Money Pit: The Sequel - Full Repaint Project

Collapse

X

-

As much as I don't care for black kidney grilles, they do look amazing against the red and with blacked out headlights! -

Ha wow I forgot all about this. The car has been done since ~November 2023 and I have been enjoying it. As usual, I finished the project and did not bother to take many pictures. The car looks awesome and I get compliments on it which is fun. With all of the rain we have been getting lately, it spends a fair amount of time parked with a car cover since I am determined to keep water out of the sunroof cassette as much as possible.

Once we get some sunnier days, I plan to take it for its first detailing, and then maybe find somewhere interesting to snap some pictures.

Here are a few of the pics that I took last year inside of the reassembly tent and in front of a friend's office.

Leave a comment:

-

Thanks for the details of the vapor barrier replacement.

I need to do that exact job on my E30, the original stuff on my car looks awful and is held in place with gorilla tape in a few spots.

Was planning on using universal material but since you provided the OEM part number and the details of the sealant I may give that a go!

Any updates with your E30 now that we're solidly in a new year?Leave a comment:

-

yah, pain in the ass to mask the trunk off with those things there. I'm dropping my 318iS off for paint this Friday after work. stripped it down to bare metal, whole 9 yards.

That pic was texted to me by the painter, so I am not sure how he did it. I assume that he used some wire or bungee cords inside the trunk.

Update: The car is basically done now. I am waiting for some touch up paint to dry in the sunroof area, and I had to respray the windshield wiper arms which will need a couple of days to cure. Pics will be incoming soon!Leave a comment:

-

That pic was texted to me by the painter, so I am not sure how he did it. I assume that he used some wire or bungee cords inside the trunk.

Update: The car is basically done now. I am waiting for some touch up paint to dry in the sunroof area, and I had to respray the windshield wiper arms which will need a couple of days to cure. Pics will be incoming soon!Leave a comment:

-

how did you get the trunk support pieces to stay down without a board or something holding them down?

Leave a comment:

-

More progress today. I tackled the mechanical portion of the sunroof assembly. It is not the hardest thing to deal with on the car by far, but it is sort of annoying. Being done with it is a bit of a relief!

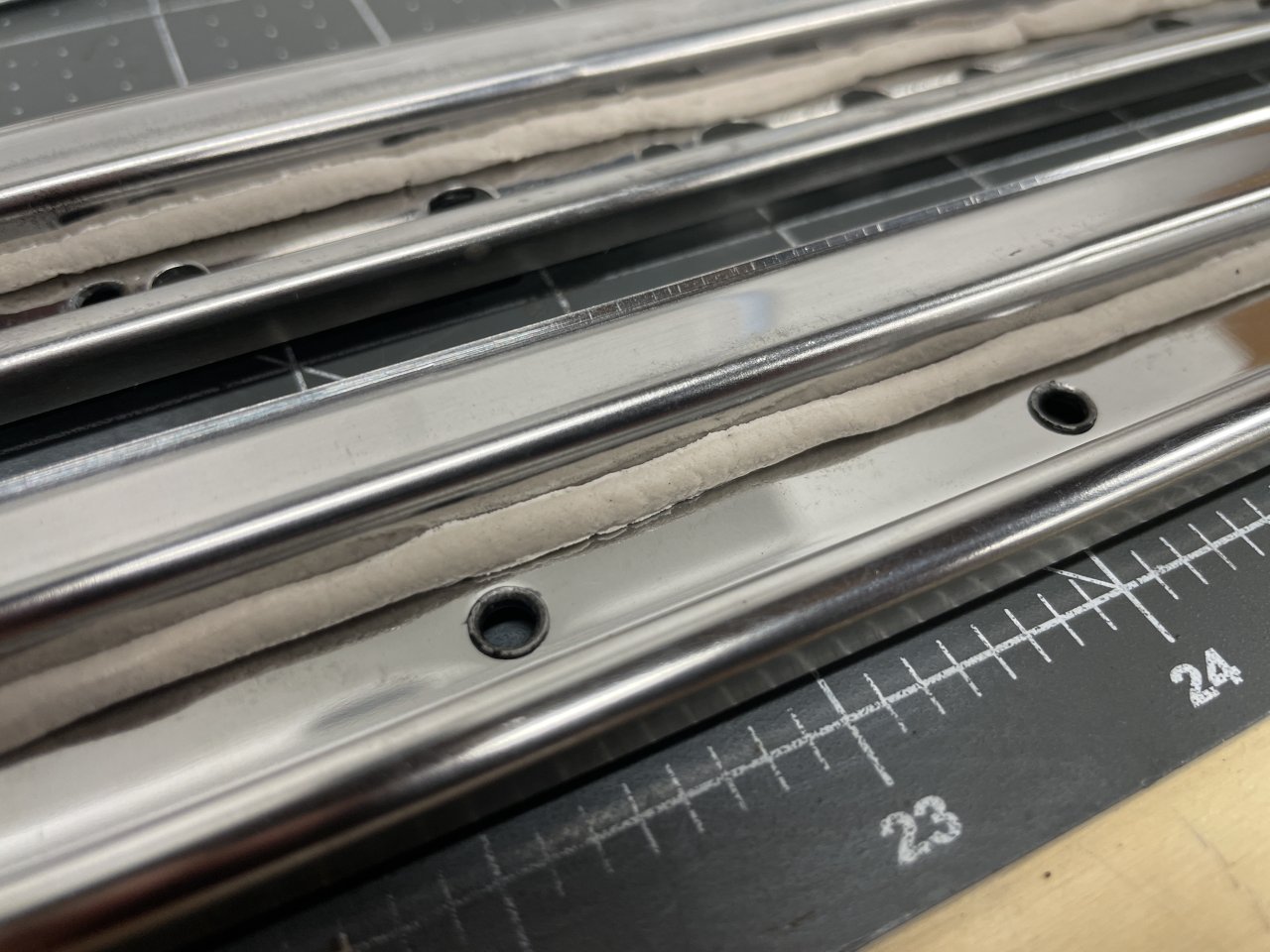

When I removed the long guide rails, there was some sticky grey butyl sealant all over the underside in the grooved portion. I assume that this was to keep water from wicking up into the interior side, and/or for preventing vibration of the rails against the cassette insert. Whatever the case, I opted to put some new stuff in since I don't want water or rattles up there. The new material is some generic butyl mastic caulk that I got on McMaster Carr.

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

I applied a bead down the outer-side of the channels.

After most of the main guide parts were in, I smushed a bit more of it in up at the front to ensure that the big gap was sealed. It'll all get squished down even more once the black top plates are in place.

Getting the new sunroof cables in was pretty easy. They come dry, so apply new grease to their full length and on any of the sliding parts on the carrier bodies. I put on a nitrile glove, squirted a big blob of grease into my palm, and then dragged the cable through my hand until the cable was thoroughly lubed. There's a joke in there somewhere, but I'll leave that to the good citizens of r3v. Also, I squirted some grease into the rear portion of the cable channels in the long guides, and used an old toothbrush to try to spread it a bit more evenly in there.

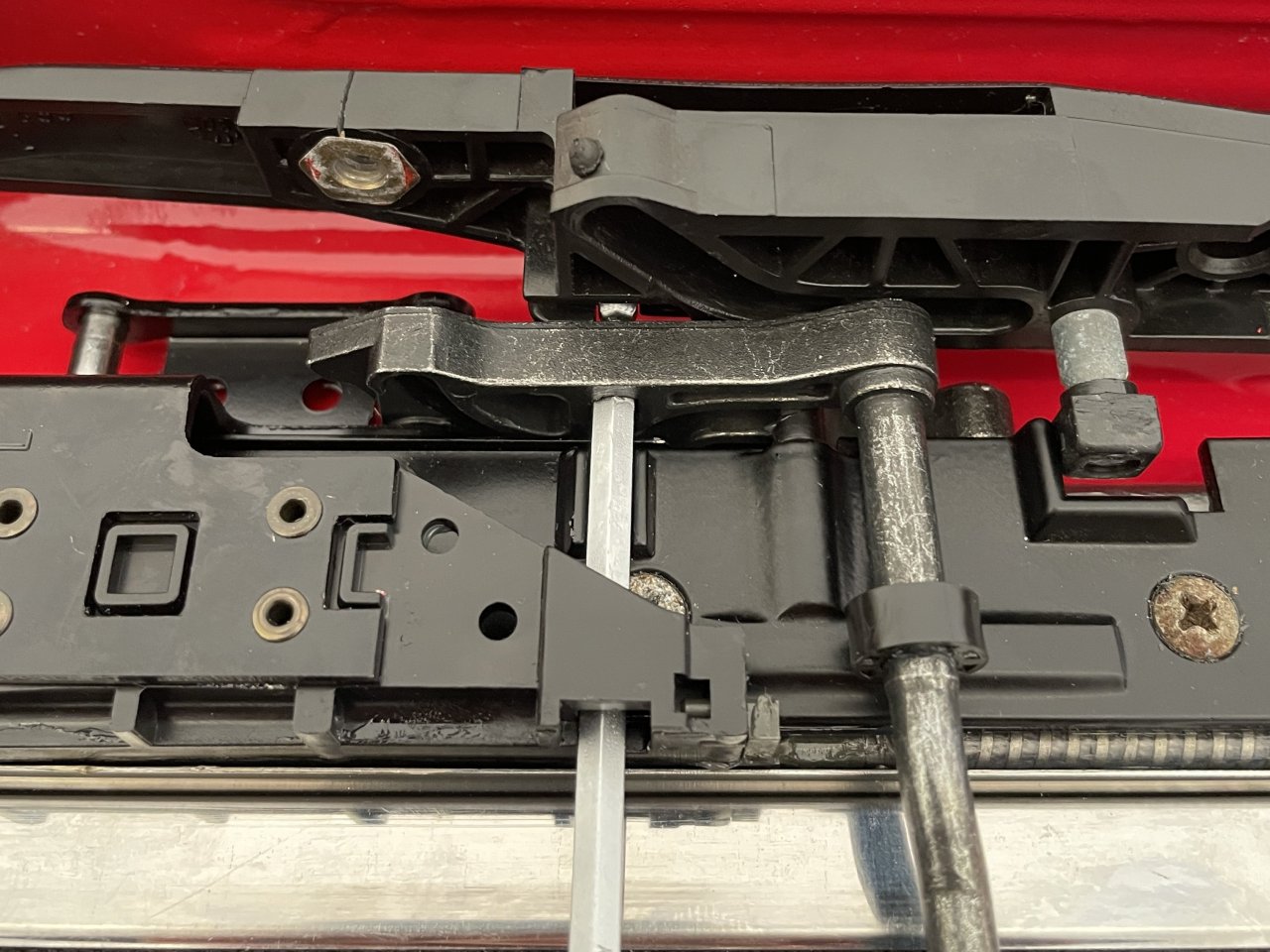

After that I secured the rest of the guide parts. Move slow and take care when putting in the little cast cover plates that connect the front covers and rear portion of the main guides. The sunroof arms and cable carriers all have little things protruding from them which need to be slotted together properly. Forcing things is going to give you have a bad time, as is having things improperly engaged.

Synchronization of the sunroof cables is pretty simple.

1 - First, get both sides aligned as shown in the pictures. A 4mm or 5/32" hex key inserts as shown to hold the carriers in the proper position for when the sunroof is in the closed position.

2 - On the body of the crank mechanism, which should be in your hand not in the car, rotate it until you feel it click into the closed/locked position.

3 - With it in the closed position, you can carefully put it up in to the bracket in the roof. Do NOT tighten down the screws beyond loose finger tight.

4- Chances are that the sunroof cables' teeth are not perfectly aligned with the crank gear's teeth, and you don't want to mash them together. With the crank loosely secured up there, you can try turning the crank ever so slightly to rotate the drive gear until you feel it pop into alignment with the cables.

5 - At that point you should be able to easily push the crank mechanism upward and see that it fully seats on its bracket. If it is not pushing all the way up, the gear and cable are not correctly meshed, so take the crank off and try again.

I needed a couple of tries to get things just right...the first try ended with the left side cable being off by 1 whole tooth.

6 - Once you think you have it all aligned and synchronized, try cranking the mechanism backward a couple of inches, and then return it forward to the closed/locked position.

7 - When you look through the alignment hole, it should all look like this on both sides. If not, try again.

8 - PROFIT?

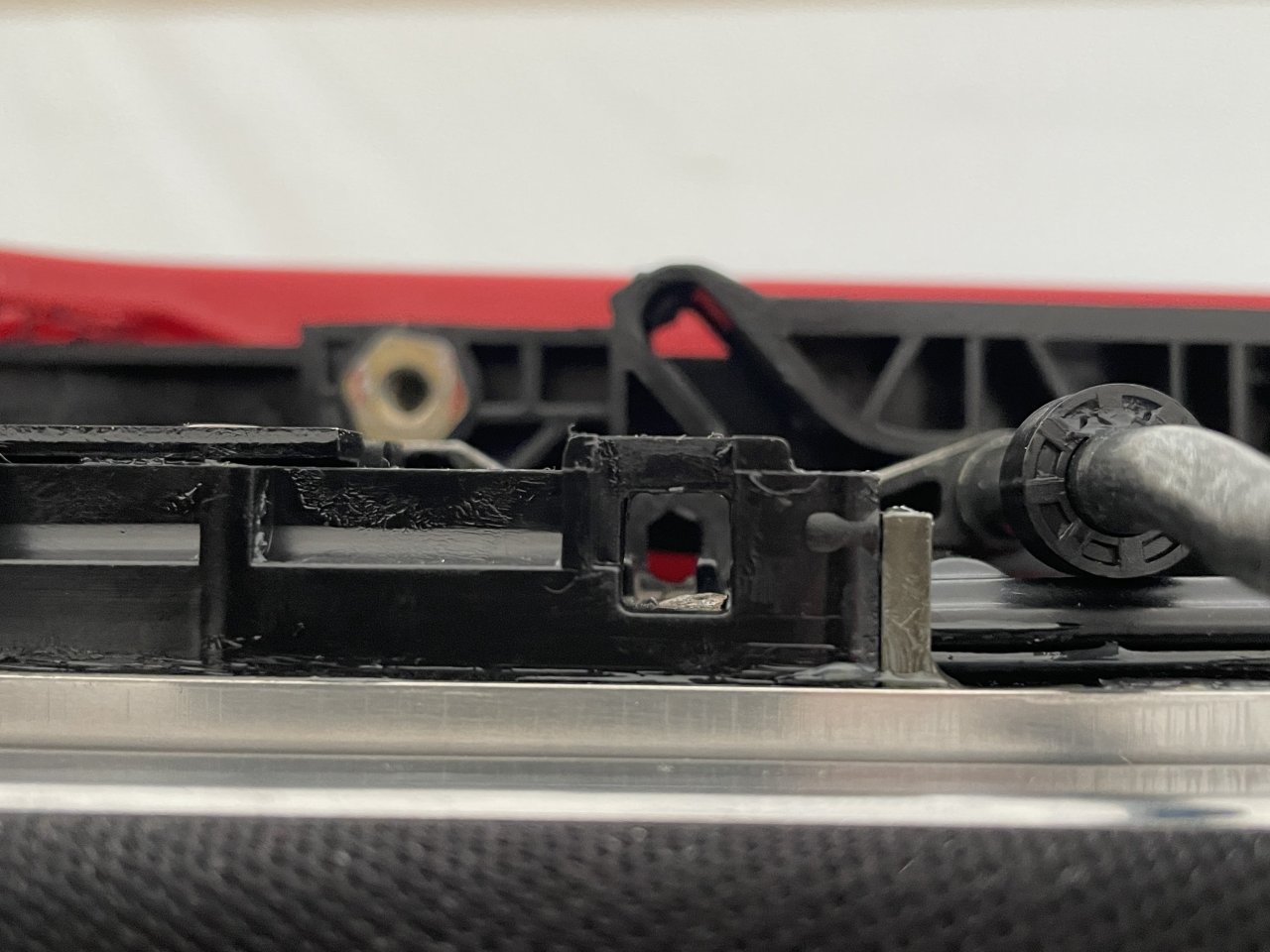

One thing that you need to be careful of is scraping up the paint in the cassette recess. There are some little "wings" on the outside of the arms, and without the sunroof panel attached the little plastic springs in the sleds will push these outwards enough to scrape stuff up. I found this out the hard way, so I have a little bit of touching-up to do in there. One other issue is related to the new butyl mastic. Since it is sort of firm, it was biasing the long guide rails outward by 1mm or so. Once I realized this, I loosened all of the screws on the guide and pushed it inward as hard as I could, and then retightened the screws while still pushing on it. This bought me some clearance, but I still would not move the mechanism around without the sunroof panel in there as the arms will still move outward and scrape stuff.

My next item to tackle was the sunroof headliner panel. I had to reattach the little arms on the sides first. So, to start I used a sharp awl to poke through the cloth in preparation for the pop rivets. I was able to force some standard 1/8" diameter ones in there without any additional drilling or attempts to cut the cloth. It is tight, but you can get them through, and I'd say that you want to avoid cutting the headliner material if at all possible.

So, initially I thought "that was easy!" I got the arms attached, and all looked good. The original rivets were the double-flush type, but I figured that I would have plenty of room for the standard type. This was incorrect, and the protruding part will NOT fit under the top cover plates up in the sunroof guide assembly.

Additionally, I had added some heat shrink tubing onto the arms. They originally had some rubber over-molded onto them, which was burned off when I got them powder coated. Well, the shrink tubing was too large and was also binding on the top covers of the guides. So, I cut off the rivets and shrink tubing. I'll take my chances with the arms as-is without any outer coating or anything. It is probably fine.

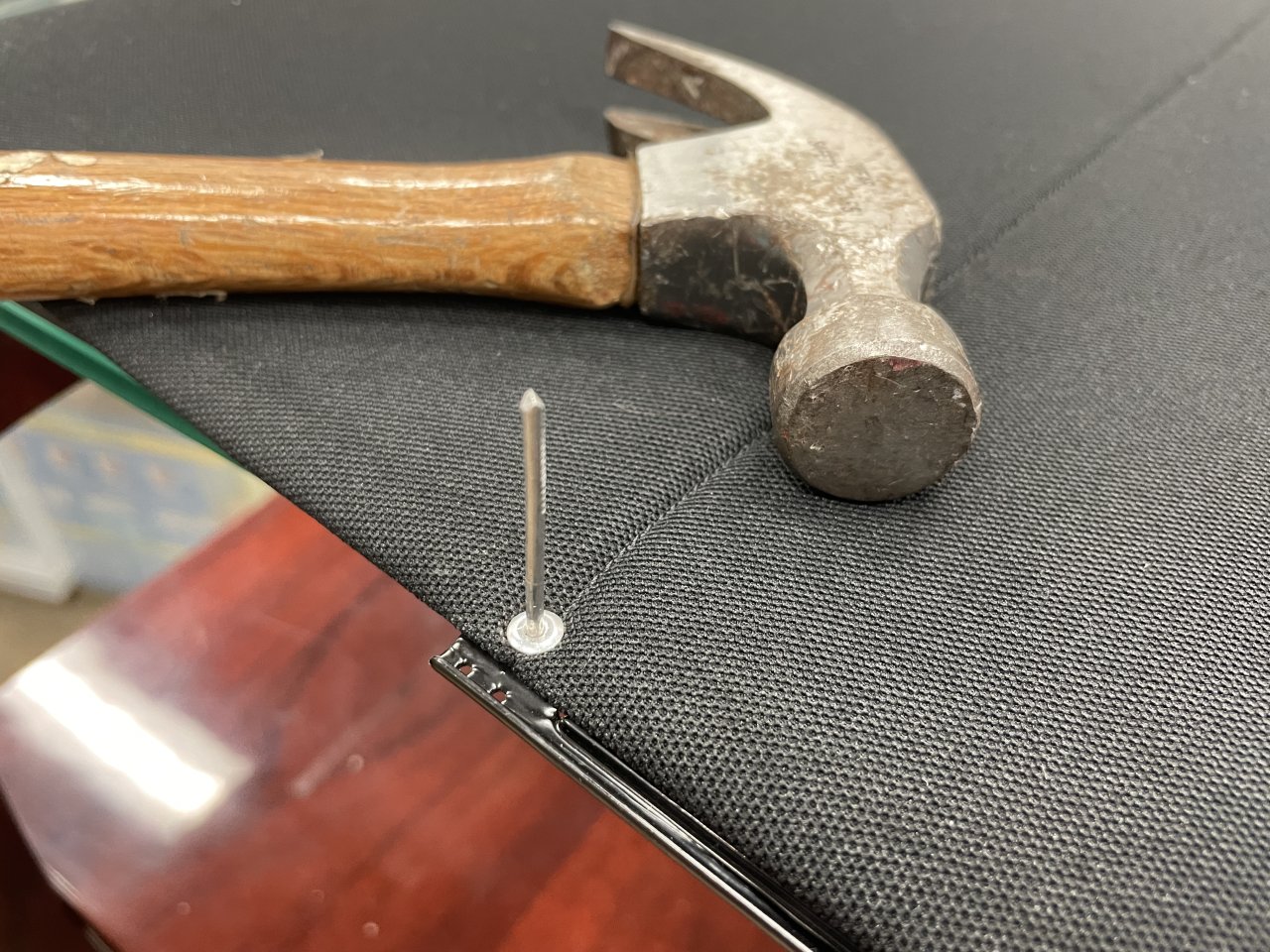

So, faced with spending $8 for double-flush rivets on McMaster (and not even really being sure which length would be the right one) + $11 for shipping, I put on my redneck engineering cap and tried to think about how to make the regular hardware store rivets work. Using some scrap steel, I prototyped the following procedure, which is now deployed in the car.

First, rivet the arms on as usual. Then take the mandrel that broke off, and use it to knock out the remaining ball end that is still in there.

Next, get a center punch and GENTLY flare the open end a little bit.

Finally, use a hammer and flat punch (or scrap of metal rod, or anything hard, cylindrical, and flat) to flatten it out. You need to back up the other side in order for this to work. In my case, I had a piece of 16mm steel scrap that I placed under it. A couple of firm blows was all that was needed.

You need to be careful to not go too crazy here. If you smash the rivet too much, the new "head" will be too thin and can easily rip off, and you risk having the head on the bottom side punch through the fabric. Just get it mostly-flat. Also, you will probably find that the flared part wants to tear in 1 or 2 places. In my case, one side was perfect after the first try, and the other side took 3 tries to get flat without tearing/splitting.

As you can see this solution fits really nicely under the guide covers.

And with that. the most obnoxious part of the sunroof assembly is done!

Leave a comment:

-

Oh, and I asked them if they have a recommended contact cement for stuff like this. Their shop has to use some CA compliant low-VOC stuff (which is still really sticky), but for home use they said that the DAP Weldwood cement is the way to go. Thankfully that is the stuff that I had bought to fix up the roof foam panels. So, good stuff that professionals would use if they could is easily available at home improvement stores!

Leave a comment:

-

One more big item is checked off now. I got the car back from the upholstery shop this morning. The headliner is installed, the front upper console is rewrapped, and the A-pillar trim pieces are also enjoying some new covering.

Now that I have the car back and have taken a good look at the workmanship, I can recommend this shop to others on here. They were professional, friendly, fast, and fairly priced (definitely not inexpensive, but they made every effort to come in under the quoted hours of labor and the quality of the work is exactly what I would have hoped for). It took them 1 week from drop-off to completion since they have about a dozen cars in the shop right now. Apparently a lot of BMW's of this era are coming through lately.

https://www.yelp.com/biz/wardell-aut...ps-santa-clara

The front upper console looks as good as new now. They were able to rewrap it with a single piece of textured vinyl, which is awesome since they had initially thought that they would need to sew together some pieces for the visor recesses. Thankfully, a little bit of heat and stretching got it all laid down securely! They did leave some overage in the places where it wraps onto the body, since I had said that I would be doing the final trimming and reassembly after the glass gets reinstalled (that is next on my list).

The A-pillar trim pieces also look nice and new. Same deal with the overage...I will trim it once it is installed.

My new sunroof headliner panel is looking really great.

I was impressed that the shop even put some tape over the door sills to protect my new paint from shoes while they were working on the car.

Much to my relief, the tight corners in the sunroof opening came out perfectly with no wrinkles or creases.

This new headliner really breathes some new life into the car, and honestly a lot of that "old BMW" smell is gone now. Maybe a big part of it is the decaying OEM vinyl headliner. This material is an actual woven textile, so it should also be a heck of a lot more durable than the thin textured vinyl stuff that was in there originally. Also, the little black clip thing in the upper corner of the rear window is just a little clamp to hold the ends of the headliner down until the window seal goes in. There is no real risk of it coming loose, but the shop put them in a few spots just to be safe so that the passing air while I was driving home would not mess with anything.

So, at this point I just need to call around to find a glass installer for the 4 fixed windows. From there, it is a matter of reassembling the sunroof mechanism, putting the interior back together, and doing a couple of little odds and ends. The end is in sight!Leave a comment:

-

It's been a little bit since my last update, but progress has continued. Things were mostly in a holding pattern as I waited for the upholstery shop to have some availability to do the headliner, A-pillar trim, and front upper console.

Prior to the drop-off at the shop, I finally sorted out the new door vapor barriers. This involved some OEM plastic film and 3M butyl rope sealant. The plastic sheet is adhesive backed, but it isn't going to seal well on uneven metal, so I got some of the rope sealant based on a bunch of E34 guys who seemed to have good results with it.

OEM vapor barrier material PN: 51951924961

It comes in a big sheet which is enough to do 3 E30 doors as far as I can tell.

3M rope caulk: https://www.amazon.com/dp/B000CQ4AOO...roduct_details

You might be able to do both doors with one roll if you stretch it out. I bought 2 rolls just to be safe.

I also bought one of these to really get good adhesion between the sealant and film: https://www.amazon.com/dp/B094QRCN9K...roduct_details

Once I had put the rope sealant into place, and applied the film on top of it, I used the roller to really set it all in place firmly.

I started by cleaning off the mating surfaces very thoroughly with some 99% isopropyl alcohol. It will take a little of your paint off, but as long as you don't go nuts it is fine. The sealant will not stick if the surface is dirty or otherwise contaminated.

As far as placement went, I tried to keep the path on the same plane so that there were no dips or bumps. You will see at the bottom that I had some tight turns around some of the openings. This was deliberate. Basically, I wanted all of the lowest points to be at openings so that water would drain out rather than pool up in any sealed pockets. Also, before applying the sealant and after cleaning, I did apply some touch-up paint in a couple of spots where the paint was scraped off down to the metal. Rust is not something I wanted to have forming.

With the sealant installed, I then carefully laid the film onto it. My wife helped to hold the sheet flat so that I did not have any bunching or crowding as I pressed it into the sealant. Once it was mostly in place, I trimmed off the excess around the perimeter and then used the roller to fully seat it all. Last, I trimmed out an opening for the door handle. In the case of the driver's side, I made a small incision for the power mirror harness, and then used some scrap film to patch around the slit. Also, I noticed later that I was missing the 3rd / upper bolt for the window regulator lol. So, I cut a small hole for the bolt, installed it, and then patched over the hole with some of the left over film.

As for the upholstery work, I am having the shop recover the A pillar trim since the old vinyl is coming off and I want it to match whatever is on the new upper console.

The upper console was not in terrible shape, with only some small-ish bubbles, but I had to mess up the vinyl in order to repair the area around the rear view mirror where the hardboard stuff was broken.

In the middle area around the mirror opening, a few things were wrong. The thin section was fully broken, and cracks were forming in some adjacent corners. The cracking was easy enough to fix with some toughened CA glue which wicked into the cracks. As for the broken middle part, I 3D printed a brace from ASA filament. It was pop-riveted and epoxied (3N DP420NS) in. The middle area should not have any issues ever again lol.

I clamped the brace into place and used a really long 3mm drill bit to match-drill the needed holes for the rivets.

Before applying any epoxy, I have everything a light sanding with some 60 grit and a wipe with alcohol.

The little mount bosses for the rear portion had also both broken off, probably because I had forgotten about them and the 2 screws that hold them. Again, a stiff wire brush and some alcohol were used to prep things before I generously applied some DP420NS epoxy.

Other than that, I just needed to do a little but of prep/repair on the foam headliner backing in the roof. The original contact adhesive was failing in several places around the perimeter, so I applied some fresh cement. The stuff in the link is cheap, readily available, and sticks like crazy. Some of the left over cement even worked really well to stick the vinyl in my door cards and rear quarter cards back onto the chipboard backing.

So that is where things are for now. I dropped the car off at the shop last Friday, and I expect to have it back sometime this week. I'll update you all once I have it back.Leave a comment:

-

yeah the red is really great. I am not sure if I have ever seen the paint on this car look so good...even back when there was enough of the original left to polish/wax it lol.

Replacing all of the fasteners and stuff is a pain, but I don't ever want to have to do it again. Most of the original ones made it 30 years (sometimes just barely), so I figure I can get a couple more decades out of some new ones!

Thanks for the kind words. This is in fact my first restoration on this scale, but I guess I have some practice with project management from past efforts!

Yeah the blower cover was not my favorite thing. Now that I have been through there, it is not so bad, but with any luck I will never need to mess with it again.It's looking very nice. I hate dealing with that blower cover too. Believe it or not it's even worse to deal with in the E34, which also has a terrible wiper linkage. Thanks for posting the part number for the sealing foam tape, I will file that one away for the next time I have to deal with a blower cover.

Thanks! I hope that documenting all of this will be helpful to anyone else who is foolish enough to undertake this kind of project on their E30.Leave a comment:

-

As said, your organization and work is top notch. Love these updates.Leave a comment:

-

It's looking very nice. I hate dealing with that blower cover too. Believe it or not it's even worse to deal with in the E34, which also has a terrible wiper linkage. Thanks for posting the part number for the sealing foam tape, I will file that one away for the next time I have to deal with a blower cover.Leave a comment:

-

This obviously is not your first restoration.

Your organizational skills are excellent and order of operation is going to help get this project done in no time.

GlwpLeave a comment:

Leave a comment: