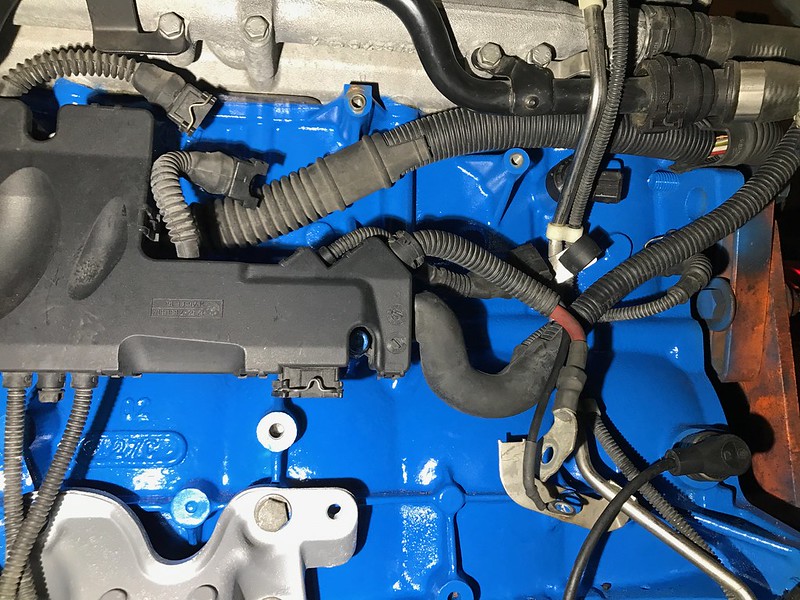

These little air pipes for the idle control/evap plenum aren't really visible, but I gave them a brushing before putting on new o-rings.

The plenum and the fuel rail shined up easily with just a good wipedown..

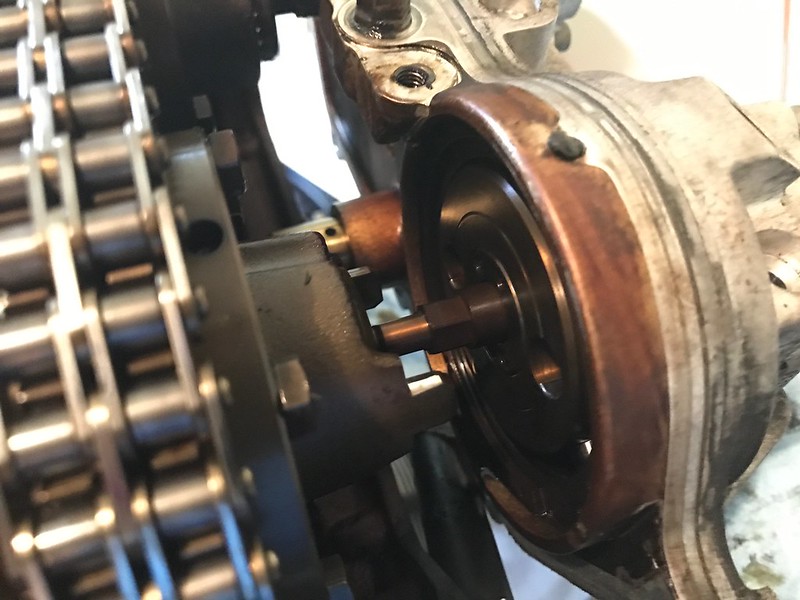

Got the rebuilt injectors in, after I realized they need to be squeezed into the throttle bodies first before they go into the fuel rail.

The plenum and the fuel rail shined up easily with just a good wipedown..

Got the rebuilt injectors in, after I realized they need to be squeezed into the throttle bodies first before they go into the fuel rail.

Comment