So it looks like I'd also be interested in a Stock sized set of aluminum rods! These sweet looking aluminum rods turned out to be way more of a headache than they should have been. Turns out that they are 3.3mm longer than oem rods. The kid I bought them from was surprised too, I guess he didn't really know what he was selling. I'm pretty sure when the person that bought the pistons that go with these rods, they might be as upset as I was when I figured out the "customness".

Either way, I had already sold my eagle rods with intent to use these. So I have another new set of eagles and rod bearings coming to get this god damn engine together finally. Its just money right?

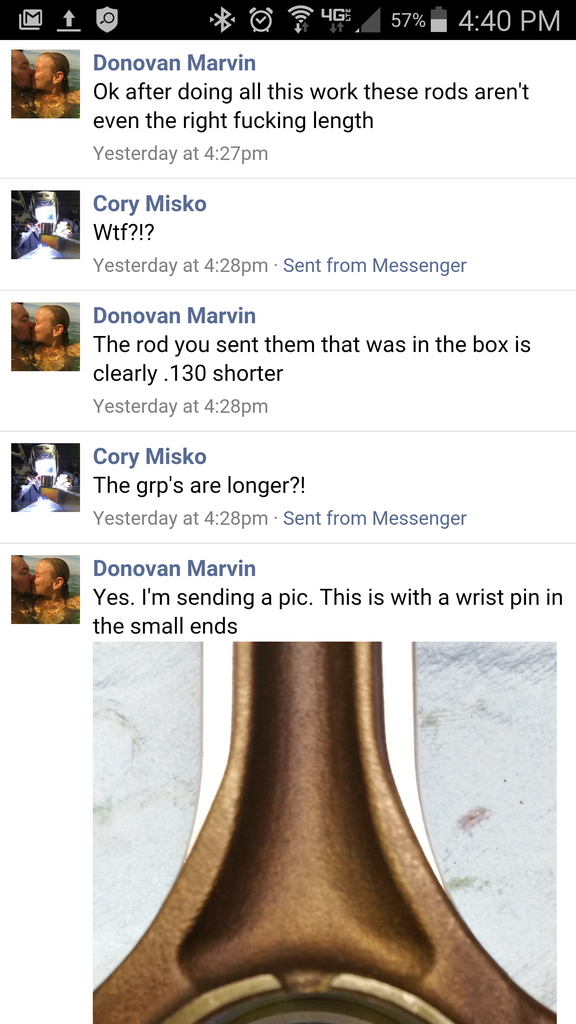

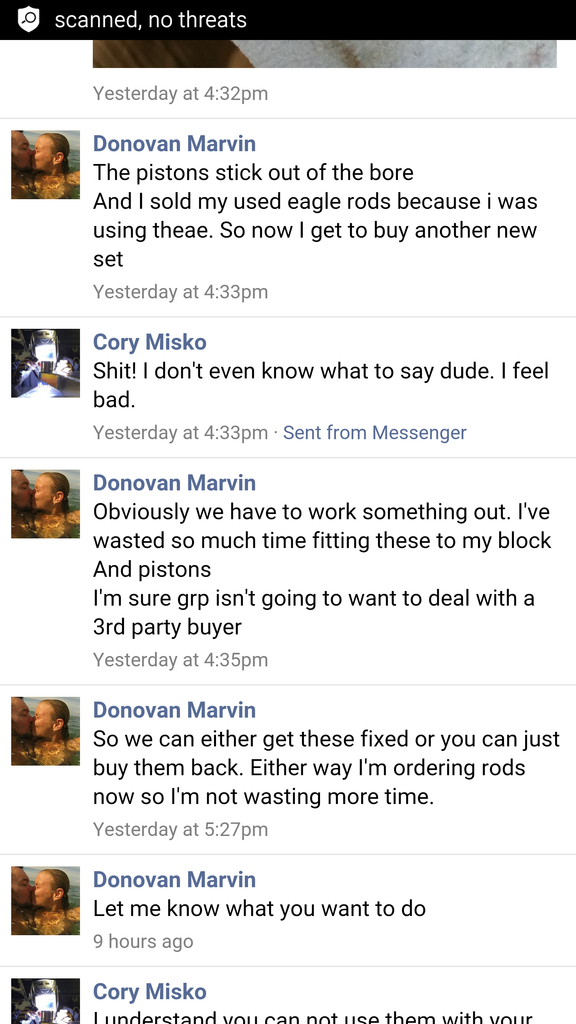

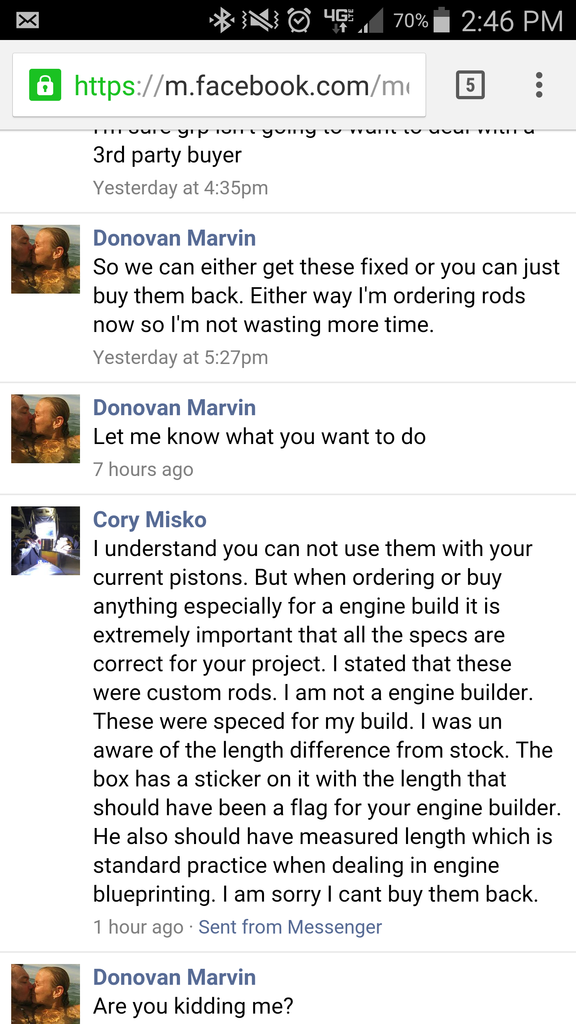

So first, the small end didn't fit in the piston. Then once they were machined down to clear, the small ends needed to be honed for the standard sized wrist pin. Not too much of a problem yet. Then the big end with the cap off wouldn't fit though the bore, maybe wouldn't have been an issue with a bigger bore, I'm at 85mm. The rod bearings are dowel pined on the cap side so I had to fixture and drill my rod bearings. Also found out the block needed to be ground down to clear the throw of the big end of the rods. With enough die griding, I was finally able to install the rod from the bottom and install the wrist pin on the deck. Then after rotating the engine to TDC, the piston was sticking out of the bore by about 3mm. If your still reading here's a couple pictures of the story...

heres the original fs thread too.

One more example of why you should never trust anything for sale.

If anyone needs some 138.3mm aluminum rods, I got you! They could definitely be used with custom made pistons. But I've been struggling to get this motor together and I'm relying on the only person I can count on now, not waiting for custom parts.

Either way, I had already sold my eagle rods with intent to use these. So I have another new set of eagles and rod bearings coming to get this god damn engine together finally. Its just money right?

So first, the small end didn't fit in the piston. Then once they were machined down to clear, the small ends needed to be honed for the standard sized wrist pin. Not too much of a problem yet. Then the big end with the cap off wouldn't fit though the bore, maybe wouldn't have been an issue with a bigger bore, I'm at 85mm. The rod bearings are dowel pined on the cap side so I had to fixture and drill my rod bearings. Also found out the block needed to be ground down to clear the throw of the big end of the rods. With enough die griding, I was finally able to install the rod from the bottom and install the wrist pin on the deck. Then after rotating the engine to TDC, the piston was sticking out of the bore by about 3mm. If your still reading here's a couple pictures of the story...

heres the original fs thread too.

One more example of why you should never trust anything for sale.

If anyone needs some 138.3mm aluminum rods, I got you! They could definitely be used with custom made pistons. But I've been struggling to get this motor together and I'm relying on the only person I can count on now, not waiting for custom parts.

Comment