crimps are preferred by most auto wiring professionals over solder.

are you sure those two eyelets aren't grounds?

butters 318i project, S54door...

Collapse

X

-

The booster and master cylinder are in, the reservoir is just a placeholder until I receive the correct grommets to work with the tii hose barbs. At first glance it appears the stock E30 clevis fork will work, but I have misplaced my pin so I'll have to wait to confirm that until a replacement comes.

The custom hydraulic hose aspect of this is looming over me, I'm unsure where to even begin.

Leave a comment:

-

Lowering the subframe wasn't that bad, I'm sure having the trans bolted in place helps. I did need to drop the bolts and put my studs back in order to get enough room to work. I wound up removing this "supporting bracket" from the rear of the cylinder head:

...I wasn't using it to support anything, so hopefully that's no biggie. I then had room to pull the harness up, and re-route the O2 harness through the E30 cover.

Leave a comment:

-

Hopefully not more than another week. The wiring has me a bit confused - while the e46 harness is pretty neat and straightforward, the adapter harness is a bit of a rat's nest to manage. I am not very familiar with the wiring diagrams etc.

I've started at the C101 and worked my way over to the firewall opening, and I think the main thing now is understanding what goes on the battery terminal and where the main fuse goes.

There's really not much under the 318 harness cover!

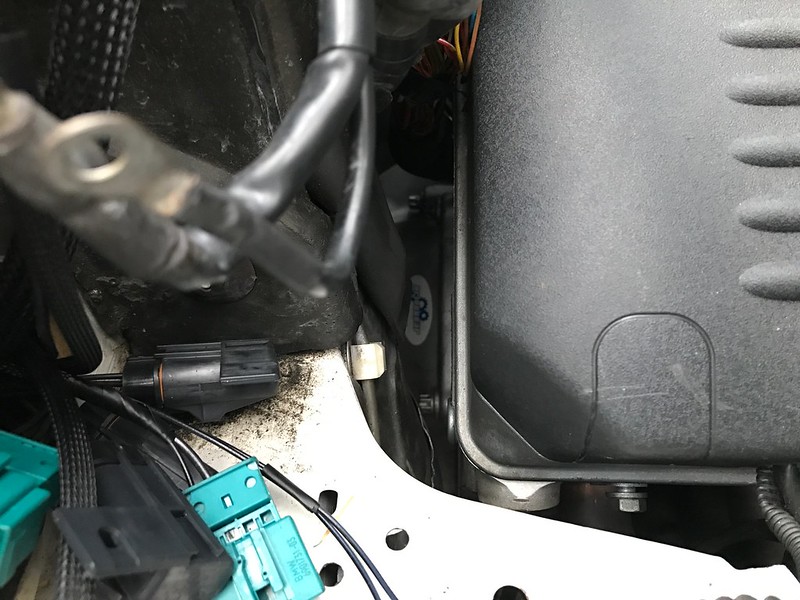

This photo shows two things:

One - there are two ring terminals shown, which I believe need to get fastened to B+.

Two - I think I made a big mistake and assumed the main engine loom should run just above the bellhousing. The problem is, that doesn't allow enough length to reach into the cabin, let alone plug into the DME. With the engine installed, there is no room to squeeze this loom between the insulation and the cylinder head... so I'll have to drop the subframe

I'd love if I can just lower the subframe without completely unbolting it, but I can't imagine that's going to be enough.Leave a comment:

-

Putting a flathead slot into them is a great idea, I just kinda knurled the OD at the end of it so I could grab with pliers. I was able to get it lined up and installed with new bolts, which is probably a good thing because my original subframe bolts were heavily oxidized and pitted.

I also have the trans bolted in along with the driveshaft, and the shifter is in place. The slave cylinder is on with just the lower nut, I need to get creative with applying pressure and then threading on the upper nut. Next is the steering rack and lollipops and she'll be ready to roll onto a trailer.Leave a comment:

-

A rubber mallet was my friend to help line up the subframe.

Good luck! On my wiring harness/ Z4M I did not have the firewall side vacuum solenoid that connects to the airbox and idle air pipe...interesting. Car started fine without it.

As seen from your pic:

Leave a comment:

-

One trick is to cut heads off the subframe bolts and dremel a slot into the stud so you can use a flat head screwdriver to remove it once you get everything lined up and ready for a real boltLeave a comment:

-

Thanks guys. I played around with it this afternoon trying to see if I could get things lined up by myself, but that was an exercise in futility. It's just too difficult to get small position adjustments out of crappy casters on such aged asphalt, I'm sure it would be doable on concrete.

Tomorrow my plan is to get new front subframe bolts, then cut the heads off the old bolts so that I can use them as studs. That, plus the help of a friend, should allow for an easier time getting it bolted up. Then I can work towards being ready to roll onto a trailer.Leave a comment:

-

This was a great read for the day. Thank you for documenting this process for us. I feel like i forgot this was even an e30 build by about page 7. So much great engine porn.Leave a comment:

-

I got the other connector extended, and got cold feet with the crimp-on butt connectors. I picked up some heat shrink insulation and broke out my old soldering iron, and re-did all the wiring I had modified.

On Saturday I tidied it all up.

I dropped in a fresh filter kit with a little oil to prime it, then drained any remaining coolant from the block and put a new washer on the drain. The oil distribution block got new washers, and I put the stock oil pressure switch on the rear port. The control arms will need weight on them in order to tighten the nuts, but I put them on loosely anyway.

From there I hoisted the motor off the stand and onto the dolly, then tackled the rear main seal as a while-I'm-in-here item. Next I installed the new flywheel and clutch kit. I went with the OEM S54 Z3 parts, for that stock drivability I've missed with the South Bend stuff I had on the S50. Oh and I did put a new fork lever, spring clip, and steel pivot pin into the trans.

That priority mail box holds the harness adapter - Andrew's instruction says to start in the engine bay, but I wanted to get the temp sensor connected ahead of time.

Putting the transmission on is never easy, I sure wouldn't want to deal with that under the car. I forgot the plate between the bell housing and block, which set me back an hour and brought us to darkness. At this point I knew I wouldn't get the subframe bolted up, but wanted to just get it all under the car for another day.

Here's my angle of approach:

My driveway needs work, but this is very easy in concept.

And here it is under the car at last:

I'm now at the mercy of the weather, which has degraded to blustery and cold here in southeast PA. I have a friend who will do the exhaust work and offered to pick the car up with his trailer, we've agreed on Wednesday. So it looks like Tuesday afternoon/evening I'll get the car rollable and hope that he lets me finish up some things indoors at his shop.Leave a comment:

-

The intake manifold is comically large from this angle...

I think I have a handle on all of the vacuum and electrical connections at this point, after some confusion when I had a 2-pin connector with 2 possible plugs. Turns out I was missing another 2-pin connector, which is off the main DME loom.

At the right side of the image above, there is a Y-connector for vacuum that runs up to the idle air pipe. The missing connector goes into the valve or sensor between the smaller hose and the hard plastic hose that connects to the side of the intake, while the other larger hose goes to the brake booster. I cut that off and I'll cap the open port since I'm going to use hydraulic brake assist.

The routing of the hard plastic air line should work, but from factory it actually runs over the top of the intake elbow. I'm hoping to hide it better. This also requires re-routing another connector from the M3 harness which wasn't mentioned in the DME mount discussion, but maybe it's a component that is coded out, related to DMTL? I'm not sure but I'd rather just re-route and extend it now to be sure.

I finally drilled out my Technica water pipe adapter and threaded it to M14x1.5:

Used a slight amount (2 wraps instead of 3) of Teflon tape to help prevent any leaks, and torqued to 85 inch-pounds:

Then routed the adapter wiring and installed the pipe with the thermostat and housing. I just realized I forgot a pic of the t-stat, save that for next update.

Looks good in there! Too bad it's well hidden from view..

My AKG mounts came in and I now have the subframe installed. I'm very happy with the quality as well as the fit - the E28 mounts have way-oversized studs on top too.

Tomorrow is a big day, hope to get the motor and front axle in the car.Leave a comment:

Leave a comment: