Now it makes sense that you are in Vegas, this must keep you super busy!

So basically once you have gone 5 lug, you will have two of the same cars just with different bodies.

I'm almost ready to finish up all my engine bay prep in my swap, my last step is going to be wrapping the firewall since I pulled all the foam insulation. How well does the gold foil work? My local speed shop can get me the DEI tape but they also have this 1/8" thick silver foil that's backed with matted insulation that I think will work better but won't look as nice.

cameras ready prepare to flash

Collapse

X

-

Been really trying to get the car on the road for a short weekend trip. I was trying to make it out to socal vintage with a few friends. So I was in full "GO" mode a few days ago.

first off, I was having super hard start ups....thought it was the check valve on the pump. turns out sitting for 2 years did some work on this walbro 255. I've never seen anything go bad so fast!! the hose and filter were both brand new when installed.

I replaced it with a brand new pump/assembly from autozone. I also replaced the brake light switch which i noticed was sticking.

I took it on a test drive, everything seemed okay besides the super sketchy alignment.

2nd test drive was a little longer, came home to a puddle of brake fluid on the floor mat.

Turns out the nipple on the clutch master cylinder broke. good thing i kept my older one around! No idea how this happened though....I had to figure it out as I had squeezed in an appointment the next morning.

woke up early to get an alignment, and refill a/c at local Southwest Bimmers. (super nice guys there btw)

The ac was charged but the compressor won't kick on......great. I'm going to have to triple check the wiring that was done 6 mo ago...

but at least the alignment was done! The car sounds great! I'm super happy with the exhaust. I'd like to maybe do a few more cuts to make the canister sit more level, but that's just my ocd kicking in.

It was good to get the car on a lift though....I was actually making contact from the header to subframe....I know a few people with m50 swaps who use these same headers with no issues. I also have a leak from the trans - front seal it seems. DAMN.

Fast forward....soo something is super wrong with my brake system, bled the full system...... but I think my booster is bad, power assist isn't there and my rear brakes seem to be getting more and more stuck......it progressively has been getting worse from every test drive. On the drive home it was so bad that I only got 1/4 mile away and started to see smoke. I pull over for a tow because the pads were starting to smoke. And it seems I have an oil leak from the oil cooler thermostat. things aren't going so great on this shake down run.

After I got it home, the next day I decided to throw a spacer between the mount and engine arm. I found some 6mm washer/spacers which worked out real nicely. It now clears the a/c tensioner and headers. I wish akg or condor (someone) would just make the mounts 4-5mm taller since this is a popular swap.

So the rear brakes....turns out the ebrake cables were stuck. I still have no power assist so I'm going to just get all new stuff. New parking brake cables, shoes and hardware ordered. Also have a Porsche 944 booster, 20/20 brake master, wilwood bias valve, on the way and I'm going 5 lug apparently.

I got a heads up from a local shop they are parting out a 98 m3, so I went in and got the fronts for a good deal. I'll be getting those adapters for the z4 hub/e46 rear calipers because I really like the idea of having a vented rotor back there with a a working parking brake.

The plan is right now to use my fortune auto's from my m3. I have the fk konigsports somewhere in storage I can put back on. Hopefully my ground controls and rx7 brakes will make this a pretty even swap.Last edited by s14brent; 08-26-2020, 12:29 AM.Leave a comment:

-

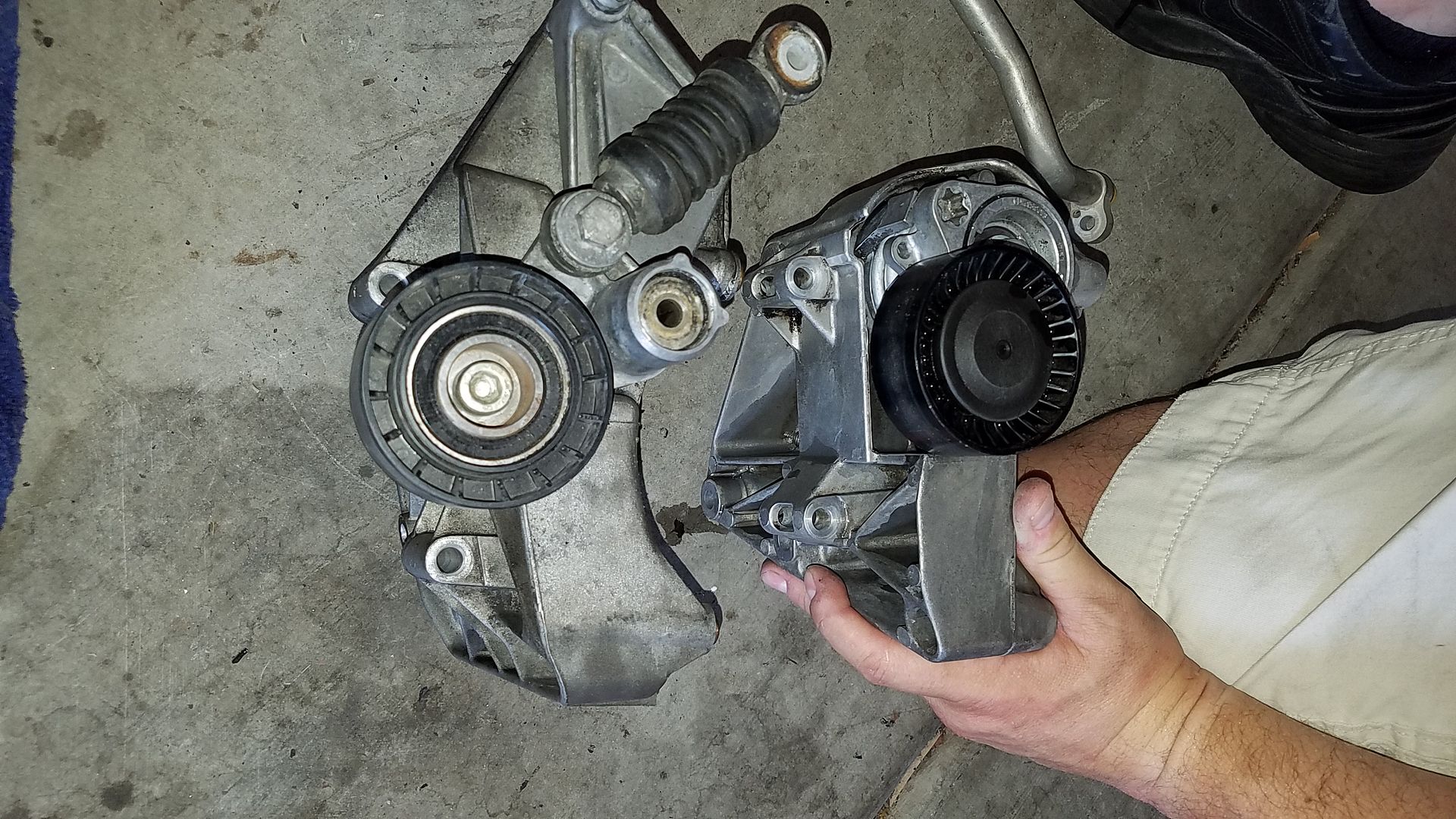

Probably, but I 'd rather just swap the whole ac bracket/tensioner for the m54 clearance. TBH i might just grind down as much as i can (off the tensioner and bracket) just for now....

a local e21 guy with a s50 swap told me about swapping the brackets. Apparently it bolts right up and has a good amount of clearance, but I'd like to get the bracket and order a new tensioner, but apparently there are some differences depending on what car you pull it out of - so that will have to wait.

-Pic stolen from his thread-

thanks!Leave a comment:

-

Can you take a whole saw and cope the pipe similar to roll bars near Where the tensioner makes contact.Leave a comment:

-

AKG rules. got the adjustable fcab's this morning. they're sooo shiny!!

had to wire wheel the paint off the lca so these could slip on. tolerance is a lot tighter than the treehouse or even the slrspeeds. There's still slightly over an inch of threading in the block.

much better! I'll be able to turn the wheels next drive!

I put the stock brake ducts back in....used a screw and a speed clip to fasten it down.

tightened all the steering rack components down again, should be good to go. I just need to address one more issue.

The a/c tensioner hits the skid plate brace. =\ I thought there was paper clearance...but it's causing a nasty vibration..... I was told a m54 tensioner may fix this. damnit. not sure if I'll be able to make it since I work day/night the rest of the week. Last edited by s14brent; 08-26-2020, 12:32 AM.

Last edited by s14brent; 08-26-2020, 12:32 AM.Leave a comment:

-

I finished the rear section of the exhaust finally.

yes. it really sucked.

I drove it around the neighborhood a few times, steering felt weird, and the caster is horrendous! Tried to order some SLRSPEED fcabs (same as what's on my m3) but their site was down....got impatient and placed an order a few hours ago with AKG. I'm going to put a smaller tie rod spacer on the rack and triple check all the nuts and bolts again. I'm pretty sure what I'm feeling is a caster issue.

I threw a CEL for the o2 sensor/lambda control. This is the second junkyard o2 I've tried, I have a brand new oem bosch o2 arriving in the morning.

these pics are of the "good side"....damn i love it!!

Trying to get this drivable, maybe go to socal vintage with a bunch of local guys'. We'll see! *fingers crossed!*

--------------------

edit: insomnia's a bitch....swapped out the 6+mm rack spacer for just 4mm using 1mm shims in the correct ID/OD from mcmastercarr (98055A232). (Not sure what i was thinking when i got the 6mm ones! LOL!) I didn't check all the bolts because tie-rod boot was being a bitch and a beer sounded more rewarding.

That should increase the life of the rack significantly! driving around the neighborhood with 6mm rack spacers was kind of hilarious (go kart status!)

update: o2 sensor picked up.

installed

Last edited by s14brent; 08-26-2020, 12:34 AM.

Last edited by s14brent; 08-26-2020, 12:34 AM.Leave a comment:

-

Thanks man, super stoked on progress! and yes, all 4 door cards were acquired. They cleaned up very well with all the dust/dirt that was on them. There are a few small imperfections, but I'm not too worried about it. I reused a bunch of clips that didn't break from my set, so it was a quick swap.

Thanks, I'm a freelance concert/event photographer, so I will be out at the iheartradio music festival this weekend while one of my staff photogs will be at Life is Beautiful music festival this weekend.Leave a comment:

-

-

Looking good now in there

Black speaker planels

Black door panels

Black seats

That gauge pod

All winning.

Did you get black door panels for the rear doors?Leave a comment:

-

I eventually settled on just having a black vinyl seat since it matches the current black vinyl door cards I have (exactly like yours).

btw Im going to sell mine, shame you arent local I would give you a good deal. Pretty sure mine is for a 4 door since it doesnt quite fit right in my 2 door

Thanks guys'!! What kind of spray paint did you use on the rear shelf? I'll be in touch about the rear seats! I might go check out socal vintage and a drift event oct. 7-9. So if I don't have a black rear seat by then I will definitely take one of you guys up on the offers!you can also paint the speaker covers with vinyl black paint and get a decent result as long you degrease the parts really good before painting

i spray painted my rear shelf and it turned out pretty good one of my buddies has a rear back seat in black for free in orange county

both of the front speaker covers are imperfect. I will eventually find a pair of black ones at the junkyard. meanwhile I sanded them down, primed, then sprayed with sem trim paint, since I had that laying around (more of an acrylic based paint). better that than bbq black!

The door panels I got had manual window crank - cut outs. I had to cut the panel to fit the rear window switches. The hole bugged me so I went to Lowes in search for a plug of some sorts.

Found these hillman 1" plugs (884313 furniture tip) that were perfect.

-------------------

So as for the exhaust...I placed an order on some flanges, hangers and one more 30 degree bend. It's been 10 days since the purchase, i'm getting very impatient over here. Good thing it is a HUGE work weekend in Vegas again!Last edited by s14brent; 08-26-2020, 12:37 AM.Leave a comment:

-

you can also paint the speaker covers with vinyl black paint and get a decent result as long you degrease the parts really good before painting

i spray painted my rear shelf and it turned out pretty good one of my buddies has a rear back seat in black for free in orange countyLeave a comment:

-

The parcel shelf is easy enough to paint, just remember to brush it otherwise the fabric becomes stiff and weird.

The rear seat is tough, I tried to dye a tan cloth seat black and failed miserably so then I had a houndstooth rear seat to match the houndstooth door panels I had at the time and still didnt like how it looked. I eventually settled on just having a black vinyl seat since it matches the current black vinyl door cards I have (exactly like yours).

btw Im going to sell mine, shame you arent local I would give you a good deal. Pretty sure mine is for a 4 door since it doesnt quite fit right in my 2 doorLeave a comment:

-

Massive recaro seat adapters are super nice and easy to install.

acquired some black sedan door cards locally!

and both seats mounted...(had to install the driver seat by passing it through the passenger side since the car is still up on jackstands). Very happy with how it looks. I just need a black rear seat, black parcel shelf, and front speaker kick panels in black to make it look how I want it.Last edited by s14brent; 08-26-2020, 12:39 AM.Leave a comment:

Leave a comment: