It was padded to increase diameter yes. Sort of... He doesn't like doing wheels because of the time involvement, finger pain, and the like. He agreed to do mine as part of the full interior deal. I don't know if he wants to do single wheels but I'd guess no.

Yeah, rubber is inert so it won't be bothered. Per a suggestion from Ed on the FB post I'm going to pull the pistons, seals and make sure the bores get plated too.

The elusive Matt shows himself :D Thanks!

Sound deadener aka CDL tiles is one of those diminished returns items. Covering open panel expanses with tiles in key places give you 80% of the effectiveness with 10% of the added weight. 50% coverage may yield only a slightly better affect, and further diminishing as you go all the while accruing weight.

The whole idea of CDL tiles is simply to add mass to a panel to stop resonance. There are whole forums full of mobile audio fanatics that argue over these principals at lengths I care not to get into.

Think of a drum set cymbal. You can stop it vibrating with a single finger, you don't need both hands covering it.

Project Lessmeister: 91 318iS Restomod w/ MTech2 and modern drivetrain

Collapse

X

-

beautiful work. beautiful car and great attention to detail. This build is wonderful.

I am curious that with all this meticulous detail you've spent on making this car so minty, why did you decide against possibly doing a full dynamat treatment on the floors or everywhere else in the car?

Sorry if this is an obnoxious question.Leave a comment:

-

Jordan, I've been following this thread the whole way through and thoroughly enjoyed it!

Really looking forward to seeing the finished product!Leave a comment:

-

so they can plate the calipers with all the rubber parts still in them? thats awesome. you are giving me lots of good ideas for my projects.I started this evening off by spending a few more hours blasting loose parts at my buddies shop, then headed back home. I'm very happy to be done blasting parts, its kinda tedious and my hands kept falling asleep lol.

When I got home I went ahead and pressed the new OEM trailing arm bushings into the trailing arms. This is really simple and took about 1 minute per bushing.

I slapped it in place real quick to get a feel for how it looks. It looks killer. I almost don't want to touch it.

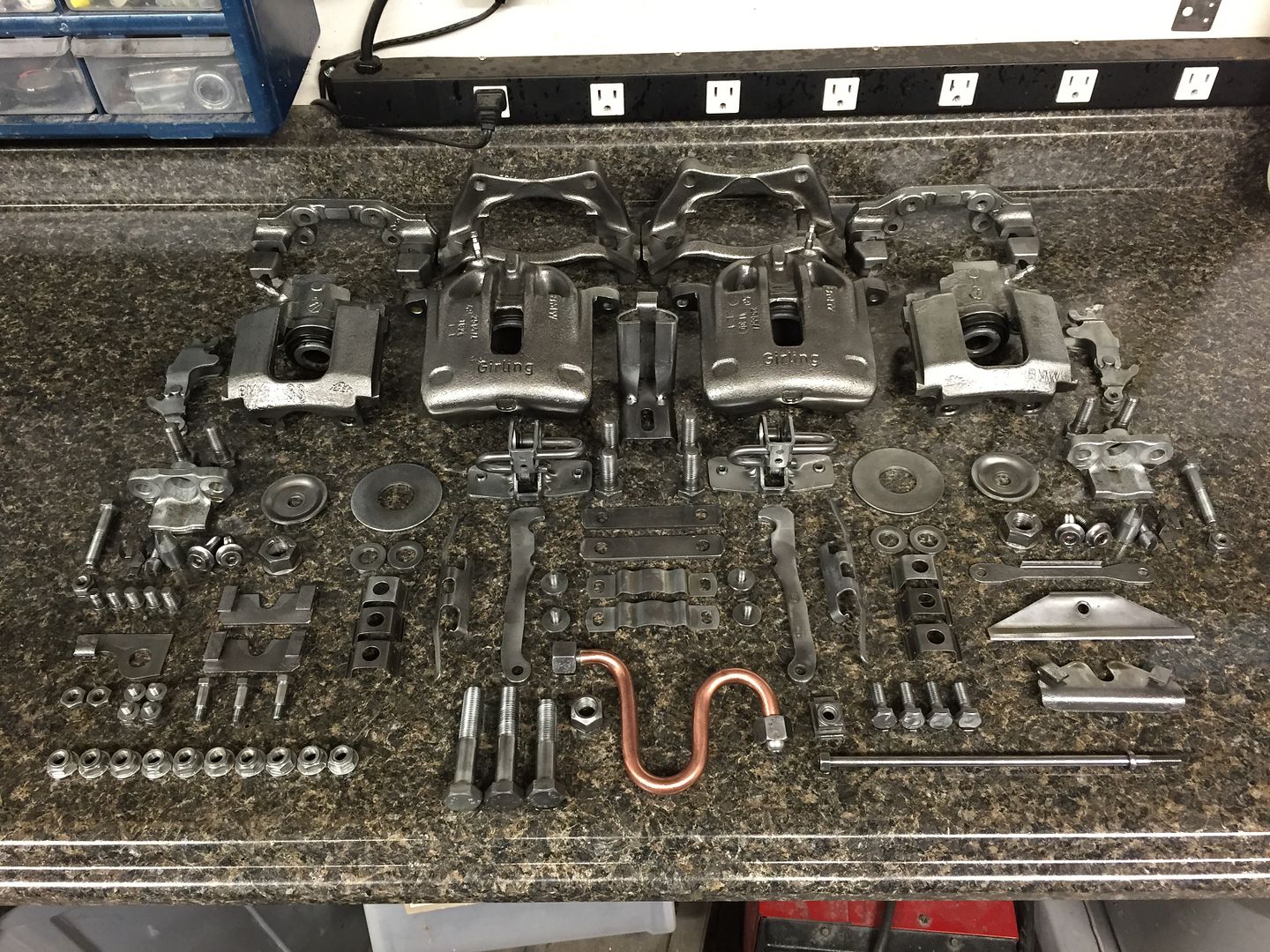

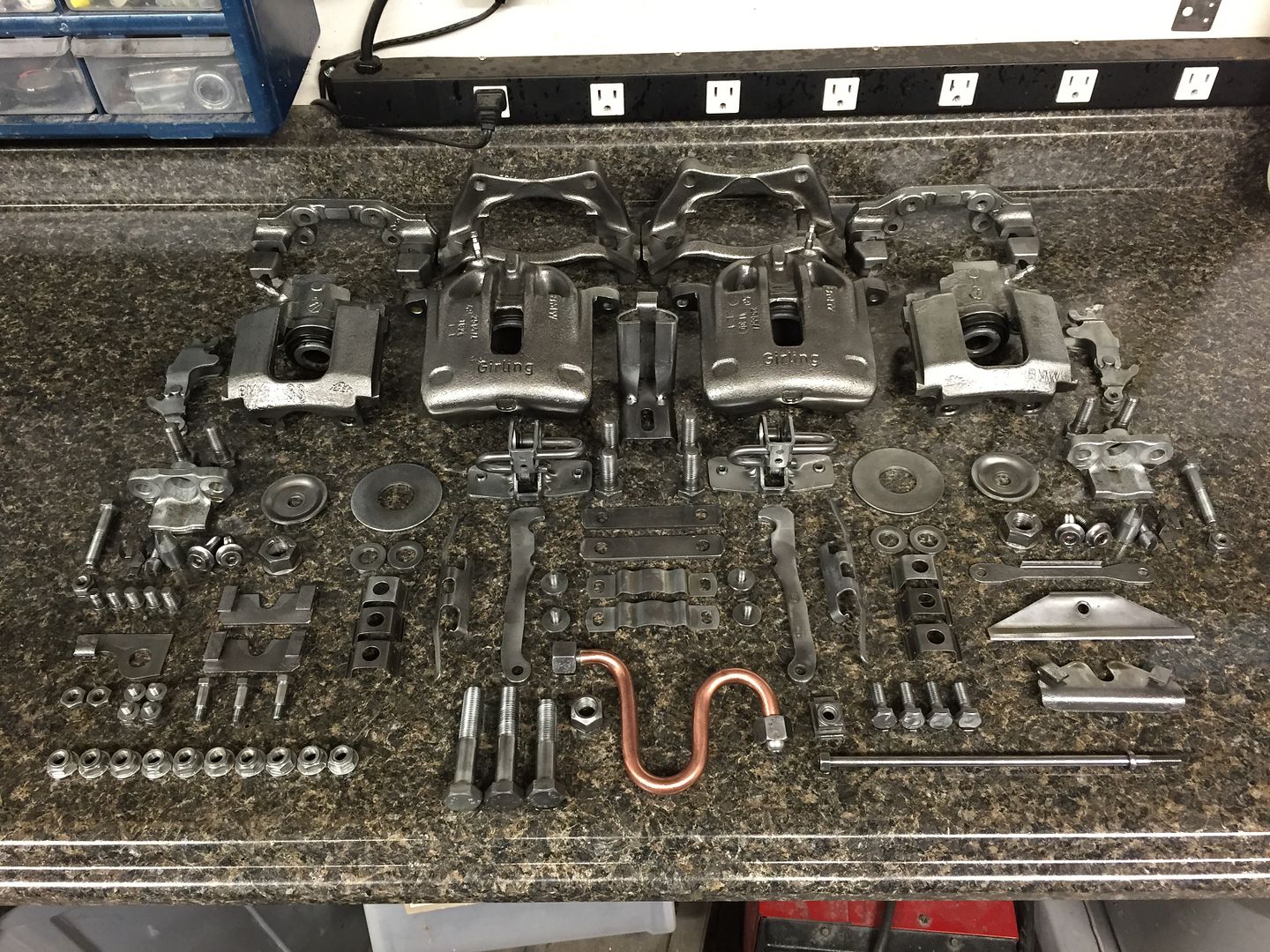

Not having had enough punishment this evening I decided to go ahead and wire wheel polish the remainder of the loose parts as they are going to the plater on Wednesday or Thursday and I want to get them out of the way. It took about 2 hours to finish this up, and when I was done I applied a light oil (WD40) to all the parts so they will not flash rust.

I went ahead and laid them out in an OCD fashion, partly because I has OCD, but also so I can account for everything when it gets back from plate and quickly determine what if anything is lost in the process. Knock on wood they haven't lost anything yet!

Leave a comment:

-

Very nice work by both Jordans. Was the wheel thickened? I take it he is back to doing wheels?Leave a comment:

-

-

A+ photo. It's going to be frustrating putting them all in a box after that.Leave a comment:

-

I started this evening off by spending a few more hours blasting loose parts at my buddies shop, then headed back home. I'm very happy to be done blasting parts, its kinda tedious and my hands kept falling asleep lol.

When I got home I went ahead and pressed the new OEM trailing arm bushings into the trailing arms. This is really simple and took about 1 minute per bushing.

When I went inside to eat I realized I had a care package from Jordan @ Stitched Wheels. My MTechnic II steering wheel was in the box, along with matching parking brake, shift boots all cut from the same OE BMW hyde as the seats were.

I slapped it in place real quick to get a feel for how it looks. It looks killer. I almost don't want to touch it.

Not having had enough punishment this evening I decided to go ahead and wire wheel polish the remainder of the loose parts as they are going to the plater on Wednesday or Thursday and I want to get them out of the way. It took about 2 hours to finish this up, and when I was done I applied a light oil (WD40) to all the parts so they will not flash rust.

I went ahead and laid them out in an OCD fashion, partly because I has OCD, but also so I can account for everything when it gets back from plate and quickly determine what if anything is lost in the process. Knock on wood they haven't lost anything yet!

Leave a comment:

-

I have a original 318ic on the way feom California, i am relying on his knowledge to make my envisions a reality

Sent from my SM-N920P using TapatalkLeave a comment:

-

His work is impressive that's for sure. I'll be picking his brain on the wiring a lot I'm sure if he's willing that is haha. I'm going to pull my car down to the shell and catalog what needs replacing and pretty much use this thread as a modleLeave a comment:

-

I stopped by Jordan's house today (2nd time) and the quality of his work and knowledge of these cars is very impressive!

Sent from my SM-N920P using TapatalkLeave a comment:

-

Both trailing arms are back together now with the hub and axle pressed together. I somehow forgot to order the trailing arm bushings but those will be here tomorrow. Not a big deal as I will be waiting on hardware to come back from plating before I can throw the rear suspension back on the car.

I spent the remainder of the afternoon cleaning the rear undercarriage of the car. Leaky diff sling and grime of that sort. I think I am going to relocate the carbon canister and the MS43 fuel filter/FPR to the location of the original fuel filter. It looks like it may fit and work well there with minimal modification to the metal hard lines that run up to the engine bay.Leave a comment:

-

I've been using Del's for years, and everyone outside Houston knows about them from my RC090 rebuild thread on BFC ;-) Del's will be doing my yellow zinc chromate. They do great work for the money, they have got to be a bit more picky about the condition of parts over the years though. They said too many people send them rusty crusty bolts and whine if they charge for the surface prep to get the results they want...

Hence why I spent several hours this morning continuing to work on the sand blasted parts and polishing them to a nice luster.

Took a break to go catch The Force Awakens with the family. It was pretty good, not sure if it was all up to the hype however.

This evening after the movie I spent some time on the rear suspension parts, cleaning the trailing arms, subframe and axles.

Right rear trailing arm, before any cleaning with one test swipe. Roached half pulled apart wheel bearing in place.

She cleaned up real nice, all of that dirt revealed a good deal of cosmoline that was removed with lacquer thinner. New wheel bearing ready to go back in.

Wheel bearing installed, new brake backing plate, parking shoes, springs, etc.

The other arm will get the same treatment tomorrow, along with the subframe. I already pressed the old subframe bushings out and new ones in.

Leave a comment:

Leave a comment: