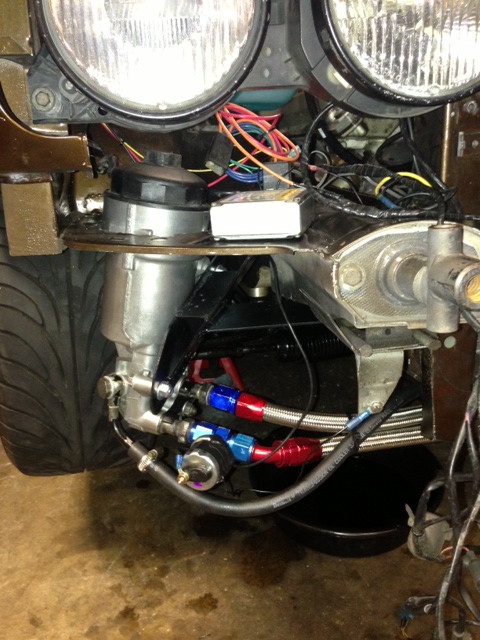

So, I've got my Rovah. I keep blowing the trans cooler line. Basically, to fit the engine the cooler line had to be cut and spliced, not by me. It blew apart, so I repaired it better....I though. It blew off again. So I'm trying to figure out a more, permanent solution.

Here is the pipe. 1/2" outside diameter....this translates to -8AN if I'm not mistaken.

So, making a hose to fit this, I'm thinking thread the end of the pipe and make a SS hose from these bits:

Or braze and end onto the pipe that the AN fitting with thread onto, and continue with the SS hose, etc.

Or just take it to a place that will make hydro hoses and have them make it for me, but I do want to have it so I can remove the hose for use on new trans lines, if something happens to these at some point.

I know, dumb question, but figured a second, tired, and fuck off opinion would help.

Here is the pipe. 1/2" outside diameter....this translates to -8AN if I'm not mistaken.

So, making a hose to fit this, I'm thinking thread the end of the pipe and make a SS hose from these bits:

Or braze and end onto the pipe that the AN fitting with thread onto, and continue with the SS hose, etc.

Or just take it to a place that will make hydro hoses and have them make it for me, but I do want to have it so I can remove the hose for use on new trans lines, if something happens to these at some point.

I know, dumb question, but figured a second, tired, and fuck off opinion would help.

Comment