I'm working on getting the domestic transmission mated to the BMW engine. The E39 540i automatic bellhousing has been mapped out on a CMM where my dad works... I need to buy a copy of SolidWorks or similar to design the adapter to bolt the Corvette front plate to that bellhousing. And of course I need to buy the front plate.

Right now I intend to disassemble the E30 iX steering rack and machine the left mounting boss off the left "end fitting" (The aluminum casting on the left end of the rack to which the spool valve bolts) and machine a new mounting clamp which will allow me to rotate that fitting to any orientation I want and still bolt it down. That will let me rotate the fitting forward (making the spool valve more upright) until it clears the mount tower, mount bracket and front diff. I'll then build a multi-u-joint steering shaft to connect it to the steering column.

E30 M3 S62 Build - Loads of queries about 4x4 drivtrains

Collapse

X

-

:weak:of course, lol ..

Will, have u actually managed to the engine in yet? what rack are you considering using?Leave a comment:

-

Other way around... Longer steering arm at the hub means that the same travel at the rack will give less turn of the wheel/tire.Leave a comment:

-

Its an e30 M3 rack, slightly skinnier then standard e30 and e36 racks. I still don't think it will work though. Your are definitely right a boy the rubbers. I am thinking some 'remodelling' may need to be done to both the rubber area on the subframe and the corresponding area on the sump.

Some people on the e30zone have suggested a steering box like racing cars do. don't know much about these.

The next thought i had was to make mounting points to the front of the subframe in order to mount the rack. Then the steering pushrod arm connected to the strut could be extended toward the front. The issue with this is the longer the arm the more leverage there will end up being, this will result in more 'Steer' per 'turn'. so either a higher geared rack, or one with a shorter travel.Leave a comment:

-

What steering rack is that?

I don't have a body on which to measure yet, but I think that the pan/sump will have to be forward against the rubber bumpers bolted to the rear surface of the crossmember.

The spool valve on the stock iX rack interferes with the E53 diff, which is the only diff that bolts up to the E53 pan/sump. There really isn't room to move the spool valve outward... it has to be tilted forward to clear the diff, but if you tilt it too far, it will interfere with the engine mount tower (between crossmember and mount) and bracket (between mount and engine).Leave a comment:

-

SO... Today:

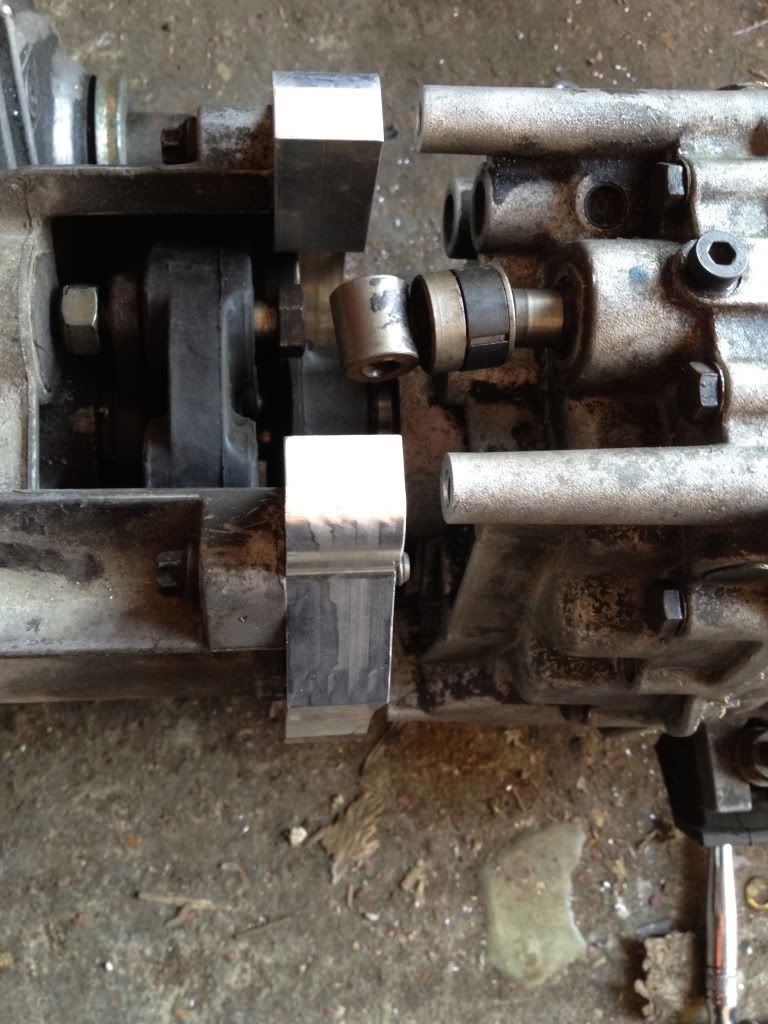

I picked up my bracket for the gbox/tcase. Its looking very nice, so I mocked bolted it up.

I need a gear selector base bracket specific to the m3 boxes i think. Let me know if u have a one.

Now onto the car. I corrected my previous mistake regarding the subframe, flipped it round and when I put the sump in realised that I was fortunate enough for it to just bolt straight on.

In fact the Ix's subframe starts one bolt hole further forward then standard cars. This mean there is some boxing in and tapping to be done. Hopefully DaveTheGoat will be helping me here ;)

The steering column is really going to cause problems. Once a diff is bolted in place and the sump dropped in there is going to barely any room. In these pix it looks doable but when the steering rack is in the sump is pushed back an icy or so, and i think this will make the engine foul the bulkhead.

The e30 Ix strut towers has its strut top nut at 37cm from the scuttle lip. As you can see here i am going to be a fair bit out even with a caster adjustment plate.

Leave a comment:

-

-

Dowels are kept mate, and more in the other end as I said above. Only thing left to do is fashion a groove for the gear selector gumph!Leave a comment:

-

The right answer is a pair of locating dowels of some sort. The T-case has two (unless you removed them... in which case I'll really berate you) and you will need to dowel the interface between the trans rear cover and the adapter in order to assure accuracy in locating the adapter when you bolt the assembly together.Leave a comment:

-

the plate is being 'Locked' into place using the 4 pre threaded holes, 10mm at the top and 8mm at the bottom, The larger bolts are to anchor is down to the main casing. More pics tomorrow as is nearly finished.Leave a comment:

-

That won't be sufficient for *locating* the adapter on the transmission. Relying on the bolt holes to locate the adapter to the transmission could easily put you off 0.020" in concentricity. How much do you think that will affect your guibo, which will already have a hard life with 400 HP and AWD?Leave a comment:

-

It's not hard to make just Time consuming. These can be banged out using CNC easily if you know a little CAD.

Nando, can you take a look at the holes in the subframe and let me know if they're the correct configuration to be using with the Ix. Or should I be using the front hole Only and make up the rear hole out of section etcLeave a comment:

-

no thanks - I've got the other half of the case that your t-case mounts to, and it was only $180.. ;)Leave a comment:

-

I wouldn't mind seeing the measurements :)made some progress on the tcase plate. Gonna pick up some dowels to extend the case to the 8 of the mounting points of the rear case. so should be nice and strong. My mate has taken the datum point so Ill be able to remake one if anyone want one, or I need a spare for a 2nd attempt :P

Leave a comment:

Leave a comment: