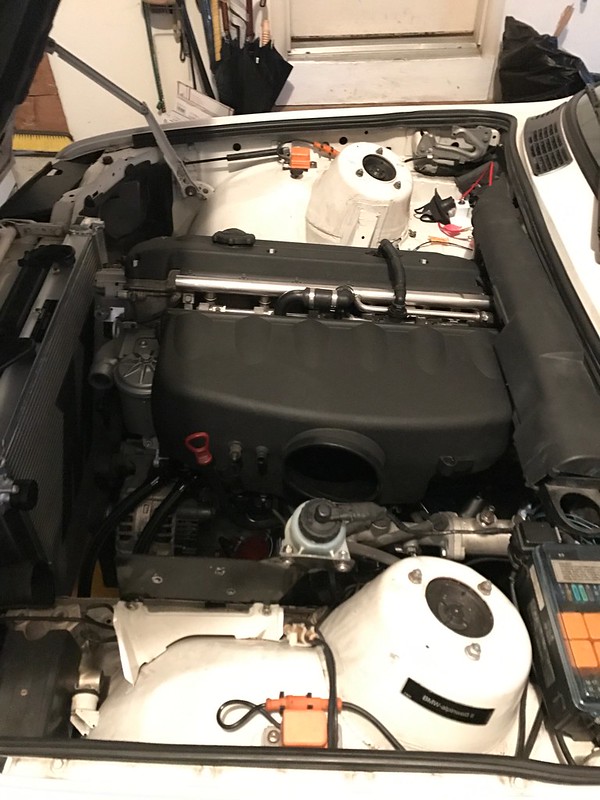

I couldn't get the top hose on the pipe without kinking it, so I needed to use another brass connector here and extend the line with an agle. I picked up a right angle hose and cleaned it all up, but the intake manifold wouldn't go all the way on. It's possible to reach under and feel that there's just a little interference to the top hose as well as the battery cable where it connects to the starter, so some bending of that and the core pipes is in order. I wound up pointing the lower hose towards the right side of the car a little, while I was at it, and looping the upper hose under the lower for better clearance. I got the intake manifold on for the first time, just need some hose clamps and the heater plumbing is done.

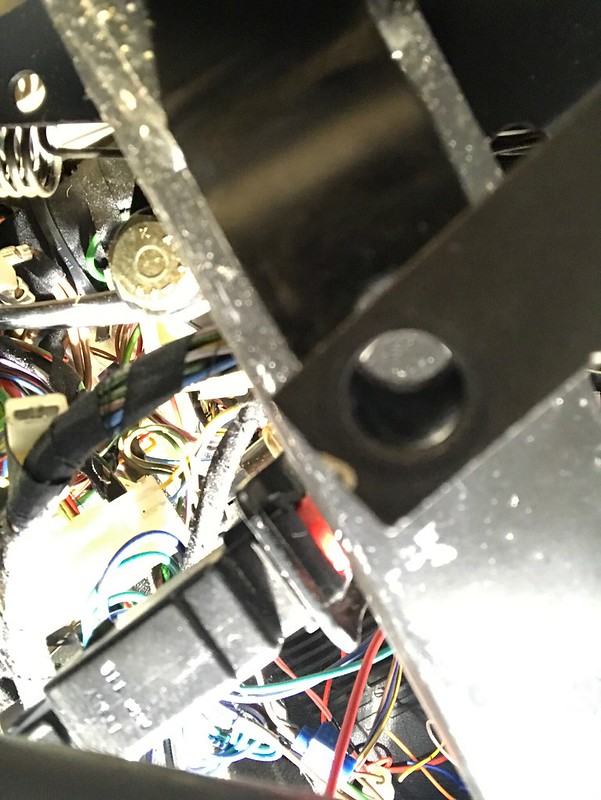

The M42 harness cover fit with the cuts I had made for the S50, but the bracket underneath had to be clearanced a bit.

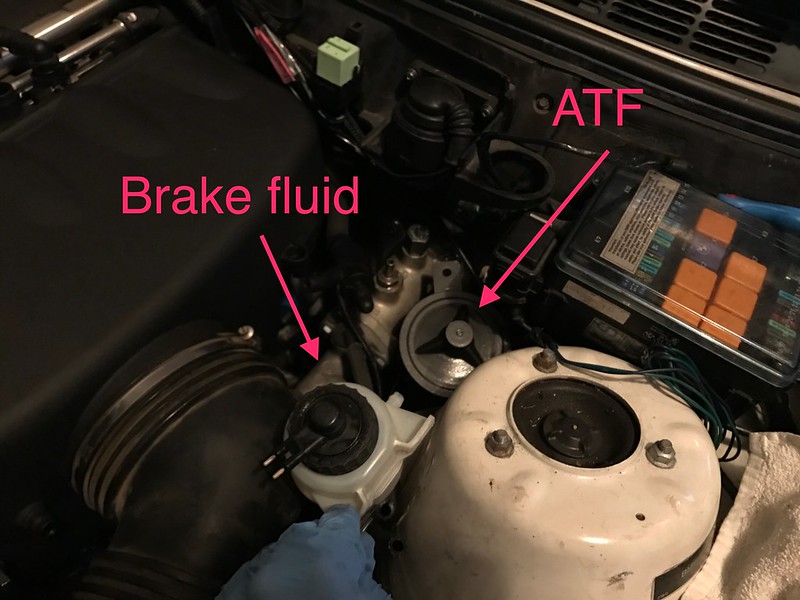

The brake fluid reservoir clearly has to be relocated to make room for the intake elbow, but I think I can still use that mounting plate and just put the res closer to the strut tower.

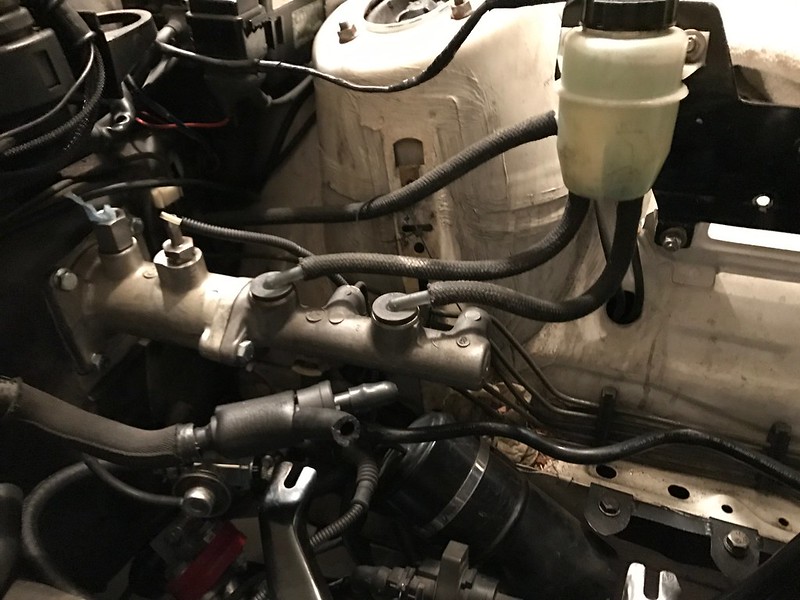

As for the big tall E23 power steering fluid reservoir, that thing won't fit really anywhere around the intake, so I tried and was able to snake it behind the strut tower next to the booster.

I'm hoping I can use the bracket I have on the frame rail that held the S50 atf canister to mount the E23 accumulator, or maybe the motor mount arm. I have to figure this out and then measure for the hoses to be made to new lengths.

Leave a comment: