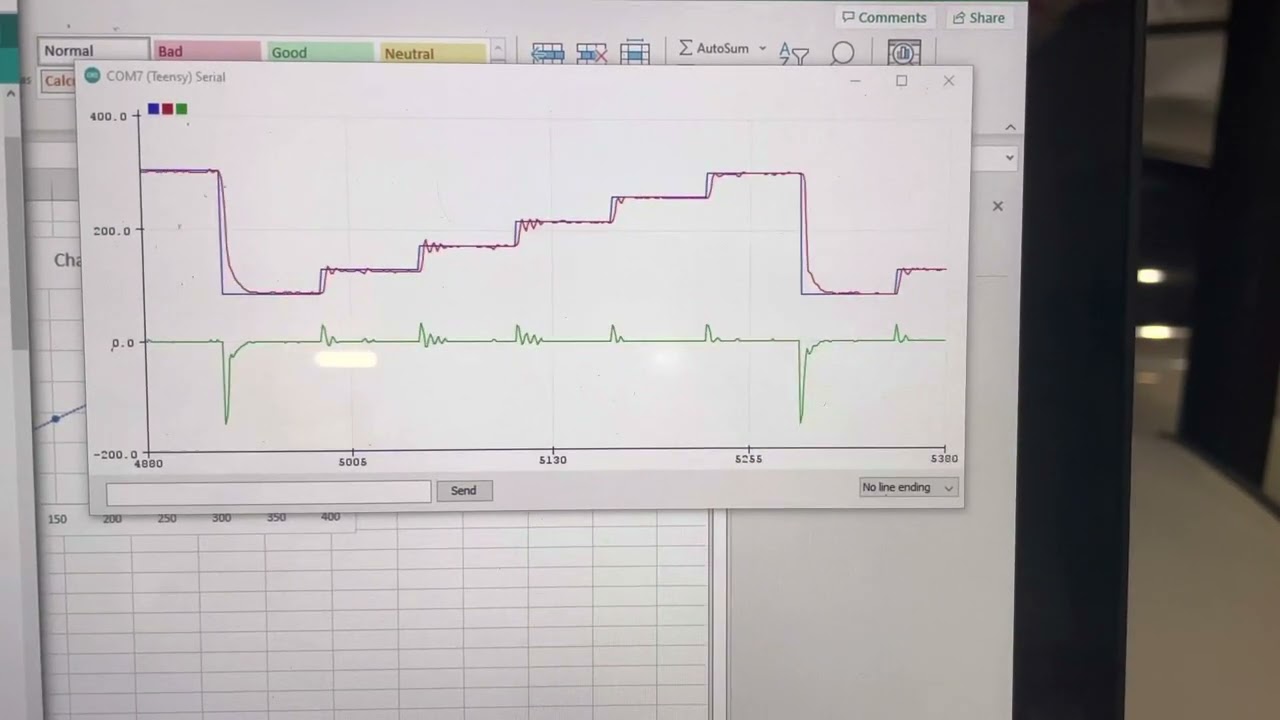

Here's a quick and dirty model of the VGT response, comparing the previous algorithm to the new one. Qualitatively, it ramps the vanes open as soon as boost starts to build, and opens them fully once the boost target is reached. The old version kept the vanes fully closed until MAP gets to 65% of the boost target, then ramps to full open. So, kind of the opposite approach. There's a lot more nuance than that, but that's the simplest explanation. In practice I think this means I can get more aggressive when I initially close the vanes.

To add one level of nuance: the "most-closed" vane position is currently engine speed-dependent and has been tuned seat-of-my-pants. I shouldn't close the vanes the same level at 5000rpm that I would at 3000rpm, the flow would obviously choke more at 5000rpm. The concept here is to try to find this choke point empirically: measure things at a specific engine speed like initial boost response rate when going WOT, or monitor AFR, adjust the most-closed position, repeat. There's going to be an ideal "most-closed" position for a given engine speed where the initial boost response is best, and significant choking of the mass flow will show up in AFR. I have a feeling the point of best response is similar to the point where the flow starts to choke. Initial boost response vs. most-closed setting should have a hump shape, need to find the setting that gives us the peak.

Using the speed-density concept, should be able to then estimate relative mass flow from that initial response level, and map out in two or three dimensions how to open the vanes. Adjust from that calibrated ideal "most closed" point proportionally to engine speed, MAP, and VE (from the fuel table) and that should give a decent starting point for the VGT calibration. There will be a little error since VE table is set to richen the mixture, but heck, I could even correct that out by monitoring AFR. Might have to correct for EGT too. In any case, the math/algorithm is model-based, but model will be calibrated to match the real world as much as possible.

Example: Hypothetically I measure initial boost response a bunch of times at 3000rpm when MAP = baro (80kPa for me), and find the ideal most-closed nozzle area is 7cm^2. Now I want to calculate most-closed nozzle position at 5000rpm:

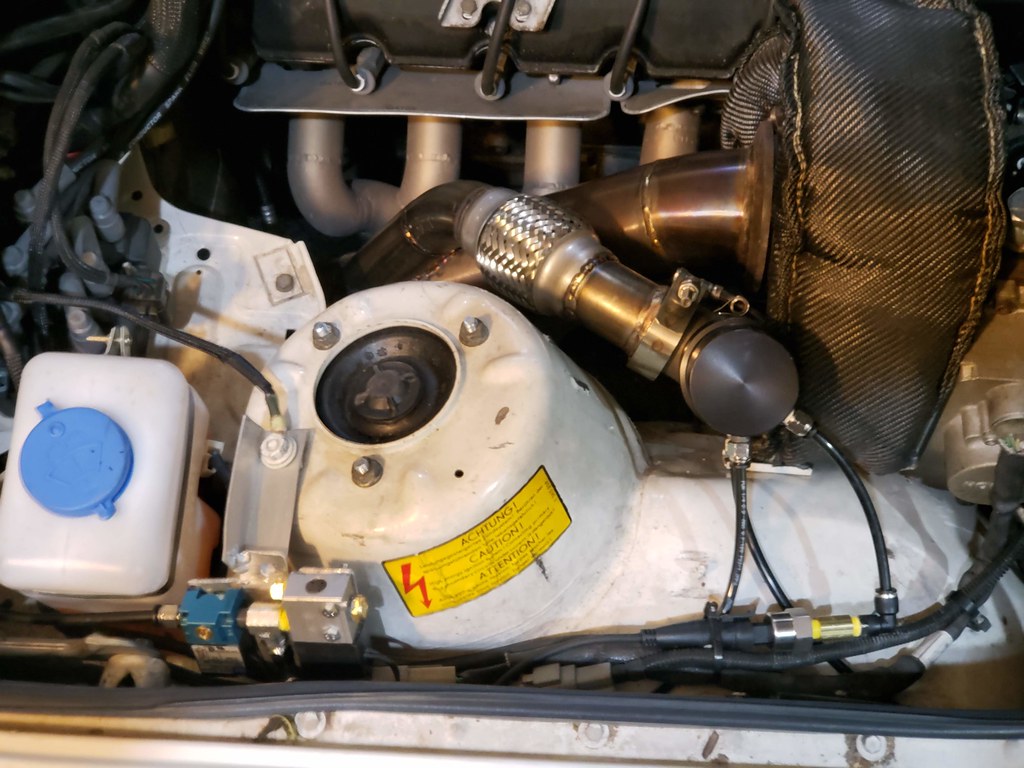

VGT Algorithm analysis by Mikey Antonakakis, on Flickr

VGT Algorithm analysis by Mikey Antonakakis, on Flickr

To add one level of nuance: the "most-closed" vane position is currently engine speed-dependent and has been tuned seat-of-my-pants. I shouldn't close the vanes the same level at 5000rpm that I would at 3000rpm, the flow would obviously choke more at 5000rpm. The concept here is to try to find this choke point empirically: measure things at a specific engine speed like initial boost response rate when going WOT, or monitor AFR, adjust the most-closed position, repeat. There's going to be an ideal "most-closed" position for a given engine speed where the initial boost response is best, and significant choking of the mass flow will show up in AFR. I have a feeling the point of best response is similar to the point where the flow starts to choke. Initial boost response vs. most-closed setting should have a hump shape, need to find the setting that gives us the peak.

Using the speed-density concept, should be able to then estimate relative mass flow from that initial response level, and map out in two or three dimensions how to open the vanes. Adjust from that calibrated ideal "most closed" point proportionally to engine speed, MAP, and VE (from the fuel table) and that should give a decent starting point for the VGT calibration. There will be a little error since VE table is set to richen the mixture, but heck, I could even correct that out by monitoring AFR. Might have to correct for EGT too. In any case, the math/algorithm is model-based, but model will be calibrated to match the real world as much as possible.

Example: Hypothetically I measure initial boost response a bunch of times at 3000rpm when MAP = baro (80kPa for me), and find the ideal most-closed nozzle area is 7cm^2. Now I want to calculate most-closed nozzle position at 5000rpm:

- Let's say VE at 3000rpm is 86%, and at 5000rpm 98%

- I use that to calculate the most-closed area at 5000rpm: 7cm^2 * (5000rpm / 3000rpm) * (98% / 86%), gives 13.3cm^2

- As boost rises at 5000rpm, I now adjust my VGT nozzle size position proportional to boost:

- Let's say I'm now at 130kPa MAP and baro is still 80kPa:

- 13.3cm^2 * 130kPa / 80kPa gives 21.6cm^2.

- Let's say I'm now at 130kPa MAP and baro is still 80kPa:

VGT Algorithm analysis by Mikey Antonakakis, on Flickr

VGT Algorithm analysis by Mikey Antonakakis, on Flickr

Comment