Hello my name is Matt, and this is my 87 325e 4-door sedan….

Untitled by mattrides, on Flickr

I have completed most of the build already, and I am posting this as a thank you to the forum for helping provide inspiration, knowledge, and of course free reign the classified ad section! Believe it or not, car wouldn’t be were it is today if it wasn’t for this forum. Thank you!

A quick rundown of the car….

The car came from the west coast (Washington) and has absolutely NO RUST!!!!! She was an automatic and has about 200,xxx miles on her; everything was original minus the wheels, exhaust, and driveshaft…. The drive shaft was the whole reason why I started to tear the thing apart to begin with (gnarly vibrations coming from the transmission tunnel), and it took about 8 months and 4 drive shafts to get it back on the road!

What I have done to the car…

Motor

-Re-sealed (all gaskets replaced minus head gasket)

-Cleaned everything and painted the block

-Port matched intake to head

-19lbs type III yellow top injectors (Then swapped back to rebuilt stock...)

-eBay headers (OBX pieces of shit... should have kept stock manifolds)

-A/C delete

-P.S. delete

-New motor mounts

Transmission/Driveline (Manual swap)

-Lightened ETA single mass flywheel (18lbs)

-New clutch and associated parts

-Cracked the trans and did a FULL re-seal

-New drive shaft and associated parts

-2.93 LSD re-sealed and inspected (Car already had one though?.... oops…)

-AKG Dssr and Delrin carrier bushings

-All new shift linkage and lever

-New transmission mounts

Suspension

-Cut front springs -1 coil paired with e90 drop hats

-m3 rear springs

-Bilstine HD’s all around (cut front bump stops)

-21mm vert front sway paired with I.E. adjustable links and new rubber

-14.5mm m3 rear sway with new links and rubber

-AKG 80A poly rear sub-frame bushing set

-AKG old soft poly front CAB’s (he just gave these to me when I picked up my order. Thanks Andy!)

-OEM rear trailing arm bushings (Less noise than poly)

-New front and rear strut mounts with AKG reinforcement plates in the rear

-Standard 2.8L e36 3.2 turn rack (new tie-rods) with e30tech spacer kit and Silence P.S. delete

-AKG 75D steering “not so flex” disk

Other

-Replaced sunroof seal

-Replaced tail light seals

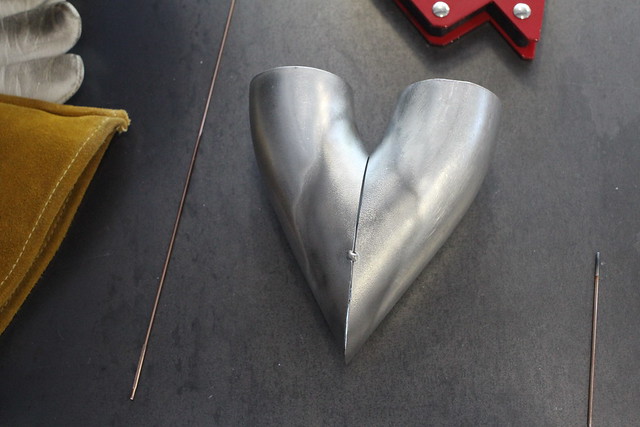

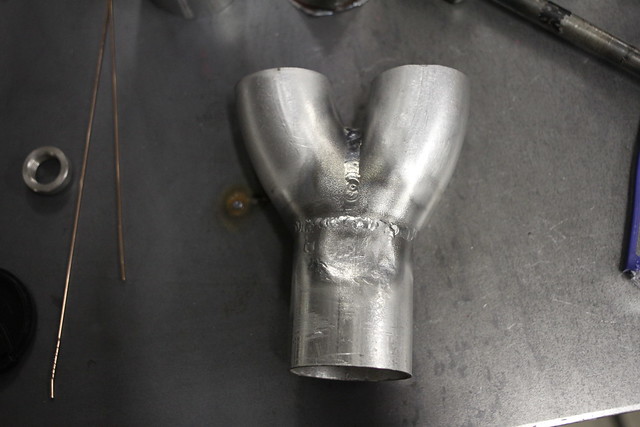

-Full custom 2.25” exhaust (In the works as I type, buying TIG welder soon)

-Plastic bumpers

-Antenna delete with delete plug that is sold here on the forum

-Replaced fuel filter and soft lines in the back

-All new fluids and such

I think that’s about all I did to it. The car already had some Borbet type ?’s on it, and it has a stock interior.

Again I would like to thank all the members that I bought parts from, or members threads that used to help with the build. I would also like to thank the P.O. Chis for bringing the car out here from the west, Andy at AKG for hooking it up with free parts, and Steve at Blunt-tech for supplying all of the OEM stuff for the build. Thanks Everyone!

Here are a few photos from the build that I liked; you can see the rest in the link below.

http://www.flickr.com/photos/79466738@N03/

IMG_3878 by Los Pantelones!, on Flickr

IMG_3893 by Los Pantelones!, on Flickr

IMG_3906 by Los Pantelones!, on Flickr

IMG_3683 by mattrides, on Flickr

IMG_3935 by Los Pantelones!, on Flickr

IMG_3996 by Los Pantelones!, on Flickr

IMG_3999 by Los Pantelones!, on Flickr

IMG_4007 by Los Pantelones!, on Flickr

IMG_4006 by Los Pantelones!, on Flickr

IMG_4023 by Los Pantelones!, on Flickr

IMG_4016 by Los Pantelones!, on Flickr

Untitled by mattrides, on Flickr

I have completed most of the build already, and I am posting this as a thank you to the forum for helping provide inspiration, knowledge, and of course free reign the classified ad section! Believe it or not, car wouldn’t be were it is today if it wasn’t for this forum. Thank you!

A quick rundown of the car….

The car came from the west coast (Washington) and has absolutely NO RUST!!!!! She was an automatic and has about 200,xxx miles on her; everything was original minus the wheels, exhaust, and driveshaft…. The drive shaft was the whole reason why I started to tear the thing apart to begin with (gnarly vibrations coming from the transmission tunnel), and it took about 8 months and 4 drive shafts to get it back on the road!

What I have done to the car…

Motor

-Re-sealed (all gaskets replaced minus head gasket)

-Cleaned everything and painted the block

-Port matched intake to head

-19lbs type III yellow top injectors (Then swapped back to rebuilt stock...)

-eBay headers (OBX pieces of shit... should have kept stock manifolds)

-A/C delete

-P.S. delete

-New motor mounts

Transmission/Driveline (Manual swap)

-Lightened ETA single mass flywheel (18lbs)

-New clutch and associated parts

-Cracked the trans and did a FULL re-seal

-New drive shaft and associated parts

-2.93 LSD re-sealed and inspected (Car already had one though?.... oops…)

-AKG Dssr and Delrin carrier bushings

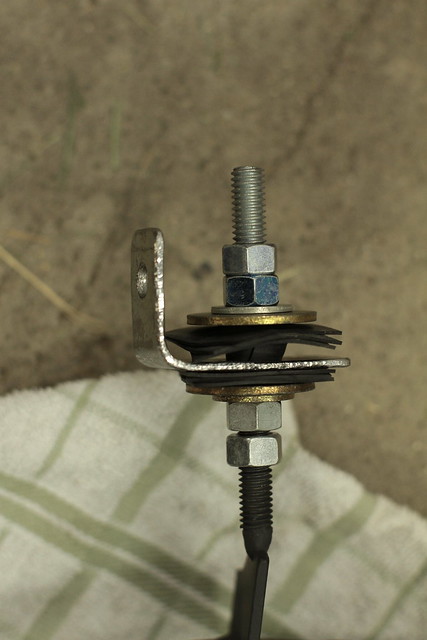

-All new shift linkage and lever

-New transmission mounts

Suspension

-Cut front springs -1 coil paired with e90 drop hats

-m3 rear springs

-Bilstine HD’s all around (cut front bump stops)

-21mm vert front sway paired with I.E. adjustable links and new rubber

-14.5mm m3 rear sway with new links and rubber

-AKG 80A poly rear sub-frame bushing set

-AKG old soft poly front CAB’s (he just gave these to me when I picked up my order. Thanks Andy!)

-OEM rear trailing arm bushings (Less noise than poly)

-New front and rear strut mounts with AKG reinforcement plates in the rear

-Standard 2.8L e36 3.2 turn rack (new tie-rods) with e30tech spacer kit and Silence P.S. delete

-AKG 75D steering “not so flex” disk

Other

-Replaced sunroof seal

-Replaced tail light seals

-Full custom 2.25” exhaust (In the works as I type, buying TIG welder soon)

-Plastic bumpers

-Antenna delete with delete plug that is sold here on the forum

-Replaced fuel filter and soft lines in the back

-All new fluids and such

I think that’s about all I did to it. The car already had some Borbet type ?’s on it, and it has a stock interior.

Again I would like to thank all the members that I bought parts from, or members threads that used to help with the build. I would also like to thank the P.O. Chis for bringing the car out here from the west, Andy at AKG for hooking it up with free parts, and Steve at Blunt-tech for supplying all of the OEM stuff for the build. Thanks Everyone!

Here are a few photos from the build that I liked; you can see the rest in the link below.

http://www.flickr.com/photos/79466738@N03/

IMG_3878 by Los Pantelones!, on Flickr

IMG_3893 by Los Pantelones!, on Flickr

IMG_3906 by Los Pantelones!, on Flickr

IMG_3683 by mattrides, on Flickr

IMG_3935 by Los Pantelones!, on Flickr

IMG_3996 by Los Pantelones!, on Flickr

IMG_3999 by Los Pantelones!, on Flickr

IMG_4007 by Los Pantelones!, on Flickr

IMG_4006 by Los Pantelones!, on Flickr

IMG_4023 by Los Pantelones!, on Flickr

IMG_4016 by Los Pantelones!, on Flickr

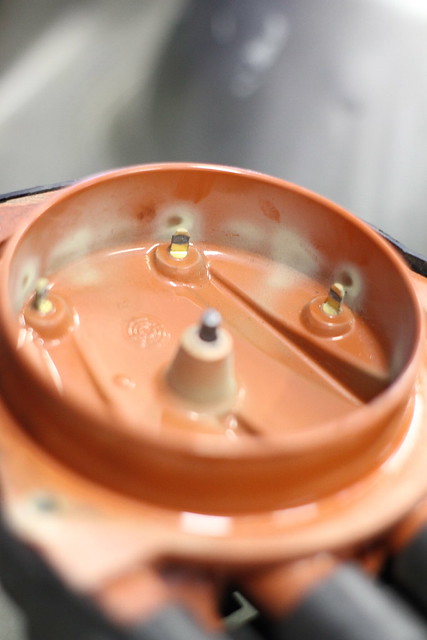

If you look in the center you can see the small gray patch of primer, and that's where the ground was at first. As I quickly learned, the arc went straight to the sheet metal and not the thicker bracket! Fuck! My original plan was toast... I had intended to: tack from the top, the get a nice solid beefy tack on the bottom, and then finish weld the top. What I had to do instead was: tack from the top, then fill/finish weld the top, and then I had metal to tack the bottom. By this time the bracket was not sitting 100% flush and I deemed it to be good enough...

If you look in the center you can see the small gray patch of primer, and that's where the ground was at first. As I quickly learned, the arc went straight to the sheet metal and not the thicker bracket! Fuck! My original plan was toast... I had intended to: tack from the top, the get a nice solid beefy tack on the bottom, and then finish weld the top. What I had to do instead was: tack from the top, then fill/finish weld the top, and then I had metal to tack the bottom. By this time the bracket was not sitting 100% flush and I deemed it to be good enough...

Comment