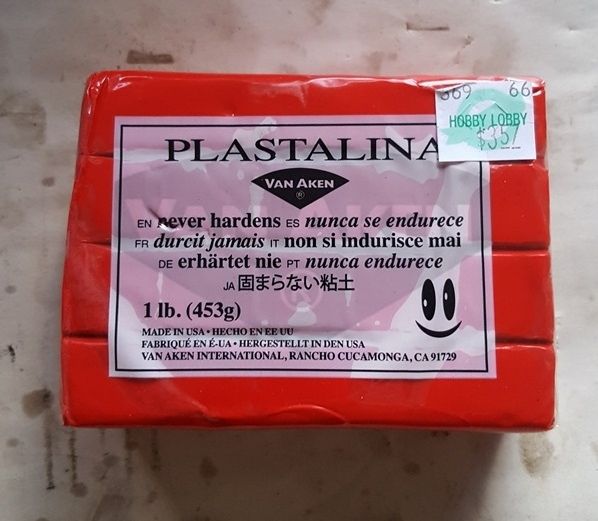

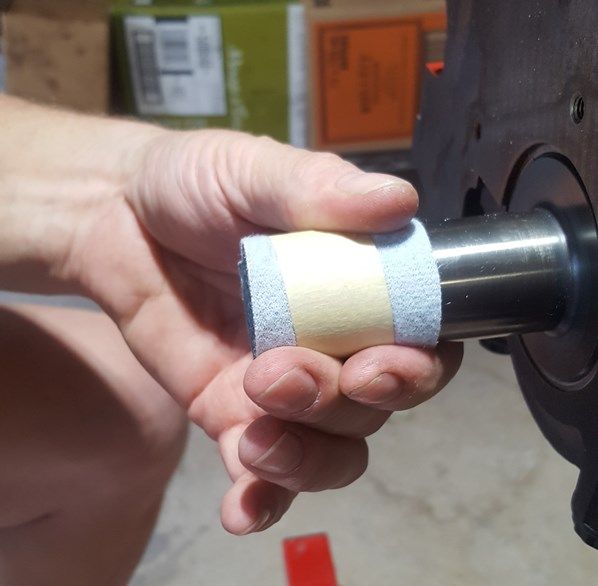

Just ordered one of these beauties. Highly recommended by my Dad, who has built everything from V8s to massive 2 story marine diesel engines. Great for checking our rotating assembly during the build.

He laughed about the bearing trouble. Apparently when installing 3 FOOT diameter bearings on marine diesels, they would blip the compressed air starter and turn the crank after every one was placed ... just to be sure. :devil:

He laughed about the bearing trouble. Apparently when installing 3 FOOT diameter bearings on marine diesels, they would blip the compressed air starter and turn the crank after every one was placed ... just to be sure. :devil:

Comment