The Welding Thread

Collapse

X

-

sigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforge -

Pantalones, when you go to replace your front cover lenses, you can just get the standard 4 1/2" x 5 1/4" flat plates, the one you have on there now is for the W60 ADF filter Jackson makes. They're salty too, much more than the standard ones.

Eric, are you cleaning it up with a SS brush before welding as well? Looks like it, just making sure, a Mild Steel brush will contaminate the surface and make your welds terrible.

Are you running a WP-17 150A torch on that machine and are you running pure tungsten as well?Comment

-

WP-26 FTW! 2% lathinated.......yeaaaah buddy.Pantalones, when you go to replace your front cover lenses, you can just get the standard 4 1/2" x 5 1/4" flat plates, the one you have on there now is for the W60 ADF filter Jackson makes. They're salty too, much more than the standard ones.

Eric, are you cleaning it up with a SS brush before welding as well? Looks like it, just making sure, a Mild Steel brush will contaminate the surface and make your welds terrible.

Are you running a WP-17 150A torch on that machine and are you running pure tungsten as well?sigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforgeComment

-

I was of the opinion that %2 lanthinated isn't very good for the old transistor boxes. I have a pack of them, but I bought some green tips just for this project.

The machine is archaic, it has the foot pedal and a knob (numbers worn off) for current.

I was having a problem even getting the pool started. once it got a little shiney , i'd dip and it would just goo everywhere. I was using a 3/32" tungston, 1/8" rod and I think it was a 19 torch.

Thanks for the tips above, I thought I was pretty good in school, passing objectives in one or two passes, but I got a big slice of humble pie with this project!!!

Here are some of my work from school... thinner stock, inverter machine, much more comfortable.

3G aluminum:

1G lapjoint. No filler, just glueing to sheet's together.

Pipe to plate mild steel. First attempt at running a bead on round items...

Red - Yes, brushed with a SS brush, but I could still see the oxide burning up, should I brush through it?Comment

-

Red is 2% Thoriated, I usually tell our customers to run the Green Pure ones on the older rectifier machines and 2% Thoriated or 2% Lanthanated on the newer Inverter machines.I was of the opinion that %2 lanthinated isn't very good for the old transistor boxes. I have a pack of them, but I bought some green tips just for this project.

The machine is archaic, it has the foot pedal and a knob (numbers worn off) for current.

I was having a problem even getting the pool started. once it got a little shiney , i'd dip and it would just goo everywhere. I was using a 3/32" tungston, 1/8" rod and I think it was a 19 torch.

Thanks for the tips above, I thought I was pretty good in school, passing objectives in one or two passes, but I got a big slice of humble pie with this project!!!

Here are some of my work from school... thinner stock, inverter machine, much more comfortable.

3G aluminum:

1G lapjoint. No filler, just glueing to sheet's together.

Pipe to plate mild steel. First attempt at running a bead on round items...

Red - Yes, brushed with a SS brush, but I could still see the oxide burning up, should I brush through it?

I think if you were to preheat like IronFreak said, that may help to burn out any contaminates in the material as well as getting you a more distinguished puddle.

Those welds from school are fantastic, esp. the 3G Tig Alum, nicely done!Comment

-

You can't avoid it entirely, but it's a bad habit a lot of welders have. It's just due to running too hot/fast and not shielding properly. I thought this was pretty neat...

That is a replacement... The original one was flat, and this one was only $10. I was already grabbing a tank refill so I didn't care.

The original one was flat, and this one was only $10. I was already grabbing a tank refill so I didn't care.

And Eric, Pre-heat bud... The general rule of thumb is 1 AMP per .001" and with aluminum that could go up 10%.Comment

-

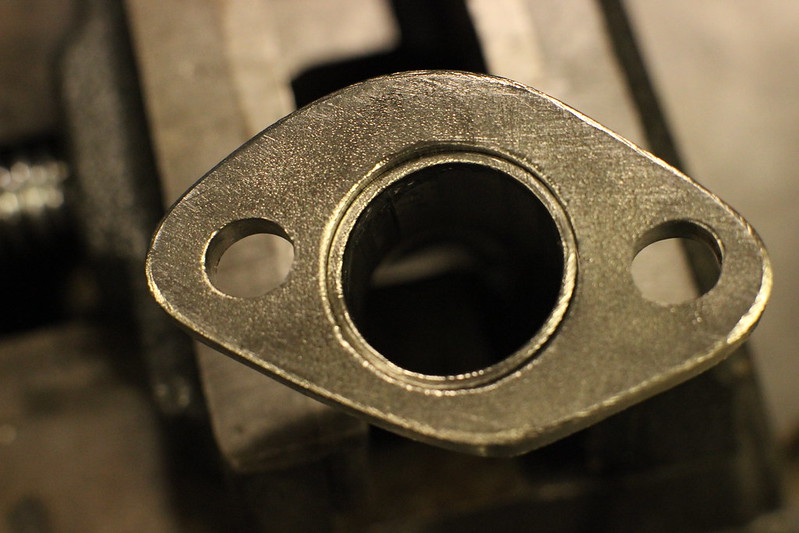

So, I wasn't just playing around with stainless for nothing... Here are a few photos of my current project.

IMG_0126 by Los Pantelones!, on Flickr

IMG_0126 by Los Pantelones!, on Flickr

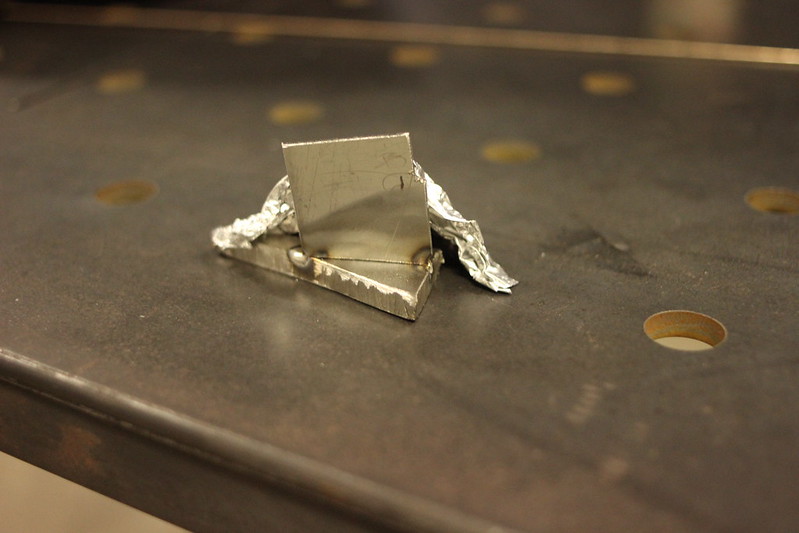

IMG_0128 by Los Pantelones!, on Flickr

IMG_0128 by Los Pantelones!, on Flickr

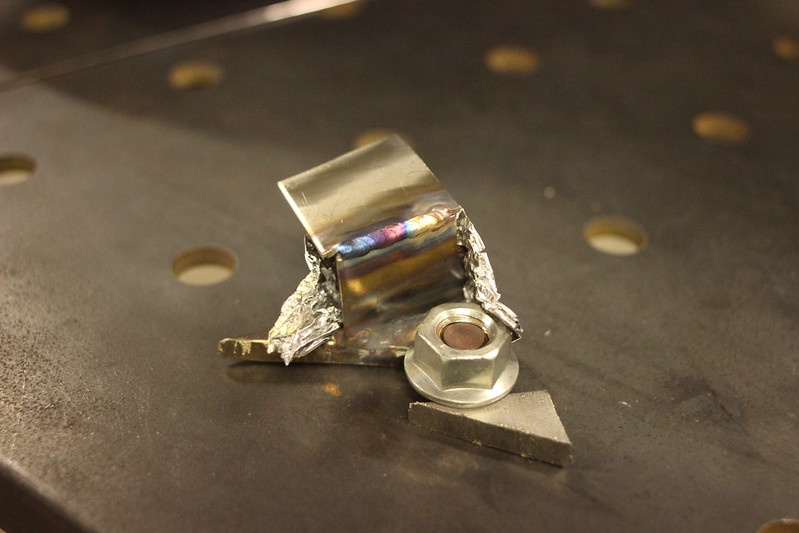

IMG_0129 by Los Pantelones!, on Flickr

IMG_0129 by Los Pantelones!, on Flickr

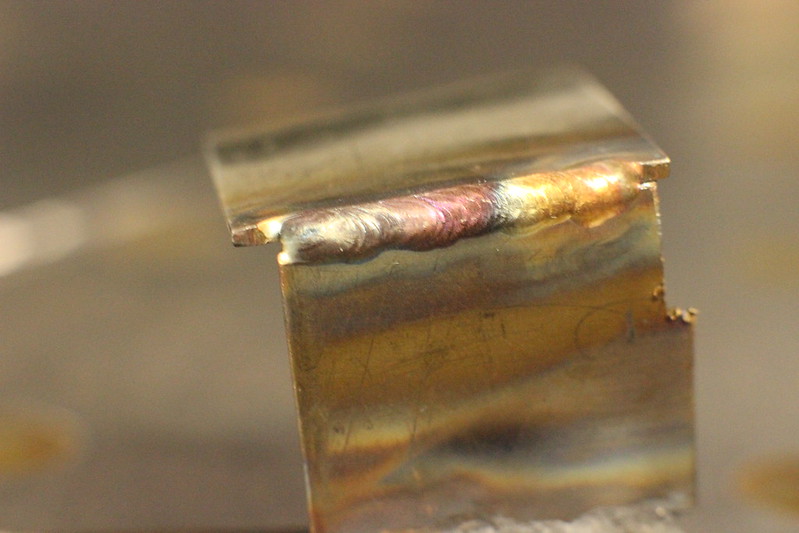

IMG_0131 by Los Pantelones!, on Flickr

IMG_0131 by Los Pantelones!, on Flickr

I ran less amps for the fillet on the exhaust and it turned out better. The silicon bronze rod is interesting to work with, and I am glad that I used it. I took the idea from the Burns Stainless web site, and I guess they stole it from NASCAR.

IMG_0137 by Los Pantelones!, on Flickr

IMG_0137 by Los Pantelones!, on Flickr

IMG_0138 by Los Pantelones!, on Flickr

IMG_0138 by Los Pantelones!, on Flickr

IMG_0140 by Los Pantelones!, on Flickr

IMG_0140 by Los Pantelones!, on Flickr

I really have been enjoying how much stick out you can get away with using a large gas lens ;)

IMG_0141 by Los Pantelones!, on Flickr

IMG_0141 by Los Pantelones!, on Flickr

Comment

-

Silicone bronze is a really cool filler. Not for structural purposes but for us car guys it's great. Has significantly less shrinking properties then the majority of your other fillers.sigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforgeComment

-

Welded things this weekend.

sigpic

sigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforgeComment

-

Neither of my flanges warped after welding, and I think that is also part of the reason why Burns recommends it. Fillets pull all sorts of nasty, even when you run a perfect bead, and have the part in a jig.

Looks nice :)

What do you use for a purging set up? Another tank and reg? I was going to order a dual regulator, but they are out of stock until may... :( I ordered Solar Flux B for the time being, and it should be here this week.Comment

-

I have a Smith dual flow gauge. Purge setup is pretty basic. 5-10cfm through a hose and I have a diffuser from a smaller torch threaded into the end. Just use tin foil. Have purge blocks for t3/t4 flanges and 38/44 wastegates.sigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforgeComment

-

Little time Lapse I did welding up one of the runners.

sigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforgeComment

-

thats....really....cool.sigpic

Gigitty Gigitty!!!!

88 cabrio becoming alpina b6 3.5s transplanted s62

92 Mtech 2 cabrio alpinweiss 770 code

88 325ix coupe manual lachsilber/cardinal

88 325ix coupe manual diamondschwartz/natur

87 e30 m3 for parts lachsilber/cardinal(serial number 7)

12 135i M sport cabrio grey/blackComment

-

Bonus! One of the 300 cu ft ranks has 750 psi of argon left in it. The other registers nothing. Argon doesn't go bad, does it?Si vis pacem, para bellum.

New Hawtness: 1995 540i/6 Claptrap

Defunct too: Cirrusblau m30 Project

Defunct (sold): Alta Vista

79 Bronco SHTF BuildComment

-

No, use that up! I'd kill that in an afternoon hahahahasigpic

Rebellion Forge Custom Fabrication

1988 325is - TrackRat in progress

Instagram @rebellionforgeComment

Comment