How fast is 4000rpm in 5th gear?? That had to be an open road!

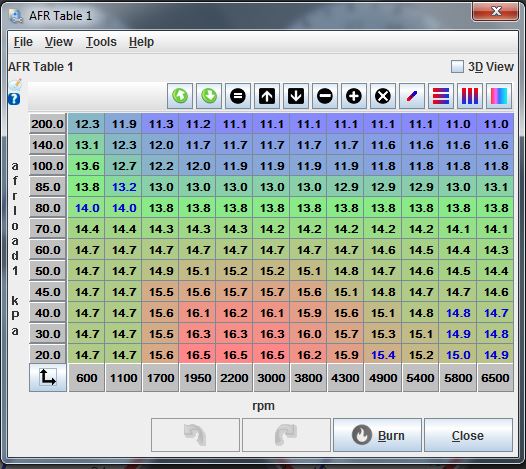

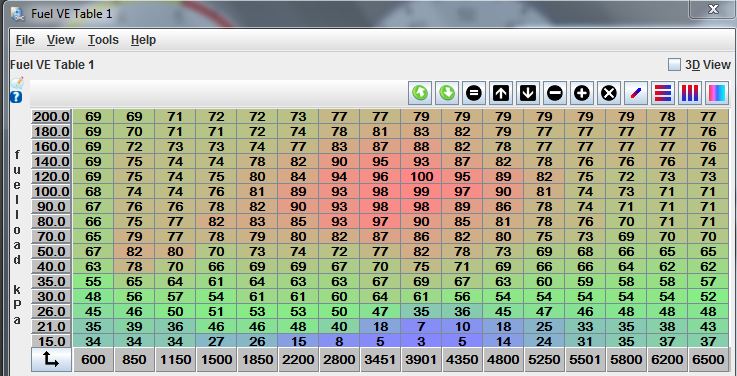

I'd investigate your AFR table or add some fuel in your VE map so your mixture doesn't move towards lean like you are above 3500rpm.

I do think the variation between the two graphs is MAT density table settings (being leaner in higher temps.). You can obviously use Virtual Dyno or MegaLog viewer to see if AFR's are appropriate for the given ambient temp. And adjust that temp value correction to bring the graph either up and down.

1986 325iX 3.1L Stroker + Turbo

Collapse

X

-

Today was our first 90 F day this year and I spent lunch driving around for my first high temp testing with the car.

At cruise my IAT senor after the intercooler was reading ~100 F and after a quick boost run would creep up to 110 F.

I turned the car off and the intake heat soaked to ~130 F. Even after idling that started to drop back to 110 and then went lower as I drove. Ambient temp was somewhere around 85 F. I had guessed on my MAT based ignition retard and adjusted them slightly.

Here is my current MAT adjustment,

I may need to move the 120 up 5 F or so but it is decent for now until i do some more testing.

I also looked at the gauges in tunerstudio and wanted a more convenient gauge setup that I can glance at to see temps, pulsewidth, and ego correction as well a few other things to monitor. I stole some of this from my brother but here is my current dash that I see while tuning. i'll probably change this again but its got most of what I look for when tuning.

The last thing on here is using the Virtual Dyno software to see what kind of power i'm at. I made a two runs the other night but I kept hitting boost cut as my boost crept up so it skewed my results and i can only map a portion of the rpm range. Anyway I used 0.35 cD for the e30, 22 ft^2 frontal area, tire size of 205/50/15 and weight of 2700 lb with another 135 for me in it. I'm not sure how accurate this is but intake temp was 65 F and barometer was 80 kpa and this shows a run in 4th gear and a run in 5th gear. Both are close and have a significant torque figure and show my boost creeping up to 8 psi. I may have to try this again somewhere that isn't slightly uphill and increase my boost cut to see how it changes. It might boost creep higher as the rpms climb. One of the runs is the datalog shown in my last post.

Leave a comment:

-

Molnar 135mm rods are good and cheap will be machined properly from the box etc they also provide the best clearance of all the rods you'll see. best BFYB is probably OE 24V rods thoughLeave a comment:

-

I have had good success with the JE pistons ordered from RaceTEP but I did have one break somehow. The ottoco seems good if you can find it anymore, VAC might be the only one for 86mm bore headgasket. The 86 mm crank has larger crank counterweights so they may not clear the block. I'd run stock rods since they are strong and cheap, but my current engine has Eagle H beam rods I believe at 135 mm in length.

86 mm x 86mm would be a square engine. I believe the s50 crank is actually 85.8 which would put you at 2990 cc with the 86mm cylinder overbore.Leave a comment:

-

I'm building an M20 stroker with 86mm crank, but I'm staying NA, would you recommend the JE pistons and that Ottoco 86mm MLS Head Gasket?

What about rods?Leave a comment:

-

it can be a bit of a rabbit hole. For the cost of this car i could have bought another rwd e30 af turbod it a long time ago, but that doesnt have the same cool or rare factor.

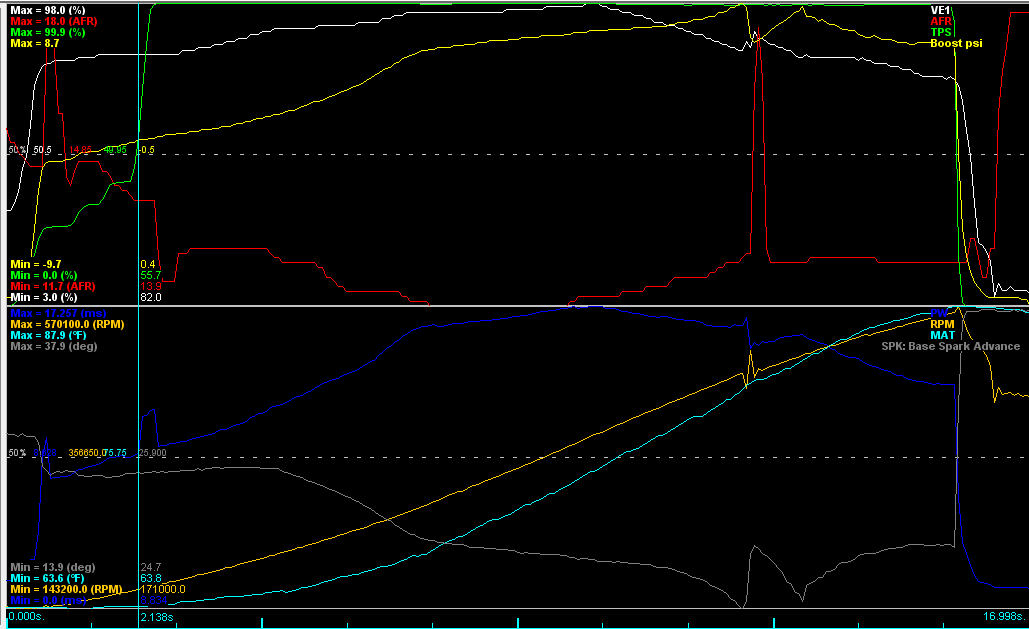

I have been looking at my car decided I needed a few more datalogs. I went out and this is a run in 4th gear, slightly uphill at about 9 at night. atmospheric pressure was 80 kpa with intake temps at 65 F at the start. It is 17 seconds long starting at about 1400 rpm and going up to 5700 rpm. Boost starts building once I put the pedal to the floor. You can clearly see where the wastegate opens at about 2800 RPM and boost at 5.4 psig. I believe I am running a 0.4 bar spring (5.8 psig spring).

Boost creeps up and I had my boost cut set to 140 kpa (60 kpa above atmospheric, or 8.7 psig)

At 12 seconds my boost creep hits 140 kpa (8.7 psi), engine at 4750 RPM, boost cut turns it off so afr spikes and boost drops to 6.3 psig and as engine rpm rises the boost drops off. My engine AFR was climbing up in the 12s at this point so I may have to add some more fuel in the 4500 rpm range and 130 kpa area.

After a quick check of my 32# fuel injectors, they should be able to run the current power. At 6000 rpm and 9 psi with the temp/pressure conditions shown above, I am right at 85% injector duty calculated here (http://www.stealth316.com/2-calc-idc.htm). I have a couple 42# injectors and it may make sense for me to swap them soon.

Here is that datalog in 4th gear.

One thing to note, depending on EGO control settings, the oxygen sensor does nothing under WOT conditions. I have it set that there is no EGO control over 70% throttle so this is straight off my fuel map and I havent really tuned this upper section of the map. I will have to add some fuel and try again.

As you can see my boost creeps quite a bit from 6 psi to almost 9 psi. What can i do about this? It isn't a bad thing because it is sort of a boost by rpm, stay in it longer for more boost, but not ideal to have boost building with the wastegate open. I am running the TiAl 44mm MVR with a 1 foot bend and screamer pipe. Is it the manifold limiting my boost, or the turbo just flowing too much for this little of a boost pressure?Leave a comment:

-

great pic! I've been pretty adamant about keeping my IX coupe stock, but damn.Leave a comment:

-

I like the Cripple Creek overlook photo, nice!

This photo was pretty neat also:

In the 540i I was foot to the floor through 2nd and 3rd gear. Into 4th you were approaching pretty quick in my rearview and I hadn't let off!

Of course we were at like 8000ft, but still the 540i doesn't feel slow at altitude either.Last edited by tschultz; 06-12-2017, 12:12 PM.Leave a comment:

-

the main difference between the 3.1L m20 and 24V engines such S52 /S54 is the piston barrel length/compression height/skirt length/materials and resulting piston to bore clearances. this is where lower durability can come into it as the piston and rings need to be kept as parallel/concentric to the bore axis to maximize lifeLeave a comment:

-

thanks for the comments guys. I need to work on better videos for you guys. I love how my car is still running an M20... I got a comment from a local guy who i saw on the highway in his e46 M3 coupe, and he asked, "what's under the hood?' and when I told him turbo M20, he said it sounded great.

The car seems to be running great. i took it on mountain drives about 3 of the last 4 weekends and I don't even have to shift out of 5th at 11,500 feet (atmospheric pressure of about 9 psi or about 66 kpa). I have been wondering about the strength of the M20 as well. It turns out the S54 has a larger bore and stroke than my engine with the same cylinder spacing and still has an 8000 rpm redline.

My engine has 86mm bore, 89.6 mm stroke, 135 mm rod, forged crank, pistons, rods, 206.2 mm deck height, 9.5:1 CR

S54b30 has 87mm bore, 91 mm stroke, 139 mm rod length, forged crank, 216.9mm deck height, 11.5:1 CR

The main difference is the height of the engine which allows the s54 to have longer rods which keep piston speed under control with the longer crank. Because of this, I have my current rev limiter set at 6000 rpm. This puts the piston speed somewhere around 58.8 FPS This is an equivalent piston speed to a stock m20 (75 mm stroke) spinning up to 7170 RPM. Outside of piston speed I don't really worry much about the engine but have been cautious to run too much timing or too much boost without knowing what I'm doing.

One thing I have done since the last post is I found a 3/8 NPT female bung and an 8" section of aluminum pipe that i could use to replace the AFM. With a GM IAT sensor I was able to remove the barn door and see how it changed the drivability of the car. One of the biggest differences was the instant response. It seems the barn door would be mostly shut on light throttle not allowing air through to the idle valve. Without it, there is less of an on/off bucking of the engine at light throttle positions. I had to use a blue silicone coupler to get it to work for now since the AFM inlet was 3", but I just ordered a black one to replace it. To connect the GM IAT, I had an old AFM that was junk that I took apart. I removed the male portion of the AFM connector and connected to the GM sensor to that so I could plug it directly in to the engine harness. I wrapped it in electrical tape to prevent corrosion and debris from damaging it, but I plan to rotatre the pipe upsidedown so the bung is on the bottom and the sensor and wiring is not visible.

It turns out the car is as fast as my brothers e39 540i/6.

And for the drive i took on Saturday I removed the heavy steamrollers form the picture above (17x7.5, 235/40/17, wt about 20+ lbs) and I put on this autocross setup (falken hanabi 15x7, 205/50/15, wt 12 lbs on RE-11a Bridgstones) but I ended up drving them in rain and snow at 9000+ ft. it is even faster and i managed over 25+ mpg.

And here is a video my brother took when I let him drive it about a month ago. 2nd gear, shifting at 4000 rpm, you can hear the wastegate dumping.

Leave a comment:

-

Cool to see 3.1L stroker kit whit turbo..Also see some results to how much boost it can handle and how long it will last. I have heard some saying that 3.1L stroker will not last so long etc etc..Leave a comment:

-

love this thread - always learn something from you. damn nice work on the tune. can't wait for some vid.. really want to hear that motor in action. I'll be pulling the trigger on a whodwho MS and 3.1 stroker next year hopefully. won't be going the turbo route though.Leave a comment:

-

Another update.

I was planning to drive my 318 to Moab until a winter storm moved in last month. We got slush and snow and i had to head west and cross the Vail Pass (elevation over 10,500 feet) and i wasn't going to chance that being a winter nightmare so I took the turbo. It drove great and I ended up get over 27 MPG for 800 miles including some dirt and rock roads. Note, Utah has 80 mph speed limits!

Then I decided to look into my tune and have since adjusted timing, fuel, and target Afr. I was pretty lean on cruise so I made some changes. After talking with Sssquid tuning, he suggested I go more advanced on cruise, so i bumped it up 5 degrees. I also noticed my idle was stronger with a few more degrees advance so that is now at 16 degree and pulling close to 20 map at idle.

I advanced timing through the midrange as well and the engine seemed to like it. I have no detonation at this point but still have a bit of boost creep on long pulls and have a Boost Cut function at 135 kpa enabled to protect it until I can get it dialed it. I also fixed a problem I had after cold starts where the engine would stall during first gear accel. i ended up adding some WUE and that seems to have gotten rid of that issue

The idle settings seem to be pretty good with only a bit of fluctuation of afr's at idle.

I got my IAT sensor and piping to replace the AFM but need a bung and need to weld in the bung somehow before I install it. I may end up using JB weld to get the bung attached since I can mount it on the back side of the piping. Besides that, the car is running great and is super fast. I should get a video sometime probablyLeave a comment:

-

Thanks, yep replaced the pistons and its back boostin around.

I have been researching a few changes to the car.

The first is the afm delete. I took apart an old AFM and was able to remove the connector and I plan to reuse it when I plumb in the gm IAT sensor. I ordered an 8' section of pipe which should drop in. that leaves me with figuring out how to either tap a 2mm walled aluminum pipe with npt threads ofor the sensor or weld in a bung for it. Either way I should be able to swap back and forth between the two and see what difference the AFM really makes on power/throttle response with a datalog.

The second option I am looking at is a knock sensor. The e36 m42 has a single knock sensor and the m50 engine had 2 sensor that connect to a single loom. Either way the sensor needs to be interpreted before it can be used. this is my only option so far www.viatrack.ca. Then i have to figure out how to connect it to my whodwho ms board. Why does it not seem like this is done very often? I can't find anything on it.

I also have a spare 16" SPAL puller fan that i am considering installing. It would replace the fan clutch, open up the front of the engine more etc. I'm on the fence on this one as the fan clutch works fine at the moment.

I also have toyed with the idea of installing an m42 integrated radiator which would get rid of my coolant res. This of course eliminates the coolant level sensor, but at the moment mine is not hooked up since in an early car the wiring to the sensor is on the passenger side. Not sure this would do anthing besides removes som stuff from the engine bay. there is also that pesky 3 way hose to replace, maybe I could use a stock m24 hose to from the heater core to replace that also.

Car is running good at 6 psi, slight coolant leak I need to find, but other than that no problems and a couple thousand miles driven on her.Leave a comment:

Leave a comment: