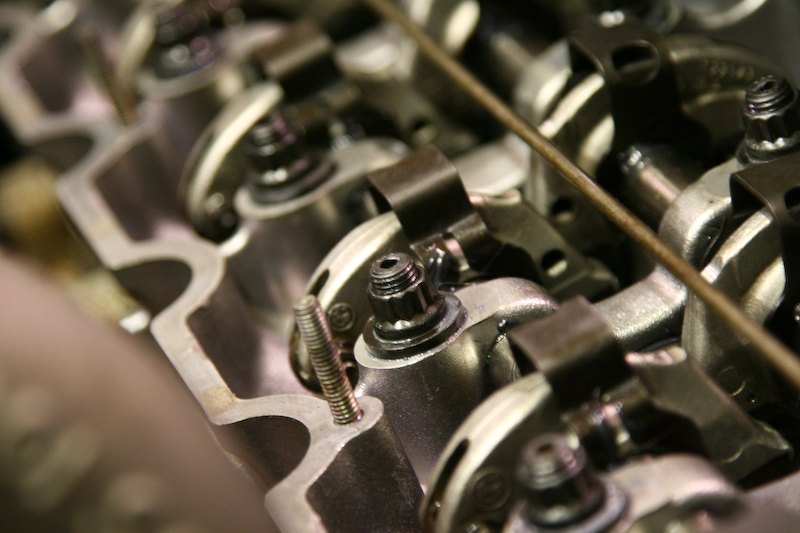

Well, I'm awake after a late night building the head, if all goes as planned, the engine should be back together today. Just a few gaskets to pick up and it should be good to go. I have to swap all of the exhaust studs too from my old head, but that doesn't take too long. Anyway, look for an update tonight.

BBY1104, thanks, I hope it all goes as planned.

Jonsku, that's good information, I'm glad it fit! I was literally on my back for an hour or so removing it from an e28 hoping it would work haha.

dude8383, yeah, i though that too, it's Permatex High Tack sealant.

matt

Comment

-

-

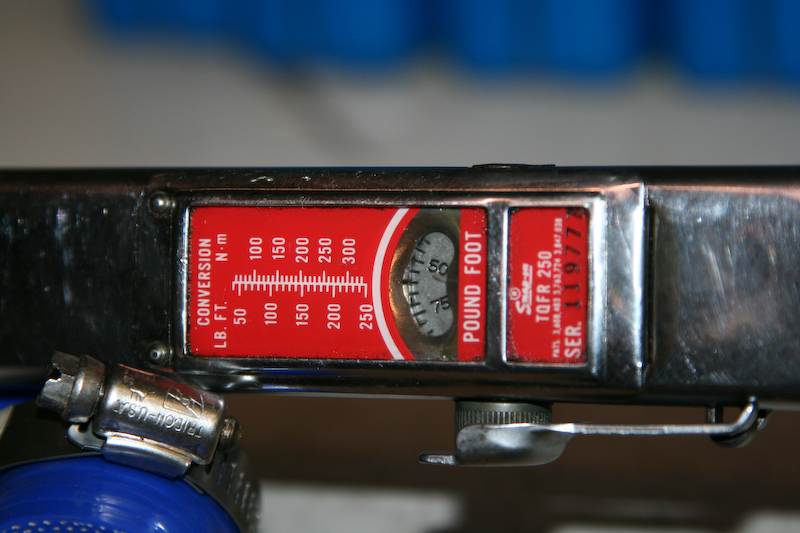

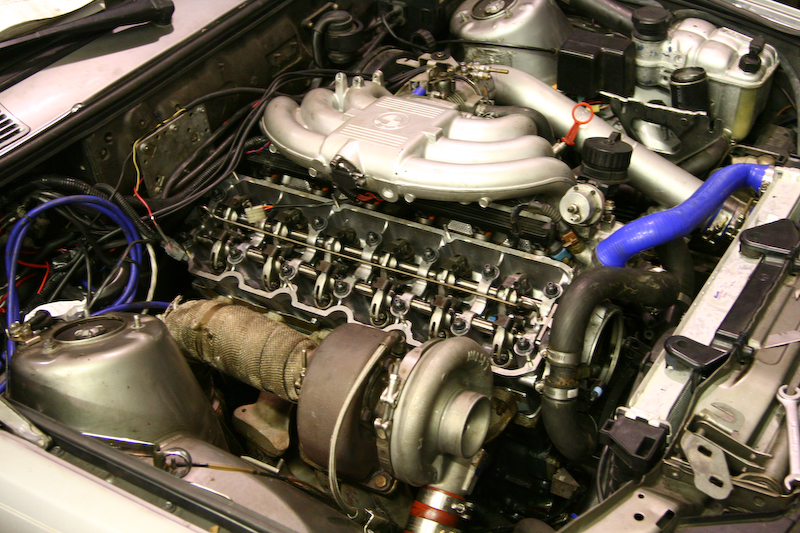

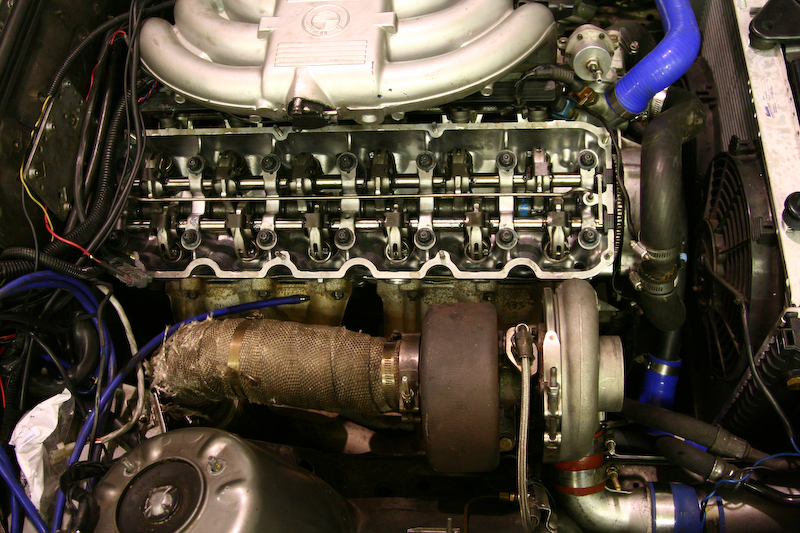

Another night, another update. I got the head back on the block with ARP head studs. All I have left is to hook up fuel lines, some coolant lines, some wires, coil pack, valve cover, change oil, coolant and bleed the brakes and it should be ready to rock. If I have time, I may strap it to the dyno since it's about 20 feet away... Oh, and I finally put on the Bimmerworld coolant hoses, I've had them for almost a year now, and just put them on. Anyway, here are some more shots.

Brandon, I have to go back to Oly on Sunday, I have to work for a few days next week.

eyagel, it's a Holset H1C.

Should be done tomorrow!

matt

Comment

-

Comment

-

It's not noobish, no worries, welding the head increases the clamping area of the head, as well as reduce the tendency for the head gasket to blow into the cooling passage next to the combustion chamber. All but one of my blown head gaskets have been into the cooling passages, known as a head gasket push. Basically too much cylinder pressure (21psi and 9:1 compression in my case) and not enough clamping pressure from head bolts/studs. The new ARP studs should also provide better clamping force than the metric blue bolts.

Anyway, I'm off to the shop soon to finish her up.

matt

Comment

-

Comment

-

-

Comment