Drift Trike Project - any else have one?

Collapse

X

-

Disk Brake Caliper mount

The mig nozzle clogged at the end. =(

My welders. Nothing too fancy, just Hobby/DIY level stuff.

My garage bench and e30. Doing some patch panels and repair the rear battery tray cause of rust.

Other cars

VW CC is just a bunch of bolt ons

A4 Avant is bored and stroked to 2.0l with a 5858 turbo and bunch of stuff.

E30 is m50 swapped with zf trans on shitty coils.

Comment

-

I'm a pretty big guy and it doesn't flex too much with me jumping on it. It's still going to get a gusset at the lower bend going into the seat to reinforce the bend so we will see. I'm still not totally convinced it won't need some additional structure to help with flex, maybe a "spine" with fancy holes cut out running the entire length of the bottom side of the downtube, but that's what test runs are for... :-D

Comment

-

It's high comp (+12:1) 140cc, 26mm Mikuni carb, ported head with custom cam, E85 fuel, probably made around 15hp N/A (as reference in a pitbike frame it kept up with my 160cc pretty well).

Turbo wasn't really optimal, it made some boost and engine worked happily with it, never tried it with sticky tires to get more load for the engine.

Now the frame is for sale, no time for this hobby :(Comment

-

Bad.

Freaking.

Ass-Christian

'02 ///M3 CarbonSchwartz 6MT daily beast

08/91 Mtechnic II 325IC alpine/lotus

318iS, slow build/garage queen...

'37 Chevy pickup, the über project Originally posted by roguetoasterBe sure to remind them that the M42 is one of the best engines ever made, but be sure to not mention where it actually falls on that list.

Originally posted by roguetoasterBe sure to remind them that the M42 is one of the best engines ever made, but be sure to not mention where it actually falls on that list.Comment

-

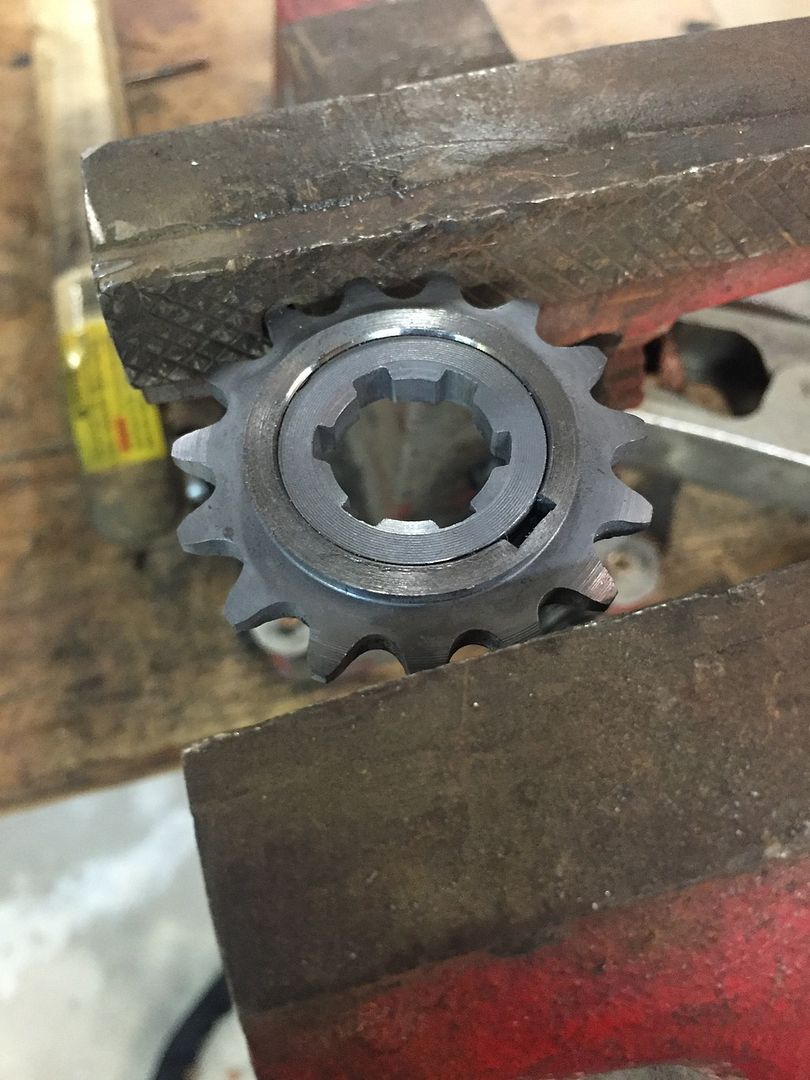

did some machining today to adapt the #420 type chain and sprocket on the Lifan 125 to a more common #35 chain sprocket used for the back.

I knocked off the majority of the sprocket because I just needed the center spline. The hardened steel so it was easier to use a grinder with a cut off wheel to hack it up.

Then i had to find a way to chuck it to my lathe and keep it all concentric so I made this hub adapter to match the ID of the splined center and and bit of a relief so i had to room to work with. Then used a bolt to clamp it all together.

Next was the #35 chain sprocket. I just had to knock off the flange and the open up the ID a bit

Then beveled the edges so i could get some penetration tig welding it.

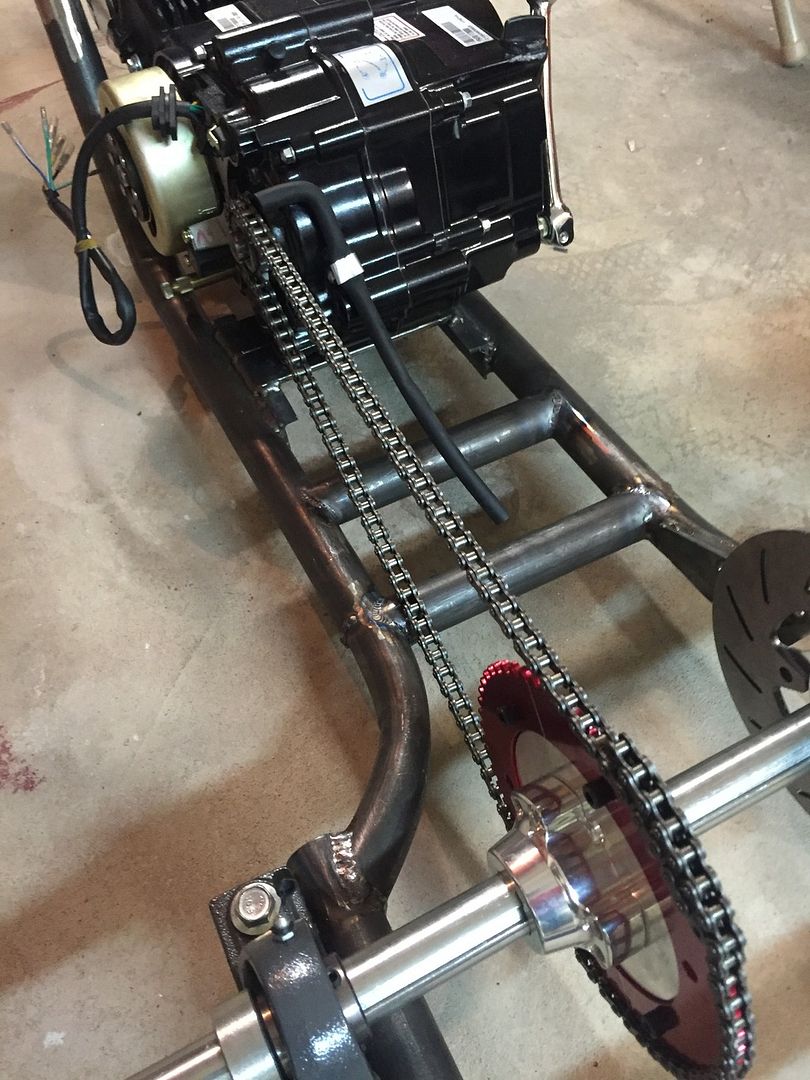

Set up the chain and now one of the tubes interferes so I'll probably have to notch it and add a small u channel for clearance.

threw on the throttle cable and the carb and need to figure that out.

Comment

Comment