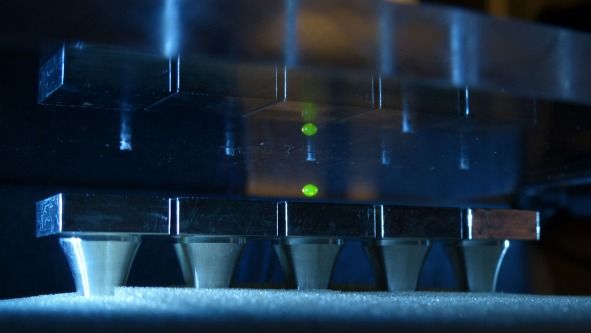

My bench fits the manifolds and Digger borrowed that pic from my posts. We do real world testing with the manifolds attached and TB pinned open.

As far as blow and draw through bench, you would only ant to blow through in a turbo situation, just like the engine it would be running on.

Usually the problem lies in people testing with too little depression, we use as much depression as we can, then convert to the typical 28". When flowing at 10" (which a lot of companies do), the numbers are skewed higher.

Not sure if boundary is being used in the same sense I am used to discussing it, but boundary "layer" has a lot to do with flow.

Does the CFD take sound waves into consideration? The runners are a good length for capturing them and curious if they help cylinder filling.

As far as blow and draw through bench, you would only ant to blow through in a turbo situation, just like the engine it would be running on.

Usually the problem lies in people testing with too little depression, we use as much depression as we can, then convert to the typical 28". When flowing at 10" (which a lot of companies do), the numbers are skewed higher.

Not sure if boundary is being used in the same sense I am used to discussing it, but boundary "layer" has a lot to do with flow.

Does the CFD take sound waves into consideration? The runners are a good length for capturing them and curious if they help cylinder filling.

Comment