The complete repair, rebuild, repaint, and v8 swap of my early model sedan

Collapse

X

-

I tore the engine and trans out this weekend to pull the clutch, since the slipping is getting worse.

The clutch is trashed. The disc itself is worn a lot more then I was expecting, and both the pressure plate and flywheel are covered in grooves and hot spots. So I ordered a new flywheel friction disc and a SPEC Stage 1 m52 clutch rated for 345 lbs ft. I'm going to do a few other little things while the engine is out, and hopefully have it back in and running within a few weeks.

Leave a comment:

-

The other day, I thought I felt the clutch slip when going into third. Today, it slipped a lot, several times. It seemed to stop slipping after the car was warmed up, but I'll be babying it, as I leave for the 4 hour drive to h2oi tomorrow morning. I just hope it makes it there and back!

I'm pretty disappointed. It's a $500 ClutchMasters clutch with 12k miles on it. Granted, it is made for an m52, and I beat the crap out of it, so I can't complain about it's capabilities. But, I'll definitely be doing a 6 speed swap with a stock 540i clutch this winter.Leave a comment:

-

I dropped the oil filter hard lines off at a local hydraulic hose & fitting company, they just cut them down, grabbed some steel male 10an fittings and brazed them on.I like what you did with the AN fittings. I have a couple of quick questions...

How did you braze the fitting on there as you show in the picture?

Are the AN fittings steel or aluminum?

Where did you get them from?

How did you clamp your braded hose to the red adapters??

AN hoses aren't 'clamped'. The hose ends use a special type of assembly design that locks the hose into the fittings as they're assembled.

You can get everything from Summit, Jegs, ebay, amazon, local stores, etc... AN is really common.

I have an e53 X5 oil filter adapter plate mounted on my block, which Garey welded male 10an bungs on for me, so the whole setup is really simple and serviceable. 10an male fittings on the block, 10an male fittings on the filter. 10an hose in between, with 10an female hose ends.Leave a comment:

-

Would these lines be applicable? And did you use crimp style for high pressure or did you use the "triple grip design"?Leave a comment:

-

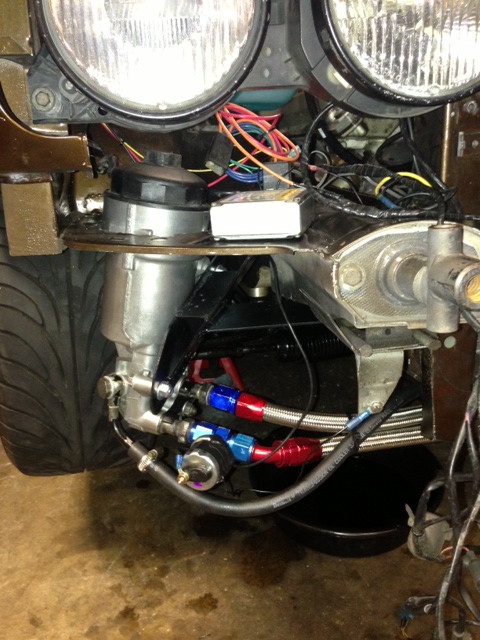

Blast from the past, Justin.I blew out another oil filter, even with that box that I built covering the filters. That was it, I had enough.

So i installed the factory m60 oil filter housing, remotely, with AN hoses/fittings. This should solve my problems. It's a hell of a tight fit, between the valance, fog light, tire, frame rail, fender, wheel housing, etc... I have about 1/2" of clearance in any direction. It took me about 15 hours to do all of this.

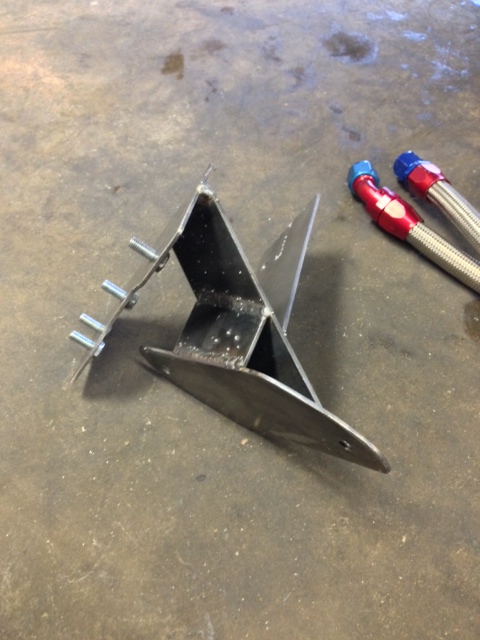

Had some 10 AN bungs brazed onto factory metal lines that I cut down:

So I also have a remote filter housing on my S62 and I couldn't use the factory lines, but needed to maintain the factory bungs that went into the filter housing. So what I decided to do was use high pressure hose cut to length and use an oetiker clamp to keep it secure on the cut-off oil line nipples.

Well, it leaks, moreso under hard acceleration, so they need to be fixed CORRECTLY.

I like what you did with the AN fittings. I have a couple of quick questions...

How did you braze the fitting on there as you show in the picture?

Are the AN fittings steel or aluminum?

Where did you get them from?

How did you clamp your braded hose to the red adapters??

Thanks, buddy, good work!Leave a comment:

-

-

Got this installed. Still some bugs to work out... but it'll be nice when it's finished!

Leave a comment:

-

My SAC has been fine with the UUC, probably one of the nicest feeling clutches I've ever had honestly. Replace that lock pin/ spring before you install the six speed.Leave a comment:

-

It's really no big deal at all, I just don't know how the SAC will perform with the UUC flywheel, since it's originally designed for the DM flywheel. Maybe no issue at all. Contact UUC and see what the have to say. The clutch/PP installs the same way as the non-SAC, except it has a lockdown ring that gets removed after its installed. Now that I'm thinking about it, isn't the E39 clutch 240mm diameter and the E34 265mm? Wasn't that the big thing that necessitated us having to use the M52 setup? Check that out and make sure the SAC will work on the non-DM flywheel. That may make or break the deal... or go to an aftermarket E39 clutch/pp if the SAC won't work on the lightweight flywheel... make sense?

G.Leave a comment:

-

I did read a little about the SAC... Do you have any experience with that? Seems like it's not a huge deal, just need the alignment tool.The biggest and really only weakness in the 6 speeds are the syncros... not really a way to "benchtest" them with the trans out of the car, either. Safest bet is to drive the vehicle before it's removed, but that's hardly ever realistic. Get some kind of warranty or keep looking. To your second point, yes, the trans' are the same, so your UUC flywheel with a Sachs OEM clutch/PP will work. Just remember that the E39 used the SAC setup, whereas the E34 did not... Also, if you're ever thinking of going the route Frank has, source an E39 trans, which will have the CPS location already machined... saves a step in the swap...

G.Leave a comment:

-

The biggest and really only weakness in the 6 speeds are the syncros... not really a way to "benchtest" them with the trans out of the car, either. Safest bet is to drive the vehicle before it's removed, but that's hardly ever realistic. Get some kind of warranty or keep looking. To your second point, yes, the trans' are the same, so your UUC flywheel with a Sachs OEM clutch/PP will work. Just remember that the E39 used the SAC setup, whereas the E34 did not... Also, if you're ever thinking of going the route Frank has, source an E39 trans, which will have the CPS location already machined... saves a step in the swap...What are the common failure modes? Anything easy to check while they are off the car? I did read that there's no parts available, that sucks!

e34 and e39 g420's are the same, correct? So I can use my e39 UUC 540i flywheel with an e39 clutch/PP on either a e34 or e39 trans?

G.Leave a comment:

-

Yes, Robert K is very good to source parts, use him as he might help you.

You can use ANY M60, M62, or S62 6 speed tranny. In fact I think that the s62 m5 transmission is slightly more robust with different gear ratiosLeave a comment:

-

I picked up a 6 speed and M5 driveshaft, clutch and PP from RobertK last year. Great guy. he may know where to source another one.Leave a comment:

Leave a comment: