First off, let me state that I am an electrical technician with over 21+ years professional experience in electronics repair, rework, and restoration. I specialize in custom electronics fabrication and electronics repair. I can build / repair electronics from high current applications to surface mount technology and circuit board repair. Please trust this service is performed with the utmost quality and standards.

Below is an outline of the service that I offer. The part number for this AFM is 13 62 1 466 350. This was used on many of the classic BMW motors but this particular unit came from my 1989 325is. Should work with all M20 motors. However, many Bosch AFM's are very similar and can be refurbished using these techniques.

Let me tell you that this is one of the most important sensors for your engine. After 20 or so years, these units really start to send your ECM poor and inaccurate feedback. The AFM has two sensors in one unit.

-There is a Air Inlet Temperature sensor, which provides feedback to the ECM for incoming air temp.

-There is a potentiometer which provides the ECM feedback voltage that is linear with respect to the opening of the internal flap. Non-linear for older sensors and eta's.

After many years of use, the inaccurate feedback will affect economy, poor running, poor idle, symptoms of misfire, and loss of power.

Here are some photos of the process that I used to test and refurbish the unit:

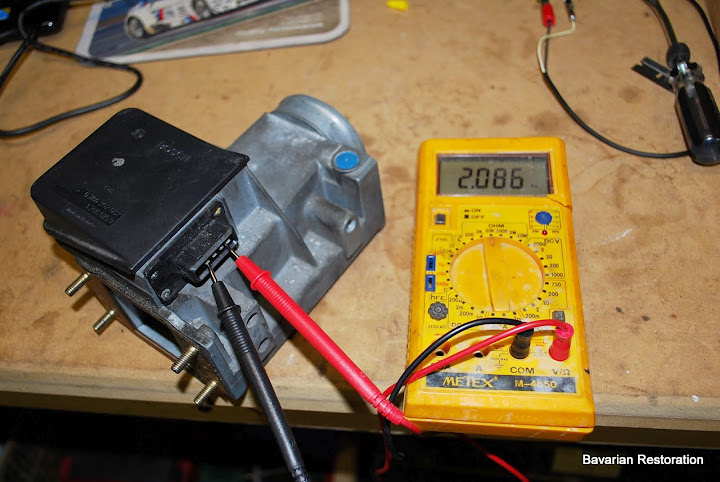

1. I first test the temperature sensor circuit. If this is bad, the AFM must be replaced. There are no replacement parts for this as of now. I am working on finding a suitable replacement that replicates the OEM electrical range. It should range from 1k ohms to 3k ohms (70F to 100F approx)

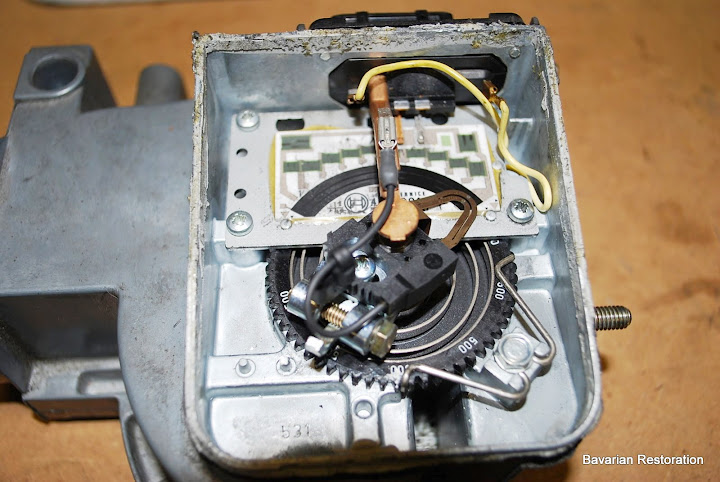

2. Unit is opened up and inspected for wear. This is the potentiometer circuit. In addition, I also check the spring tension vs. a known good and laser calibrated AFM that I use as part of my test setup. It is important to never adjust this spring tension as it was calibrated to very fine tolerance by Bosch.

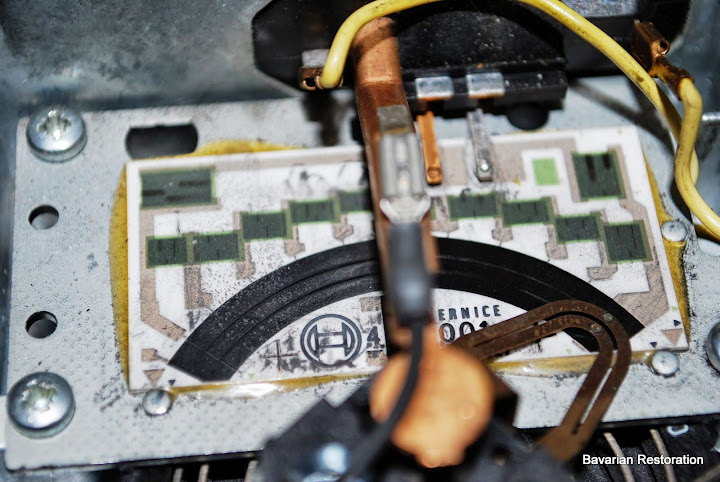

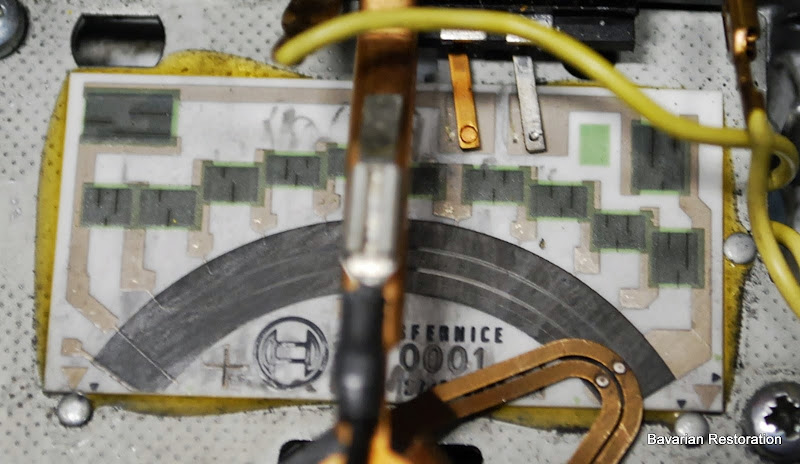

Close-up of the "resistor strip." As you can see there is severe wear along the resistor strip. Once this resistor strip is worn away, the car will start to idle rough, provide poor fuel economy and all other symptoms listed above. You can also see the input and output contacts coming out of the black connector. These must be refurbished too.

3. Entire arm assembly disassembled and all electrical contacts thoroughly cleaned.

Cleaned using special electronics cleaner, although this is not much help once the resistor strip is worn out.

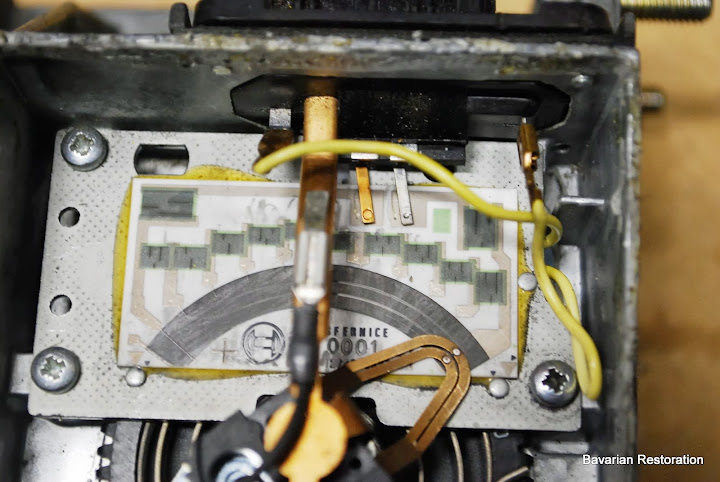

4. Once the resistor board is cleaned, I make adjustments to the connector contacts onto fresh resistor board. I also modify the wiper contact to make contact with fresh resistor strip. None of the old wear tracks are used. Connections are now used on fresh material only.

Close up of the action. Notice the wiper contact is now centered over fresh resistor strip. Noticed the electrical contacts now make contact with fresh resistor pads. Again my refurbished units contact only fresh resistor pads and strips.

5. Once re-assembled. The unit is tested for voltage output and drop out of any feedback during the length of travel of the internal flap.

Here are oscilloscope image "captures" of the voltage feedback of a bad AFM over 10 seconds. Notice the signal drops repeatedly to zero near the 0% open.

Here is another bad AFM. This one drops voltage output near the fully open position. Does your car suddenly loose power near full throttle? This is your problem.

After electrical refurbishment. Very clean signal throughout, no drops to 0 volts.

Here is another "after" capture of the feedback. Notice there are NO drops to zero and the output curve is smooth with no irregular drops or increase in resistance.

Here is a repeatability test to verify there so no drops to zero near the fully open range. Nice clean signal with no signal drop out.

Once all is done. I lubricate all mechanical joints with Teflon and I sealed the unit up with silicon sealant. Electrically, these units are in near new condition and you will find better MPG, smoother idle, smoother power of lower RPM'S.

Again my process is this:

Those interested in purchasing an AFM service, the cost is $300 not including return shipping, 2 year repair warranty!.

Note: for older AFM's and MAF, I will include an additional service free of charge. This service is to ground the wiper contact arm to the grounding pin in the connector. This provides a more reliable and stable feedback and is the reason why the later versions implemented a ground in the design.

A quick testing note. Never use a mutlimeter on an AFM. Multimeters measure and display an average. So if you measure your AFM output resistance or voltage, your meter is showing you an average of that measurement. A meter will never "see" the microsecond voltage drops that occur when these fail.

Thanks and if there are any questions, please post them up or PM me. info@bavrest.com. www.BavRest.com. www.Instagram.com/BavarianRestoration www.Instagram.com/BavRest

Greg

Below is an outline of the service that I offer. The part number for this AFM is 13 62 1 466 350. This was used on many of the classic BMW motors but this particular unit came from my 1989 325is. Should work with all M20 motors. However, many Bosch AFM's are very similar and can be refurbished using these techniques.

Let me tell you that this is one of the most important sensors for your engine. After 20 or so years, these units really start to send your ECM poor and inaccurate feedback. The AFM has two sensors in one unit.

-There is a Air Inlet Temperature sensor, which provides feedback to the ECM for incoming air temp.

-There is a potentiometer which provides the ECM feedback voltage that is linear with respect to the opening of the internal flap. Non-linear for older sensors and eta's.

After many years of use, the inaccurate feedback will affect economy, poor running, poor idle, symptoms of misfire, and loss of power.

Here are some photos of the process that I used to test and refurbish the unit:

1. I first test the temperature sensor circuit. If this is bad, the AFM must be replaced. There are no replacement parts for this as of now. I am working on finding a suitable replacement that replicates the OEM electrical range. It should range from 1k ohms to 3k ohms (70F to 100F approx)

2. Unit is opened up and inspected for wear. This is the potentiometer circuit. In addition, I also check the spring tension vs. a known good and laser calibrated AFM that I use as part of my test setup. It is important to never adjust this spring tension as it was calibrated to very fine tolerance by Bosch.

Close-up of the "resistor strip." As you can see there is severe wear along the resistor strip. Once this resistor strip is worn away, the car will start to idle rough, provide poor fuel economy and all other symptoms listed above. You can also see the input and output contacts coming out of the black connector. These must be refurbished too.

3. Entire arm assembly disassembled and all electrical contacts thoroughly cleaned.

Cleaned using special electronics cleaner, although this is not much help once the resistor strip is worn out.

4. Once the resistor board is cleaned, I make adjustments to the connector contacts onto fresh resistor board. I also modify the wiper contact to make contact with fresh resistor strip. None of the old wear tracks are used. Connections are now used on fresh material only.

Close up of the action. Notice the wiper contact is now centered over fresh resistor strip. Noticed the electrical contacts now make contact with fresh resistor pads. Again my refurbished units contact only fresh resistor pads and strips.

5. Once re-assembled. The unit is tested for voltage output and drop out of any feedback during the length of travel of the internal flap.

Here are oscilloscope image "captures" of the voltage feedback of a bad AFM over 10 seconds. Notice the signal drops repeatedly to zero near the 0% open.

Here is another bad AFM. This one drops voltage output near the fully open position. Does your car suddenly loose power near full throttle? This is your problem.

After electrical refurbishment. Very clean signal throughout, no drops to 0 volts.

Here is another "after" capture of the feedback. Notice there are NO drops to zero and the output curve is smooth with no irregular drops or increase in resistance.

Here is a repeatability test to verify there so no drops to zero near the fully open range. Nice clean signal with no signal drop out.

Once all is done. I lubricate all mechanical joints with Teflon and I sealed the unit up with silicon sealant. Electrically, these units are in near new condition and you will find better MPG, smoother idle, smoother power of lower RPM'S.

Again my process is this:

- AFM is heat tank soaked, ultra sonic cleaned, bead blasted clean, and clear coat painted.

- Test intake air temperature sensor resistance over the heat range specified by Bosch.

- Test AFM door spring tension and adjust accordingly to known Bosch specs.

- Disassemble wiper arm and connector assembly. Clean incoming, and outgoing contacts and bend them to contact fresh material. Clean wiper arm contacts and primary grounding post. Adjust wiper arm to contact fresh material.

- Reassemble wiper arm and connector. (all contacts touch fresh new material only!)

- All mechanical pivot points are lubricated with liquid Teflon. Its important to understand these 30+ year old sensors develop a lot of mechanical wear which may affect calibration, this is corrected.

- Measure voltage signal output with oscilloscope and adjust if necessary. We run a variety of tests including quality repeatability, linearity testing (or non linear for eta AFM's,) quality repeatability in the idle genre and the fully open genre. Every AFM is thoroughly tested over a variety of conditions.

- Lid is sealed with silicone to ensure a moisture and water proof AFM.

- Every successfully refurbished AFM will receive a quality control decal.

Those interested in purchasing an AFM service, the cost is $300 not including return shipping, 2 year repair warranty!.

Note: for older AFM's and MAF, I will include an additional service free of charge. This service is to ground the wiper contact arm to the grounding pin in the connector. This provides a more reliable and stable feedback and is the reason why the later versions implemented a ground in the design.

A quick testing note. Never use a mutlimeter on an AFM. Multimeters measure and display an average. So if you measure your AFM output resistance or voltage, your meter is showing you an average of that measurement. A meter will never "see" the microsecond voltage drops that occur when these fail.

Thanks and if there are any questions, please post them up or PM me. info@bavrest.com. www.BavRest.com. www.Instagram.com/BavarianRestoration www.Instagram.com/BavRest

Greg

Comment