So you had a spun bearing? I take it the bearings were aftermarket. Where they miced prior to assembly?

my 24v build, slightly different than the norm. Now with dyno numbers!

Collapse

X

-

Engine build #2 is almost done, I think early January Im flying up. Before then I'll decide whos installing the engine. Still leaning towards having him do it (crazy, right??) but I still think thats the best way to do it. We've chatted more lately and he seems to understand my pain. In the end, he is WAY more experienced than me and Id trust his work over mine. Its obvious Ive made some costly mistakes.Simon

Current Cars:

-1966 Lotus Elan

-1986 German Car

-2006 Volkswagen Jetta TDI

Make R3V Great Again -2020Comment

-

Glad to see this is still moving forward.

Kevin is a solid dude. It seems like a lot of issues were caused by not having a single person do all the assembly.

Also it just seems like there was some first timer mistakes. Don't worry, it happens to us all and its how we learn to be more careful next time and what to look for.-Nick

M42 on VEMSComment

-

Yea he tried to help save me some money by doing some work myself and I was pretty nervous about some of the stuff I was doing, and tried really hard to be extra careful but I still failed. Live and learn.Simon

Current Cars:

-1966 Lotus Elan

-1986 German Car

-2006 Volkswagen Jetta TDI

Make R3V Great Again -2020Comment

-

Hi,this post is very helpfull!! thanks

i've see your m50 harness scheme and i need to ask if you have check if it's all correct, looks great!Comment

-

Bought a one way ticket for 1/9/14, now it looks like I'll need to get myself a return ticket. At least now I can clean the engine bay since there still wont be an engine in it.Simon

Current Cars:

-1966 Lotus Elan

-1986 German Car

-2006 Volkswagen Jetta TDI

Make R3V Great Again -2020Comment

-

Stopped by the machine shop and saw my engine and some other fun stuff.

Here is one of my Metric Mechanic coated bearing$$$ that has 10-15 minutes of run time on it...

busted_bearing by 2mAn

busted_bearing by 2mAn

the block still looks nice

bareblockpt2 by 2mAn

bareblockpt2 by 2mAn

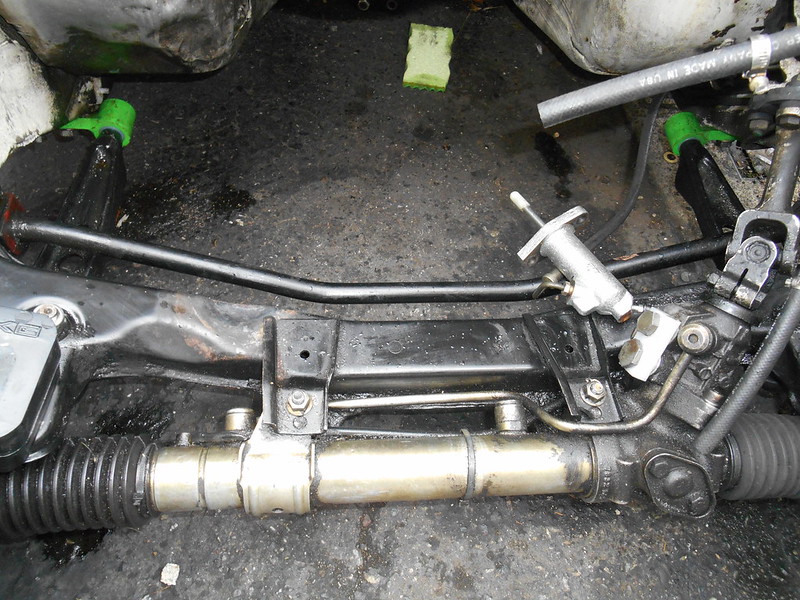

I snapped this pic so you could see some of the fun stuff that you will never see later. AKG motor mounts, Silence Power Steering delete, Treehouse CABs, and the subframe modified for the S50 downpipe

details by 2mAn

details by 2mAn

So, I had to order a Timesert BIGsert kit and according to the engine builder, engine might be assembled and ready to go by the end of the week. Kevin said he just needs one day to assemble the engine and install it into the car. I am planning on a final (one way) trip in February, but haven't bought a ticket yet. I just might be driving this car soon. Fingers crossed....Simon

Current Cars:

-1966 Lotus Elan

-1986 German Car

-2006 Volkswagen Jetta TDI

Make R3V Great Again -2020Comment

-

So not quite a spin bearing, but one that was very unhappy. There are a number of reasons that could have cause this; oil starvation, improper torque, no pre-lube, not enough oil clearance, etc.,.

My guess is the not enough oil clearance (wrong bearing size) or no prel-ube. Is the machine shop going to micro-polish the crank journals and mic the new bearings prior to final assembly?

Also, was that a main or rod bearing?

Comment

-

the car is definitely getting driven hard for all the shit Ive been going through since I bought it...

Im hanging on by a thin thread. It seems like everytime I go balls deep into a build (like this) I end up in a shitty position and I end up selling the car, and regretting it. Im trying hard to prevent this, but its been a rough road.

Wrong bearing size would be a big WTF because its not an overbore size. I HIGHLY doubt the machine shop didnt put any assembly lube on it, assuming thats what you mean by pre-lube. I was told the crank was fine and cleaned up good. I'll ask about mic-ing the bearings and also if it was a rod or a main. I only had a small window to go visit. Its a tough situation to be in (1200 miles away) and I hope nobody else tries to do a build this way. just seems to be the way things go in my life.:curse:So not quite a spin bearing, but one that was very unhappy. There are a number of reasons that could have cause this; oil starvation, improper torque, no pre-lube, not enough oil clearance, etc.,.

My guess is the not enough oil clearance (wrong bearing size) or no prel-ube. Is the machine shop going to micro-polish the crank journals and mic the new bearings prior to final assembly?

Also, was that a main or rod bearing?Simon

Current Cars:

-1966 Lotus Elan

-1986 German Car

-2006 Volkswagen Jetta TDI

Make R3V Great Again -2020Comment

-

Plastigauge every rod journal.Wrong bearing size would be a big WTF because its not an overbore size. I HIGHLY doubt the machine shop didnt put any assembly lube on it, assuming thats what you mean by pre-lube. I was told the crank was fine and cleaned up good. I'll ask about mic-ing the bearings and also if it was a rod or a main. I only had a small window to go visit. Its a tough situation to be in (1200 miles away) and I hope nobody else tries to do a build this way. just seems to be the way things go in my life.:curse:

Honestly, the Metric Mechanic bearings are wasted $$$. OEM bearings go 250k and come out looking nice without any special coating. I highly recommend just getting some OEM bearings. That bearing looks like it was way too tight and the spotting shows that something has contaminated the bearing and bedded into it.

Also check the rod caps and make sure they match up. A close friend of mine learned that lesson the hard way.Comment

_(edited)_IMG_20200926_170054(2).jpg?width=1920&height=1080&fit=bounds)

Comment