Just finished up my r134a conversion last night, went the whole 9 yards:

- custom barrier hoses to replace the rubber

- new compressor

- new condenser

- new drier

- new expansion valve

- o-rings with Nylog throughout

- M44 aux fan (puller mounted on radiator) - deleted stock aux fan &

mechanical fan

I charged it up last night with my gauges, and its definitely running colder, I didn't have a thermometer so I can't be 100% certain, but the vent temps at idle didn't feel any colder than probably 60°.

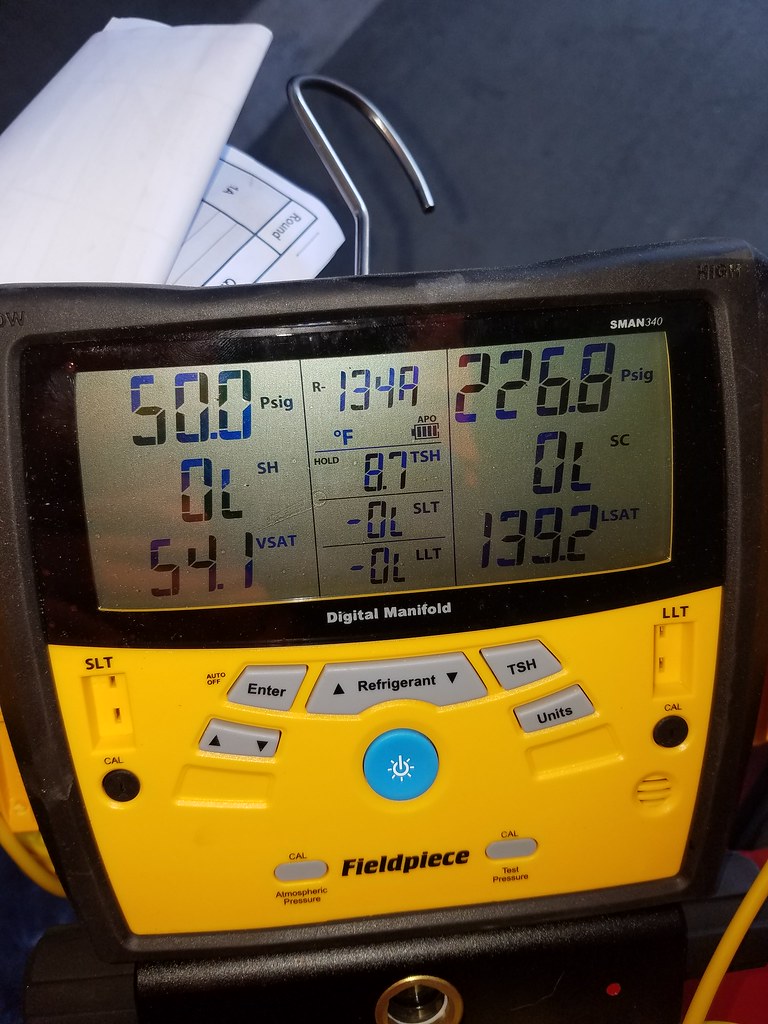

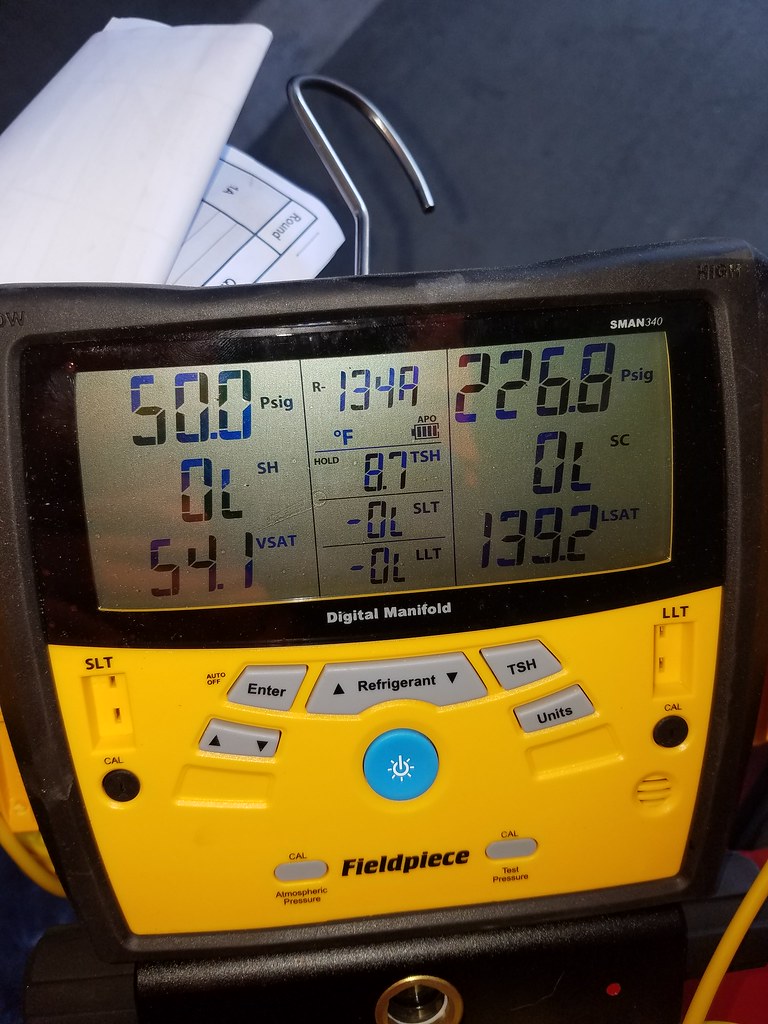

I took a snapshot of the gauge pressure readings early this morning, conditions were 86°, humidity 63%.

Does this look right? Seems my low pressure reading might be a little high? Not sure how it works in conjunction with the high pressure reading and if I overfilled or not.

- custom barrier hoses to replace the rubber

- new compressor

- new condenser

- new drier

- new expansion valve

- o-rings with Nylog throughout

- M44 aux fan (puller mounted on radiator) - deleted stock aux fan &

mechanical fan

I charged it up last night with my gauges, and its definitely running colder, I didn't have a thermometer so I can't be 100% certain, but the vent temps at idle didn't feel any colder than probably 60°.

I took a snapshot of the gauge pressure readings early this morning, conditions were 86°, humidity 63%.

Does this look right? Seems my low pressure reading might be a little high? Not sure how it works in conjunction with the high pressure reading and if I overfilled or not.

Comment