Ksjdan's 1990 325is Thread - S52 Swap Complete

Collapse

X

-

So stoked to start working on this bad boy again man. I've been hella busy with my own project though. I'm in the middle of swapping my E30 steering rack with an E36 rack that we I found at our local Pull-A-Part. Once I'm finished with the swap though, I'll swing on down as often as possible to help you out brother! It's really awesome that you're documenting all of the work you've been putting into this old girl. Seeing this thread for the first time has really got me wanting to finish my project this very second and give you a helping hand! -

July 11 2014

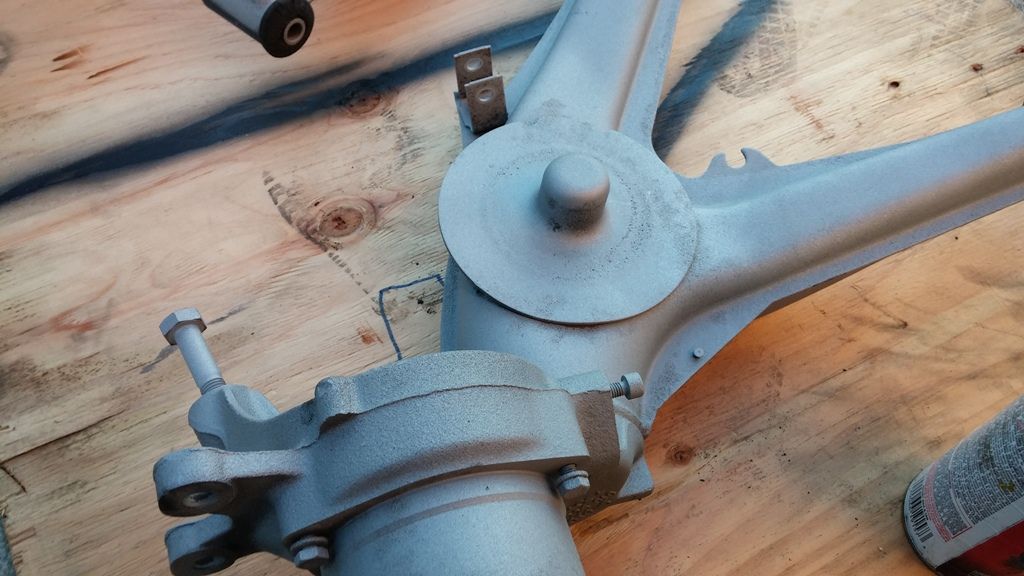

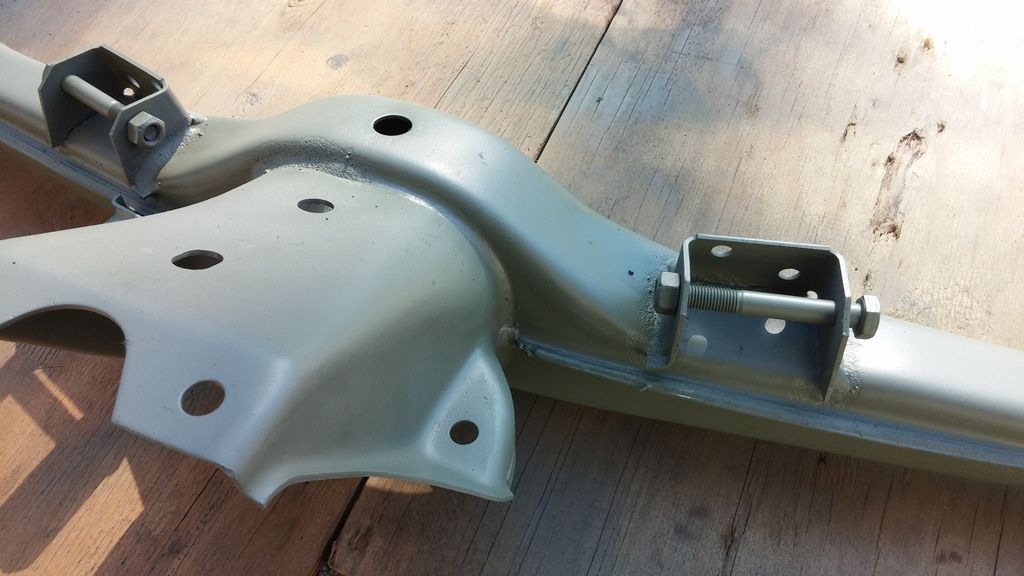

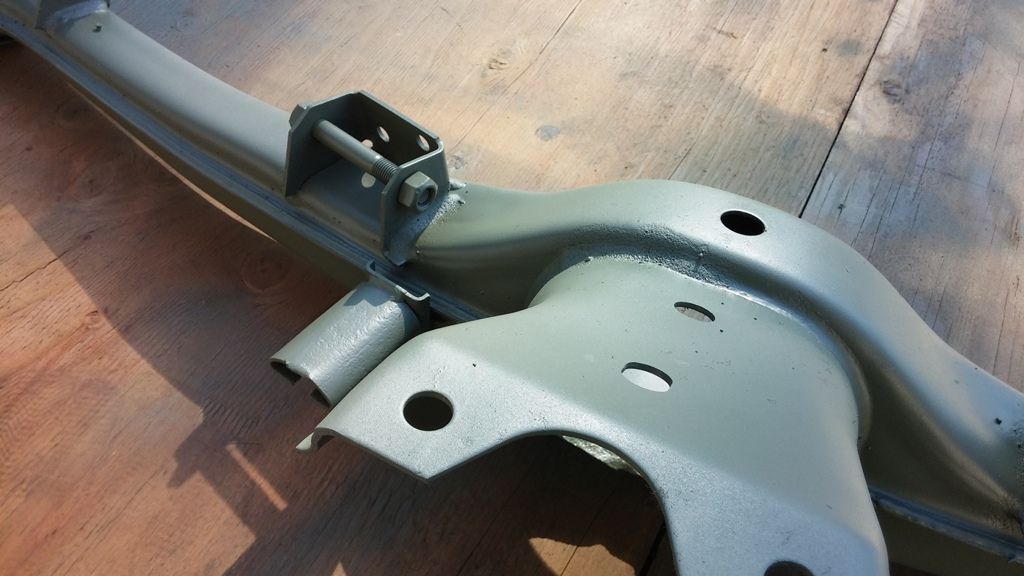

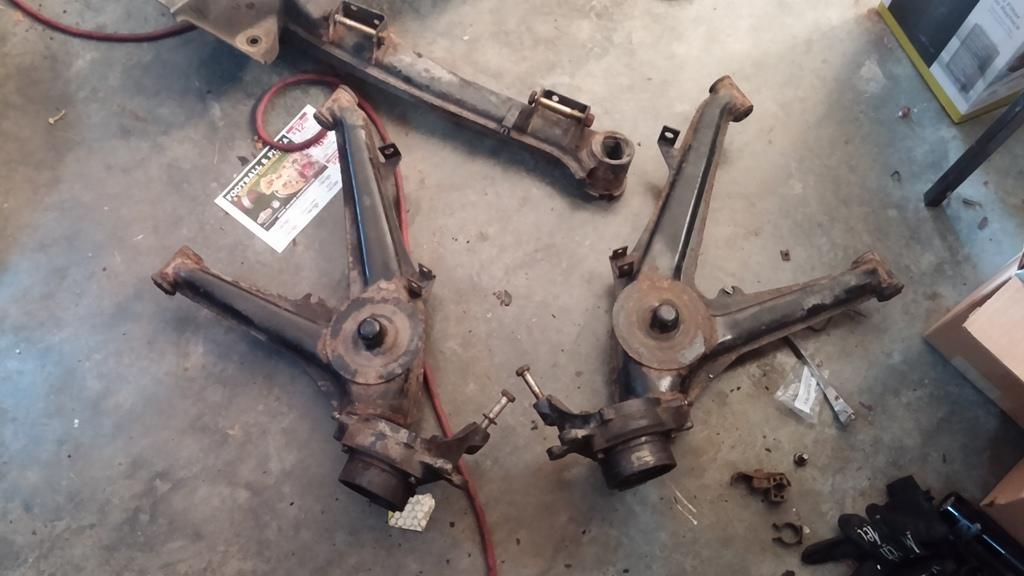

After a long break, Ive started working on the E30 again few days ago. I halted last time after removing the rear subframe, sandblasting them and putting on a few coat of undercoating. Im sure this doesn't float everyone's boat, and theres some who would recommend powdercoating or painting it red. But I prefer the conservative look of textured mtate black.

Also there is no pictures taken because my phone has been broken all week (fixed now).

I was working on the car for all of the last 3 days, but there's really not much to show for... First thing I did was remove the e-brake cable that was stuck on the chassis tube. I remember trying to get it off for few hours last time, pull it so hard that the car almost fell off the jacks. This time I gave it some heat by torching it for few minutes. Lo and behold, it just slid right off.

Next was the rear wheel bearings, control arm bushings and subframe mounts. The control arm bushings came off very easily with a use of c-clamp and brute force of the impact wrench. The wheel bearing and subframe mount on the other hand, was a biatch and a half.. Im just going to blame it on the lack of proper tools for now. All I really had to work with was a big ass C-clamp rented from Napa and some 3 legged pullers. The biggest issue I faced with all the tools was fitting them on the part.

Stolen Image

The wheel bearing on the trailing arm is deep inside the housing and nearly impossible to reach with even a large 3 or 2 legged pullers. I also tried using the gigantic C-clamp (its a $130 c-clamp so they mean business), but even that couldn't fit around the housing. After going on and off for few days, I gave up.... Went to a harbor freights, bought a wheel bearing removal set.

Without the tool, 2 days of stress and no results. With the tool, 10 minutes of work and done. If you plan on changing the wheel bearing, get the tool!

The rear subframe mounts were a mixed story. While removing the subframe, One of the bushing broke off and the inner piece was off. While the passenger side stayed in and the inner was still held in. The one without the inner turned out to be slightly easier. I noticed a lot of people just burned them off, but it didn't seem civilized (lol) and also it would leave a nasty residue. So I tried fitting a c-clamp (the big ass one), no luck. The bottom side of the bushing is flanged so its needs to be done with a legged pullers...yeah right!

As it shows in RTauto's pic

I tried fitting the legged puller tool, but there wasn't enough space to fit all 3. this is before I went to rent out a 2 legged puller that I didnt own. It didn't work out, so I ended up setting it on fire. After about 15 minutes, I got tired of waiting so I started hitting it with a mallet. This consequently turned the fire off, and punched out the bushing about 0.5 inches. From here I was able to fit a 3 legged tool and slide it off. Easier said than done though. It took about an hour.

After about 15 minutes, I got tired of waiting so I started hitting it with a mallet. This consequently turned the fire off, and punched out the bushing about 0.5 inches. From here I was able to fit a 3 legged tool and slide it off. Easier said than done though. It took about an hour.

The passenger side turned out to be a bigger problem. The subframe bushings also had a stupid design where its nearly impossible to remove the rubber using conventional tools. After numerous hours fiddling with a C-clamp tool and legged pullers, I used the wheel bearing tool (This is about right after I bought it) and got few centimeters out. It was getting late so I called it a day.

So after 3 days, I was able to knock out trailing arm bushings, remove 2 wheel bearings and one subframe mount. Stressful week and slow progress, but at least now I know what to do with the crazy BMW bearings and bushings. After I get the bushings and bearings done, Ill re-seal the diff, put the rear end together and start moving the S52! :DLeave a comment:

-

Ive pushed the trailing arm bushings out with a bottle jack a few times. Just put it between the 2 bushings with a socket on the bushing heat the trailing arm a bit with a heat gun and pump the jack they slide right out

The poly ones will go back in with a vice no problemLeave a comment:

-

So I'm at the same point with my rear subframe. I have ordered the same bushings. How exactly do you get the whole assembly apart on the trailing arms? And how did you get the trailing arm bushings off?Leave a comment:

-

January 23 2014

Just finished getting the subframe and control arm sandblasted at a local shop. It always surprises me how drastic the difference is. After degreasing the parts, I layed some self etching primer.

Leave a comment:

-

Also this just arrived in mail! Set of Ireland Engineering polyurethane subframe and control arm bushings.

Leave a comment:

-

We tried the impact screw driver, but it was not enough to loosen the bolt. ...Using a small hammer probably didnt help. So we got a torch and gave it some heat, and voila, came right off.

January 4 2014

So I continued disassembling the subframe, control arm and all the little bits and pieces attached to it. Dropping the subframe was pretty straight forward and simple task. The shocks and roll bar were already detached so I only need to remove a handful of bolts and undo the brakes.

Ta da! Thankfully the body looks really clean!

The hardest thing to remove (by a effing mile) is the parking brake cable lines. The tubes that feed up to the cabin is rusted pretty badly. I was told it should just be an easy tug and pull, but it was more like "wow not so hard, the car might fall off the jack stands!". I failed to remove it from the tube, but I was able to remove it from the control arm. Ended up cutting the lines, twisting the metal casing off, and torching the hole to clean out the rubbery casing. After fighting the parking brake cables for few hours, I gave up and just started working on the wheel bearing side. took off the calipers, rotors, wheel hub (impact wrench is pretty much required for this) and I ended up with this.

At the end of the day, this is what my work space looked like. Beware: if you have OCD, this might give you a heart attack

And finally some pictures of the subframe before I take it for sandblasting

Leave a comment:

-

either try to use a massive easy out, or try to hit a damaged bolt remover over the head to remove the allen bolt.

If you can't get it out, you could just grind the head off, slide the halfshaft off, then figure out how to pull the remaining stud out with vice grips, or welding a nut to it.Leave a comment:

-

Usually I would try hammering in a torx socket, but the rubber boot gets in the way and makes it difficult to hit it hard. Im planning on purchasing an impact wrench and using it to remove the stuck bolt. It'll be fun.Try hammering in a torx socket to get that stripped allen head loose!Drilling is over kill!

your gonna have to take apart the parking brake to ge those cables out, there alittle pink youll need to drive out at the end of the cable once you get the parking break dissassemled. soak it liberally in PB.

Awesome progress, really going for everything at once Eh?

Leave a comment:

-

Try hammering in a torx socket to get that stripped allen head loose!Drilling is over kill!

your gonna have to take apart the parking brake to ge those cables out, there alittle pink youll need to drive out at the end of the cable once you get the parking break dissassemled. soak it liberally in PB.

Awesome progress, really going for everything at once Eh?Leave a comment:

-

December 15 2013

My friend and I started working on the rear subframe today. I was hesitant on rather I should rebuild the rear subframe, but after seeing what we dropped, Im really glad we did this. The work was fairly straight forward, but it being 20+ yrs old and never seen a wrench since the day it was put together, everything was frozen. The first thing I tried to unbolt was the subframe bolt, and after a few flexing, it broke the breaker bar. :down: After few hours of "man handling" every single bolts and nuts, came off.

Fun pic before we got started

It was difficult getting pictures because it was freezing cold outside and the garage door was down.

Here is the subframe and diff lowered. The e-brake cables are still stuck in their, and I have no idea how it is suppose to come out. Anyways we were taking out the allen bolts on the CV axle, but I managed to strip a bolt. doh!

Im going to need to drill a hole and extract it out...maybe.

Here is how far we got. Everything will be sandblasted and recoated. I purchased some polyurethane subframe and trailing arm bushings from Ireland Engineering.

Leave a comment:

-

December 14 2013

I forgot to post the pictures from the suspension updates I made. To be specific, I got a set of Eibach springs and KYB shocks. I heard the KYBs were made for casual driving and not much of performance parts. But price was good, so Ill just try these out. If they blow, then Ill be getting some more heavy duty shocks.

I was expecting Taiwan or PRC, but its made in Japan. :)

Height difference between Eibach and Stock is pretty drastic

Locking down the top nut. I remember first time worked on this nut on my e46 m3, it was a true pita and took me forever. Pretty simple now.

All reassembled and ready to install!

Also the front seats were completed today. Here are the before and after of my Leather World Tech dye kit. I used the original BMW silver leather color that my e30 came with. Leather world didnt have my color for some odd reason, so I had to get it special ordered using a small leather patch from my car. It seemed like a very standard color,but they didnt have it in stock.

The result are good as you can see in the picture below. I had some visible lines showing through the dye, but it looks 100 times cleaner. If you ever dye your seats, I also recommend using a very fine spray aerosol if you can. It'll have a cleaner finish and take less time.

Here's a before taken a while back by the PO

After pic. I just put on the 3rd layer of dye today. It'll need to dry and cure for several hours before I can apply the conditioner and "polish" the leather.

Last edited by ksjdan; 12-14-2013, 08:51 PM.

Last edited by ksjdan; 12-14-2013, 08:51 PM.Leave a comment:

-

November 30 2013

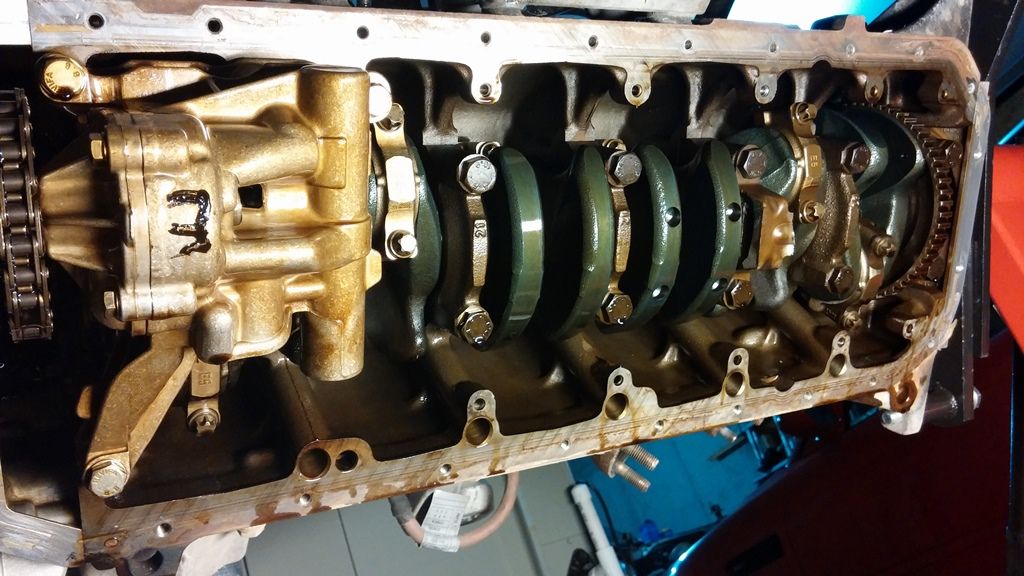

Did a little bit of work on the S52 today. It was probably ideal to finish the project over the Thanksgiving week, but I got really lazy and barely did anything productive. I somehow forced myself into the garage today and started the oil pan swap. First I drained the oil, and collected in a separate clean container in case I decide to get it tested by Blackstone. Oil looked clean and showed no sign of contamination.

After draining the oil, I started taking out the 100 bolts holding the oil pan in place! As you can see in the picture below, the oil pan is bone dry and the entire engine shows zero sign of oil leak. Not even the S54 in my M3 is this clean.

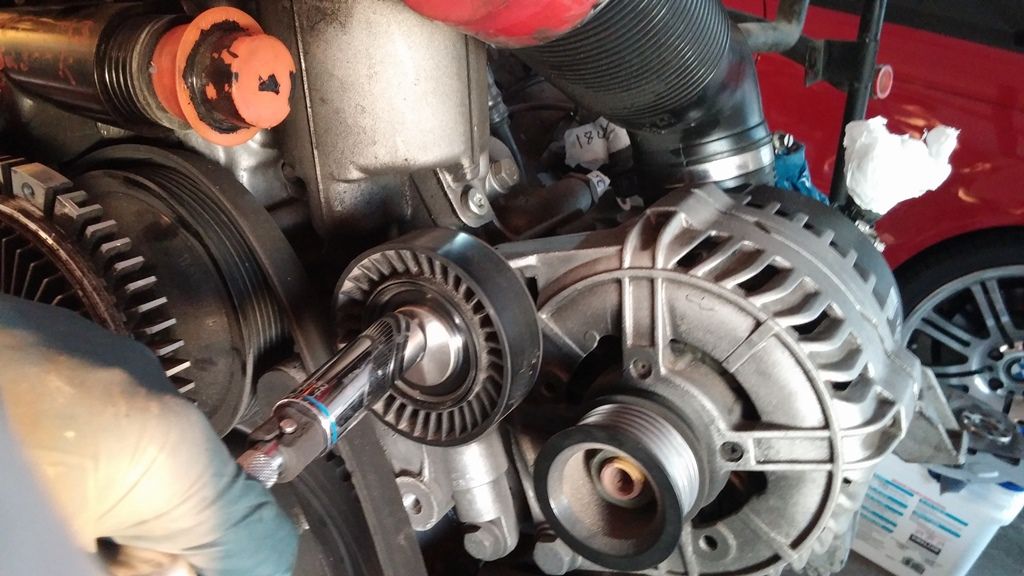

After releasing about 5 bolts, I noticed the PS pump is actually bolted down on the oil pan...and the belts and pulleys needs to be released in order for PS pump to come out. So I got a bit side tracked and started working on the front end of the motor. Despite having only 52k miles, the pulleys still sounded like some old skateboard wheels.

Old pulleys coming out

New belts and pulleys. No Napa or Autozone stuff here.

Next I removed all 300000 oil pan bolts and slowly dropped to finally view the interior of the engine. And just as I have expected, very minimal build up. :D

Everything looked to be in order so I continued on. After removing the original oil suction tube, I tried test fitting the e34 oil pan. But the hanger that bolts the suction tube down was hitting the pan. So I removed the shield piece, took a rubber mallet and punched it back and forth and it just broke off.

This concludes today work. I shouldve probably started working earlier and at least got the oil pan done today. lol To prevent dust getting on the interior, I just put the e34 pan on, threaded a few bolts to hold it in place and called it a night. Things should start picking up a bit once the harness comes back.Leave a comment:

-

September 18-20 2013

The project I am currently working on is no doubt the biggest one I have tackled so far. For this work, I actually called my friend over to help remove the old m20 and the trans. I did most of prep work such as exhaust, driveshaft draining fluids, disconnecting the harness etc the day before and some on the day of. The work was relatively easy as its only been several months since the exhaust and driveshaft bits were re-installed. I was really excited about the engine removal as it was the first time I performed this. After asking a few questions and reading a few articles, the work didn't seem all that difficult. I picked up a cherry picker locally, and my friend and I started removing the old motor from the bay later that night.

The removal was pretty straight forward and not that big of a problem. The powersteering pump and the AC compressors were in the way so they were removed (picture taken before). But other than that, the engine came out swiftly without much of a fight.

Here are some photos!

Last photo before it was removed. Despite having 150k+ miles on it, it ran strong and pretty smoothly right until the removal. The M20 and a 5 spd mt transmission is going to be listed on the classified, so look for it soon! :up:

Shot with the ///M.

November 22 2013

I decided to do some work on the car (mostly the S52 motor) today. Weather is starting to get colder and the temperature is more comfortable to work in, but the daylights are getting shorter. I guess its a even trade off until it starts getting freezing cold. Then Ill start missing the hot summers again.

Ill start by introducing the almighty S52B32 motor I decided to go with. It was a complete set, sold with block, intake, harness, DME, etc. Pretty much every thing but the transmission. But the best part is it only has 52k miles on it! I intentionally picked up a low mile engine because I didn't want to spend a lot of time and hassle disassembling the motor and rebuilding a 200k mile motor. Its too much work for me, and I dont think I have that kind of patients.

I intentionally picked up a low mile engine because I didn't want to spend a lot of time and hassle disassembling the motor and rebuilding a 200k mile motor. Its too much work for me, and I dont think I have that kind of patients.

So after evaluating the S52 for about 10 minutes, I started undoing the bolts and wires to slowly disassemble the intake manifold. Since there is no way I can remember every single plug and hose that is attached to the harness and manifold, I got some masking tape and a sharpie, and started number all the male/female connections. It took some more time, but hopefully it'll make my life easier later on. As I was taking it apart, I was very satisfied with the overall condition of the engine. Cant wait to take the oil pan out to see the (lack of) inside build up! The intake came off first in about 30 minutes. The fuel rail and injectors removed, some hoses and plugs undone and it just came right off.

I noticed some people going with a S50/M50 intake manifold for better flow, but Id rather not spend extra when a S52 intake works without any problem. Id be way more interested in something like.. oh you know ITBs for S52!! Now this is really tempting! According to WOT, this is only a prototype, and they're in the process of making these units for both E36 use as well as E30 S52 swaps.

(Source: WOT-Tech)

Anyways back to taking apart the intake.

Here is a shot before the harness was completely removed. I believe 99% of the plugs/hoses were disconnected by this point.

Here's a close up

To conclude todays work, I removed the harness and sent it off to Andrew for adapter modifications. Ive always been impressed by his S54 swap build and I am confident the harness is in hands of a skillful guy. :up:

My current goal is to get the E34 oil pan installed and drop the S52 in the bay before Christmas. Long term goal is to have the E30 running before 2014 and possibly have all the exhaust work done by then too.

Happy Turkeyday!

Leave a comment:

Leave a comment: