awesome work, you should be proud....

My FX-R Projector Retrofit Thread

Collapse

X

-

-

-

OK, a little update.

I have dragged my ass for so long on this that there is even a new version of the FX-R projectors out now. I have version 1.1 units presently, and now there is a version 3.0 with an improved lens and beam pattern. So I ordered some 3.0 projectors and will see if they can still fit. They are slightly smaller overall, so I don't see an issue there. The lens assembly is a bit shorter though, which might mean interference with the plastic "dish" cover thingy in the stock lights. We'll see once I get them and model them in CAD.

I don't expect to get much fabrication done on this until December though. I am getting married in a couple of weeks and then going to Hawaii for a few weeks after that. After my engine swap shenanigans, I don't think that it would be wise to do any more car projects before the wedding lol! She's tolerated the engine swap, but I sort of need to pay some amount of attention to the wedding to stay out of the dog house lol.Comment

-

OK, I got the new adapter plates mocked-up for the FXR-3.0 projectors. I'll post up some pics of the "prototyping" process later tonight. Let's just say that it involves inexpensive craft-store stuff. You'd be amazed how accurate you can get things with some foam-core boards and calipers.

I also paid a visit to the local metal supermarket and pocked up some 6.5" diameter x 5/8" 6061 aluminum scraps, as well as some 8.5" diameter x 3/4" 6061 aluminum scraps. That should be perfect for the adapter plates themselves, as well as the fixtures that I will need to make to hold the adapters when I am machining them. Hell, the fixtures will probably be as much work as the adapters lol.Comment

-

Have you thought about using ABS bars? It is cheap, should not have heat issues and is easy to machine. I know that is what i am going to use when i get around to making these.seien Sie größer, als Sie erscheinen

Your signature picture has been removed since it contained the Photobucket "upgrade your account" image.Comment

-

-

I have considered plastics for this. Aluminum is readily available and relatively cheap at REM centers. Plastic would be difficult to clamp and machine when it comes to the final cuts. I think that it would easily deflect in the thinner sections and get messed up. Anyway, aluminum is about as easy to machine as plastic as far as I am concerned.

Thanks! Hawaii was nice! Mega relaxing, great weather and amazing water.Comment

-

Alrighty, picture time.

So I mocked-up an adapter plate from foam core board to try to get things to fit. The FX-R 3.0 projectors are a little too complicated (geometrically) for me to bother trying to make an accurate model of them with calipers. It was easier just to go arts-and-crafts style instead. Not too bad!

The thickness of the foam core board is a little more than what I will need, so the actual bracket will hold the projector a little closer.

Here is the adapter bracket mock-up.

I went through a number of iterations. Getting the right positioning of the 4 mounting holes was a real pain. They are not symmetric about the projector center in one direction, at least as far as I can tell. That took me a few iterations to figure out!

The projector adapter plate I will make is going to look like this.

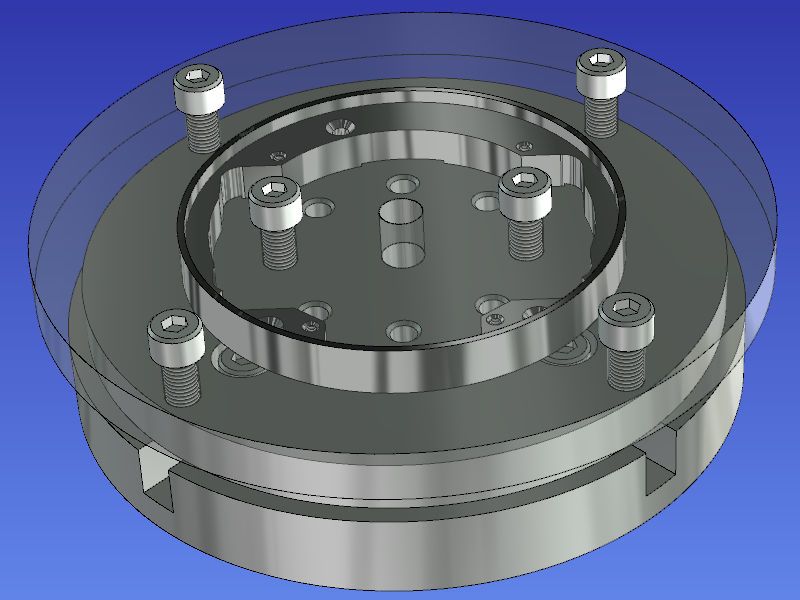

Making the bracket is a little complicated since I am doing it all on a manual mill (Bridgeport Series I). I want to apply the lessons I learned while making the first prototype bracket many months ago to get a really clean result. It requires me to machine some additional fixturing to get things done accurately on the rotary table. The fixture will let me clamp the work piece from the outside, and later from the inside once I knock the center portion out and need to cut out the perimeter. The transparent disc seen in the CAD model is the work piece blank.

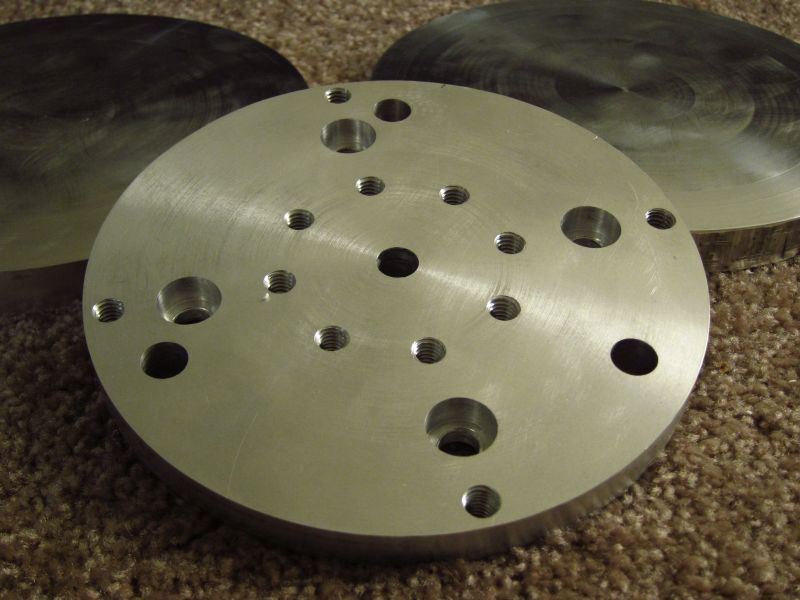

I got the fixturing plate done this weekend, and surfaced/honed the work pieces to the desired 0.689" (17.5mm). The surfacing was done on a lathe, and I used a 1000 grit water stone hone to knock off the burrs and get things flat.

Here's a closer shot of the fixture. The 3 "extra" holes are there because these discs were picked up at a local aluminum remnant/scrap center. $3.50/lb for 6061 is a lot better than what I would pay if I had the local supply house cut me pieces from raw stock. I got lucky and the scrap place had exactly what I needed!

I should be starting on the brackets themselves in the next week or two.Last edited by bmwman91; 11-25-2012, 09:38 PM.Comment

-

Comment

-

I cannot recall how far I had to cut the housings, but I can check when I get home. Unfortunately, the FX-R projectors are large enough that there is no physical way to mate them to the E30 light housings without cutting them.

The Morimoto Mini projector assemblies are small enough that I believe they can be installed without cutting. In fact, someone here is working on a kit with TRS that just involves unscrewing the stock rear reflector dish and putting the projector on with a custom adapter plate.Comment

-

So I am about 60% done machining one of the two adapter brackets. I spent ~3 hours on Sunday evening working on it. Although it does not affect functionality in ANY way, I did make one "oops" lol. Somehow I added things incorrectly in my head and set the radius of a semi-circular cut 0.100" too far out lol. No biggie though (thankfully)! I have some pictures at home that I'll post when I am back from my business trip to Austin. I am hoping to get the first one finished up this weekend so I can trial-fit it and see if any design changes need to be made.Comment

-

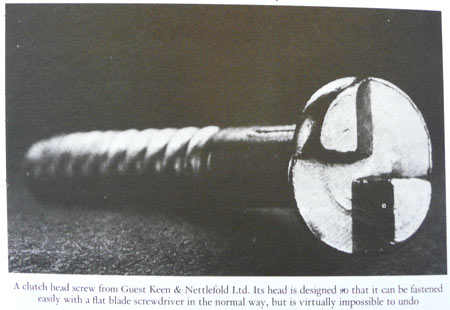

How did you get the stock projector out of the housing? My Hella ellipsoids (US Spec) have the one way screws that you can't back out like you find in public restrooms and such (couldn't think of anywhere else I've seen them).

Last edited by benyen soljax; 01-11-2013, 05:46 AM.

Last edited by benyen soljax; 01-11-2013, 05:46 AM.Comment

-

Comment

Comment