This is the borescope I used. $200 isn't cheap, but it's super handy to be able to aim it. Professional ones are a LOT more expensive. Also, the little diagrams were made by me...the borescope does not come with software to do that.

https://www.amazon.com/gp/product/B00GY7C9ZW/

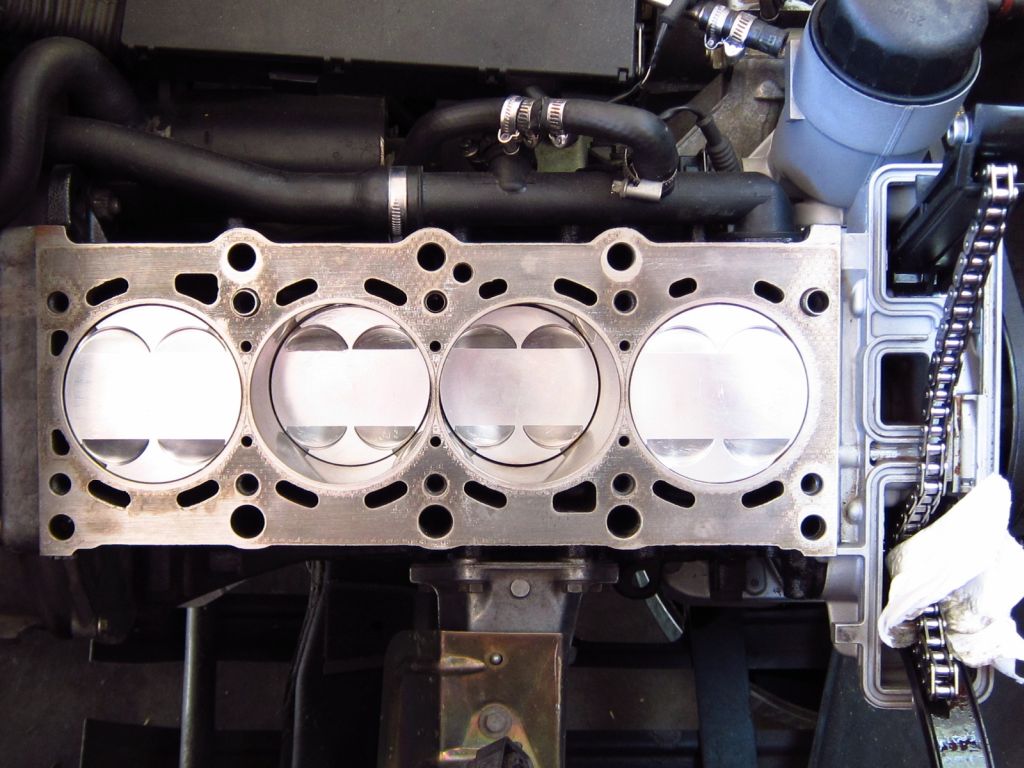

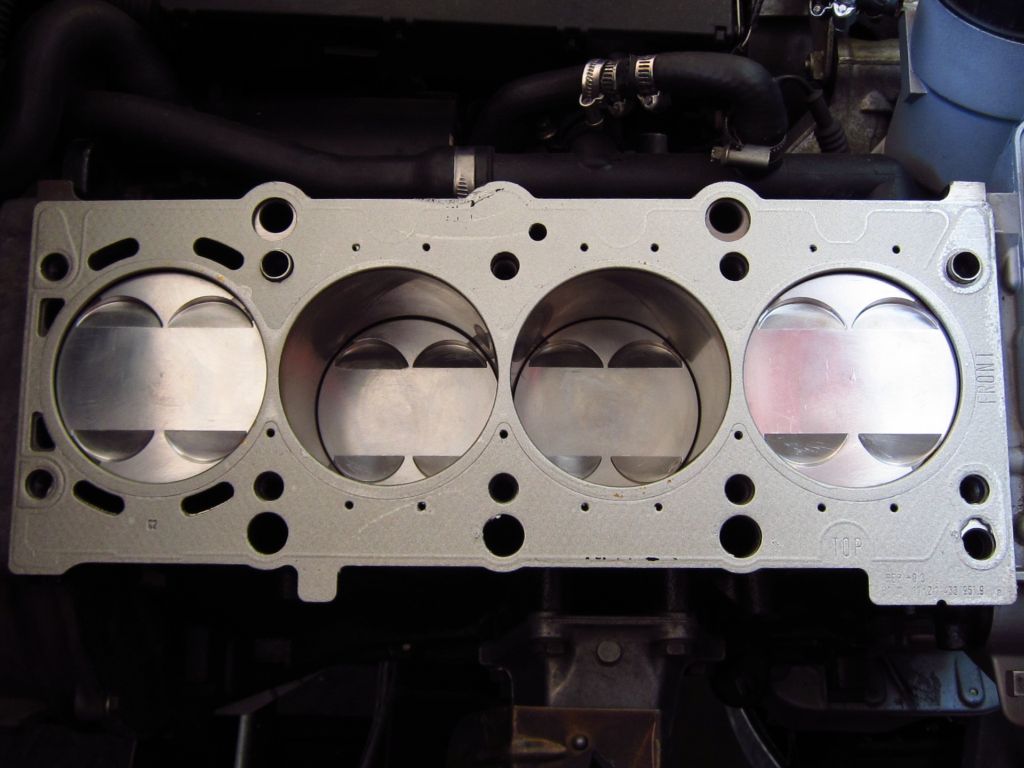

I will be stripping the head (maybe the whole engine) over the next week or so, and I will get a look at the ports then. Fingers are crossed that there are no cracks!

I'll get a look at the injector wiring to see if anything is amiss there. It's unlikely, but worth looking. Earlier in the year I was doing a lot of data logging to get the tune dialed in, and I had EGT probes for each cylinder. As far as I could tell, they were all within 5% of one another. I am having Sssquid clean and flow match the injectors anyway, though.

https://www.amazon.com/gp/product/B00GY7C9ZW/

I will be stripping the head (maybe the whole engine) over the next week or so, and I will get a look at the ports then. Fingers are crossed that there are no cracks!

I'll get a look at the injector wiring to see if anything is amiss there. It's unlikely, but worth looking. Earlier in the year I was doing a lot of data logging to get the tune dialed in, and I had EGT probes for each cylinder. As far as I could tell, they were all within 5% of one another. I am having Sssquid clean and flow match the injectors anyway, though.

Comment