I originally posted this on E30Tech. When I first started my 32V swap project, it looked like E30Tech had a better AWD section, while R3V had a better 32V swap section. That appears to have changed.

Original thread: http://www.e30tech.com/forum/showthread.php?t=116657

I've been reading up and doing a lot of RealOEM research related to my 32V AWD swap. I'll be coming back to this post to complete it and add more information.

I've come across several 24V swaps that are in the works, but only one, IIRC, that has been completed.

Some of the information in this post is from my own research, much of it is from information I've read here on the forum and elsewhere. Feel free to contribute information; I'll edit this post to add it.

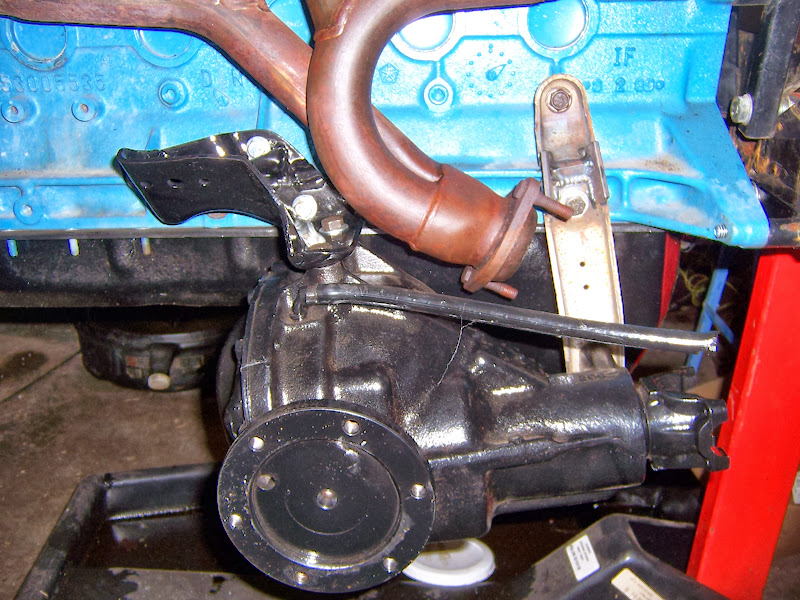

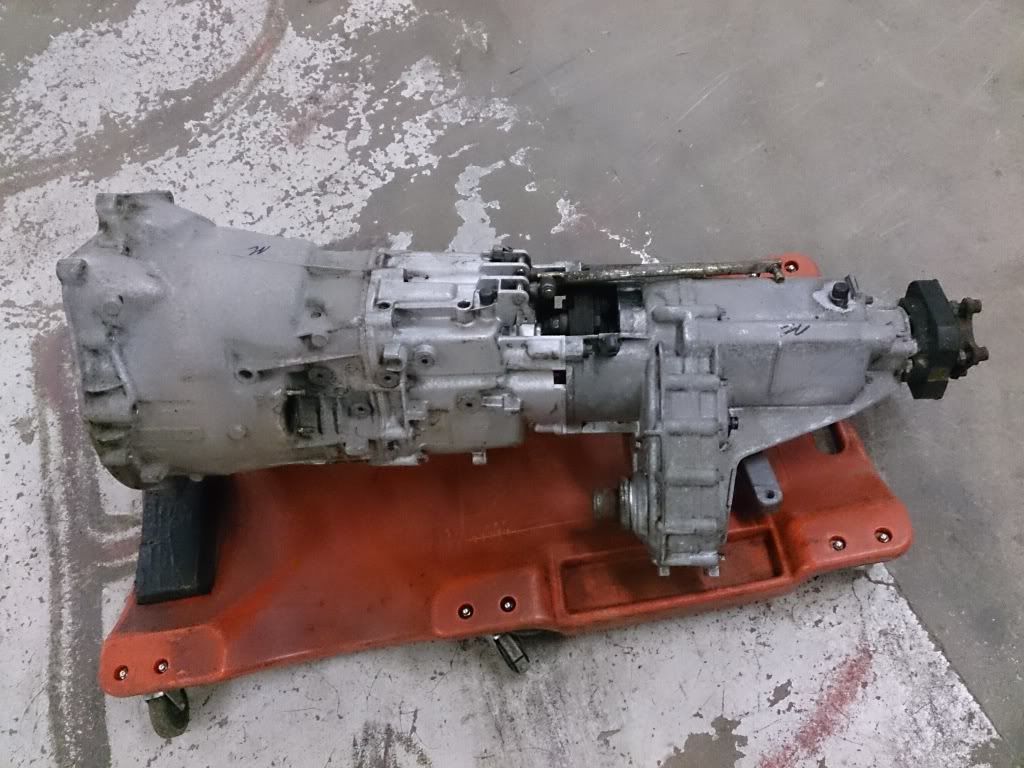

Transfer Case: The additional driveline component that AWD cars have which sends drive power forward as well as rearward and controls the power split front to rear. The transfer case is bolted to the output end of the transmission, but is sealed from the transmission and has an independent lubrication oil supply.

Drop: The portion of the transfer case that is offset from the main driveline and provides drive power to the front differential.

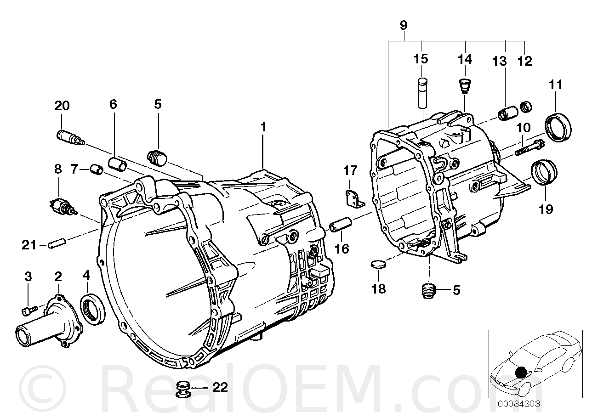

Semi-Divorced: Describes transfer case mounting BMW used in the E30 325iX and E34 525iX with manual transmissions. The space between the transmission output shaft seal and transfer case input shaft seal is accessible with the two units bolted together. BMW installs a guibo in this space to cushion driveline shock and to reduce the required precision for assembly of the transfer case to the transmission.

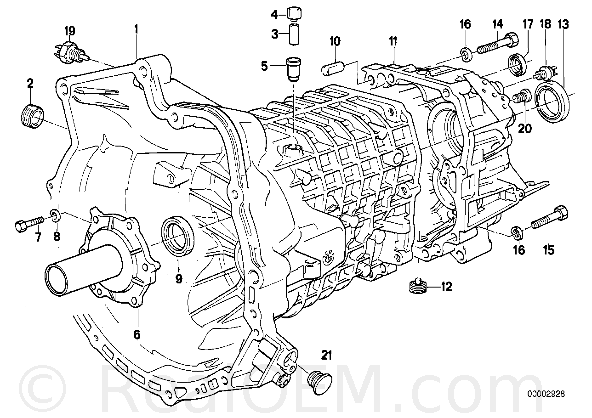

Integrated: Describes transfer case mounting BMW used in the E30 325iX and E34 525iX with automatic transmissions, as well as the E53 X5 and E46 325xi and 330xi with manual or automatic transmissions. The flange on the rear case of the transmission fully encloses the shaft coupling between the transmission and transfer case. The volume between the transmission output seal and transfer case input seal is only accessible by removing the transfer case from the transmission.

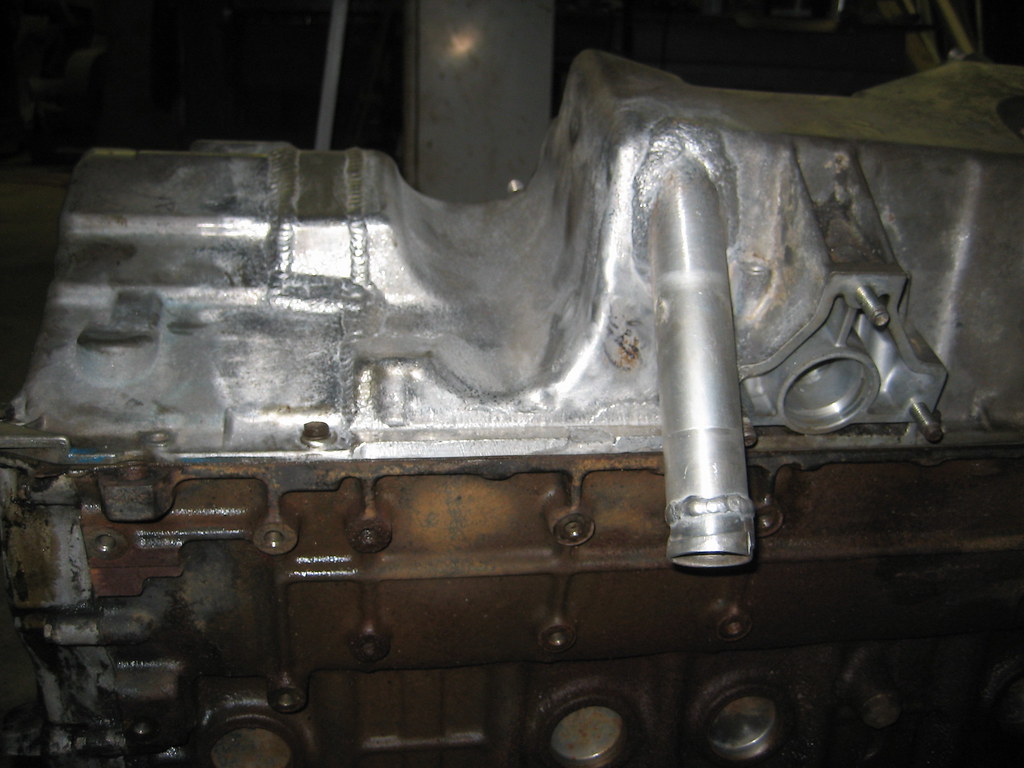

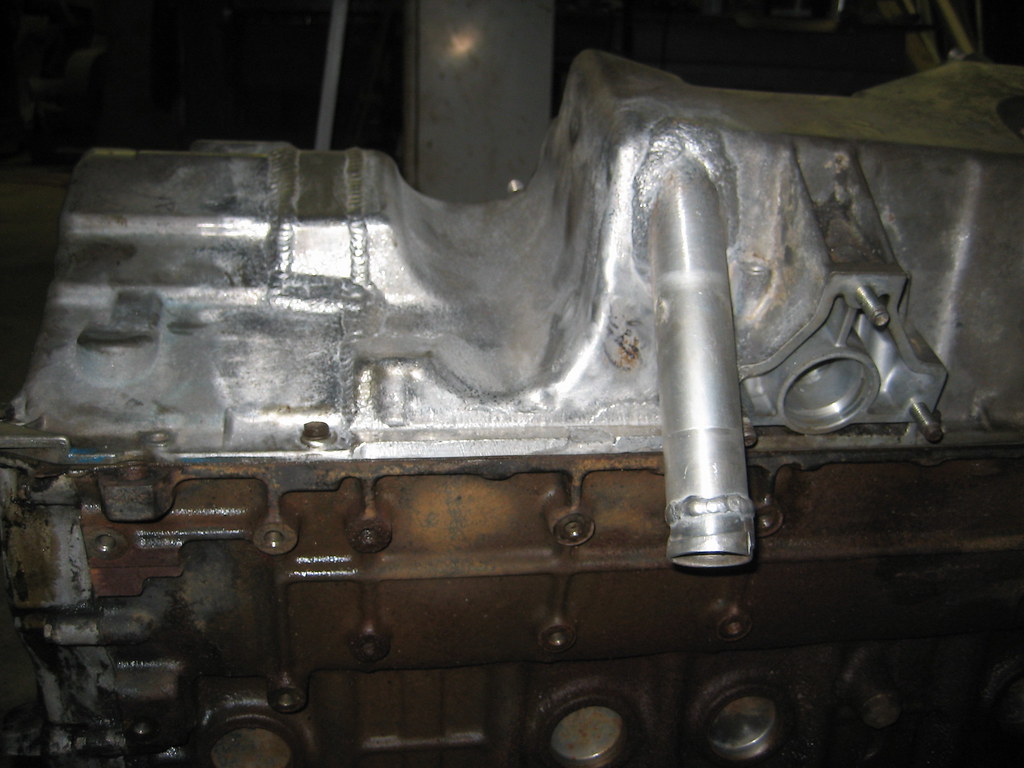

Bearing Block: The casting that bolts to the right side of the AWD oil pan and carries a bearing that supports the extended shaft of the right side inner CV joint. It also carries the right side axle seal. It seals to the oil pan with the same P/N o-ring that the differential uses to seal to the oil pan. This part is specific to the front sump assembly. E30 and E34 bearing blocks are not interchangeable.

Oil Sump: The combination of oil pan, oil pump and oil pump pickup tube all from the same original application which assemble without modification

Front Drive Assembly (FDA): The combination of oil pan, differential, bearing block and inner CV joints all from the same original application which assemble without modification.

2. Discussion

The 24V AWD swap is electrically nearly identical, but mechanically more complex than the 24V RWD swap. The only electrical difference is the location of the oil level switch and sensor on the engine. The RWD engines have this sensor at the front, while the AWD engines have it at the rear. This is because the RWD oil pans are front sump while the AWD oil pans are rear sump.

The AWD strut towers are located further forward than the RWD strut towers, giving the AWD cars less caster. The AWD floor pan stamping is different than the RWD floor pan stamping.

The alignment of the transfer case front output and front differential pinion centerline is an important interface that must be understood when assembling a driveline.

The bellhousing patterns of the M20 and M50 (and all other 24V engines) are the same, but the 24V engine is leaned over an additional 10 degrees compared to the M20 in order to keep the larger cylinder head under the low BMW "Flying Wedge" hood lines. In a RWD swap, it is possible to bolt the Getrag 260 transmission to the 24V engine. As a result, the transmission is tilted 10 degrees and adaptation of the rear trans mounts and shift linkage is necessary. Once accomplished, this adaptation works well. This is not possible in the AWD E30 because the extra tilt would raise the transfer case drop such that it would interfere with the floor pan.

Mechanical differences vs. RWD swap:

-Engine mount arms: The AWD e30 has engine mounts in different locations than the RWD cars. The E36 mount arms will not work. E34 24V engine mount arms appear to be close

-Brake boost: The AWD strut towers are further forward (less caster) than the RWD strut towers. This has the potential to affect packaging of a hydroboost, but I don't know the specifics yet.

-Front Drive Assembly (FDA): This is the most obvious complication. If the swap adheres to BMW's original design, then the front diff will bolt to the engine oil pan and the right side axle intermediate shaft will go through the pan. The oil pump, pickup tube and oil pan (collectively: "oil sump") must have interfaces for the front diff and axles, as well as clearance for the AWD front crossmember, which is located forward of the RWD front crossmember position.

-The entire FDA must come from the same application. The length of the left inner CV joint spline is specific to the differential. The length of the right inner CV joint shaft and spline is specific to the combination of differential, oil pan and bearing block. Bearing blocks do not share bolt patterns and are not interchangeable. Differentials do not interchange outside their original bodies.

All BMW front differentials are variants of the 168mm rear differentials. There are a wide variety of ratios available. Known examples include:

2.35 E46 330xd M57 manual transmission

2.47 E46 330xd M57N manual transmission

2.93 E46 330xd automatic transmission

3.07 E53 X5 3.0d manual transmission, E46 330xi manual transmission

3.23 E46 325xi manual transmission

3.38 E34 525iX (Does not interchange with other gearsets)

3.46 E46 325xi and 330xi automatic transmission

3.64 E53 X5 4.4i

3.64 E30 325iX European market (Only interchanges with other E30 front gearsets)

3.91 E53 X5 4.6is

3.91 E30 325iX US market manual transmission (Only interchanges with other E30 front gearsets)

4.10 E53 X5 3.0i automatic transmission

4.10 E30 325iX US market automatic transmission (Only interchanges with other E30 front gearsets)

I have not verified that ratios in the same "range" can be interchanged between E46 and E53 carriers/cases.

I do not know at what ratio the carrier break occurs (If any)

There is a "case breaK". Low ratio cases are cast with more pinion clearance than high ratio cases.

Differentials for a particular body are interchangeable. For the E30 and E46, different ratios are all used with the same engine, so interchangeability is obvious. E53 6 and 8 cylinder differentials use the same bolt pattern to the oil pan and are interchangeable.

The E53 front differential will accept the same part number Quaife limited slip differential as the rear of a Z3 1.9. The E34, E46 and E53 carriers all have different widths across the carrier bearings, with the E34 being the narrowest and the E53 being the widest.

While it is possible to fabricate brackets and use a differential housing with integral intermediate tube bolted to the oil pan rails of a RWD pan, the front sump of the RWD pan would interfere with the AWD crossmember location and steering rack. I do not know if a custom crossmember would have sufficient clearance, or if the rack itself would have to be relocated. A dry sump system would completely overcome this difficulty. If you're capable enough to do this, you really don't need me to tell you how.

AMC Eagle front differential and mounting

3. Front Drive Assembly (FDA)

No production 24V FDA will fit in the E30 AWD engine bay with the stock crossmember and rack location.

The FDA consists of the oil pan, oil pump, oil pickup tube, front differential, bearing block and inner CV joints from the same application.

For the passenger side the distance from the side gear splines to the axle seal must be the same for the differential and the inner CV joint cup.

For the driver's side, the distance from the side gear spline through the differential case, through the oil pan, through the right side bearing block to the axle seal must be the same for the sump assembly as it is on the CV joint cup.

Need axle assembly collapsed lengths

Need data to compare track widths of different AWD cars against widths of the bearing block + oil pan + differential assembly from different source vehicles to compare lengths of axle shafts

The E46 FDA can not be used as it places the axle centerline too far forward to fit in the E30 engine bay. The differential and front face of the sump would interfere with the crossmember, while the rear of the engine would interfere with the firewall.

3.a. E34 525iX

[production dates, part numbers, BMW list price(?), pics]

The International Market E34 525iX is the BMW application that is closest to the E30 in technology and production dates.

The fore/aft position of the axle appears compatible with the E30 body, as does the fore/aft length of the sump.

The only available ratio is 3.38. This gearset does not interchange with other front end ratios due to the installation depth of the pinion bearings.

The E34 FDA locates the differential pinion in the same position relative to the crankshaft as the E30 FDA does. This allows E30 and E34 transfer cases to be substituted for each other while retaining the non-jointed drive shaft.

3.b. E53 X5 6 cylinder

[production dates, models, part numbers, BMW list price (?), pics]

The E53 body appears to place the fore/aft position of the axle centerline relative to the bellhousing face very close to where it is in the E30.

The pinion centerline is placed further away from the crankshaft centerline than in the E30 and E34 applications.

Either 6 or 8 cylinder E53 pans require removal of the "cushion" from the rear face of the E30 AWD crossmember, because the E53 sumps are longer than the E30 sump, measured forward from the bellhousing surface. A lower profile cushion bracket may be built if desired.

The E53 FDA locates the differential pinion further from the crankshaft centerline than the E30 or E34 FDA's do. This requires the use of a u-jointed driveshaft if using E30 or E34 transfer case.

The E53 used the NV125 (American built) transfer case, which is much bulkier than the ZF A95 (E30) or ZF A110 (E34) transfer cases. The E53 uses a non-jointed driveshaft.

Locate info regarding width across the carrier bearings for E46, E34 and 2002 diffs

3.c. Frankenpan

Frankenpan

The E30 AWD pan can be cut apart and surgically interposed into an M50 oil pan. If you think you can do this, you don't need some guy on the internet to explain it.

Example Frankenpan swap: http://www.e30tech.com/forum/showthread.php?t=78938

Additional Frankenpan swap: http://www.e30tech.com/forum/showthread.php?t=21774

Third Frankenpan swap: http://www.e30tech.com/forum/showthread.php?t=100870 (This one uses M20 iX mount arms and mounts the engine at the M20 angle)

4. Driveline

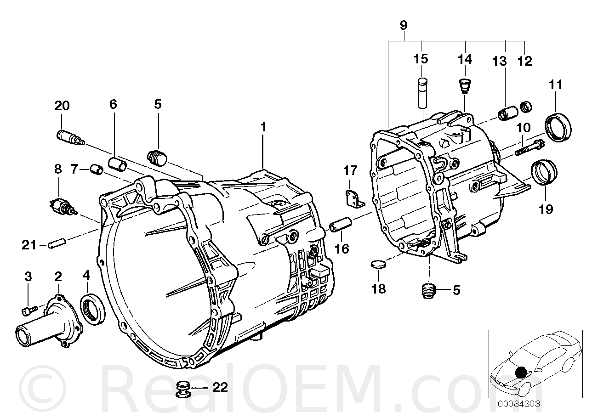

4.a. Transmission

Option 1:

ZF 5 speed manual.

The S5D-310/320Z transmission was used in the E34 525iX with a rear case half specific to that application.

The AWD rear case half PN is: 23111224968

Photos of the E34 rear case half: http://www.e30tech.com/forum/showpos...&postcount=164

This rear case half does NOT have the same bolt pattern for mounting the transfer case as the E30 AWD Getrag 260 rear case.

While it can, in theory, mount the E30 transfer case, it would still require an adapter between the two. The guibo bolts could be spaced by the adapter thickness, similarly to the way the front differential guibo is spaced to provide extra spline engagement with the OE driveline.

The S5D-310/320Z was also used in early (up to 10/2003) E53 X5 3.0i vehicles. It uses a different rear case half. That part number is: 23117511936

This case mates the NV125 transfer case with integrated mounting.

This rear case half may be the easiest to adapt to an alternative transfer case, as many more transfer cases use integrated mounting than use semi-divorced mounting.

For example, the E30 transfer case for automatic transmissions uses integrated mounting and *may* be adaptible to this rear case half.

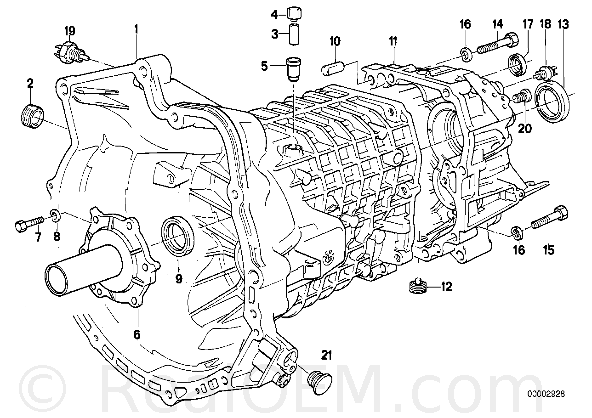

Option 2:

Getrag 5 speed manual.

As mentioned above, the Getrag 260 used with the M20 will also bolt to 24V engines. If used with the original transfer case mounting, this will cause the transfer case to interfere with the floor pan.

However, an adapter could be made that would rotate the transfer case back to its original position. This would involve spacing the guibo as mentioned above with regard to use of the E34 ZF rear case half.

The AWD rear case for the Getrag 260 was also used on the Z1 roadster to mount the front end of the torque tube.

Option 3:

4HP22 automatic.

The automatic AWD E30 cars have integrated transfer cases.

In addition to having the rear case half specific to the AWD application, the 4HP22 transmission has a separable bellhousing. This means that the bellhousing can be modified to mate the 4HP22 to the 24V engine.

Example: http://www.e30tech.com/forum/showthread.php?t=117333

Are there any applications in which BMW mated the 4HP22 to the 24V engine?

Can an A4S-270/310R bellhousing bolt to a 4HP22 (or anything else)?

I am currently working on an automatic AWD 24V swap in which the transmission mounting pattern in the bellhousing will be removed via wire EDM, rotated 10 degrees and welded back into place.

4.b. Transfer Case

Option 1:

E30 Transfer Case.

ZF A95

Manual transmission variant

Automatic transmission variant

Option 2:

E34 Transfer Case.

ZF A110

Option 3:

Borg Warner 4472.

4.c. Driveshaft

The stock E30 front drive shaft is a one-piece unit using a guibo at the front end. It is not jointed and goes straight from the T-case front output splines to the diff input flange. The E34 and E53 front driveshafts are similar.

The E46 front driveshaft has two u-joints. These are required because the transfer case front output is not aligned with the differential input flange.

No BMW driveshaft u-joints are rebuildable.

A front driveshaft must include some plunge. The engine block, aluminum transmission case and aluminum transfer case will expand as they start from cold and come up to operating temperature. The driveshaft will not have the same change in length due to temperature change. To prevent excess loads on the cases, shaft and bearings, the front driveshaft should be able to accomodate the change in length. The stock E30 and E53 driveshafts do this via the guibo and by the fact that they are not rigidly retained in the T-case.

The BMW 4 bolt differential flange is common to rear and front differentials. The 4 bolt flange at the rear of the stock E30 iX rear driveshaft will mate to the input flange on an E46 front differential.

This means that an adapter yoke produced by Jags That Run can be used to build a front or rear driveshaft using domestic 1310 series universal joints, which are readily available.

This yoke could be used at the differential end of either front or rear driveshaft to serve as the basis for a custom shaft.

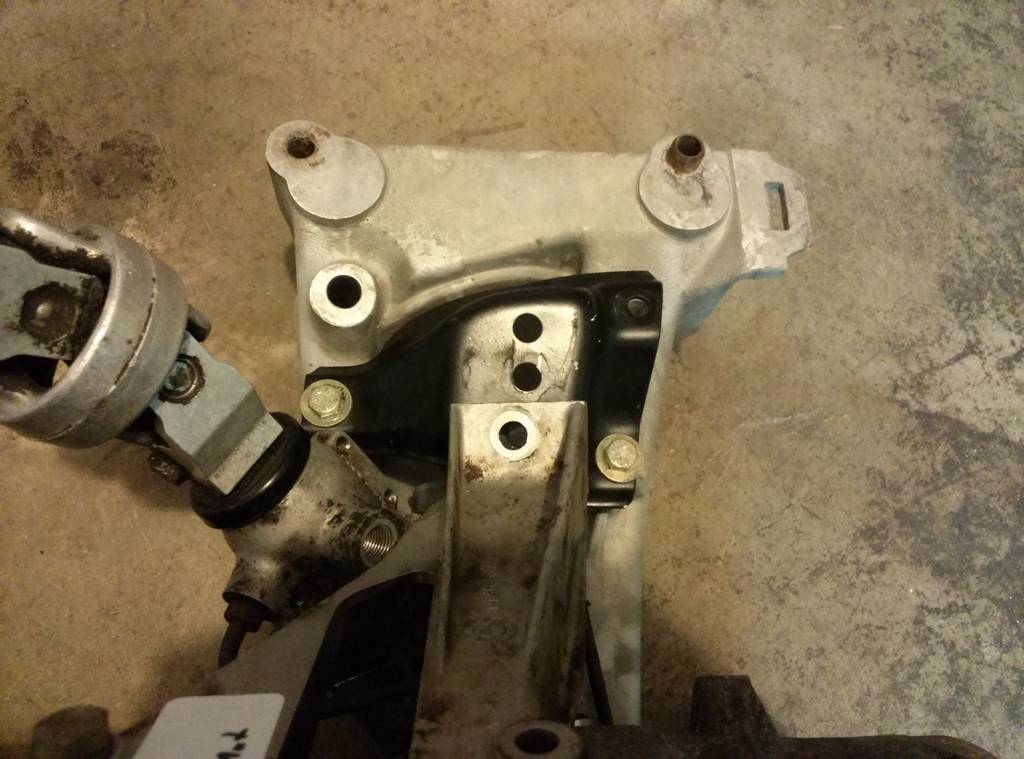

5. Mounting

5.a. Engine mount arms and mounts

E34 24V mount arms are close to the right location.

The iX uses a cast aluminum cross member with stamped steel "towers" to carry the engine mounts. Modifying these towers or building new ones from scratch is easier than building mount arms from scratch.

From: http://www.r3vlimited.com/board/show...7&postcount=18

5.b. Transmission and transfer case mounting

E53 NV125 T-case

5.c. Axles

While the inner CV joints must match the FDA, the outer CV joints must match the hubs and wheel bearings.

Original thread: http://www.e30tech.com/forum/showthread.php?t=116657

I've been reading up and doing a lot of RealOEM research related to my 32V AWD swap. I'll be coming back to this post to complete it and add more information.

I've come across several 24V swaps that are in the works, but only one, IIRC, that has been completed.

Some of the information in this post is from my own research, much of it is from information I've read here on the forum and elsewhere. Feel free to contribute information; I'll edit this post to add it.

- Terminology

- Discussion

- Front Drive Assembly

- Driveline

- Transmission

- Transfer Case

- Driveshaft

- Mounting

- Engine mount arms and mounts

- Transmission and transfer case mounting

Transfer Case: The additional driveline component that AWD cars have which sends drive power forward as well as rearward and controls the power split front to rear. The transfer case is bolted to the output end of the transmission, but is sealed from the transmission and has an independent lubrication oil supply.

Drop: The portion of the transfer case that is offset from the main driveline and provides drive power to the front differential.

Semi-Divorced: Describes transfer case mounting BMW used in the E30 325iX and E34 525iX with manual transmissions. The space between the transmission output shaft seal and transfer case input shaft seal is accessible with the two units bolted together. BMW installs a guibo in this space to cushion driveline shock and to reduce the required precision for assembly of the transfer case to the transmission.

Integrated: Describes transfer case mounting BMW used in the E30 325iX and E34 525iX with automatic transmissions, as well as the E53 X5 and E46 325xi and 330xi with manual or automatic transmissions. The flange on the rear case of the transmission fully encloses the shaft coupling between the transmission and transfer case. The volume between the transmission output seal and transfer case input seal is only accessible by removing the transfer case from the transmission.

Bearing Block: The casting that bolts to the right side of the AWD oil pan and carries a bearing that supports the extended shaft of the right side inner CV joint. It also carries the right side axle seal. It seals to the oil pan with the same P/N o-ring that the differential uses to seal to the oil pan. This part is specific to the front sump assembly. E30 and E34 bearing blocks are not interchangeable.

Oil Sump: The combination of oil pan, oil pump and oil pump pickup tube all from the same original application which assemble without modification

Front Drive Assembly (FDA): The combination of oil pan, differential, bearing block and inner CV joints all from the same original application which assemble without modification.

2. Discussion

The 24V AWD swap is electrically nearly identical, but mechanically more complex than the 24V RWD swap. The only electrical difference is the location of the oil level switch and sensor on the engine. The RWD engines have this sensor at the front, while the AWD engines have it at the rear. This is because the RWD oil pans are front sump while the AWD oil pans are rear sump.

The AWD strut towers are located further forward than the RWD strut towers, giving the AWD cars less caster. The AWD floor pan stamping is different than the RWD floor pan stamping.

The alignment of the transfer case front output and front differential pinion centerline is an important interface that must be understood when assembling a driveline.

The bellhousing patterns of the M20 and M50 (and all other 24V engines) are the same, but the 24V engine is leaned over an additional 10 degrees compared to the M20 in order to keep the larger cylinder head under the low BMW "Flying Wedge" hood lines. In a RWD swap, it is possible to bolt the Getrag 260 transmission to the 24V engine. As a result, the transmission is tilted 10 degrees and adaptation of the rear trans mounts and shift linkage is necessary. Once accomplished, this adaptation works well. This is not possible in the AWD E30 because the extra tilt would raise the transfer case drop such that it would interfere with the floor pan.

Mechanical differences vs. RWD swap:

-Engine mount arms: The AWD e30 has engine mounts in different locations than the RWD cars. The E36 mount arms will not work. E34 24V engine mount arms appear to be close

-Brake boost: The AWD strut towers are further forward (less caster) than the RWD strut towers. This has the potential to affect packaging of a hydroboost, but I don't know the specifics yet.

-Front Drive Assembly (FDA): This is the most obvious complication. If the swap adheres to BMW's original design, then the front diff will bolt to the engine oil pan and the right side axle intermediate shaft will go through the pan. The oil pump, pickup tube and oil pan (collectively: "oil sump") must have interfaces for the front diff and axles, as well as clearance for the AWD front crossmember, which is located forward of the RWD front crossmember position.

-The entire FDA must come from the same application. The length of the left inner CV joint spline is specific to the differential. The length of the right inner CV joint shaft and spline is specific to the combination of differential, oil pan and bearing block. Bearing blocks do not share bolt patterns and are not interchangeable. Differentials do not interchange outside their original bodies.

All BMW front differentials are variants of the 168mm rear differentials. There are a wide variety of ratios available. Known examples include:

2.35 E46 330xd M57 manual transmission

2.47 E46 330xd M57N manual transmission

2.93 E46 330xd automatic transmission

3.07 E53 X5 3.0d manual transmission, E46 330xi manual transmission

3.23 E46 325xi manual transmission

3.38 E34 525iX (Does not interchange with other gearsets)

3.46 E46 325xi and 330xi automatic transmission

3.64 E53 X5 4.4i

3.64 E30 325iX European market (Only interchanges with other E30 front gearsets)

3.91 E53 X5 4.6is

3.91 E30 325iX US market manual transmission (Only interchanges with other E30 front gearsets)

4.10 E53 X5 3.0i automatic transmission

4.10 E30 325iX US market automatic transmission (Only interchanges with other E30 front gearsets)

I have not verified that ratios in the same "range" can be interchanged between E46 and E53 carriers/cases.

I do not know at what ratio the carrier break occurs (If any)

There is a "case breaK". Low ratio cases are cast with more pinion clearance than high ratio cases.

Differentials for a particular body are interchangeable. For the E30 and E46, different ratios are all used with the same engine, so interchangeability is obvious. E53 6 and 8 cylinder differentials use the same bolt pattern to the oil pan and are interchangeable.

The E53 front differential will accept the same part number Quaife limited slip differential as the rear of a Z3 1.9. The E34, E46 and E53 carriers all have different widths across the carrier bearings, with the E34 being the narrowest and the E53 being the widest.

While it is possible to fabricate brackets and use a differential housing with integral intermediate tube bolted to the oil pan rails of a RWD pan, the front sump of the RWD pan would interfere with the AWD crossmember location and steering rack. I do not know if a custom crossmember would have sufficient clearance, or if the rack itself would have to be relocated. A dry sump system would completely overcome this difficulty. If you're capable enough to do this, you really don't need me to tell you how.

AMC Eagle front differential and mounting

3. Front Drive Assembly (FDA)

No production 24V FDA will fit in the E30 AWD engine bay with the stock crossmember and rack location.

The FDA consists of the oil pan, oil pump, oil pickup tube, front differential, bearing block and inner CV joints from the same application.

For the passenger side the distance from the side gear splines to the axle seal must be the same for the differential and the inner CV joint cup.

For the driver's side, the distance from the side gear spline through the differential case, through the oil pan, through the right side bearing block to the axle seal must be the same for the sump assembly as it is on the CV joint cup.

Need axle assembly collapsed lengths

Need data to compare track widths of different AWD cars against widths of the bearing block + oil pan + differential assembly from different source vehicles to compare lengths of axle shafts

The E46 FDA can not be used as it places the axle centerline too far forward to fit in the E30 engine bay. The differential and front face of the sump would interfere with the crossmember, while the rear of the engine would interfere with the firewall.

3.a. E34 525iX

[production dates, part numbers, BMW list price(?), pics]

The International Market E34 525iX is the BMW application that is closest to the E30 in technology and production dates.

The fore/aft position of the axle appears compatible with the E30 body, as does the fore/aft length of the sump.

The only available ratio is 3.38. This gearset does not interchange with other front end ratios due to the installation depth of the pinion bearings.

The E34 FDA locates the differential pinion in the same position relative to the crankshaft as the E30 FDA does. This allows E30 and E34 transfer cases to be substituted for each other while retaining the non-jointed drive shaft.

3.b. E53 X5 6 cylinder

[production dates, models, part numbers, BMW list price (?), pics]

The E53 body appears to place the fore/aft position of the axle centerline relative to the bellhousing face very close to where it is in the E30.

The pinion centerline is placed further away from the crankshaft centerline than in the E30 and E34 applications.

Either 6 or 8 cylinder E53 pans require removal of the "cushion" from the rear face of the E30 AWD crossmember, because the E53 sumps are longer than the E30 sump, measured forward from the bellhousing surface. A lower profile cushion bracket may be built if desired.

The E53 FDA locates the differential pinion further from the crankshaft centerline than the E30 or E34 FDA's do. This requires the use of a u-jointed driveshaft if using E30 or E34 transfer case.

The E53 used the NV125 (American built) transfer case, which is much bulkier than the ZF A95 (E30) or ZF A110 (E34) transfer cases. The E53 uses a non-jointed driveshaft.

Locate info regarding width across the carrier bearings for E46, E34 and 2002 diffs

3.c. Frankenpan

Frankenpan

The E30 AWD pan can be cut apart and surgically interposed into an M50 oil pan. If you think you can do this, you don't need some guy on the internet to explain it.

Example Frankenpan swap: http://www.e30tech.com/forum/showthread.php?t=78938

Additional Frankenpan swap: http://www.e30tech.com/forum/showthread.php?t=21774

Third Frankenpan swap: http://www.e30tech.com/forum/showthread.php?t=100870 (This one uses M20 iX mount arms and mounts the engine at the M20 angle)

4. Driveline

4.a. Transmission

Option 1:

ZF 5 speed manual.

The S5D-310/320Z transmission was used in the E34 525iX with a rear case half specific to that application.

The AWD rear case half PN is: 23111224968

Photos of the E34 rear case half: http://www.e30tech.com/forum/showpos...&postcount=164

This rear case half does NOT have the same bolt pattern for mounting the transfer case as the E30 AWD Getrag 260 rear case.

While it can, in theory, mount the E30 transfer case, it would still require an adapter between the two. The guibo bolts could be spaced by the adapter thickness, similarly to the way the front differential guibo is spaced to provide extra spline engagement with the OE driveline.

The S5D-310/320Z was also used in early (up to 10/2003) E53 X5 3.0i vehicles. It uses a different rear case half. That part number is: 23117511936

This case mates the NV125 transfer case with integrated mounting.

This rear case half may be the easiest to adapt to an alternative transfer case, as many more transfer cases use integrated mounting than use semi-divorced mounting.

For example, the E30 transfer case for automatic transmissions uses integrated mounting and *may* be adaptible to this rear case half.

Option 2:

Getrag 5 speed manual.

As mentioned above, the Getrag 260 used with the M20 will also bolt to 24V engines. If used with the original transfer case mounting, this will cause the transfer case to interfere with the floor pan.

However, an adapter could be made that would rotate the transfer case back to its original position. This would involve spacing the guibo as mentioned above with regard to use of the E34 ZF rear case half.

The AWD rear case for the Getrag 260 was also used on the Z1 roadster to mount the front end of the torque tube.

Option 3:

4HP22 automatic.

The automatic AWD E30 cars have integrated transfer cases.

In addition to having the rear case half specific to the AWD application, the 4HP22 transmission has a separable bellhousing. This means that the bellhousing can be modified to mate the 4HP22 to the 24V engine.

Example: http://www.e30tech.com/forum/showthread.php?t=117333

Are there any applications in which BMW mated the 4HP22 to the 24V engine?

Can an A4S-270/310R bellhousing bolt to a 4HP22 (or anything else)?

I am currently working on an automatic AWD 24V swap in which the transmission mounting pattern in the bellhousing will be removed via wire EDM, rotated 10 degrees and welded back into place.

4.b. Transfer Case

Option 1:

E30 Transfer Case.

ZF A95

Manual transmission variant

Automatic transmission variant

Option 2:

E34 Transfer Case.

ZF A110

Option 3:

Borg Warner 4472.

4.c. Driveshaft

The stock E30 front drive shaft is a one-piece unit using a guibo at the front end. It is not jointed and goes straight from the T-case front output splines to the diff input flange. The E34 and E53 front driveshafts are similar.

The E46 front driveshaft has two u-joints. These are required because the transfer case front output is not aligned with the differential input flange.

No BMW driveshaft u-joints are rebuildable.

A front driveshaft must include some plunge. The engine block, aluminum transmission case and aluminum transfer case will expand as they start from cold and come up to operating temperature. The driveshaft will not have the same change in length due to temperature change. To prevent excess loads on the cases, shaft and bearings, the front driveshaft should be able to accomodate the change in length. The stock E30 and E53 driveshafts do this via the guibo and by the fact that they are not rigidly retained in the T-case.

The BMW 4 bolt differential flange is common to rear and front differentials. The 4 bolt flange at the rear of the stock E30 iX rear driveshaft will mate to the input flange on an E46 front differential.

This means that an adapter yoke produced by Jags That Run can be used to build a front or rear driveshaft using domestic 1310 series universal joints, which are readily available.

This yoke could be used at the differential end of either front or rear driveshaft to serve as the basis for a custom shaft.

5. Mounting

5.a. Engine mount arms and mounts

E34 24V mount arms are close to the right location.

The iX uses a cast aluminum cross member with stamped steel "towers" to carry the engine mounts. Modifying these towers or building new ones from scratch is easier than building mount arms from scratch.

From: http://www.r3vlimited.com/board/show...7&postcount=18

5.b. Transmission and transfer case mounting

E53 NV125 T-case

5.c. Axles

While the inner CV joints must match the FDA, the outer CV joints must match the hubs and wheel bearings.

Comment