Digger, thank you for the detailed answer.

I understand now the part about the polishing and I will certainly ask Web Cams if the existing cam could be repaired and at what cost.

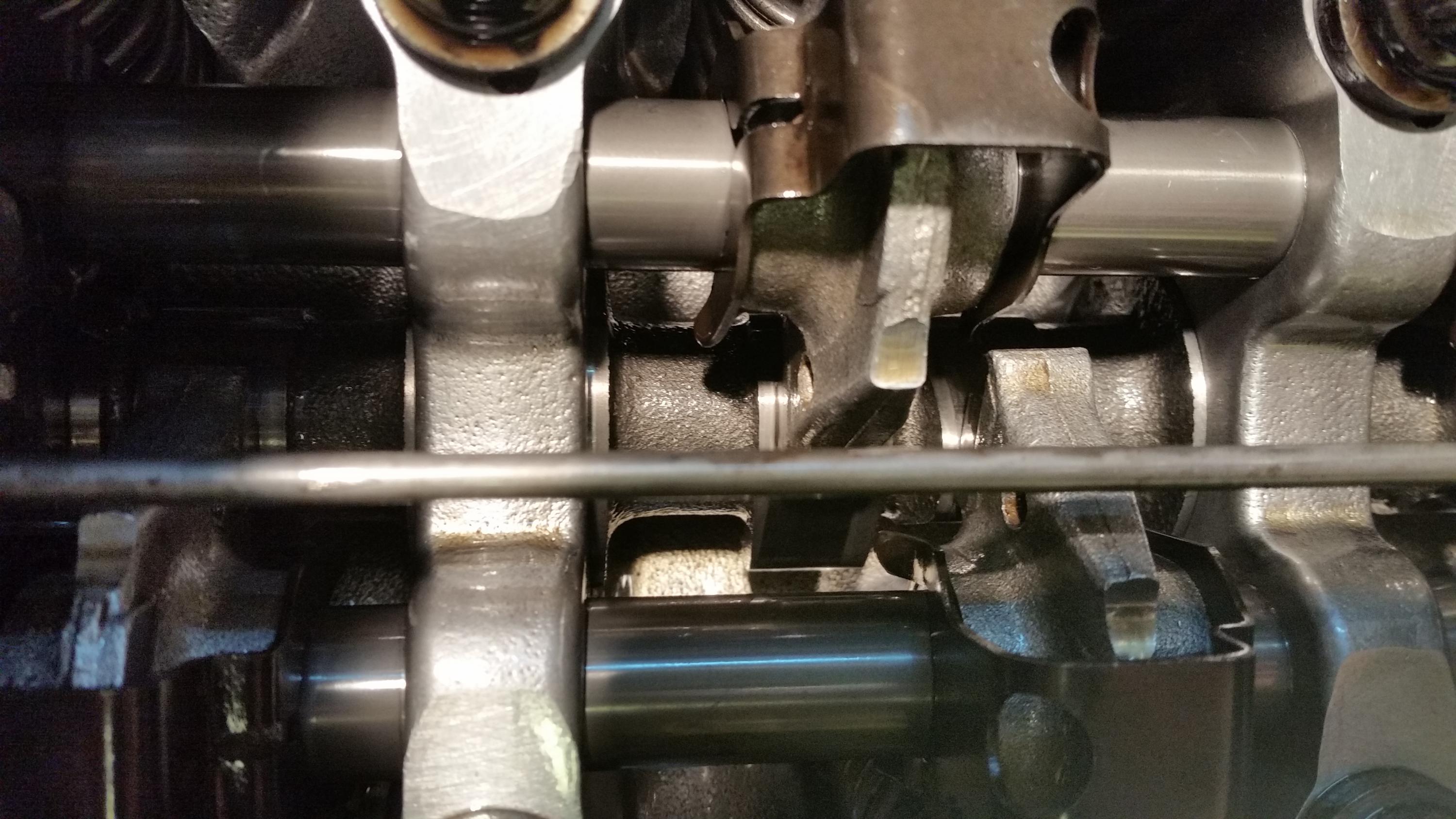

The thing about PtoV is that I measured it and was about 2.2 mm, which seemed plenty. I can't explain to myself for the life of me what lead to piston to valve contact, except I must have messed up the timing somehow.

Agreed on the differences that can only be made apparent with measurements and it is apparent to me that the next cam that goes into the engine should be carefully chosen.

What I intend to do now, in order to avoid disassembling the whole engine:

I have a lead on another m54b30 crank, zoomer's set of pistons is still around from his m20b30 attempt, currently there is a stripped m20b27 block on my engine stand and a cracked 885 head. Given the circumstances I can measure the P to V again.

If you want, I can measure the cam for you with a dial indicator and a degree wheel. Still haven't decided what to do with it, but since I have a stripped head laying around, it would be easy to measure if you would provide me the steps or a link how to do it.

I understand now the part about the polishing and I will certainly ask Web Cams if the existing cam could be repaired and at what cost.

The thing about PtoV is that I measured it and was about 2.2 mm, which seemed plenty. I can't explain to myself for the life of me what lead to piston to valve contact, except I must have messed up the timing somehow.

Agreed on the differences that can only be made apparent with measurements and it is apparent to me that the next cam that goes into the engine should be carefully chosen.

What I intend to do now, in order to avoid disassembling the whole engine:

I have a lead on another m54b30 crank, zoomer's set of pistons is still around from his m20b30 attempt, currently there is a stripped m20b27 block on my engine stand and a cracked 885 head. Given the circumstances I can measure the P to V again.

If you want, I can measure the cam for you with a dial indicator and a degree wheel. Still haven't decided what to do with it, but since I have a stripped head laying around, it would be easy to measure if you would provide me the steps or a link how to do it.

Comment