I'll tell you! Well, for the last 5 days or so, I've been tearing apart the suspension putting in new urethane trailing arm, subframe, rear shock tower, diff bushing, and delrin shifter bushings from AKG. All of the rear bushings were coming apart, especially the shock tower bushings, they were garbage. Also added SS brake lines while I was in there. Also a new 3.25LSD from an 86 535i! This was the first few days...

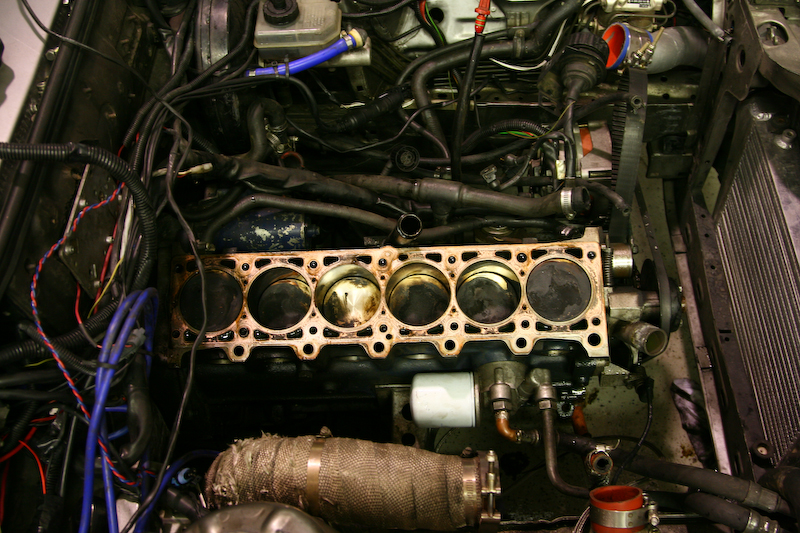

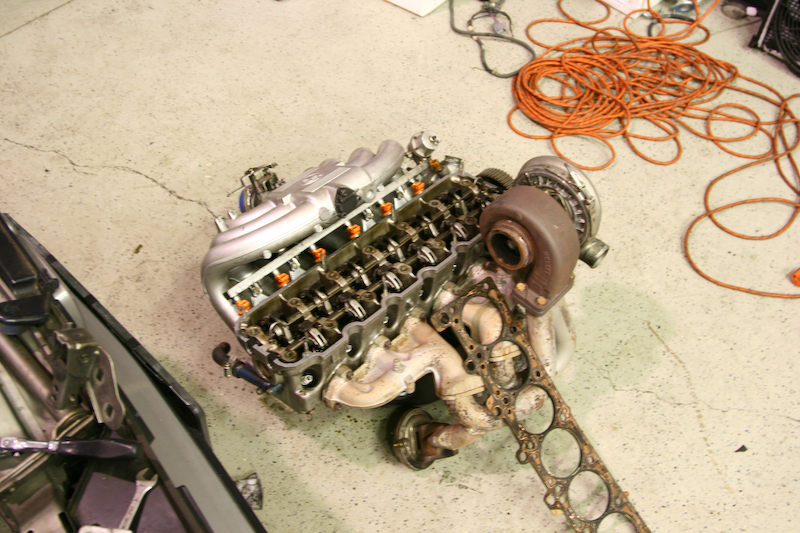

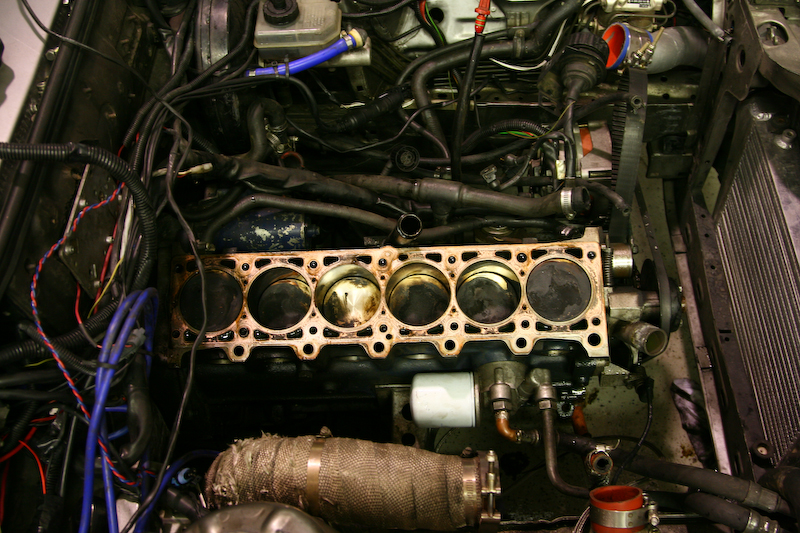

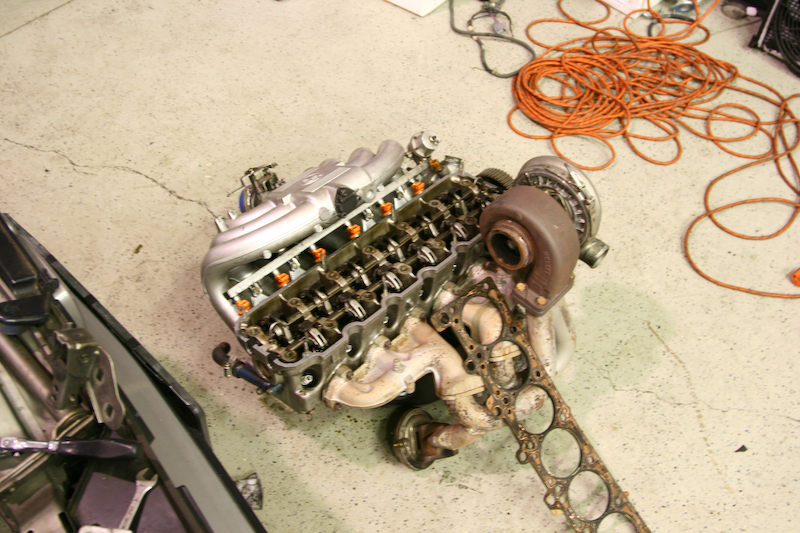

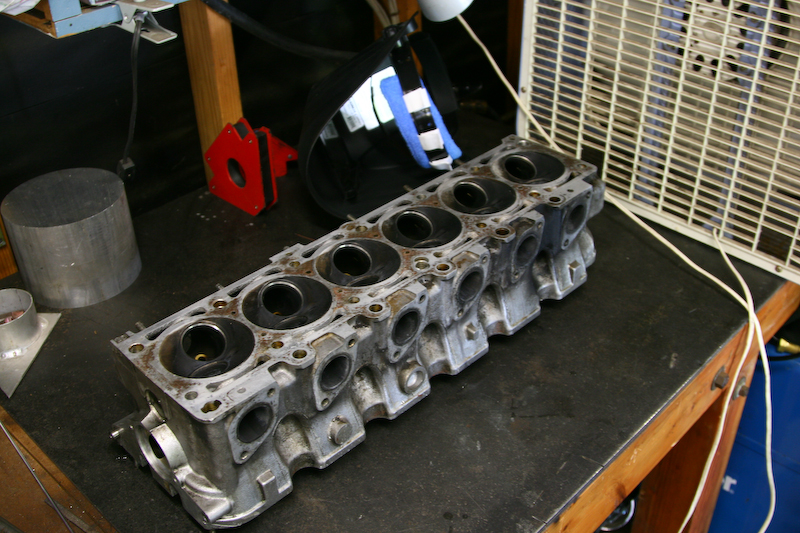

THEN, I decided it was time to check out why my cooling system has been pooping out for the last couple months or so (haven't drivin it in a while). I ripped off the head in about an hour and found out that I blew the MLS head gasket, on cylinder #4 and a little on 3, it bent the top layer up into the coolant passage next to the intake side of the head. Notice how clean cylinder 4 is compared to the rest ;) SOOOOOOO, I decided it was time to weld the cooling passages a bit on the head.

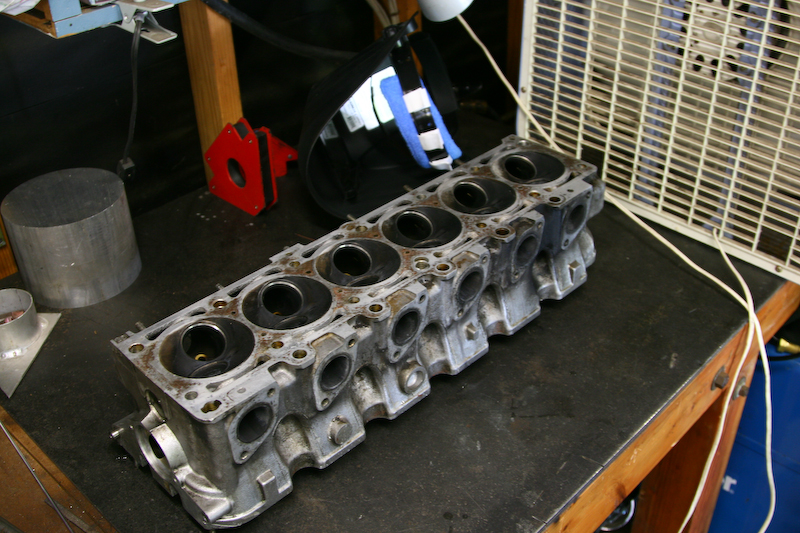

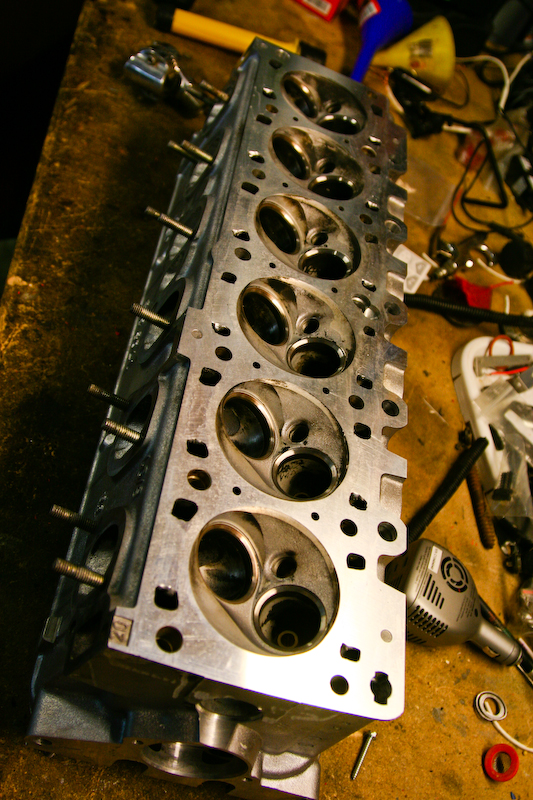

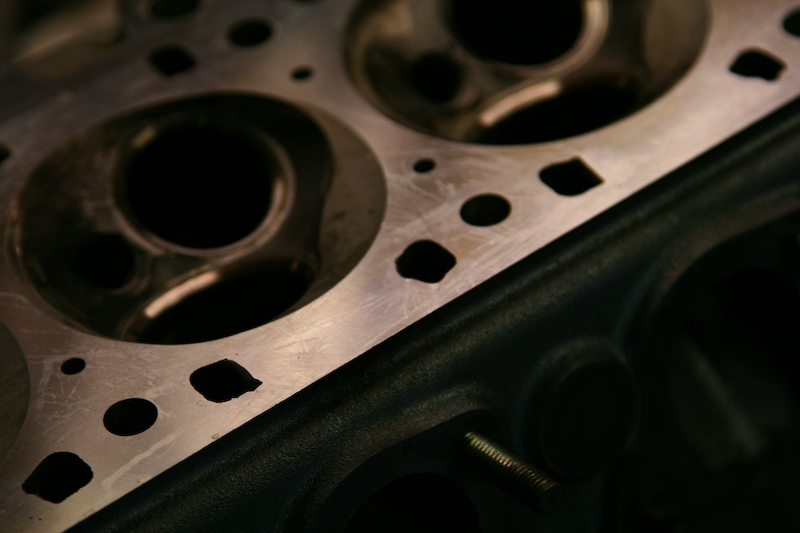

I took the head to my buddy Ben's house and cleaned up the head a bit, and he went to work with a big Miller TIG and some 4043 rod. It turned out very well, we preheated the head to about 200'F, welded (the head stayed at about 200'F for the duration of the welding process, the head cools pretty fast), then wrapped in tin foil, and put welding gloves and a blanket on top to slow down the cooling process (less likely to warp). It turned out very nice!

Today I took the head to the machine shop, they are going to clean, pressure test, check the straightness, cut the valve seats, install new guides, and resurface, and should be done tomorrow evening if the valve guides come in the late morning/early afternoon. Once that's complete, I'll take it home, install new stem seals, valves, springs, custom billet 280/280 cam, and new seals. Then I'll throw the head back on the car with a new stock head gasket (less likely to push with the welded head) with ARP head studs.

Also one morning I picked up the WSU FSAE car and put it in my garage ;)

I hope to have it running by Friday or Saturday, and to the Annual Northwest E30 Picnic on Sunday!

Anyway, on to the pics!

It's been a long 5 days work... whew!

matt

THEN, I decided it was time to check out why my cooling system has been pooping out for the last couple months or so (haven't drivin it in a while). I ripped off the head in about an hour and found out that I blew the MLS head gasket, on cylinder #4 and a little on 3, it bent the top layer up into the coolant passage next to the intake side of the head. Notice how clean cylinder 4 is compared to the rest ;) SOOOOOOO, I decided it was time to weld the cooling passages a bit on the head.

I took the head to my buddy Ben's house and cleaned up the head a bit, and he went to work with a big Miller TIG and some 4043 rod. It turned out very well, we preheated the head to about 200'F, welded (the head stayed at about 200'F for the duration of the welding process, the head cools pretty fast), then wrapped in tin foil, and put welding gloves and a blanket on top to slow down the cooling process (less likely to warp). It turned out very nice!

Today I took the head to the machine shop, they are going to clean, pressure test, check the straightness, cut the valve seats, install new guides, and resurface, and should be done tomorrow evening if the valve guides come in the late morning/early afternoon. Once that's complete, I'll take it home, install new stem seals, valves, springs, custom billet 280/280 cam, and new seals. Then I'll throw the head back on the car with a new stock head gasket (less likely to push with the welded head) with ARP head studs.

Also one morning I picked up the WSU FSAE car and put it in my garage ;)

I hope to have it running by Friday or Saturday, and to the Annual Northwest E30 Picnic on Sunday!

Anyway, on to the pics!

It's been a long 5 days work... whew!

matt

Comment