For those who considered this swap I share my findings on fitting an e36 cluster in an e30. My reason for the swap is to have a bit more updated look and the 8k RPM gauge to go with the s52 in my car. I dug into the ETM of both cars and there is no reason for an e36 cluster to not work in and e30 with M20 so you don't have to have an engine / DME from an e36 for doing this.

I looked around but couldn't find any comparison between the 2 clusters to see how it could physically fit so I went ahead and got myself one.

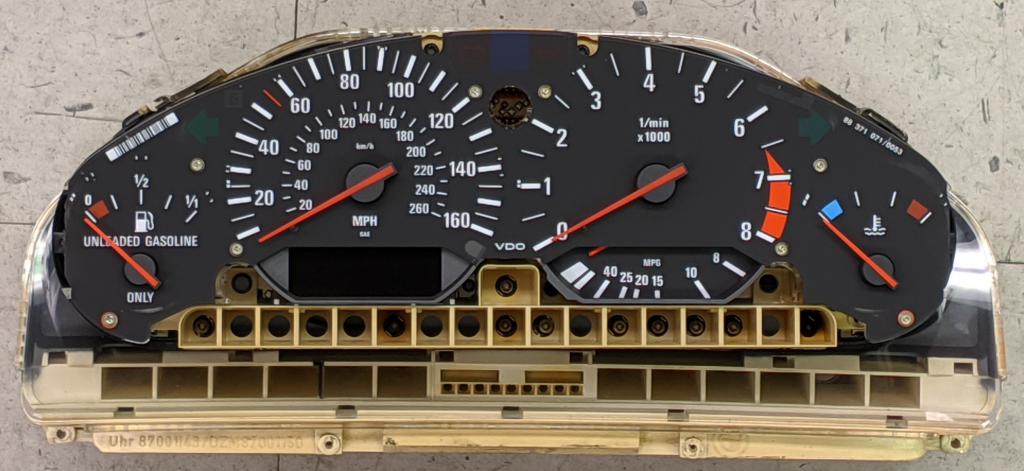

Some size comparison:

As you can see an obvious challenge is to fit a sort of round thing into a sort of rectangular (trapezoid to be exact) hole but luckily the E36 cluster is smaller so it fits. I thought about swapping the electronics and gauges over but unlike the E30 cluster where each gauge is separate the E36 one is one piece and they don't line up with the E30 gauges so that plan went out the window.

Another possibility was to try to squeeze the E36 cluster inside the shell of the E30 cluster. The next picture doesn't show it well but it seemed like it could fit.

I decided to sacrifice the old ETA cluster. After a couple days of cutting, trimming and sanding I got this far:

The entire cluster fits inside the area where the gauges were. This gives me the opportunity to use the space below for some custom stuff like oil temperature, oil pressure, exact coolant temperature, voltage, etc.

I also created a cross reference spreadsheet for wiring but I won't share that until I can confirm that it's 100% correct.

I spent some more time trimming the plastic and this is where it stands right now:

I will 3D print a cover for the crescent shaped holes to pretty it up. Another problem I have right now is the trip reset button. It does not line up with the hole on the clear front cover. My current plan is to get rid of the stud, plug the hole on both the gauges and the cover and relocate the button somewhere else. It is just an electronic button unlike on the E30 cluster where the reset button is mechanical. The plug for the gauge will be a 3D printed plastic piece but I'm planning on using clear epoxy on the front cover then sanding it down flat and polishing it to try to make it disappear. I've never done that before so if anybody has an advice on it or has a better idea, please, let me know! Thanks a lot in advance!

I looked around but couldn't find any comparison between the 2 clusters to see how it could physically fit so I went ahead and got myself one.

Some size comparison:

As you can see an obvious challenge is to fit a sort of round thing into a sort of rectangular (trapezoid to be exact) hole but luckily the E36 cluster is smaller so it fits. I thought about swapping the electronics and gauges over but unlike the E30 cluster where each gauge is separate the E36 one is one piece and they don't line up with the E30 gauges so that plan went out the window.

Another possibility was to try to squeeze the E36 cluster inside the shell of the E30 cluster. The next picture doesn't show it well but it seemed like it could fit.

I decided to sacrifice the old ETA cluster. After a couple days of cutting, trimming and sanding I got this far:

The entire cluster fits inside the area where the gauges were. This gives me the opportunity to use the space below for some custom stuff like oil temperature, oil pressure, exact coolant temperature, voltage, etc.

I also created a cross reference spreadsheet for wiring but I won't share that until I can confirm that it's 100% correct.

I spent some more time trimming the plastic and this is where it stands right now:

I will 3D print a cover for the crescent shaped holes to pretty it up. Another problem I have right now is the trip reset button. It does not line up with the hole on the clear front cover. My current plan is to get rid of the stud, plug the hole on both the gauges and the cover and relocate the button somewhere else. It is just an electronic button unlike on the E30 cluster where the reset button is mechanical. The plug for the gauge will be a 3D printed plastic piece but I'm planning on using clear epoxy on the front cover then sanding it down flat and polishing it to try to make it disappear. I've never done that before so if anybody has an advice on it or has a better idea, please, let me know! Thanks a lot in advance!

Comment