I wanted to post up some pictures and info on my K24 swap into an 85 318i to hopefully help anyone out who is doing or thinking of doing this swap. If you don't like that I'm putting a Honda engine in a BMW, too bad, I don't care. This thread isn't for you. I'm not trying to recreate the K Power swap guide here, just show a bit of how I did it.

Swap Kit: K Power

Engine:

K24A2 from a 2006 TSX

50 degree cam gear

RSX Type S Oil Pump

Two Intake Cam sensors for better clearance from firewall (Honda Part 37510-RAA-A01)

K Power Intake Manifold

K Power Oil Pan

CX Racing 3" intake tubing - 1 90 degree J and 1 45 degree bend.

AFE 3" dry filter

Acuity TPS

Honda Element IACV

2002 RSX auto ECU with Honda K-Pro 4

2002 RSX auto harness - ATTN - need to swap the power and signal wires on TPS with this harness

M42 throttle cable

Fuel system

Stock fuel rail and injectors - may upgrade to RDX turbo, not sure

Audi 4.0 bar fuel pressure regulator integrated into filter

Stock E30 pumps for now

Cooling System:

S52 radiator

stock E30 325i reservoir

Reservoir to T junction hose: Gates 18965

Lower Heater core to back of head: Gates 19021

Upper Heater Core to coupler: Gates 18922

Coolant neck to E36 radiator hose: Gates 23320

T-stat to lower radiator hose aluminum tube: Gates 23929

Intake Manifold Elbow to Thermostat Housing: 28467

Transmision/Driveline

Getrag 250

Z3 1.9 Shift lever p/n 25117527252

318ti/318i shift lever support 25111221540

E36 325is driveshaft with replaceable U joints purchased new from Driveline Service of Portland

K Power Flywheel

330i clutch with splines to match the G250

3.25 LSD

Exhaust plan (in work):

K Power Header

3" mild steel tubing - my first time doing an exhaust so I figured I'd start with the easier material

Magnaflow 3" high flow cat

Vibrant Bottle resonator

Y pipe 3" into dual 2.25"

Dynomax 2.25" muffler

2.5" vacuum actuated cutout

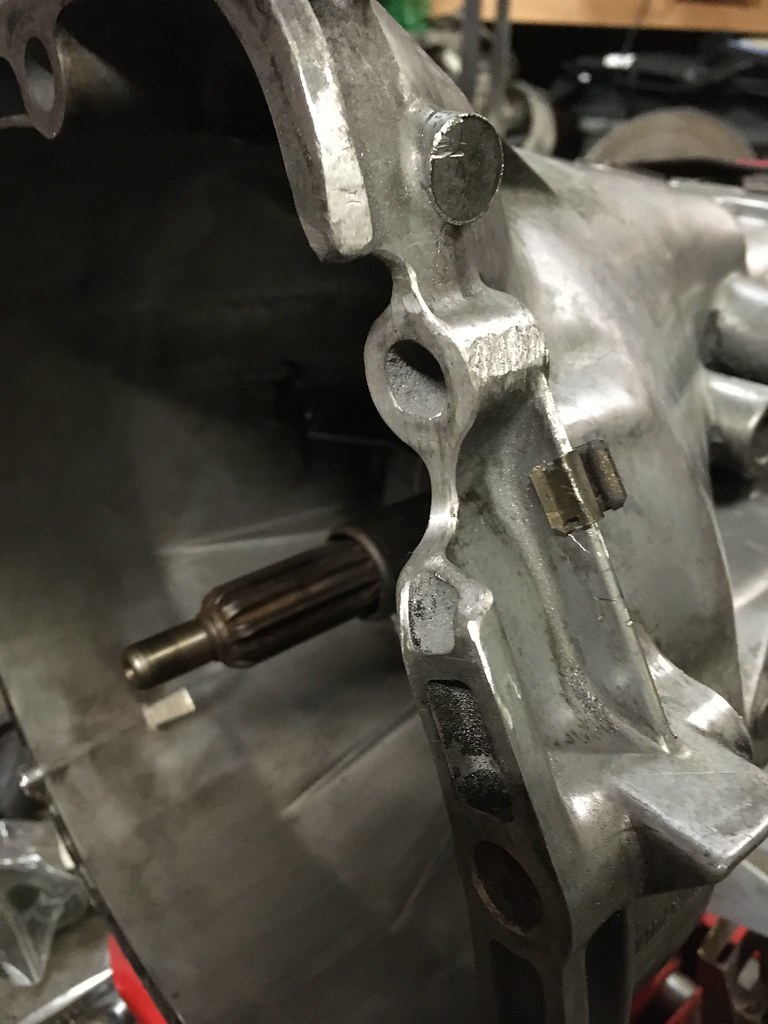

RYNV4613 by Jon Pete, on Flickr

RYNV4613 by Jon Pete, on Flickr

NDVC0195 by Jon Pete, on Flickr

NDVC0195 by Jon Pete, on Flickr

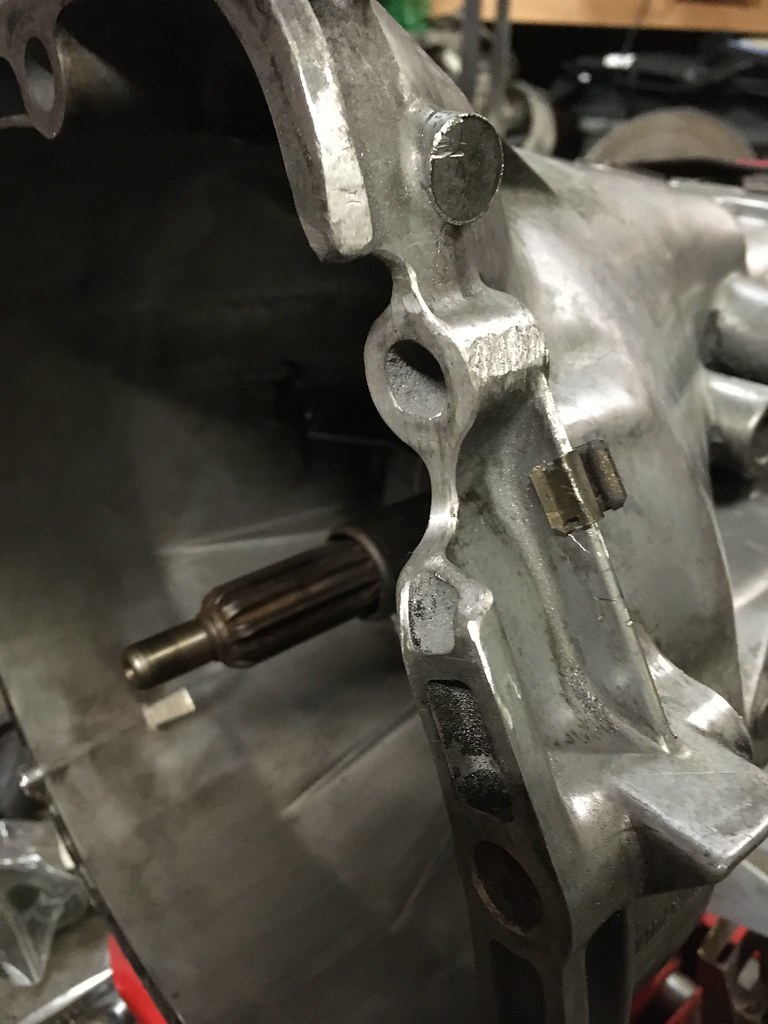

Here's the notch I cut in the transmission. It was a bit of a hack job and not very artistic but it works. I used a grinding wheel. I tried a hole saw like K Power suggests but I couldn't hold it steady.

IMG_2850 by Jon Pete, on Flickr

IMG_2850 by Jon Pete, on Flickr

Trans adaptor plate bolted up. Notice how the elbow on the intake manifold is pointing back - don't do that, it needs to point at the thermostat housing.

IMG_2853 by Jon Pete, on Flickr

IMG_2853 by Jon Pete, on Flickr

This is how close the engine sits to the firewall. It may be hard to see in this photo, but the cam sensor for the exhaust cam is so close to the fire wall that couldn't get the plug on. I ordered another intake cam sensor and swapped it. I also rotated the coolant elbow to point right at the upper heater core hose later on. You can also see the breather vents right at the heater panel, I removed it with some vice grips and an elbow and am working on a solution.

IMG_3026 by Jon Pete, on Flickr

IMG_3026 by Jon Pete, on Flickr

Hose elbow rotated. Ignore the fact that the wrong coolant sensor is installed in this picture, should be the single prong sensor for the gage.

IMG_3478 by Jon Pete, on Flickr

IMG_3478 by Jon Pete, on Flickr

Heater Hoses connected. Make sure the hose coming from the head goes to the lower heater core connection, otherwise you'll hear a weird thumping sound and have little to no heat. I also have the high pressure fuel hose attached to the stock rail. I just trimmed of a bit from the end of the rail.

IMG_3915 by Jon Pete, on Flickr

IMG_3915 by Jon Pete, on Flickr

Here's a way I found to use the stock thermostat housing, although I later decided to get an aluminum piece that rotates:

IMG_3491 by Jon Pete, on Flickr

IMG_3491 by Jon Pete, on Flickr

I ordered some 1.25" aluminum tube from McMaster Carr and made this long tube plus some couplers using an aircraft tubing flair kit I borrowed from a coworker. I cut up some stock E30 radiator hoses to make the 90s. One of them happened to transition from 1.5" to 1.25" which was perfect.

IMG_3492 by Jon Pete, on Flickr

IMG_3492 by Jon Pete, on Flickr

The upper hose uses an E36 hose plus a random gates hose I found on the shelf that happened to work perfectly

IMG_3480 by Jon Pete, on Flickr

IMG_3480 by Jon Pete, on Flickr

The lighting on this sucks, but what I'm trying to show are a few connections. The upper heater core hose goes to the aluminum heater pipe adaptor from K Power. The plastic pipe on the thermostat housing Tees off to the coolant reservoir, and also continues to the elbow on the bottom of the intake manifold. Make sure this elbow is pointing towards the thermostat housing when you install the manifold, otherwise it's a pain to reposition.

IMG_3481 by Jon Pete, on Flickr

IMG_3481 by Jon Pete, on Flickr

Exhaust in progress. K power says to use a flex pipe... I wish they had inclued an O2 sensor bung before the flange...

IMG_3530 by Jon Pete, on Flickr

IMG_3530 by Jon Pete, on Flickr

Pics of "complete" engine bay. Just needs a battery tie down.

IMG_4055 by Jon Pete, on Flickr

IMG_4055 by Jon Pete, on Flickr

IMG_4057 by Jon Pete, on Flickr

IMG_4057 by Jon Pete, on Flickr

IMG_4061 by Jon Pete, on Flickr

IMG_4061 by Jon Pete, on Flickr

IMG_4062 by Jon Pete, on Flickr

IMG_4062 by Jon Pete, on Flickr

Swap Kit: K Power

Engine:

K24A2 from a 2006 TSX

50 degree cam gear

RSX Type S Oil Pump

Two Intake Cam sensors for better clearance from firewall (Honda Part 37510-RAA-A01)

K Power Intake Manifold

K Power Oil Pan

CX Racing 3" intake tubing - 1 90 degree J and 1 45 degree bend.

AFE 3" dry filter

Acuity TPS

Honda Element IACV

2002 RSX auto ECU with Honda K-Pro 4

2002 RSX auto harness - ATTN - need to swap the power and signal wires on TPS with this harness

M42 throttle cable

Fuel system

Stock fuel rail and injectors - may upgrade to RDX turbo, not sure

Audi 4.0 bar fuel pressure regulator integrated into filter

Stock E30 pumps for now

Cooling System:

S52 radiator

stock E30 325i reservoir

Reservoir to T junction hose: Gates 18965

Lower Heater core to back of head: Gates 19021

Upper Heater Core to coupler: Gates 18922

Coolant neck to E36 radiator hose: Gates 23320

T-stat to lower radiator hose aluminum tube: Gates 23929

Intake Manifold Elbow to Thermostat Housing: 28467

Transmision/Driveline

Getrag 250

Z3 1.9 Shift lever p/n 25117527252

318ti/318i shift lever support 25111221540

E36 325is driveshaft with replaceable U joints purchased new from Driveline Service of Portland

K Power Flywheel

330i clutch with splines to match the G250

3.25 LSD

Exhaust plan (in work):

K Power Header

3" mild steel tubing - my first time doing an exhaust so I figured I'd start with the easier material

Magnaflow 3" high flow cat

Vibrant Bottle resonator

Y pipe 3" into dual 2.25"

Dynomax 2.25" muffler

2.5" vacuum actuated cutout

RYNV4613 by Jon Pete, on Flickr

RYNV4613 by Jon Pete, on Flickr NDVC0195 by Jon Pete, on Flickr

NDVC0195 by Jon Pete, on FlickrHere's the notch I cut in the transmission. It was a bit of a hack job and not very artistic but it works. I used a grinding wheel. I tried a hole saw like K Power suggests but I couldn't hold it steady.

IMG_2850 by Jon Pete, on Flickr

IMG_2850 by Jon Pete, on FlickrTrans adaptor plate bolted up. Notice how the elbow on the intake manifold is pointing back - don't do that, it needs to point at the thermostat housing.

IMG_2853 by Jon Pete, on Flickr

IMG_2853 by Jon Pete, on FlickrThis is how close the engine sits to the firewall. It may be hard to see in this photo, but the cam sensor for the exhaust cam is so close to the fire wall that couldn't get the plug on. I ordered another intake cam sensor and swapped it. I also rotated the coolant elbow to point right at the upper heater core hose later on. You can also see the breather vents right at the heater panel, I removed it with some vice grips and an elbow and am working on a solution.

IMG_3026 by Jon Pete, on Flickr

IMG_3026 by Jon Pete, on FlickrHose elbow rotated. Ignore the fact that the wrong coolant sensor is installed in this picture, should be the single prong sensor for the gage.

IMG_3478 by Jon Pete, on Flickr

IMG_3478 by Jon Pete, on FlickrHeater Hoses connected. Make sure the hose coming from the head goes to the lower heater core connection, otherwise you'll hear a weird thumping sound and have little to no heat. I also have the high pressure fuel hose attached to the stock rail. I just trimmed of a bit from the end of the rail.

IMG_3915 by Jon Pete, on Flickr

IMG_3915 by Jon Pete, on FlickrHere's a way I found to use the stock thermostat housing, although I later decided to get an aluminum piece that rotates:

IMG_3491 by Jon Pete, on Flickr

IMG_3491 by Jon Pete, on FlickrI ordered some 1.25" aluminum tube from McMaster Carr and made this long tube plus some couplers using an aircraft tubing flair kit I borrowed from a coworker. I cut up some stock E30 radiator hoses to make the 90s. One of them happened to transition from 1.5" to 1.25" which was perfect.

IMG_3492 by Jon Pete, on Flickr

IMG_3492 by Jon Pete, on FlickrThe upper hose uses an E36 hose plus a random gates hose I found on the shelf that happened to work perfectly

IMG_3480 by Jon Pete, on Flickr

IMG_3480 by Jon Pete, on FlickrThe lighting on this sucks, but what I'm trying to show are a few connections. The upper heater core hose goes to the aluminum heater pipe adaptor from K Power. The plastic pipe on the thermostat housing Tees off to the coolant reservoir, and also continues to the elbow on the bottom of the intake manifold. Make sure this elbow is pointing towards the thermostat housing when you install the manifold, otherwise it's a pain to reposition.

IMG_3481 by Jon Pete, on Flickr

IMG_3481 by Jon Pete, on FlickrExhaust in progress. K power says to use a flex pipe... I wish they had inclued an O2 sensor bung before the flange...

IMG_3530 by Jon Pete, on Flickr

IMG_3530 by Jon Pete, on FlickrPics of "complete" engine bay. Just needs a battery tie down.

IMG_4055 by Jon Pete, on Flickr

IMG_4055 by Jon Pete, on Flickr IMG_4057 by Jon Pete, on Flickr

IMG_4057 by Jon Pete, on Flickr IMG_4061 by Jon Pete, on Flickr

IMG_4061 by Jon Pete, on Flickr IMG_4062 by Jon Pete, on Flickr

IMG_4062 by Jon Pete, on Flickr

Comment