If you want 175whp there are easier ways than opening the bottom end for sure. i think most people want more than that though.

i think you are over dramatising the differences in bottom end. the differences between assembling the larger stroker and 2.7L are fairly trivial once you purchase the correct parts and have the machine shop machine the block. if you want a head that fully utlises the added stroke thats where the part selection and everything gets very bespoke.

Is this Pump Gas-able?

Collapse

X

-

I agree, and all of that sounds nice, but between building the 2.7 and the 3.1 the process was entirely different. It wasn’t just a $1500 investment difference with magical displacement capabilities, literally every aspect of the build had to change.To be clear I was talking about the eta based 2.7 but nevertheless the differential between what you did and a 2.8, 2.9, 3.0,3.1 is not as much as you one thinks especially if it requires fitting oversize OE pistons due to poor condition of block or pistons. The other thing is the torque, a bigger engine will always make more torque even if it won’t make proportionally more power due to the crap cylinder head.

i guess to me personally it’s not a small undertaking removing and stripping an engine sending to the machine shop for a moderate displacement change when for 1500 bucks more I can have an extra 400cc, bump cr, better rings, deeper valve pockets to be able to run a bigger cam and basically have a better base for future modifications

To build the 9.4:1 2.7L it was as simple as dropping off free 2.7 crank/rods with a good late b25 block/pistons, buying bolts bearings and rings and picking it up.

The 3.1L took months of buying random shit to make it right, rings were harder to fit, boring, etc was all more involved.

I literally just built both engines, and the process was dramatically less involved for the 2.7L, and my argument is not that a 2.7 is better, but that for the average enthusiast building these things, I’m not convinced going 3L+ is worth it anymore.

Even the 2.8L betz built w stock late model “I” pistons, e rods and some shaving still makes more sense to me than a long stoke m20.

If you’re going all out, sure, the argument can always be made to go bigger/better/future mod capabilities, but for someone just looking to build one hot m20 to enhance their driving experience, I am no longer convinced the extra $$ invested in a big boi stoker is worth it in a tangible sense of enjoyment, of course it’ll always look good on internet paper tho.

I only have these opinions after doing my 3.1 w worked 731 head vs the 2.7 setup for an 885 w 272 cam within a few months of each other.

Cheers-Leave a comment:

-

To be clear I was talking about the eta based 2.7 but nevertheless the differential between what you did and a 2.8, 2.9, 3.0,3.1 is not as much as you one thinks especially if it requires fitting oversize OE pistons due to poor condition of block or pistons. The other thing is the torque, a bigger engine will always make more torque even if it won’t make proportionally more power due to the crap cylinder head.

i guess to me personally it’s not a small undertaking removing and stripping an engine sending to the machine shop for a moderate displacement change when for 1500 bucks more I can have an extra 400cc, bump cr, better rings, deeper valve pockets to be able to run a bigger cam and basically have a better base for future modifications

Leave a comment:

-

I built a 2.7l w i pistons, e rods/crank and a 2mm shaved block - 175whp SAE DJ power all day long with a 272 cam and no head work. The WOT special. It was like $1600 completely out the door with everything including machine work, parts, bolts, etc etc.

Dramatically more expensive to go into 24v crank world with custom pistons. I just built both within the last year. And then the bigger strokers detonate like crazy and make shite power more than half of the time, whereas the 2.7L I described above just seems to work well without much fuss.

I see what you’re saying, but I guess my point is that keeping head work the same literally spending 2K++ for potentially 5-15 more hp. Best case that’s $130 per hp.

Maybe I just need to drink more coffee, IDK.Leave a comment:

-

An eta based 2.7 makes stock b25 power at best so like 150whp

I just picked up a hot 2.7l I had done yesterday, and honestly I can’t say that I’d ever do anything bigger than that again. The process was so simple and affordable compared to the 3.1L..... all for what... 20-30hp? And if you want the extra power you have to spend an additional 2k in head work, not to mention tuning, software/hardware, intake modifications, ITBs, etc etc.

Previously my perspective was that of which you shared above, but the cost difference of a bigger stroker trickles into every other aspect of the engine if you actually want to extract the extra horsies available from said displacement.

With the cost and hassle associated with going bigger (custom pistons, oil sleeve for crank, overbore, etc) I just can’t see the benefit anymore compared to a skimmed 2.7L with a simple 272 cam in a stock head.

Not to mention the detonation problems a stroker m20 is plagued with on what appears to be anything over a 2.8L, causing them all to pull timing in the tune, and never see the full potential on different aspects. It seems like there are always unknown limiting factors keeping big stroke M20s from making more than 200hp for the average or slightly above average owner/builder/machine shop/tuner/etc.

The cost of the 2.7L out the door was less than just buying the custom pistons and cam/rockers for the 3.1L.

s bigger stroker 2,8-3.1with mild cam even with stock head will make 180-190whp that’s without standalone or itb or head work . So it’s a couple grand spend fairly well imoLeave a comment:

-

-

I just picked up a hot 2.7l I had done yesterday, and honestly I can’t say that I’d ever do anything bigger than that again. The process was so simple and affordable compared to the 3.1L..... all for what... 20-30hp? And if you want the extra power you have to spend an additional 2k in head work, not to mention tuning, software/hardware, intake modifications, ITBs, etc etc.

the difference between a big stroker and a basic budget 2.7i (eta based one) is about $1500-2000 which is not much for the significant improvements in power and torque it allows, cost is for:

- new forged slugs;

- good used crank;

- oil sleeve, crank bolt, modified washer (for >84mm + stroke) and intermediate shaft clearance (big 89.6 stroke only);

- additional machining for over boring.

Previously my perspective was that of which you shared above, but the cost difference of a bigger stroker trickles into every other aspect of the engine if you actually want to extract the extra horsies available from said displacement.

With the cost and hassle associated with going bigger (custom pistons, oil sleeve for crank, overbore, etc) I just can’t see the benefit anymore compared to a skimmed 2.7L with a simple 272 cam in a stock head.

Not to mention the detonation problems a stroker m20 is plagued with on what appears to be anything over a 2.8L, causing them all to pull timing in the tune, and never see the full potential on different aspects. It seems like there are always unknown limiting factors keeping big stroke M20s from making more than 200hp for the average or slightly above average owner/builder/machine shop/tuner/etc.

The cost of the 2.7L out the door was less than just buying the custom pistons and cam/rockers for the 3.1L.Last edited by AWDBOB; 05-07-2021, 02:52 AM.Leave a comment:

-

the difference between a big stroker and a basic budget 2.7i (eta based one) is about $1500-2000 which is not much for the significant improvements in power and torque it allows, cost is for:You guys are something else. I have a ‘89 i that I want to make a 2.7 and have the block crank. Reading this stuff makes me want so much more but dang, I know nothing. Blown heater core has me to the point of engine out, rebuild.

Anyway, AWD, always enjoy reading your threads. Your new engine looks like it will be fun.

- new forged slugs;

- good used crank;

- oil sleeve, crank bolt, modified washer (for >84mm + stroke) and intermediate shaft clearance (big 89.6 stroke only);

- additional machining for over boring.Leave a comment:

-

You guys are something else. I have a ‘89 i that I want to make a 2.7 and have the block crank. Reading this stuff makes me want so much more but dang, I know nothing. Blown heater core has me to the point of engine out, rebuild.

Anyway, AWD, always enjoy reading your threads. Your new engine looks like it will be fun.Leave a comment:

-

Ah, I see-

yes, when I said 'stick a dial indicator on it'

I guess I set an arbitrary tdc position, didn't I?

So then by lowering that point 10mm, the volume can be calculated

as a positive quantity (i.e. fill it with liquid)

from the top of the deck.

Having the indicator perpendicular to the deck would be critical!

t

did it once by milling the piston off the crown, and dropping the crown into a bucket.

Oddly, that worked.Leave a comment:

-

Digger,

you might be saying this, but I'm not getting it.

To cc a piston in the bore, stick a dial indicator on it.

Lower it some arbitrary amount. (I said 5mm, but it can be anything that lets you put a flat cover over)

Then put your head cc cover plate over, add fluid until it's full, then

do the math to figure out how much of the arbitrary cylinder volume the piston crown is filling.

So let's say if you lower the piston 10 mm, and then get a volume of 40 cc,

your piston crown volume is ((8,4/2)^2 *pi ) = 55.4 - 40 or 15.4 cc.

Which you subtract from the chamber volume to get the tdc volume.

clear as mud?

t

worked it out on a napkin

the piston is not flat so how far down the hole is it exactly? i.e. 10mm from what point? measure from the top of deck to the CH datum point on the piston. thats what i'm talking aboutLeave a comment:

-

Digger,

you might be saying this, but I'm not getting it.

To cc a piston in the bore, stick a dial indicator on it.

Lower it some arbitrary amount. (I said 5mm, but it can be anything that lets you put a flat cover over)

Then put your head cc cover plate over, add fluid until it's full, then

do the math to figure out how much of the arbitrary cylinder volume the piston crown is filling.

So let's say if you lower the piston 10 mm, and then get a volume of 40 cc,

your piston crown volume is ((8,4/2)^2 *pi ) = 55.4 - 40 or 15.4 cc.

Which you subtract from the chamber volume to get the tdc volume.

clear as mud?

t

worked it out on a napkin

Leave a comment:

-

The reference for piston cc's is the top of piston from a compression height perspective (CH), i.e. this is the datum. This isnt the actual top of dome, it's the corner where the "chamfer" starts.

Use grease in the corner/edges to help it seal and prevent liquid getting into the crevice between the top ring and CH.

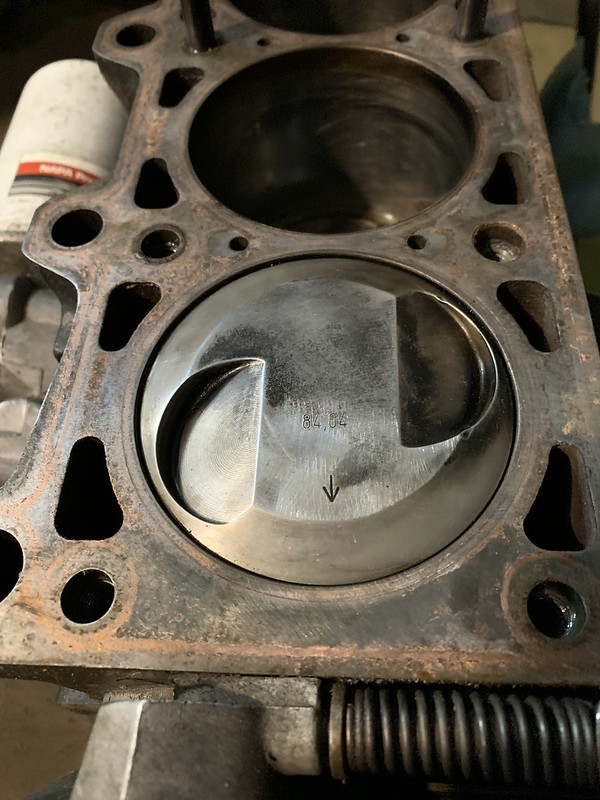

the piston position w.r.t deck is defined using the same datum as above, this also needs to be measured. Yours look like it about 1mm below deck. So your deck clearance is +1mm (insert actual number)Leave a comment:

-

Thanks all. I have a question that is likely a dumb one, but it's holding me back.

When calculating dome volume, do I only calculate the dome area that sits above deck, or does the whole dome get calculated from where it is slightly below deck?

Saying dome this many times is not satisfying..... dome

5cc = 0.9mm down into the bore, so with TobyB's suggestion, I am assuming that the entire thing gets calculated, essentially from rings up (where it'll hold fluid).

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Leave a comment:

Leave a comment: