Much progress over the weekend despite my catching some cold/flu/virus I still managed to get a lot done. Though I was again met with disappointment in the end with another failure/problem in the rotating assembly (suspecting pressure plate again). Regardless there was a lot of very positive progress made.

The accident bent this tab on the swaybar... I tried my best to bend it back to no avail. It doesn't hurt performance, and I can still bolt the end link to it no problem, so whatever.

Also bent the mount. I replaced it with one of the old ones I kept.

This photo really helps show how much I cut out of the subframe and how much clearance I gained.

Subframe assembly complete and ready for install

This was the "cleanest" coolant block draining I have ever done, with exhaust amnifolds, subframe, swaybar, everything out of the way and it still went all over my arm, floor, side of engine. Never again

First an hose end I have ever assembled. I did the first with a vague idea of what I was doing... it was a PITA. Then I watched a youtube video, threw out the first try and the second time was flawless. Should've watched the video to begin with duh.

Metric to AN adapter in the block

Finished drain extension

Installed

Interesting these fragola fittings cut into the end of the hose to help seal.

Here's some more evidence the koyorad radiator has a small leak. It seems to randomly drip from that corner.

I trimmed some studs that were for holding the heat shielding in the transmission tunnel to geive a little more wiggle room while installing/removing the trans and found rust around 2 studs. One was very minor, the other made a hole... proper way to fix it would be to weld a patch, but I don't have time for this shit right now.

Cleaned all the rust out, sprayed it with self etch, filled it with JB weld and sprayed it with rust reformer black.

Picked up a new clutch slave since the old one was pretty ragged. Also picked up a new rear main and trans input seals. And a tube of the blue schmoo for pandaboo

New clutch kit replaced under warranty by BMAparts

Found something interesting. The rear main seal I installed was victor reinz. Dunno why the hell I did that when I assembled the motor. I don't trust VR for shit and it kinda looked like it was leaking.

Looking at the joint between the seal and the crank its wet. It was more apparent before I wiped it, but you can still kinda see.

The corteco seal is a very different style without a spring loaded inner seal. We'll see how it holds up.

Little trick for torquing flywheel and pressure plate bolts when you don't have a flywheel locking pin hole in the flywheel. Zipties.

Going back in. Some tips/tricks to make it easier to get to the top transmission bolts: use an engine support bar, or a jack from the bottom to tilt the engine down towards the back of the car. You have to totally loosen the engine mounts. This made it easy to access the top bolts. You can also unbolt the subframe and drop it an inch or so.

Added a bung on the exhaust merge for a future aux O2 sensor.

And the subframe clearancing mission was a complete success!! Not bad for eyeballing it when I cut it up. I have plenty of space now to remove/install the merge section without having to unbolt the headers. You can also see where the drain extension lands just behind the swaybar.

Only issue now is that top nut. I can't get to it with any standard wrench (no room to fit a socket) while the manifold is installed. My thoughts are A) buy a 15mm wrench and cut it short enough to fit in the space or B) turn that stud/nut into a bolt/nut by drilling out the stud and then I could bolt it from the other side.

I'll probably try the shortened wrench first.

And it's finished.

Sooooo I drove it like 40 miles on monday and it was feeling good and then something happened again. It happened while I was at WOT in 1st at/close to redline. So at first I was taking it easy feeling everything out, and as it all felt good I got more aggressive. So close to home I ripped on it in first, some good wheelspin, bumped the revlimiter and then shifted and uh-oh I was feeling vibration again. Something is out of balance in the rotating assembly and I'd have to suspect the pressure plate once again. I don't get it. I put like 10k miles on the car since the swap, and I beat the shit out of it. I frequently redline in 1st with wheelspin and bump the rev limiter all the time with no ill effect until now. Any thoughts?

The accident bent this tab on the swaybar... I tried my best to bend it back to no avail. It doesn't hurt performance, and I can still bolt the end link to it no problem, so whatever.

Also bent the mount. I replaced it with one of the old ones I kept.

This photo really helps show how much I cut out of the subframe and how much clearance I gained.

Subframe assembly complete and ready for install

This was the "cleanest" coolant block draining I have ever done, with exhaust amnifolds, subframe, swaybar, everything out of the way and it still went all over my arm, floor, side of engine. Never again

First an hose end I have ever assembled. I did the first with a vague idea of what I was doing... it was a PITA. Then I watched a youtube video, threw out the first try and the second time was flawless. Should've watched the video to begin with duh.

Metric to AN adapter in the block

Finished drain extension

Installed

Interesting these fragola fittings cut into the end of the hose to help seal.

Here's some more evidence the koyorad radiator has a small leak. It seems to randomly drip from that corner.

I trimmed some studs that were for holding the heat shielding in the transmission tunnel to geive a little more wiggle room while installing/removing the trans and found rust around 2 studs. One was very minor, the other made a hole... proper way to fix it would be to weld a patch, but I don't have time for this shit right now.

Cleaned all the rust out, sprayed it with self etch, filled it with JB weld and sprayed it with rust reformer black.

Picked up a new clutch slave since the old one was pretty ragged. Also picked up a new rear main and trans input seals. And a tube of the blue schmoo for pandaboo

New clutch kit replaced under warranty by BMAparts

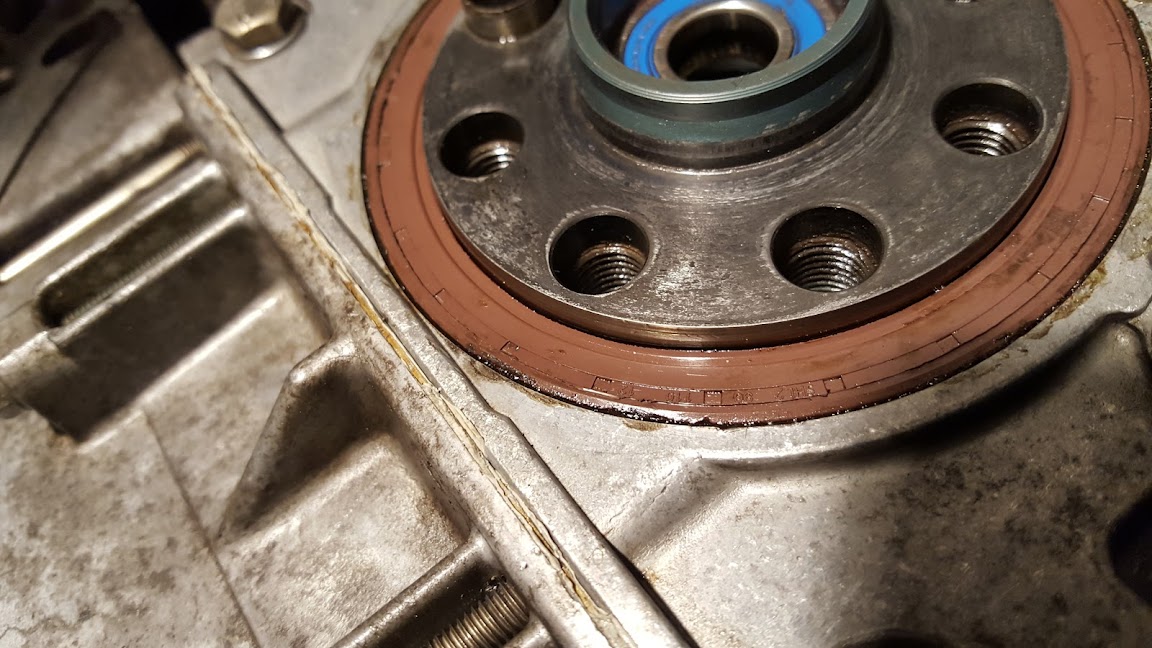

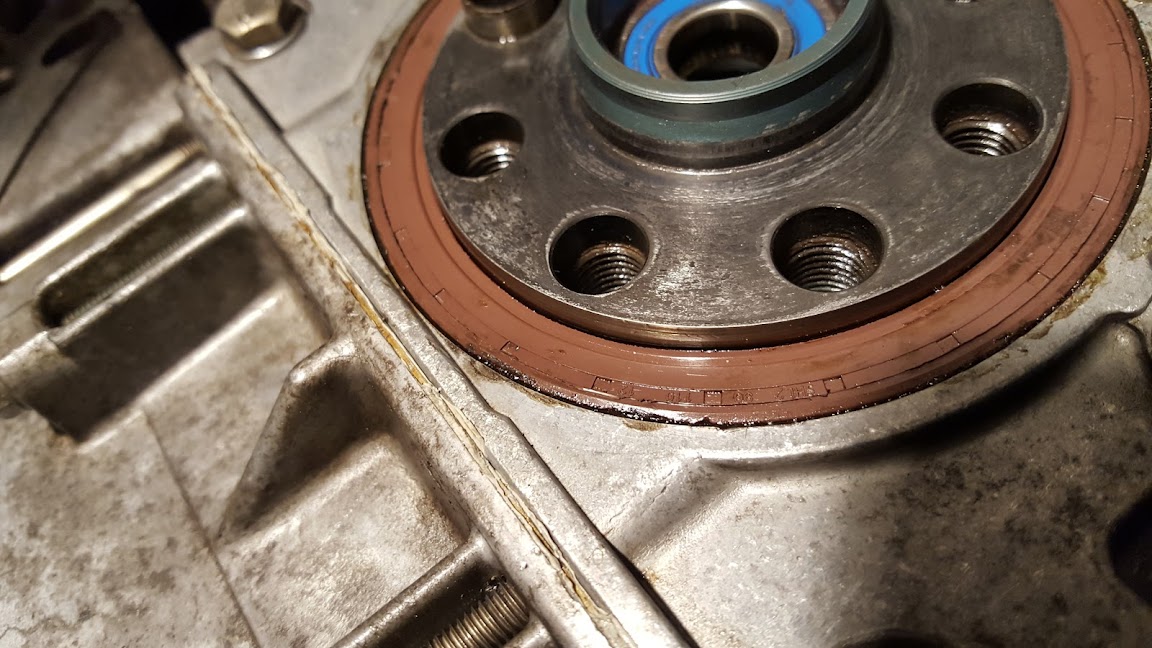

Found something interesting. The rear main seal I installed was victor reinz. Dunno why the hell I did that when I assembled the motor. I don't trust VR for shit and it kinda looked like it was leaking.

Looking at the joint between the seal and the crank its wet. It was more apparent before I wiped it, but you can still kinda see.

The corteco seal is a very different style without a spring loaded inner seal. We'll see how it holds up.

Little trick for torquing flywheel and pressure plate bolts when you don't have a flywheel locking pin hole in the flywheel. Zipties.

Going back in. Some tips/tricks to make it easier to get to the top transmission bolts: use an engine support bar, or a jack from the bottom to tilt the engine down towards the back of the car. You have to totally loosen the engine mounts. This made it easy to access the top bolts. You can also unbolt the subframe and drop it an inch or so.

Added a bung on the exhaust merge for a future aux O2 sensor.

And the subframe clearancing mission was a complete success!! Not bad for eyeballing it when I cut it up. I have plenty of space now to remove/install the merge section without having to unbolt the headers. You can also see where the drain extension lands just behind the swaybar.

Only issue now is that top nut. I can't get to it with any standard wrench (no room to fit a socket) while the manifold is installed. My thoughts are A) buy a 15mm wrench and cut it short enough to fit in the space or B) turn that stud/nut into a bolt/nut by drilling out the stud and then I could bolt it from the other side.

I'll probably try the shortened wrench first.

And it's finished.

Sooooo I drove it like 40 miles on monday and it was feeling good and then something happened again. It happened while I was at WOT in 1st at/close to redline. So at first I was taking it easy feeling everything out, and as it all felt good I got more aggressive. So close to home I ripped on it in first, some good wheelspin, bumped the revlimiter and then shifted and uh-oh I was feeling vibration again. Something is out of balance in the rotating assembly and I'd have to suspect the pressure plate once again. I don't get it. I put like 10k miles on the car since the swap, and I beat the shit out of it. I frequently redline in 1st with wheelspin and bump the rev limiter all the time with no ill effect until now. Any thoughts?

Comment