Hello all,

Just creating a thread where I can ask random questions and maybe help someone in the future with this process.

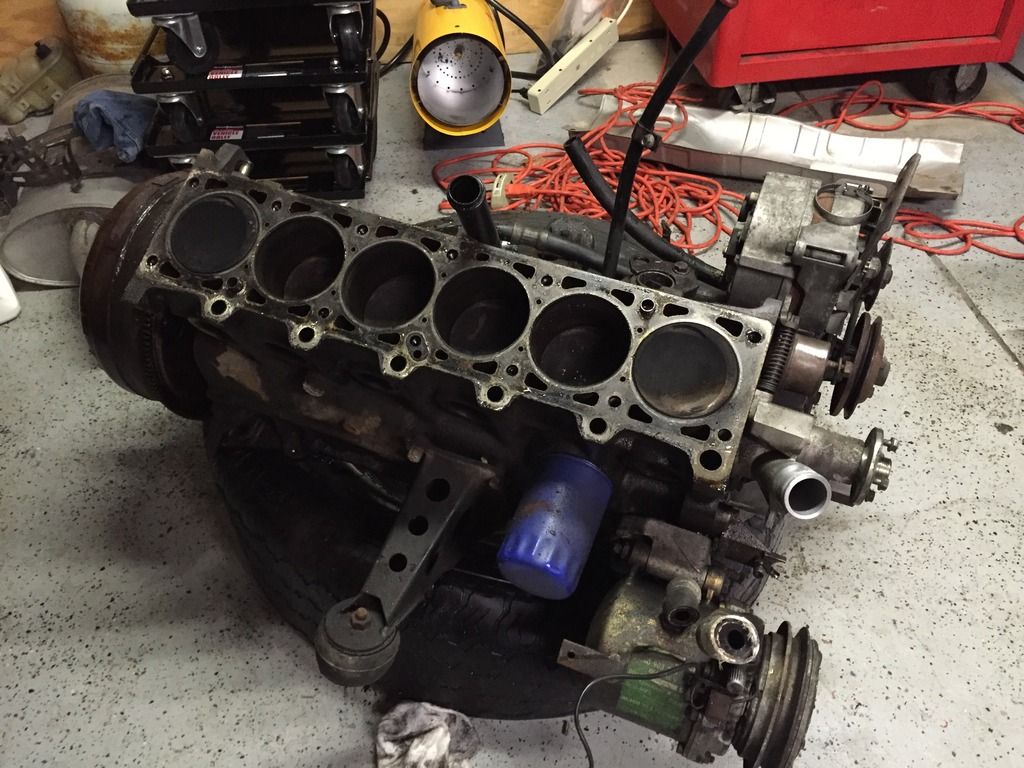

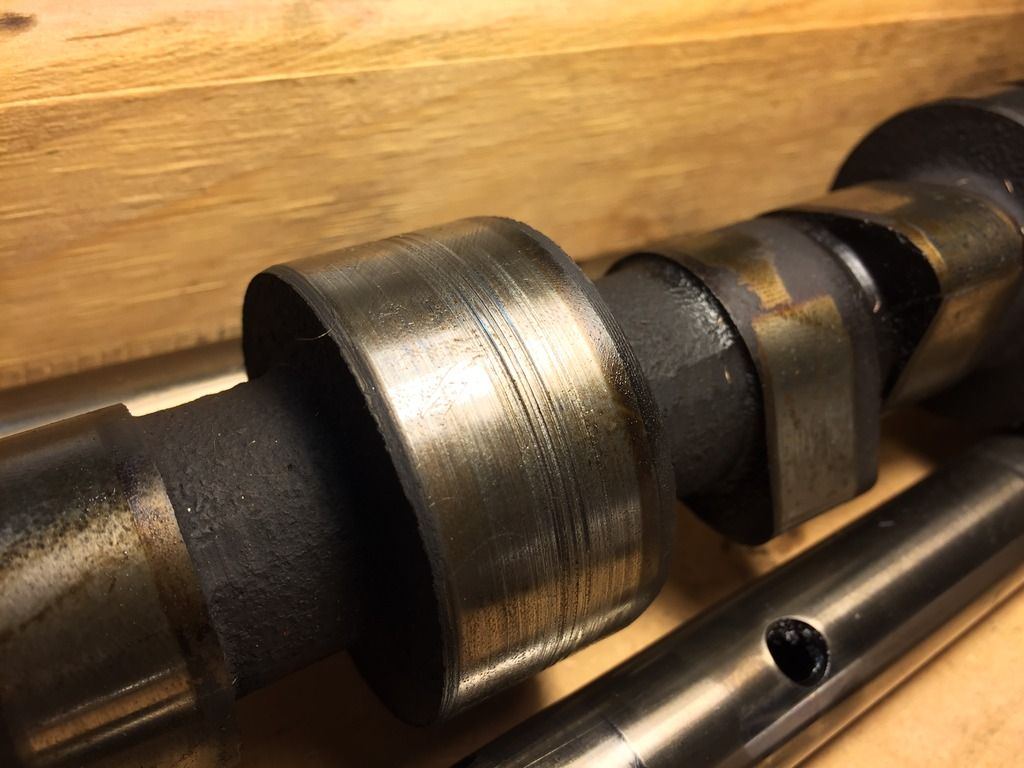

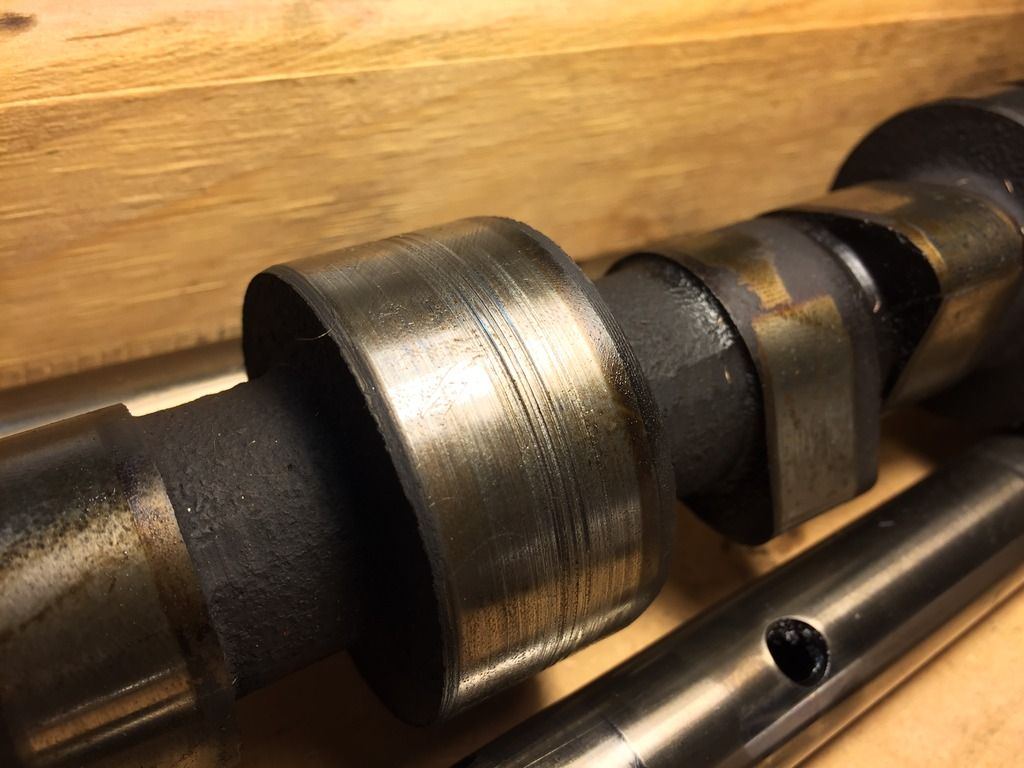

I bought this 1988 SETA motor from a local doing an LS swap for $200. The plan is new bearings, seals, rings, oring'd block with stainless wire, elring Head gasket, bimmerheads head with welded coolant jackets,280/274 dual pattern regrind cam, I intake manifold, 60lb injectors and the famous kinugawa TD06SL2-20G on a goodntight manifold.

I don't have any pics of it all together but we all know what a filthy M20 looks like right?

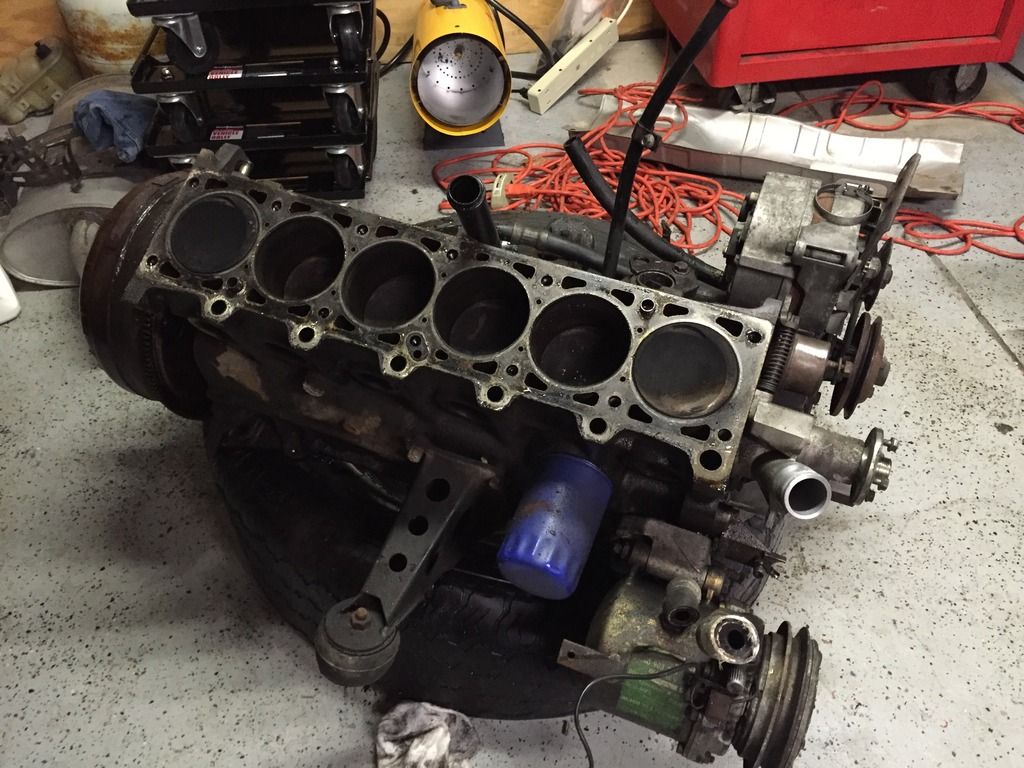

Head off:

Head was trash

Valve ding on piston number 1

Anyway I got the motor torn down

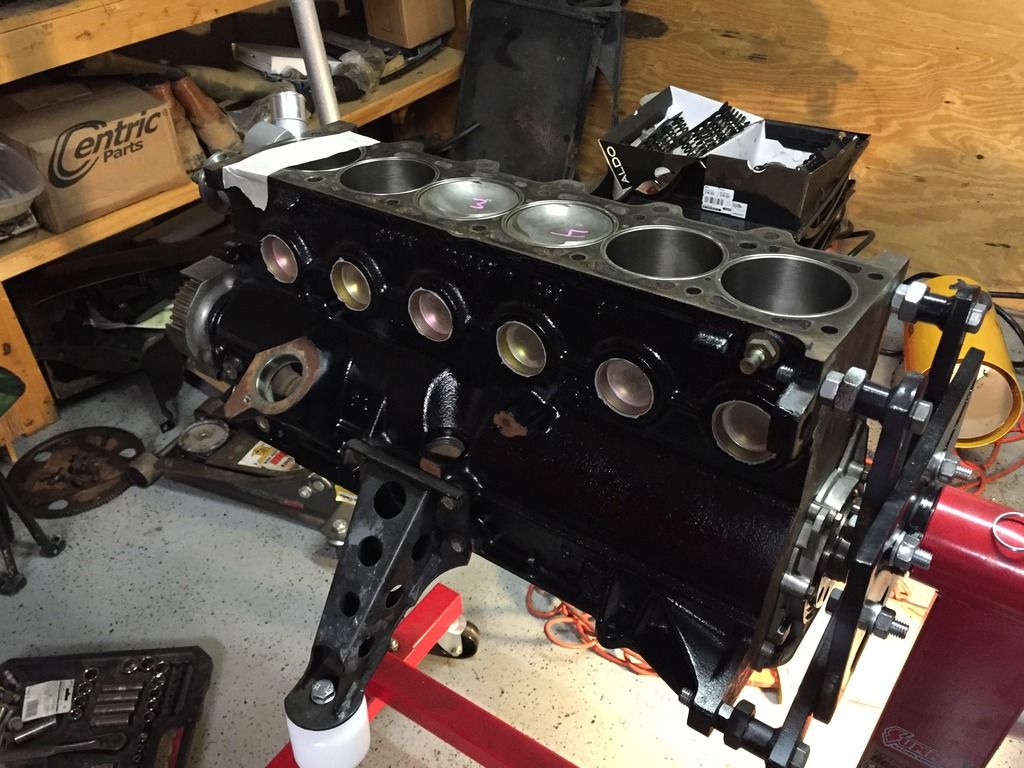

Looking good!

Why bmw? Why? Slotted screws have no place in this world.

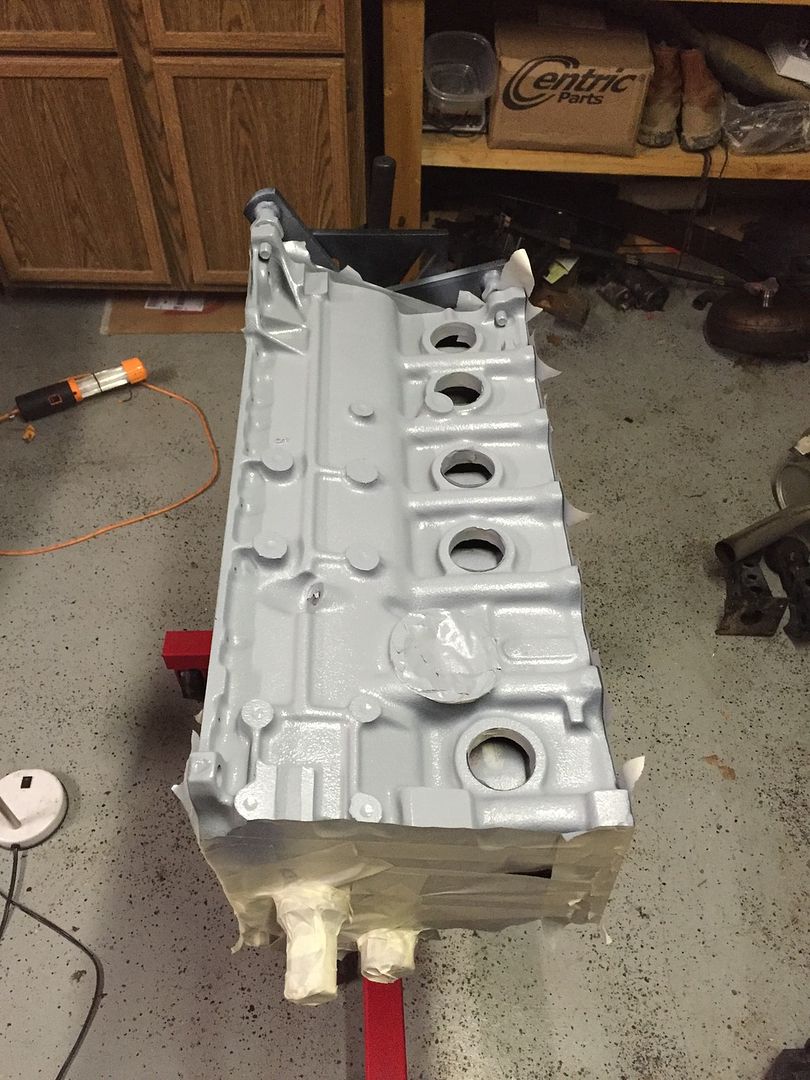

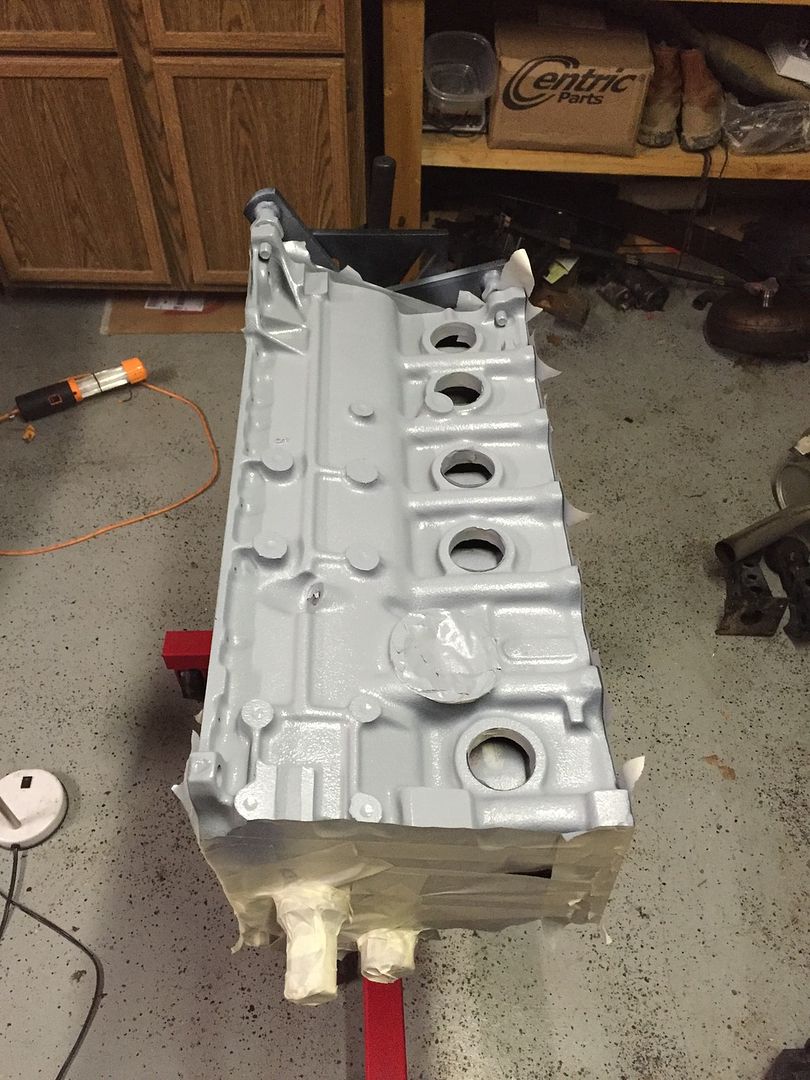

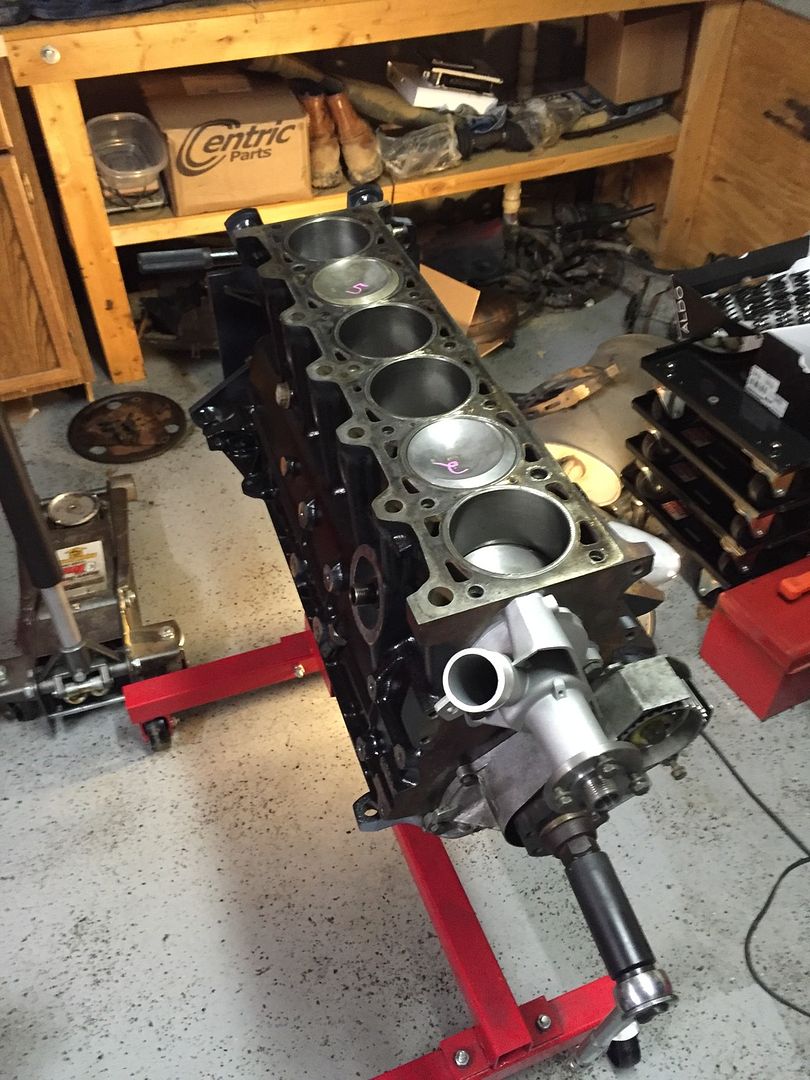

Block ready for the machine shop

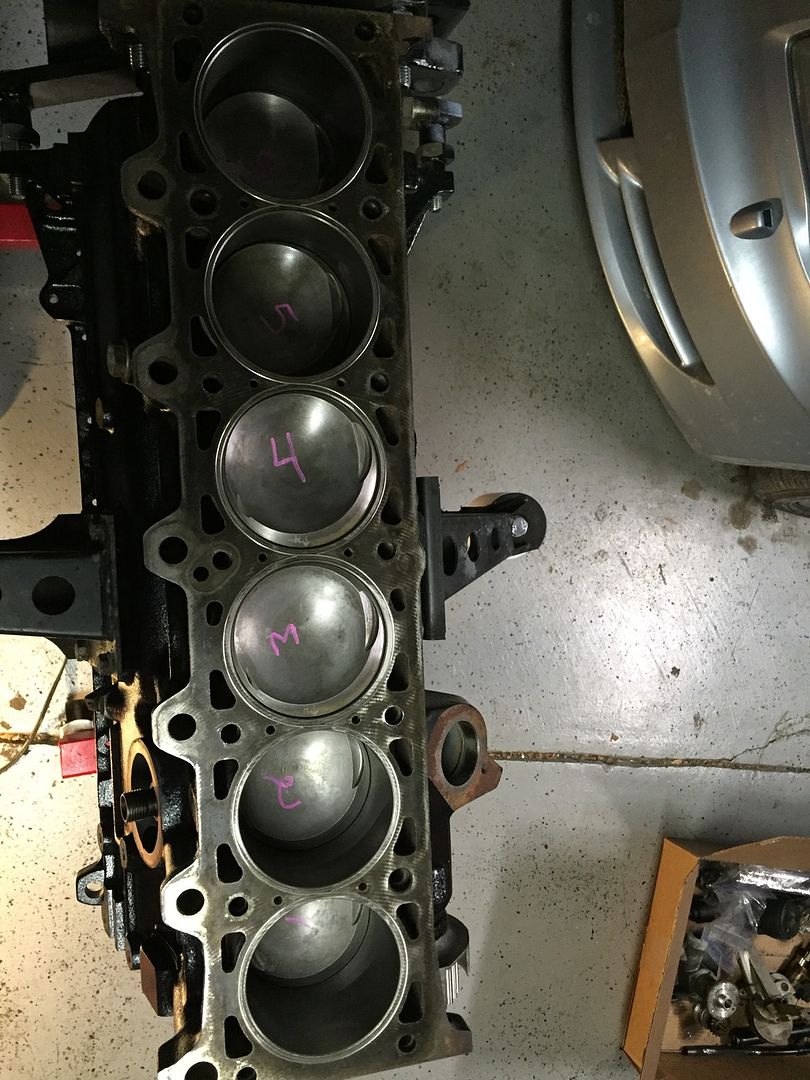

Cleaning the Pistons was an incredible amount of work. I drove out the wrist pins and soaked the Pistons overnight in some Autozone chem dip stuff, then used a piece of old ring to clean the carbon out.

Took care of that valve ding

While waiting on the machine shop I got the intercooler installed

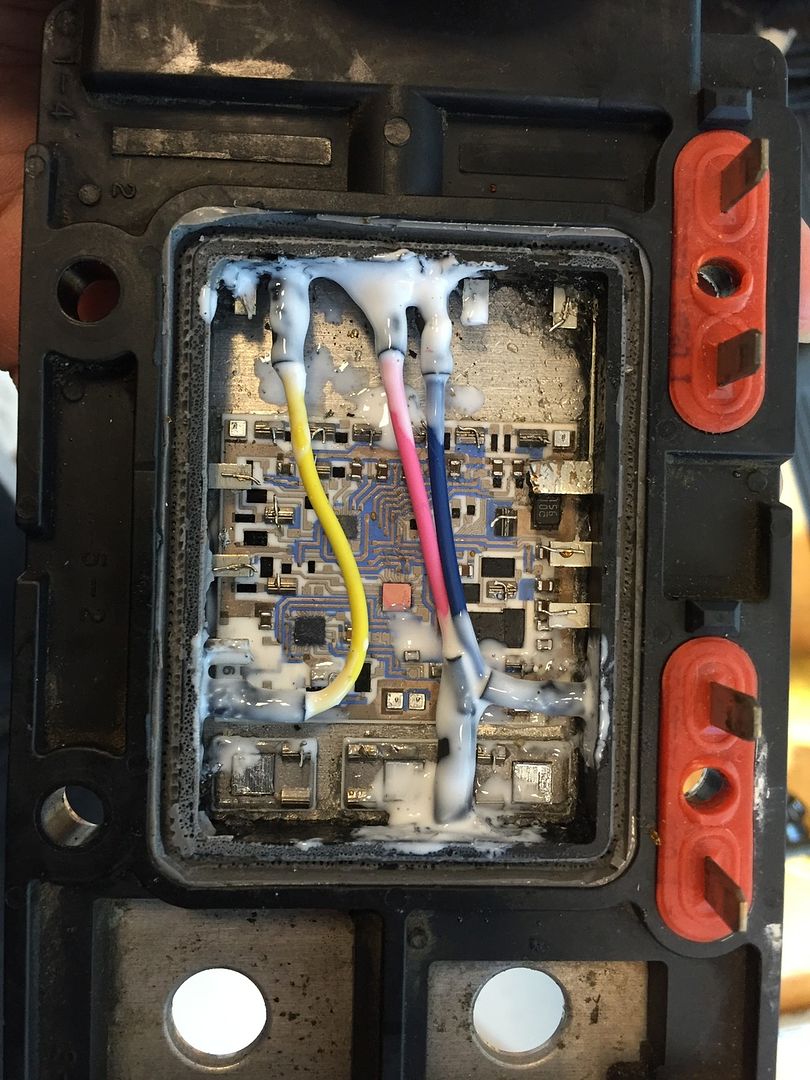

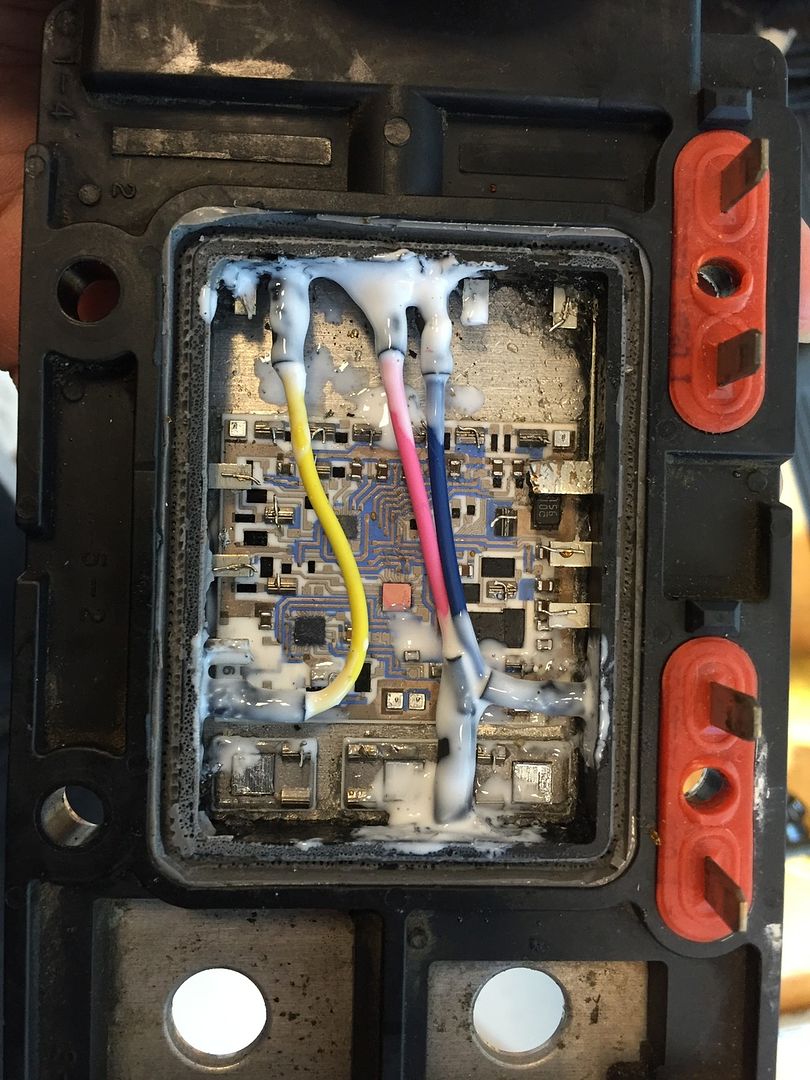

And wired up the wasted spark gm module

Then this baby showed up. Awwwww yeeaaahhh!!!

Finally got the block back

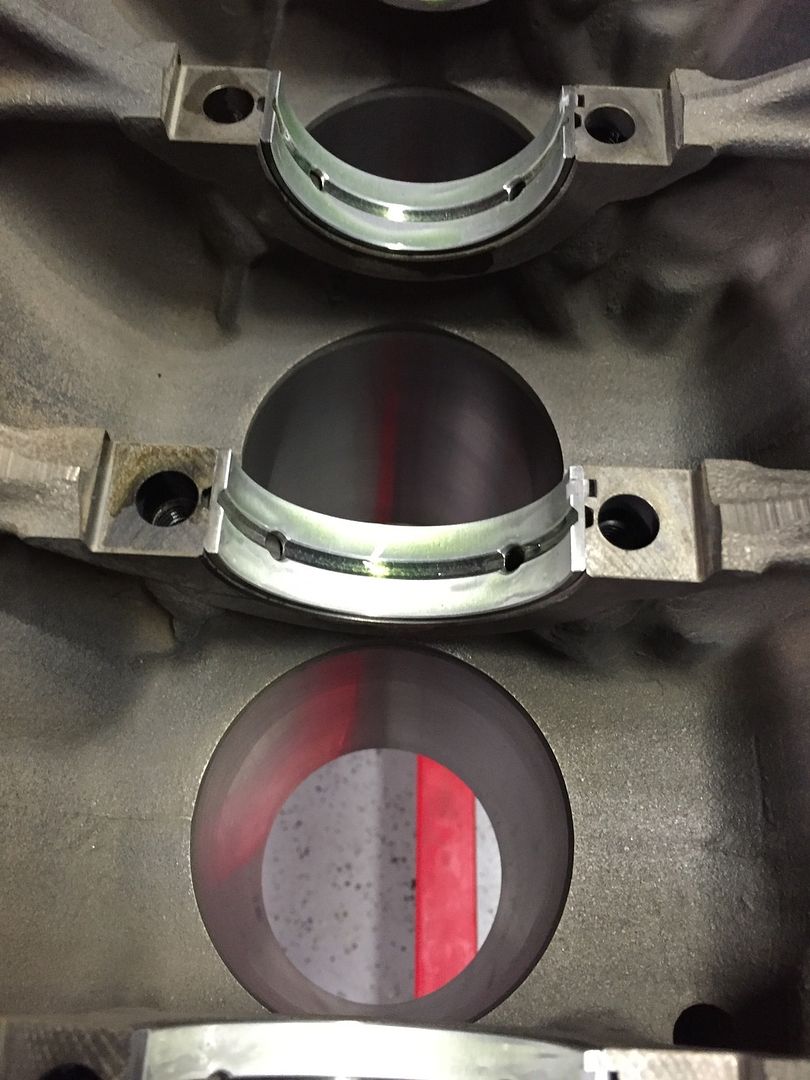

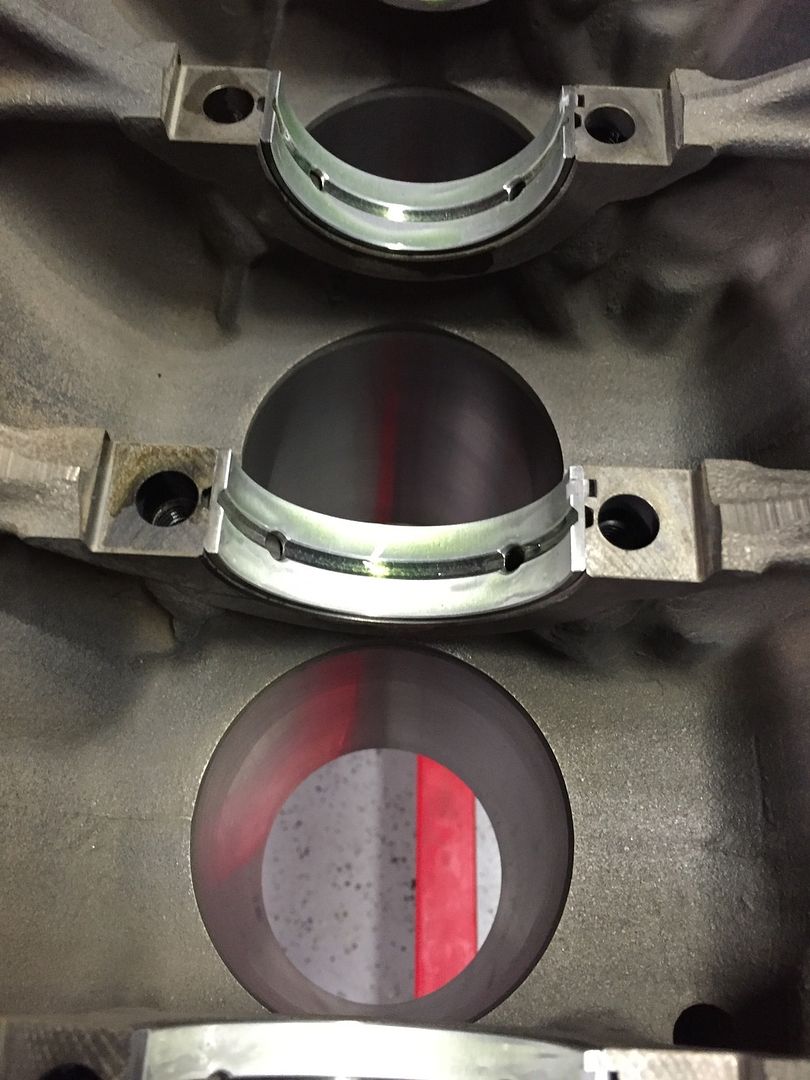

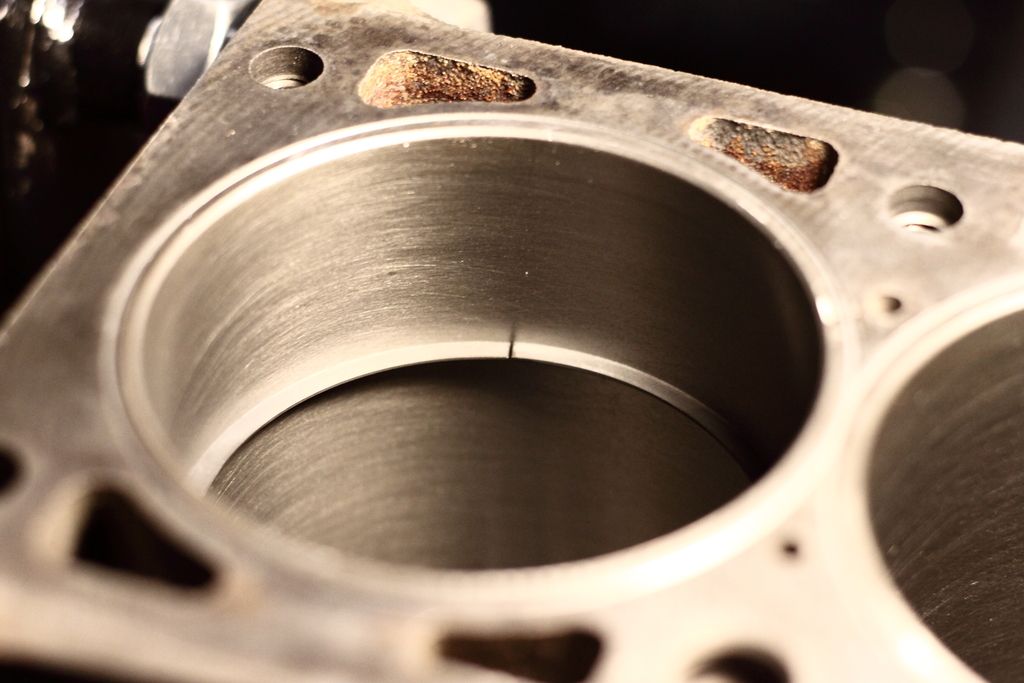

Fresh hone and he also cut the oring grooves with the boring bar. They're beautiful.

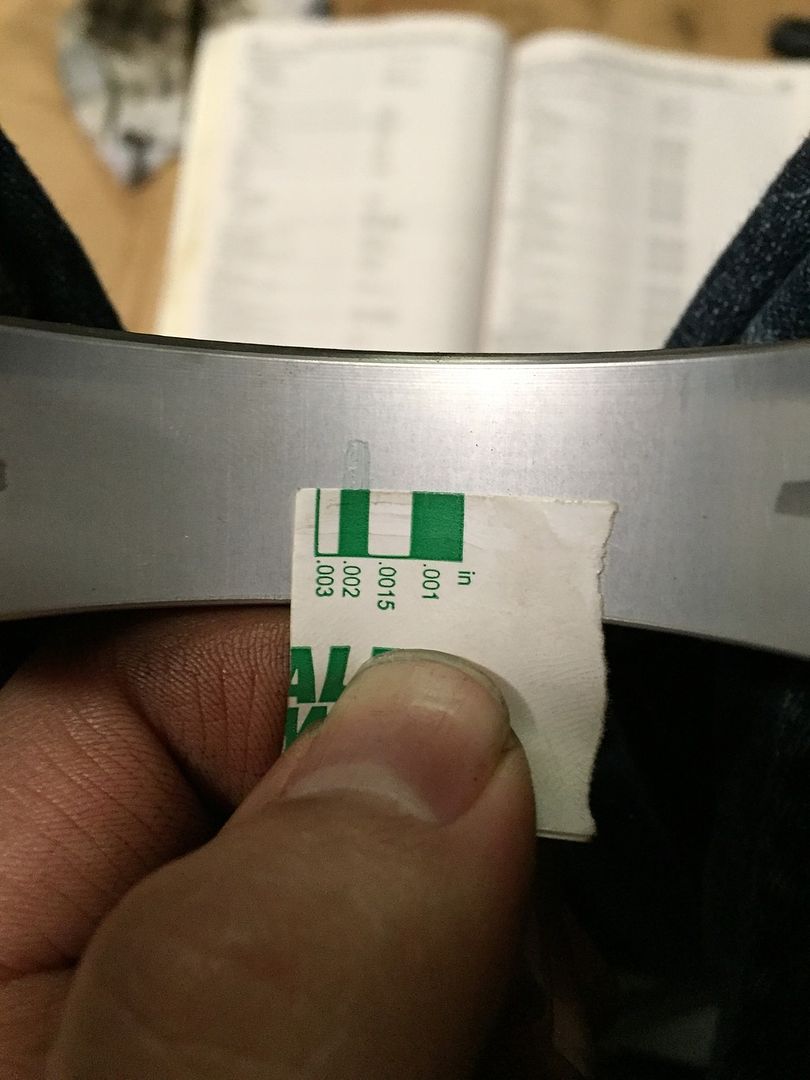

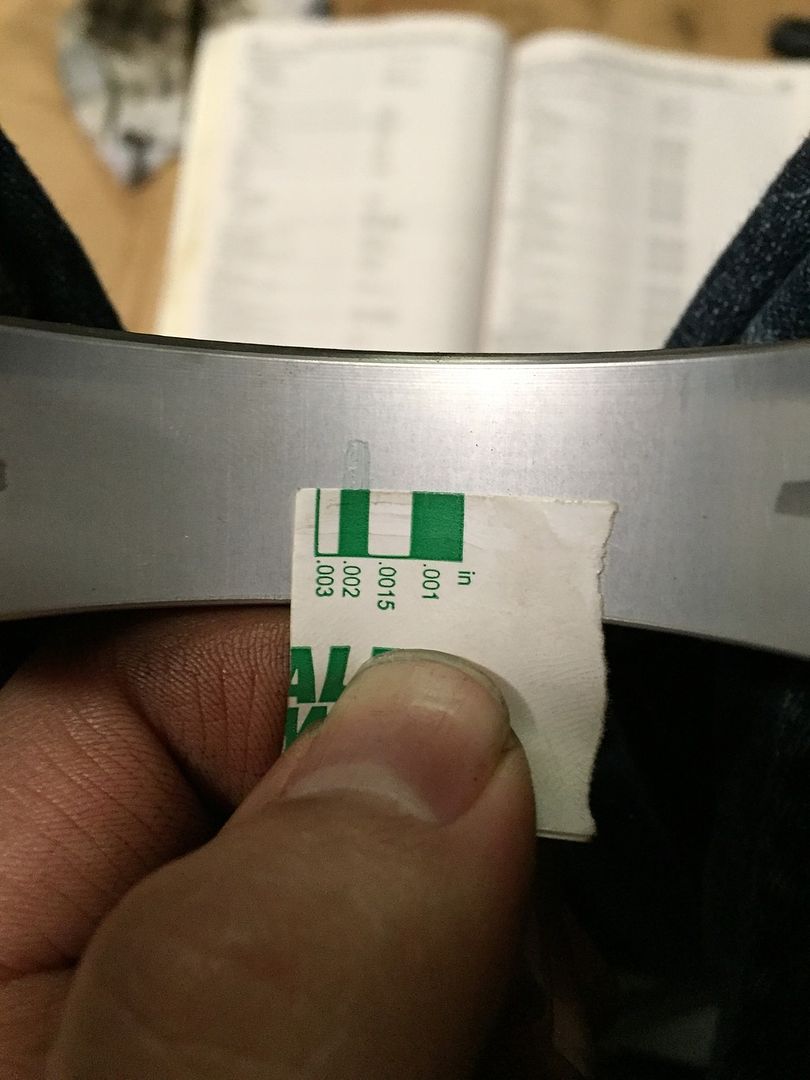

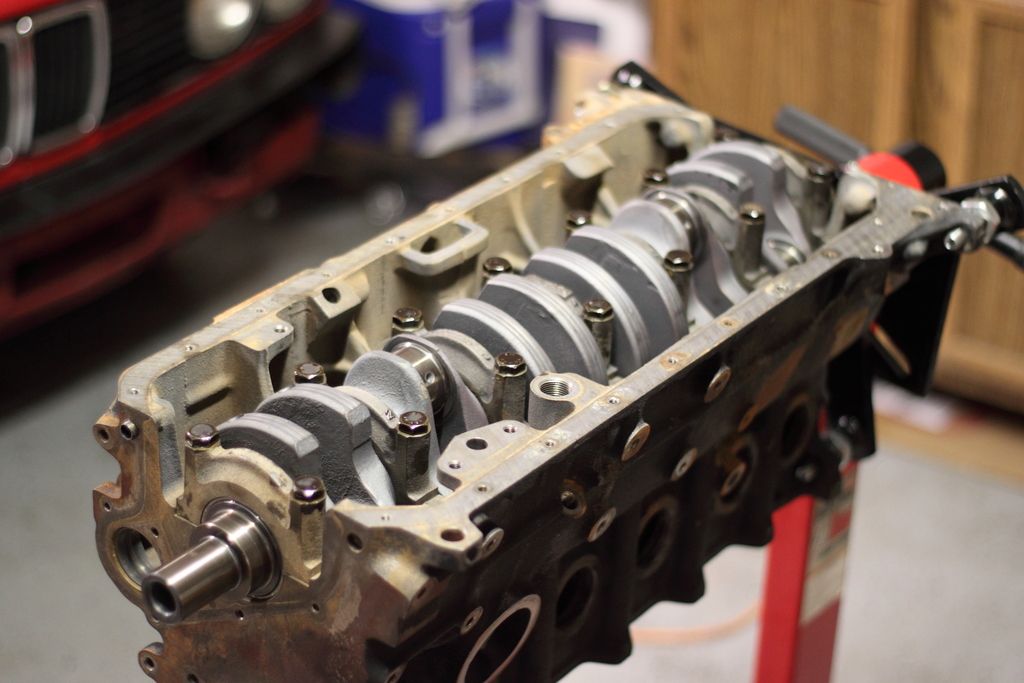

Mains were a bit on the loose side but in spec...

And that's where I'm at now. Waiting on a piston ring compressor to wrap up the rotating assembly. Also waiting on the head and crank scraper.

Stay tuned.

Just creating a thread where I can ask random questions and maybe help someone in the future with this process.

I bought this 1988 SETA motor from a local doing an LS swap for $200. The plan is new bearings, seals, rings, oring'd block with stainless wire, elring Head gasket, bimmerheads head with welded coolant jackets,280/274 dual pattern regrind cam, I intake manifold, 60lb injectors and the famous kinugawa TD06SL2-20G on a goodntight manifold.

I don't have any pics of it all together but we all know what a filthy M20 looks like right?

Head off:

Head was trash

Valve ding on piston number 1

Anyway I got the motor torn down

Looking good!

Why bmw? Why? Slotted screws have no place in this world.

Block ready for the machine shop

Cleaning the Pistons was an incredible amount of work. I drove out the wrist pins and soaked the Pistons overnight in some Autozone chem dip stuff, then used a piece of old ring to clean the carbon out.

Took care of that valve ding

While waiting on the machine shop I got the intercooler installed

And wired up the wasted spark gm module

Then this baby showed up. Awwwww yeeaaahhh!!!

Finally got the block back

Fresh hone and he also cut the oring grooves with the boring bar. They're beautiful.

Mains were a bit on the loose side but in spec...

And that's where I'm at now. Waiting on a piston ring compressor to wrap up the rotating assembly. Also waiting on the head and crank scraper.

Stay tuned.

Comment