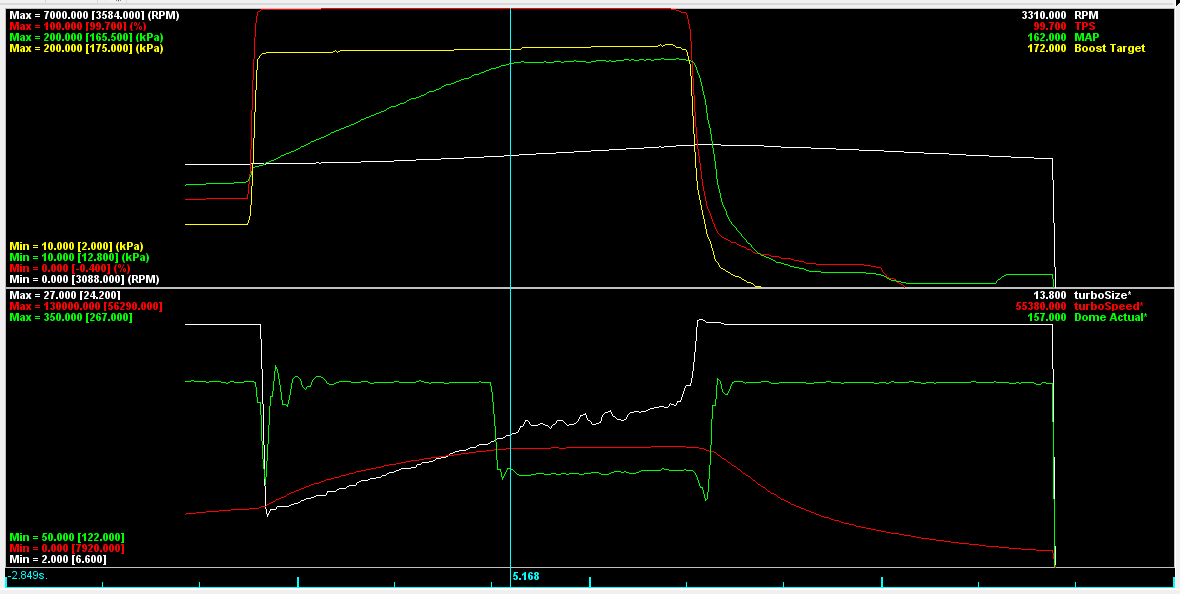

I think it's working!! I tried to record two quick pulls, but missed the fun one (1st-3rd all the way to redline and part of 4th, so maybe 20-120mph). Here's the less-fun one, just a 2nd gear pull, MAP nearly perfectly on boost target. VGT tuning can be more aggressive, and I think I can finally stop debugging it and start tuning it!

There's still a little blip in the dome target on tip-in, that one will be a little harder to avoid but it's not a big deal.

dome and VGT working 2022-06-02 by Mikey Antonakakis, on Flickr

dome and VGT working 2022-06-02 by Mikey Antonakakis, on Flickr

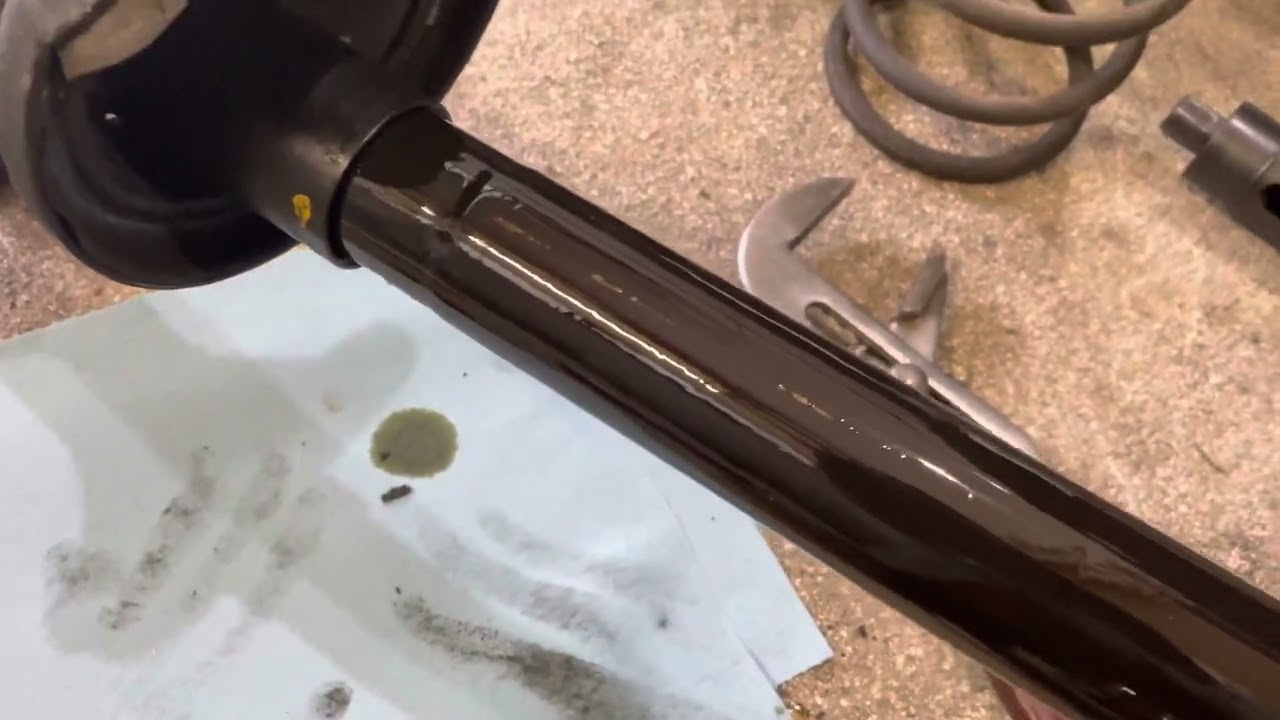

There's still a little blip in the dome target on tip-in, that one will be a little harder to avoid but it's not a big deal.

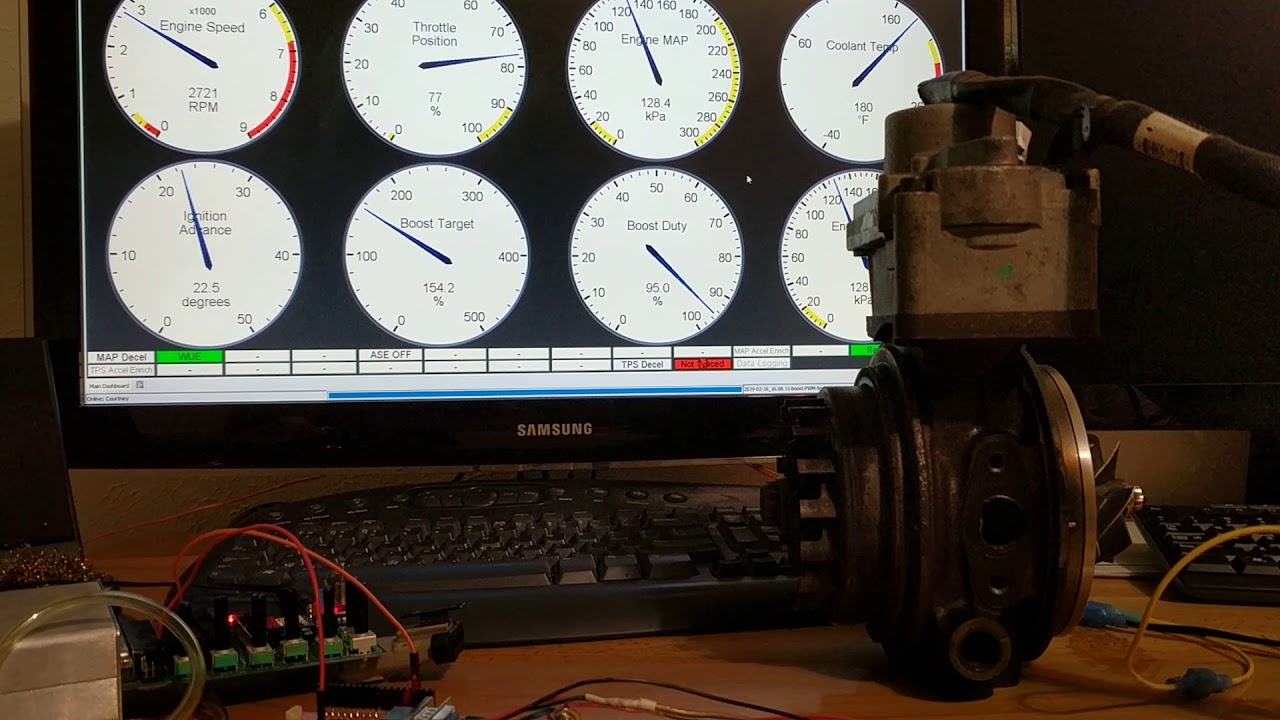

dome and VGT working 2022-06-02 by Mikey Antonakakis, on Flickr

dome and VGT working 2022-06-02 by Mikey Antonakakis, on Flickr

Comment