definitely hold on to it for me. i have my g260 sitting next to the 420 in my shed. i am going to take a measurement of the two, then measure the front section of my e30 shaft. that should get me pretty close.

edit: i just checked realoem. i think the output bolt pattern is 105mm? i wonder if i can find a 96mm flange for this trans?

Project Lessmeister: 91 318iS Restomod w/ MTech2 and modern drivetrain

Collapse

X

-

They are both the same 96mm/12 bolt pattern. You'll just have to get the car together and measure. I have the front section from an E36 AT if you want it you can have it. It is 17 3/4 long. The Z4 section is about 19 3/4.Leave a comment:

-

you have come up with some amazing ideas! looks like i am going to be taking full advantage of our friendship pretty soon.

do you think the z4 front half with work with my g420? my guess is the length is probably about right but not sure about the bolt pattern diameter. i am also trying to find a way not to go custom.Leave a comment:

-

Regarding the driveshaft rebalancing thing.... in a word "yes" but in reality? No not that I have found.

I have over time back halved and front halved at least a dozen driveshafts on different cars. I have never felt nor observed any ill effects related to it. I always take care to make sure the ujoints are properly phased if the 2 sections each have one, but where as it concerns the E30/E36 shafts both ujoints are on the rear half of the shaft. The front section is short, lightweight and likely made to a pretty respectable standard to start with.

My wife is near completely non-supportive of my car related hobbies, but then she often forgets what pays the bills..... I try not to spend more than an hour or two each evening in the garage after work, generally doing "set up" for busy weekends. IE building out sub assemblies so they can all fly into the car quickly etc.Leave a comment:

-

Is it necessary to have the driveshaft re-balanced when mixing/matching components as you are Jordan?

As always, enjoying this build. Not sure how you find the time for it with work and a family, but kudos for doing so. My wife would make me sell all of my cars if I spent more than a day a week in the garage. ;)Leave a comment:

-

Some good ideas here, I will have to do some similar things. I'll be using the E46 M4 FPR as is, haven't really decided if I want to mount it with the filter or not. I'm thinking maybe just sticking to the stock E30 fuel filter and mounting the FPR separately like you did is a good idea - hackjobtt's installation looks terrible and that's a lot of bulk in the engine bay I don't want to deal with..Leave a comment:

-

First project this evening was assembling and refinishing the driveshaft. I test fit a couple different shafts until I find the combination I liked best. I decided on the E36 M3 rear half, with a front half from the same Z4 my 6MT came from. I installed a new E30 center support bearing on the rear half. This gives the driveshaft a total length about 3/4" shorter than installed nominal, so after its in place you slide it out on the slip yolk 3/4" and boom you're there. This gives full spline engagement and then some in the front half.

With the E36 driveshaft as a complete unit the shaft was extended out so far it had maybe 1" of spline engagement, which I was not happy with.

Next order of business was fooling with an idea I had come up with earlier in the day. For weeks I've been trying to figure out what to do for the fuel filter and fuel pressure regulator. The MS43 cars all have a long fuel filter with intergrated fuel pressure regulator. I had attempted to mock this up in the factory location back by the subframe. While the filter "fit" there simply was not enough clearance at either end for proper connection of fuel lines and they would have been pressing against the body. Cannot have that.

I looked for awhile to try to find a similar filter that was shorter, again with an integrated 3.5bar FPR but came up empty handed.

The other obvious option was to do as whatshisdickface did and toss the filter/FPR assembly in the engine bay:

This of course looks like crap, and it makes servicing the filter a bit of a hassle. Just couldn't have this either.

Today I was thinking and I remembered that the E46 M3 had a similar filter, but the FPR was a stand alone outboard assembly. A quick peak under a junked M3 at work found the FPR housing and I removed it from the car. The only problem I saw was that the S54 runs a 5bar FPR, where as MS43 cars run a 3.5bar.

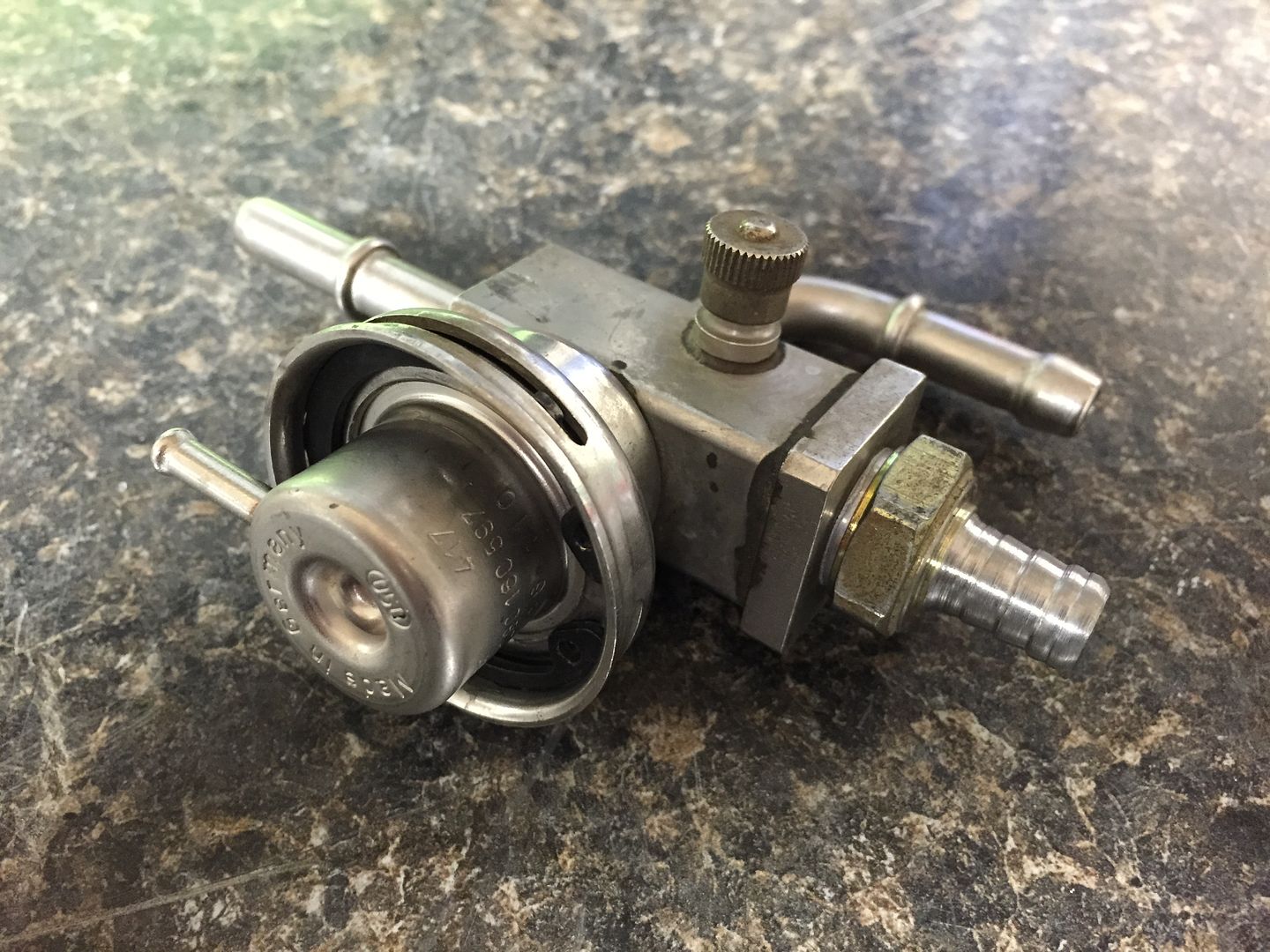

I already had a brand new fuel filter for the MS43 cars, and I was betting on the FPR's being compatible in shape/size. I pulled both FPR's and while constructed a little different the critical dimentions are the same!

The threaded fitting is the fuel inlet, the straight fitting is the fuel outlet, and the 90 degree fitting is fuel return to tank. I can install this little guy on the frame rail where the fuel hard lines come into the engine bay, handling the inlet and return at the frame rail. I then also get to run a double ended quick disconnect fuel line like from newer BMW's. I'll just need to run a vacuum line off the intake boot F connector down to the FBR, again just like it would be in an MS43 car.

Oh.. one other problem being the threaded inlet fitting. I probably could find a threaded barb to install onto the FPR housing (I believe it is M12x1.5) but I elected to take care of that myself.

I pulled the threaded fitting and chocked it in my drill. I held the drill in my vice and locked the trigger on. 2 minutes with a small file removed the threads and shaped them into a barb :-)

This is now ready to install, but I'll come back to that later.

Next order of business was sorting the temperature sensor for the instrument cluster gauge. Again whatshisdickface had installed this straight into the engine block in the block drain location. While it does thread in the sensor is too long as you are left to use several crush rings to space it out. Another halfass thing I just didn't want to do, and the bottom of the block isn't a good place to be taking an engines coolant temp from anyway.

I decided it would be better placed on the top of the engine, albeit in sight, but at the thermostat outlet. Coolant temperature at this point should not fluctuate lower than the temperature in the cylinder head considering the volume of coolant flowing. The fitting is from a E46/E39 lower hose with the fan temperature sensor fitting.

I cut the fitting down and threaded the plastic to M14x1.5 for the E30 gauge sensor. I coated the threads with epoxy for good measure. This did leave one small issue, being that plastic is a really poor conductor of electricity and this particular sensor grounds through the sensor body. A ground strap would need to be affixed to the sensor in some manner and attached to the engine.

I drilled a small hole through one of the corners on the sensor to attach a wire to.

I tinned a wire, then inserted it in that hole. After melting some flux into the area I fed some solder in and now its permanently attached.

Leave a comment:

-

I took care of the shifter linkage fabrication yesterday, although the shift lever provided works well I knew that even the shortest DSSR UUC offers would be A. Too long. B. Not the right shape.

I started from a factory selector rod. Cutting it to the correct length and offset via trial and error until I had the lever centered in the opening and the gears where I wanted them.

After that I cut into the DSSR, notching it for angle and cutting the excess length out of it. It was welded up as pictured above, then ground down until it was nice and clean looking. I forgot to take a finished picture though.

I spent the rest of the evening and some of today working on the exhaust fabrication and I have the forward section complete now, tacked and waiting to get dropped off to TIG together.

Leave a comment:

-

2.25" is as large as it gets on modern 6 cyl BMW's with dual exhaust. Truth told its slightly larger as the new 2.25" mandrel pipe tightly fits inside it.

To get something 2.5" or larger you have to go to V8/ Turbo V8.Leave a comment:

-

are there any oem cats like you have pictured above with 2.5" openings?Leave a comment:

-

I've just finished reading the build from the beginning. Amazing work man, incredible attention to detail.Leave a comment:

-

I haven't much to report over the last few days I've just been taking it easy and waiting for some things to show up.

The stepped 2.25" vbands for the headers showed up:

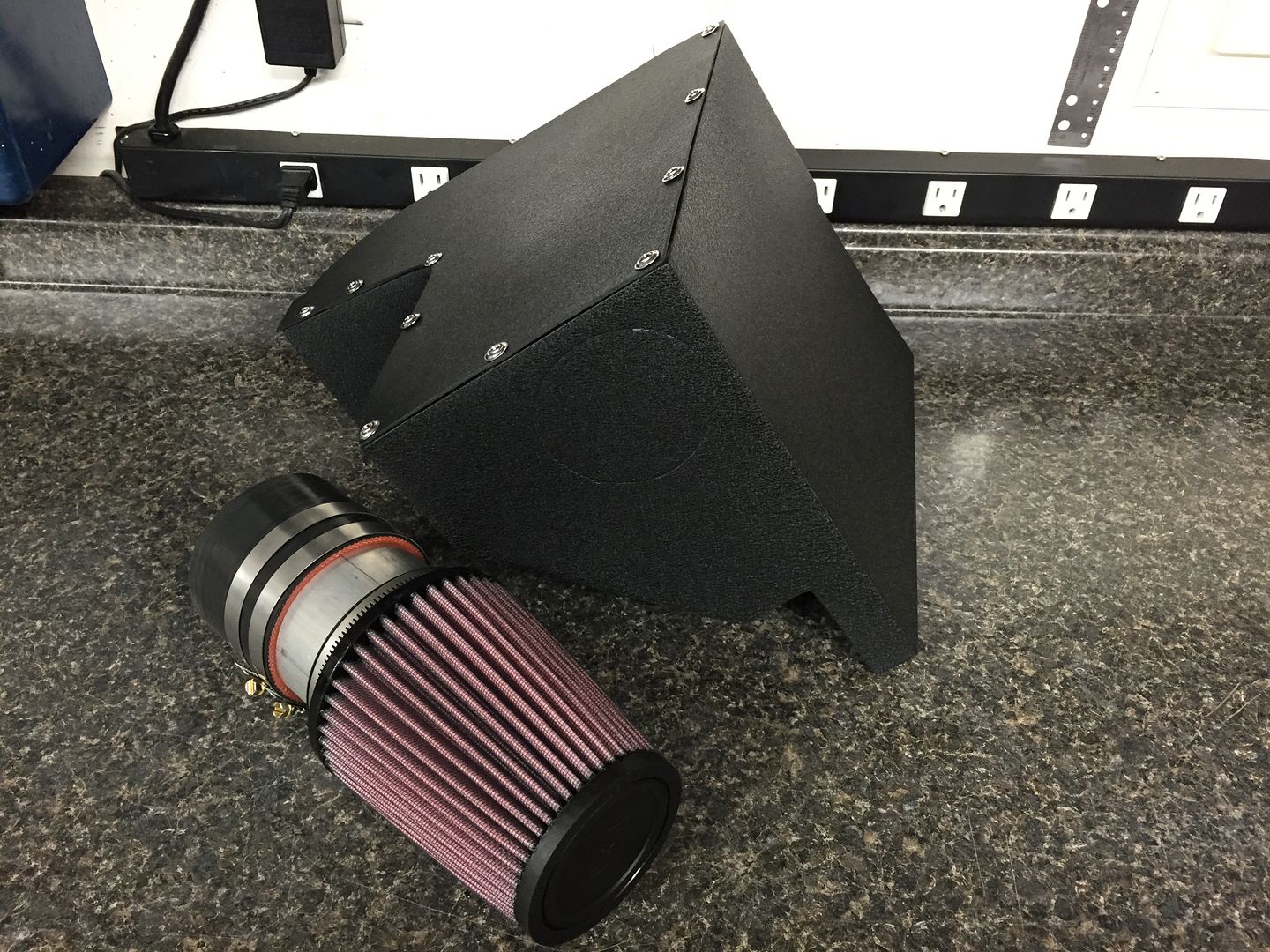

The awesome molded fit cold air cleaner box from Castro Motorsports showed up. The fit on the car is really impressive! You can tell a lot of effort and thought went into the molding of the product specifically for the chassis. I had a couple special requests like leaving the MAF uncut so I could size it for my specific application and it was delivered just as asked.

The Evo3 SSK from UUC Motorwerks showed up. I've had one iteration or another of these shifters in every BMW I've owned over the last 10 years, and installed a dozen or more in customers cars. Nothing else out there matches its quality.

New boot for the shifter, with the harness I'll crimp the end connector onto for the reverse lamps:

Pseudo mockup of the exhaust system to be. eBay headers chopped at the collectors, stepped vbands, catted mid section, Y resonator, and Remus muffler.

The vbands out of the headers are 2.25" and the 2 mandrel bend sections I bought for fabrication are 2.25"

The catted mid section is from a newer BMW. N54 twin turbo car. OEM Boysen catalysts are far higher quality than anything you're going to buy in the aftermarket. The pipes in and out of them are 2.25"

The Y resonator is OEM Eberspächer from a E83 LCI. It is dual 2.25" in, and single 2.75" out.

Both OE midsection donor parts are 100% stainless steel construction, and specifically selected for quality and overall fit to the car. I hope they will fit within the confines of the aluminum heat shield without handing too low. I think many of us have used the E36 mid section, OBDI or OBDII, and they both hang awfully low because they are too wide to tuck up and in.

I'll do 2.75" or 3" from the resonator back to the Remus muffler.

Leave a comment:

-

I'm speechless this has to be the most meticulous build I have ever seen

Leave a comment:

Leave a comment: