The woodruff key should just be for indexing/locating. Parts on the crank snout are held in place by clamping force and a tight slip fit. This is why the crank nut is torqued so much!

I wouldn’t worry about oil getting in there.

If the dampers are hard to get in good shape I would just get one from a company like ATI. They don’t have an OTS version, but its easy enough to adapt the damper they build to a custom hub. This is what the VAC kits, etc. are. There are hub specs available for a lot of other BMW engines so I would be surprised if one already on the books wont work.

I got your PM, just have not had time to respond.

Speaking of ATI you might find this interesting:

Announcement

Collapse

No announcement yet.

M42 Won't Idle, Some Backfiring [EDIT: Photo Dump Of Broken Stuff]

Collapse

X

-

Here's a question...is there going to be any issue if oil has dripped down onto the clamping faces of the timing chain sprocket on the crank? The crank bolt compresses the hub, sprocket and crank together super tightly and that is how all the torque is transmitted, but since it has been apart there's probably some amount of oil that has run down and into these interfaces. I REALLY don't want to have to pull the timing case covers off since that means ordering more gaskets, and having to realign the CPS holder (since I have an M44 timing case). I don't think that I ever bothered with this in the past, and I have not heard of the lower crank sprocket slipping / shearing the woodruff key. But, if there's one thing I have learned, it is to be overly paranoid lol.

Leave a comment:

-

It is pretty easy to tell if the damper wheel is failing if you get in there and poke around. If you see a gap between the rubber and metal surrounding, or if you can get it to deflect in the direction of the crank axis by hand, it's on its way out.

Removing it is also super easy since you just have to pull the belts and the 6 M8 bolts holding it to the hub.

Leave a comment:

-

I wonder if this is my cars current no start issue as well. I was trying to tune my idle on megasquirt and it was basically lose sync and catch itself at idle which I thought was weird, then a couple days later I had a complete no start. Took a trigger log of the crank sensor and it gets a signal then has nothing and will then randomly pick up signal again but never starts.. I find it weird because I replaced my crank sensor with an OE BMW sensor about 2.5-3 years ago.

Leave a comment:

-

Yeah, I actually went with the OEM one specifically because of stories I had read on here about the Bosch one being crap. Since the crank position sensor is THE single most important input to the ECU, there is no good reason to take chances with it IMO.

Leave a comment:

-

Thanks for sharing all the details in this thread.

It looks like your parts order also included the OEM BMW brand crank sensor (12141721504). And so even though your parts bill may hurt, you can claim a small victory by knowing that you'll avoid the frustration I dealt with after I installed the much cheaper Bosch brand crank sensor: engine idled normal, but usually died when throttle opened.

Leave a comment:

-

BMW of Silver Spring does not have any in stock, but they have one on order from Germany for me. I inquired about NLA / backorder status, and for the moment it sounds like there is a fair amount of inventory in Germany still. But yeah, I bet that a lot of M42's out there are or be in need of having this stuff replaced. These cars definitely are not getting cheaper to own!

And yes, the bill for this round of parts was pretty ugly lol. My order should show up in 1-2 weeks. Thankfully I usually commute to work by bike or train, so for the most part this isn't a big deal.

Leave a comment:

-

Glad you found the issue, but I feel for your car parts account.

That said, the dampeners went NLA a while back and they were surprisingly cheap (less than $250), so someone snapped them up. I'd expect that there are some new ones out there for not a horrible price, but right now the usual suppliers will probably list it as backordered.

However, it's these parts that are really making the M42 a poor ownership proposition these days, and it was a big part of my choice to not build an M42, but rather to M54 swap in future.

Leave a comment:

-

Very helpful and informative!

Just another thing to look out for on these old M42s.

Leave a comment:

-

Funny thing. After 20 years of working on these things, I can still learn something new (or, be dumb and not realize something). For whatever reason, the 240 ft-lb crank hub bolt gets referred to as the "crank damper bolt" a lot on forums. I have done 3 M42 timing case rebuilds over the years. At no point have I ever removed just the crank damper wheel on its own, but always as part of a timing case job. So basically, despite the fact that I have been through the motions and should know perfectly well that it is held on by 6 M8 bolts, I just went into auto-pilot mode and took off the big crank hub bolt since, "it's the damper bolt, it holds the damper on."

So, despite having the 6 M8 bolts out which freed the damper wheel, I continued to break the big bolt loose. The damper was a bit stuck on the central hub and alignment pin, so maybe if it had fallen off I would have realized that I was making more work for myself!

The crank hub seal in the lower timing case needs replacing, as I discovered. While it does not leak oil, it is sort of hard and stiff, and is not gripping the hub at all. So it is likely creating a small vacuum leak. My efforts to take the big bolt out were not totally in vain. Also, owning a tool take makes removal and installation of the big bolt a super simple affair helps to make it a couple extra minutes of work.

In other news, I took this as an opportunity to do a bunch of stuff that I bought parts for a year ago and never got around to installing. Today I replaced the thermostat and sealed up a little oil leak where the outer profile gasket has a joint with the upper timing case and inner profile gasket. The outer profile gasket and timing case gaskets were replaced as well, and the upper timing cover properly pressed flush with the rest of the valve cover sealing surfaces on the head. The engine has been running a little cool, so the thermostat needed swapping. I also put on a new viscous unit for the main fan. Tomorrow I plan to do the fuel filter and both coolant temp sensors in the head.

Hopefully the new damper wheel, sensors and lower timing cover shaft seal are stocked items so that they will arrive this week. They were ordered through getbmwparts.com.

Leave a comment:

-

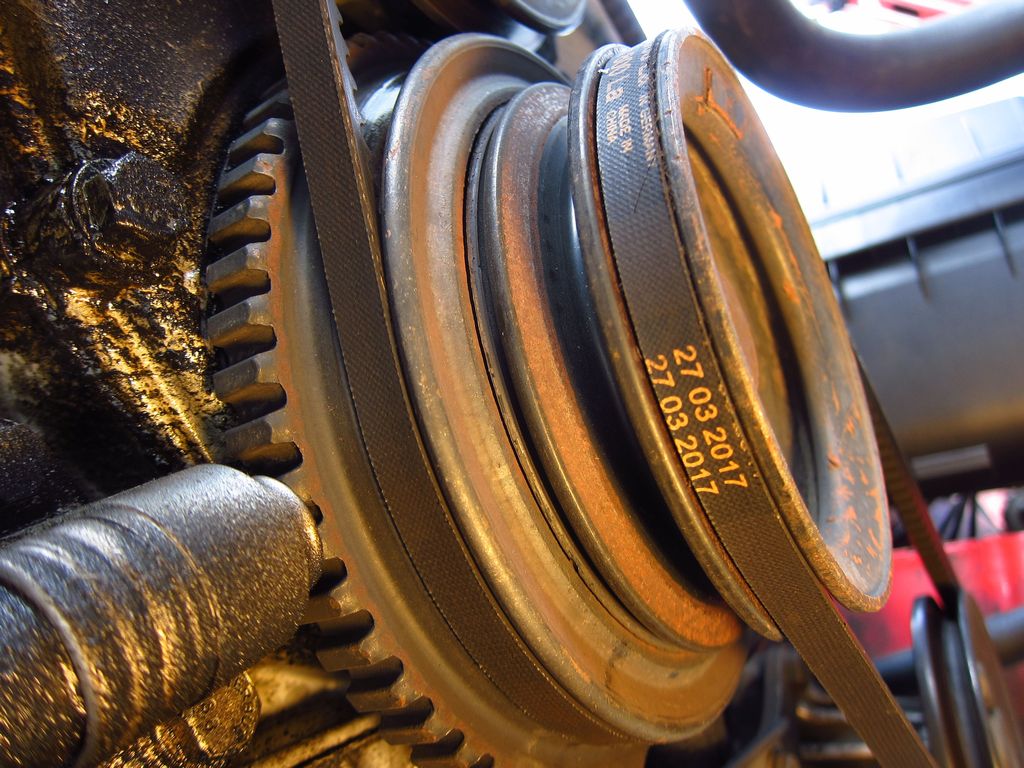

Also, just for reference, here is a shot from the factory service manual that gives expected measurement values for some of the engine sensors.

My crank sensor measured 518 Ohms cold (~20C) and 590 Ohms on a hot engine. This makes perfect sense since the temperature coefficient for resistance of copper is ~0.393% per degree Celsius. That 72 Ohm increase would correspond to a ~35C temperature increase, or a sensor at ~55C, which seems reasonable. So you can expect the resistance value you measure on this, and other resistive sensors with copper coils, to vary with temperature.

Leave a comment:

-

Alrighty party people, I think that I have found an issue, and probably THE issue. It seems like it should explain my very recent no-run / poor-running problem, as well as some intermittent wonky idle and infrequent low-load backfiring over the last year. Also, it is going to be expensive lol.

Things that need replacing:

- Crankshaft damper

- Accessory drive pulley

- Crankshaft position sensor

- Camshaft position sensor

- A crank position sensor bolt with mangled head

- Cam position o-ring

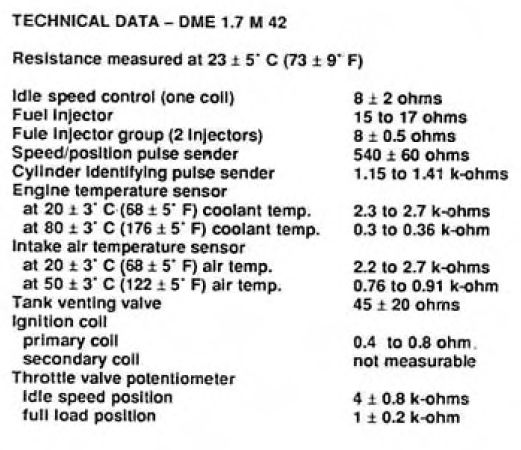

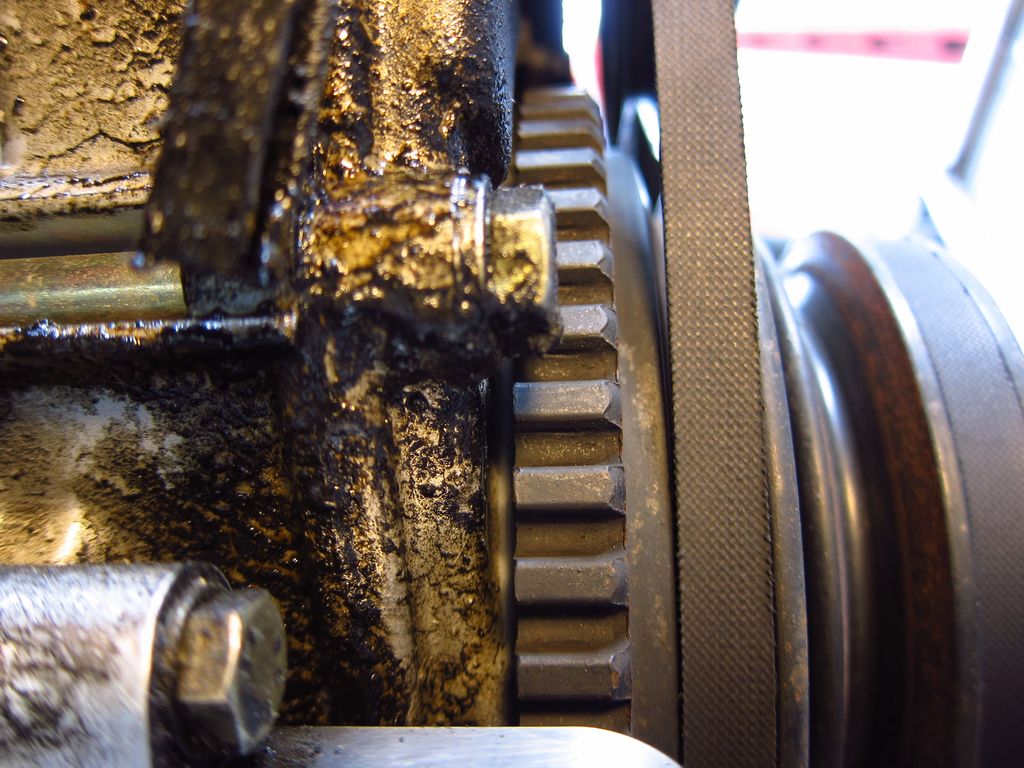

I pulled the belly pan and fan+shroud to get a good look at things today. Initially it looked like it was an obviously failing crank position sensor since the cable sheath was totally broken and the shielding was exposed.

The magnetic pickup head was a little dirty, but set at the correct distance from the teeth on the position wheel.

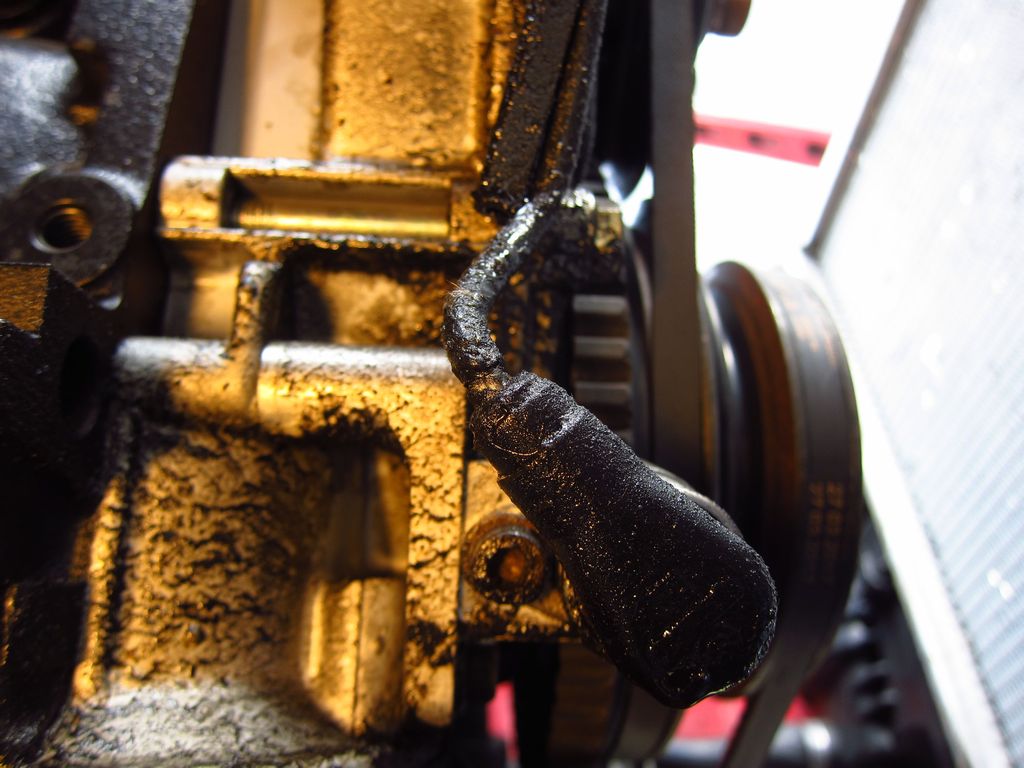

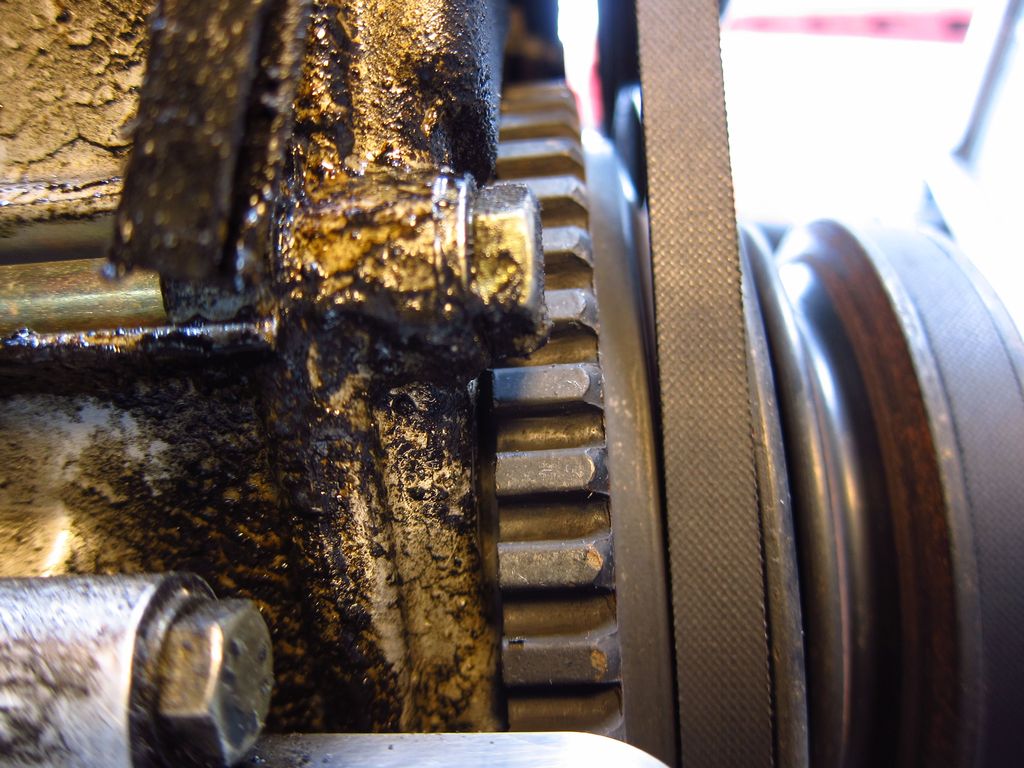

I then took a look at the damper wheel, and thought, "well I do not believe that there is supposed to be a big circumferential gap there."

Rotating the crank with a 27mm socket & ratchet, I noted that there was a lot of axial wobble, with the damper changing distance from the timing cover by a good ~3mm throughout its rotation.

There also appeared to be some evidence that the back of the teeth were making slight contact with the cover.

At this point, a number of things under the hood were clearly in need of removal, inspection and (in a week or so) replacement. I cleaned up the crank sensor and looked a little closer. While I do not think that any of the conductors were yet failed, it is only a matter of time until oil and other contamination get into the sensor body and finish it off. Additionally, the pickup face looks partially crushed, from god-only-knows what wrenching mishap in the last 13 years.

The cam position sensor's cable sheath was also failing in a couple of spots, so it is also being replaced. I did notice the super awesome micro TIG welds holding the pickup nub to the body. I thought that those were neat.

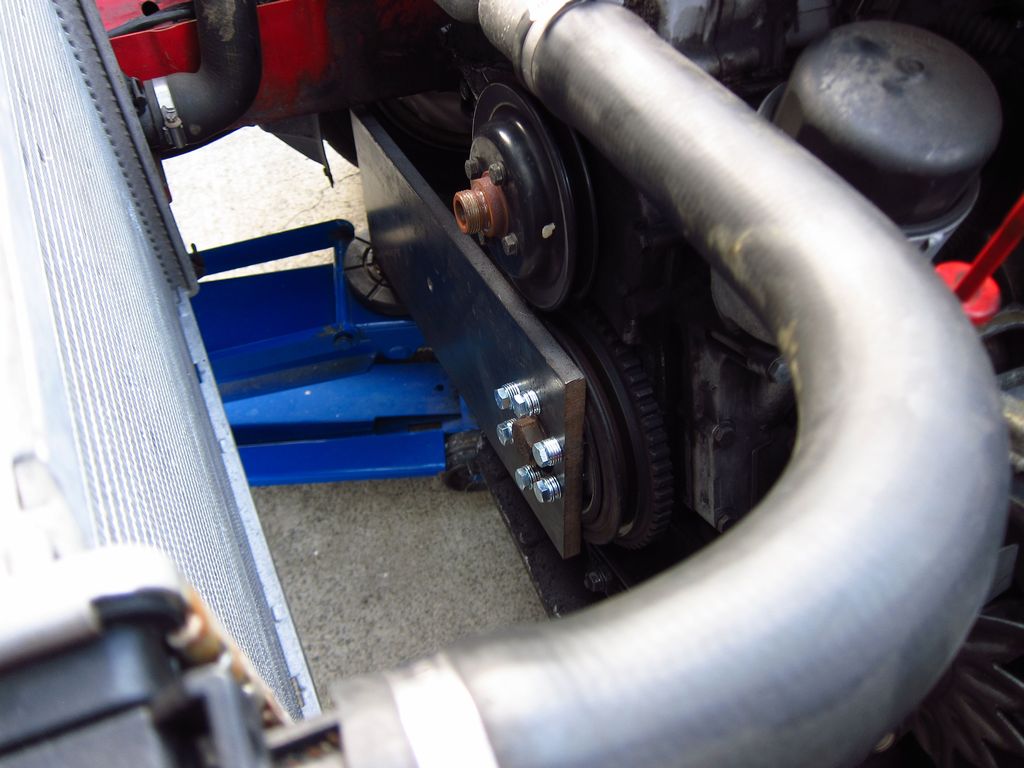

Next I wanted to remove the pulley drive hub to get a look around behind it. This time I was fully prepared, and no sweat was produced breaking the 250+ ft-lb bolt loose. 50" cheater-bar, custom crank locking plate & a floor jack to support the plate. No problem!

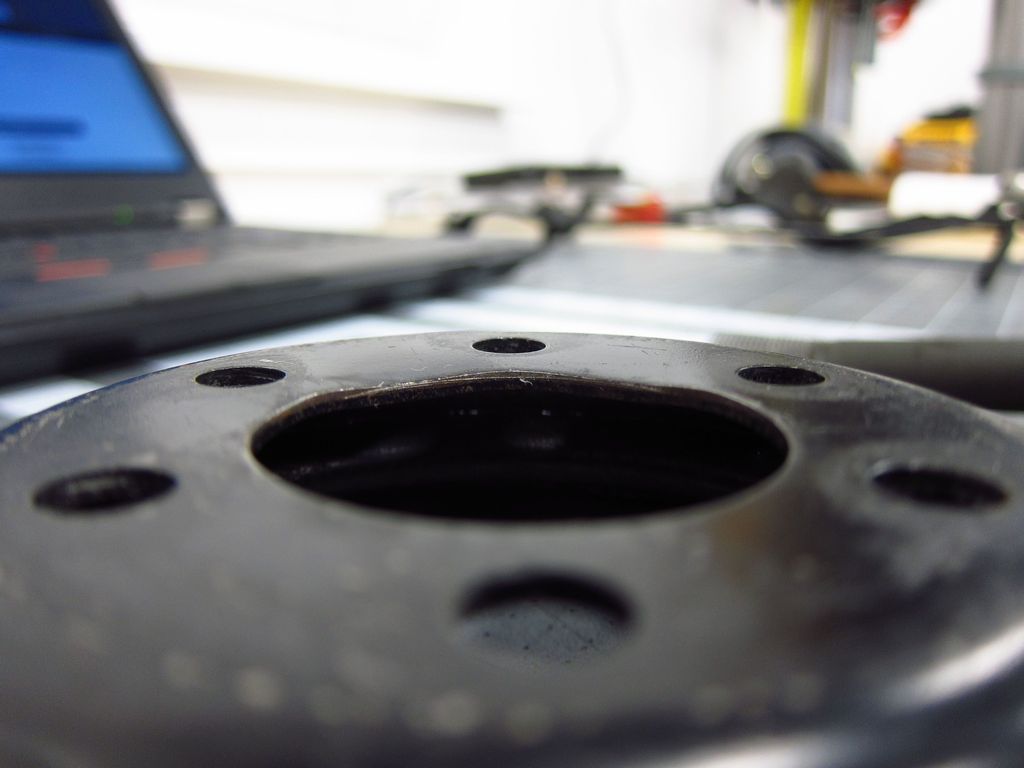

The position wheel + pulley was only ~40% attached to the driving hub. I could open it up pretty easily by hand, and a little more coaxing by my foot got it looking like this.

This thing is almost exactly 29 years old. It looks like it was produced in May of 1990.

A little more light pushing by hand completed the transformation into scrap.

I also noticed that the accessory drive pulley was a little bent up. Since the new damper wheel is ~$500, I am not going to bolt a bent thing to it (nor am I going to bother straightening it). It is getting replaced since it is simply not worth throwing the balance out or otherwise distorting the new damper drive hub.

Also, my engine uses a slightly different crank hub bolt than the stock E30 M42. Metric mechanic built it with this monster, and I will need to call them on Monday to get the proper torque spec for it.

You know you have been working on these things for way too long when taking the crank hub bolt off takes less than 3 minutes lol. Well, less than 3 if you don't count the trip to the hardware store for longer M8 bolts lol.

So there it is for now. I will be ordering the necessary parts to replace this old crusty crap, and hopefully the thing runs properly thereafter. Even if it is not the root cause, this stuff obviously needed replacing anyway.Last edited by bmwman91; 04-08-2019, 10:21 AM.

Leave a comment:

-

This does not sound quite the same as when my vibration dampener/crank trigger wheel separated and clocked over, although it did generate a 1244 that I couldn't diagnose only to cause the car to stall/not restart after a spirited drive. So if you want to check timing agreement before buying a new crank sensor it might be worth your time.

Hoping it's just a sensor.

Leave a comment:

-

I'd assume that a fuel delivery problem would mean even worse running above idle, where demand is greater? Pump, filter, injectors and regulator all have <30k miles on them.

Ignition was a thought and I'll check the coils and plugs. If it was a bad one I'd think that it wouldn't run better at higher RPM, and there would be some response to throttle input when bogging. It's easy to do a visual though.

Rubber stuff is fairly fresh, but I'll do a good check for vacuum leaks. Again, I'd think a vacuum leak would clear up as I open the throttle.

If the TPS is really messed up it might cause this, but it gave good readings on the DMM.

CODE 1244, cam position sensor. Unplugging it made no difference.

My cousin in law is bringing his E30 by later so I can swap his sensors on one at a time, so hopefully it's a simple thing. The car started and idled fine cold this morning, which is annoying. I'll warm it up fully later to see if this issue returns.

Leave a comment:

-

I was thinking CPS, too, as I was reading...

Just because it costs nothing, I would first check fuel pressure,

and also all the ignition components. And remove all the

post- maf boots and make really sure they aren't cracked/ falling off.

And see if maybe there are any codes...

t

Leave a comment:

Leave a comment: