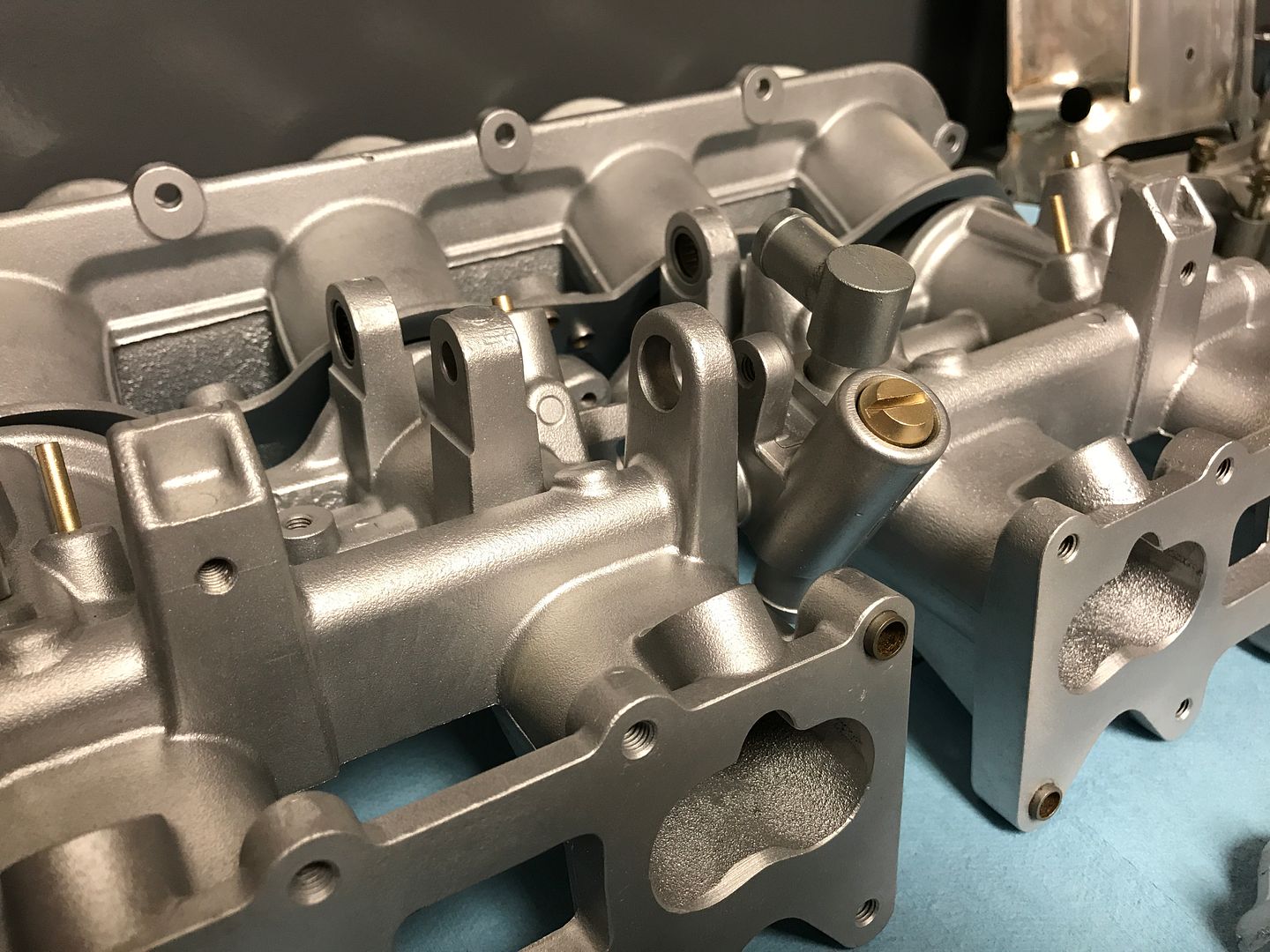

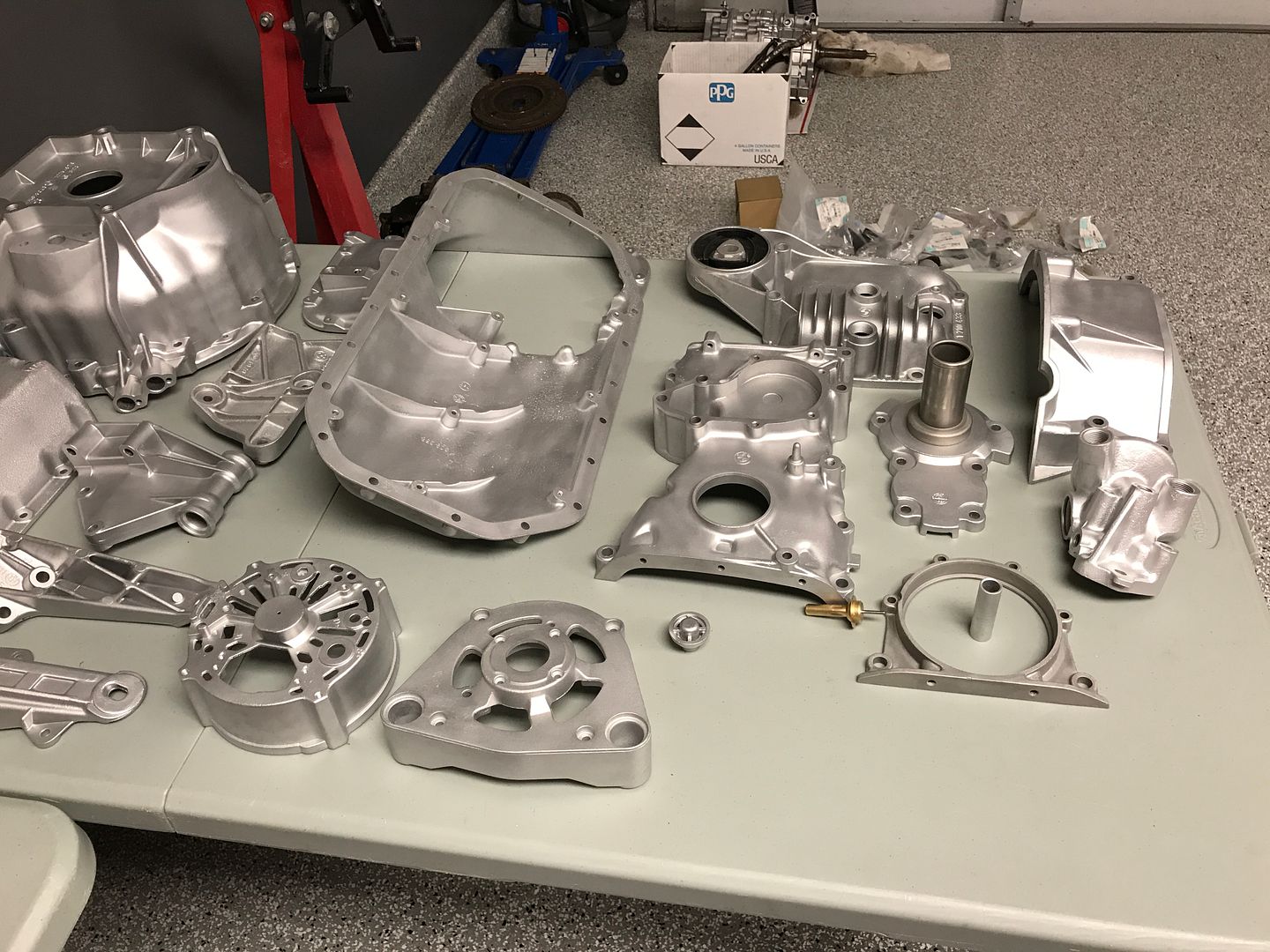

S14b23 Drivetrain overhaul and concours restoration.

Collapse

X

-

I'm curious to how much the vapour blasting generally costs? I'm not expecting you to share exact numbers but cost wise how does it compare to other methods? -

-

Exhaust valves are trash, throw them away and buy new.

Penny wise, pound foolish to try and save them. You're installed heights will be all sorts of messed up by the time you re-cut the valve seats and then those valves.

With new, you can set installed height correctly, once the seats have been re-machined.

The valves can be tipped to correct height, provided there is enough margin. Hard to tell how deep the pits are in the pics, specially contrasting with the polished surfaces. More so, the seats would be a bigger concern (on a performance stand point) since the further they go into the throat, the worse low lift flow will get.

I have seen some real crap valve jobs come out of local machine shops that just care about the engines running, hence the reason I purchased a valve machine and moved the work in-house. Nothing worse than getting some nice flow numbers on the bench, just to have it ruined by a yocal.Leave a comment:

-

Got to love the Texas car scene. Lots of big horsepower vehicles over there.

How much would new pistons be, out of curiosity?Leave a comment:

-

Oh hey Pablo, yeah right after we met at the Gaylord convention center and I got back home some fuckwad kid with no license playing on his phone ran a redlight and tboned my F10 535i. It was a total loss. Multiple airbag deployment, left front hit hard, frame rail shifted, subframe and engine mounts broken. Left rear door and quarter hit too.

That's alriiiight though as I upgraded to a M5 instead. Tuned to 780hp/730tq daily driver mode :-) I had to replace 2 barrels and 1 face but was able to salvage my custom wheels.

Leave a comment:

-

Awesome work! Hope you guys are doing good down there. This is Kyle's friend, Paolo. We took a couple classes together in Texas. Do you still have the F10 or did you get another one?!Leave a comment:

-

The block will be fine, but I'm pretty sure it is going to need more than a dusting with a bore hone... which means in all eventually new pistons. Again we'll let the machinist say whats what. The client prefers to reuse original parts wherever possible, and so does my wallet, but if the pistons need to be replaced it is what it is.Leave a comment:

-

I read up on it after you mentioned it in your other build thread, it's an interesting and very non invasive procedure.

What's the plan if the block needs to be replaced?Leave a comment:

-

I've not had an issue with it in the past, especially followed up with vapor honing. I wouldn't run a just bead blasted piston though, even super fine media leaves them rough feeling.

I'm also not really expecting I'm going to be able to use the original pistons, its likely the block is going to need more love than they can allow. Again yet to be seen. The entire bottom end is at the machine shop now and I'm awaiting work on the suck I'll have to deal with.Leave a comment:

-

Leave a comment:

-

While I certainly don't disagree my responsibility to this point is disassembly and cleaning. I fully intend to let my machinist determine what is usable with recon and what needs to be replaced. Valves are about $25 each, no big deal if needed.Leave a comment:

-

+1exhaust valves are trash, throw them away and buy new.

Penny wise, pound foolish to try and save them. You're installed heights will be all sorts of messed up by the time you re-cut the valve seats and then those valves.

With new, you can set installed height correctly, once the seats have been re-machined.Leave a comment:

-

Exhaust valves are trash, throw them away and buy new.

Penny wise, pound foolish to try and save them. You're installed heights will be all sorts of messed up by the time you re-cut the valve seats and then those valves.

With new, you can set installed height correctly, once the seats have been re-machined.Leave a comment:

Leave a comment: