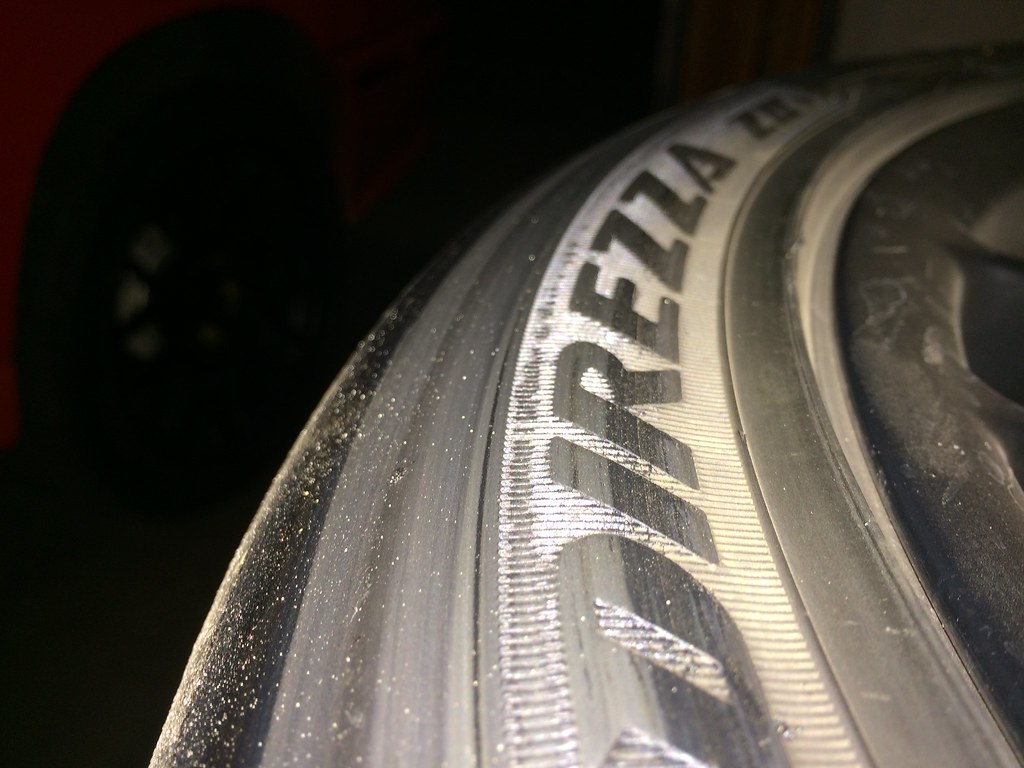

mmmm SSR Type Cs...

I wish I could find some 16x8 in 4x100 but the only way to go wider in 4x100 is to get 17x7.5 which I might do if I could ever find a pair to throw on the back. I might have to troll the Lotus forums

They did offer a 16x8 but its 4x114 and again... I doubt I can find a pair our there

I wish I could find some 16x8 in 4x100 but the only way to go wider in 4x100 is to get 17x7.5 which I might do if I could ever find a pair to throw on the back. I might have to troll the Lotus forums

They did offer a 16x8 but its 4x114 and again... I doubt I can find a pair our there

Comment