One more big item is checked off now. I got the car back from the upholstery shop this morning. The headliner is installed, the front upper console is rewrapped, and the A-pillar trim pieces are also enjoying some new covering.

Now that I have the car back and have taken a good look at the workmanship, I can recommend this shop to others on here. They were professional, friendly, fast, and fairly priced (definitely not inexpensive, but they made every effort to come in under the quoted hours of labor and the quality of the work is exactly what I would have hoped for). It took them 1 week from drop-off to completion since they have about a dozen cars in the shop right now. Apparently a lot of BMW's of this era are coming through lately.

https://www.yelp.com/biz/wardell-aut...ps-santa-clara

The front upper console looks as good as new now. They were able to rewrap it with a single piece of textured vinyl, which is awesome since they had initially thought that they would need to sew together some pieces for the visor recesses. Thankfully, a little bit of heat and stretching got it all laid down securely! They did leave some overage in the places where it wraps onto the body, since I had said that I would be doing the final trimming and reassembly after the glass gets reinstalled (that is next on my list).

The A-pillar trim pieces also look nice and new. Same deal with the overage...I will trim it once it is installed.

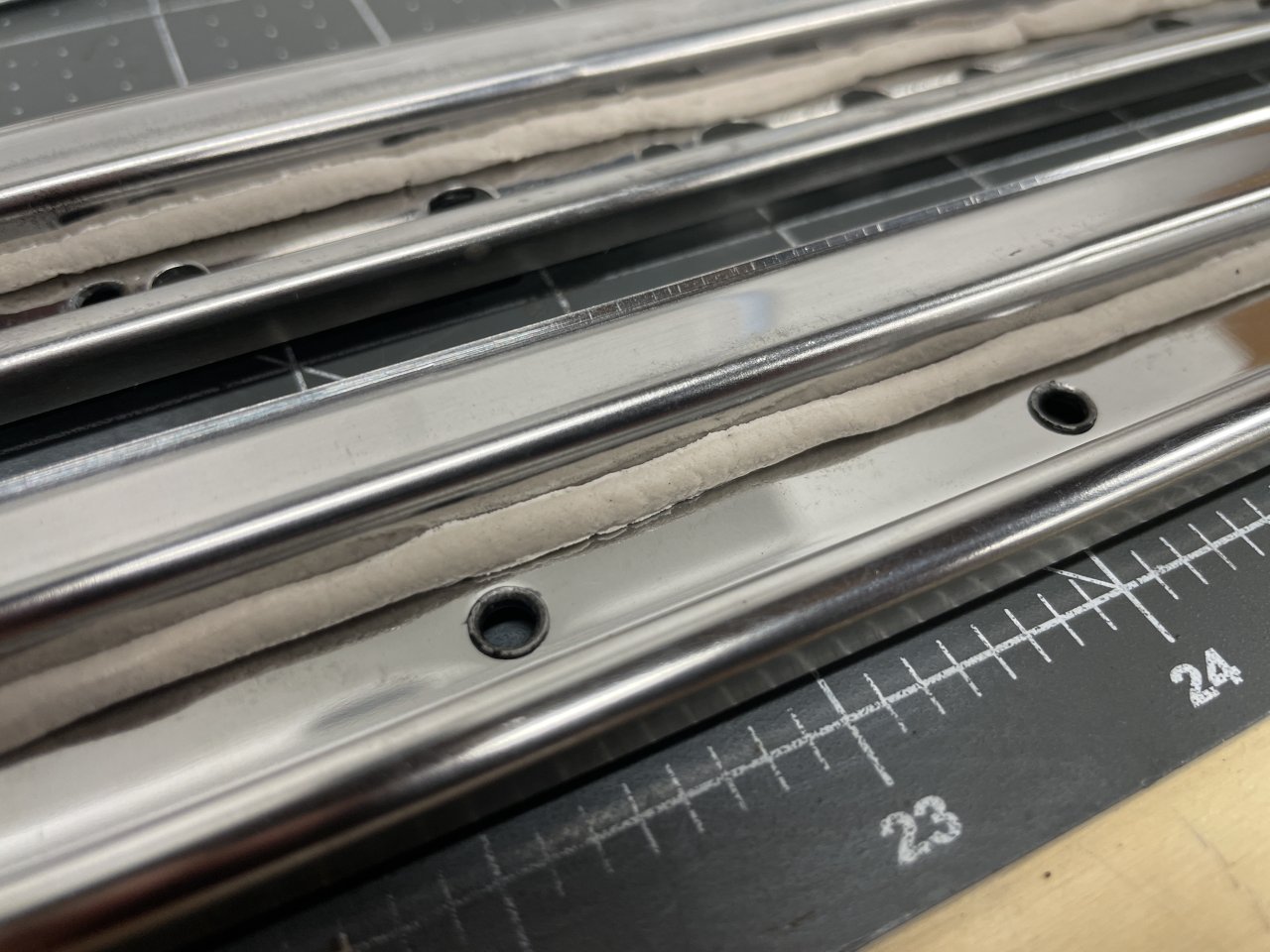

My new sunroof headliner panel is looking really great.

I was impressed that the shop even put some tape over the door sills to protect my new paint from shoes while they were working on the car.

Much to my relief, the tight corners in the sunroof opening came out perfectly with no wrinkles or creases.

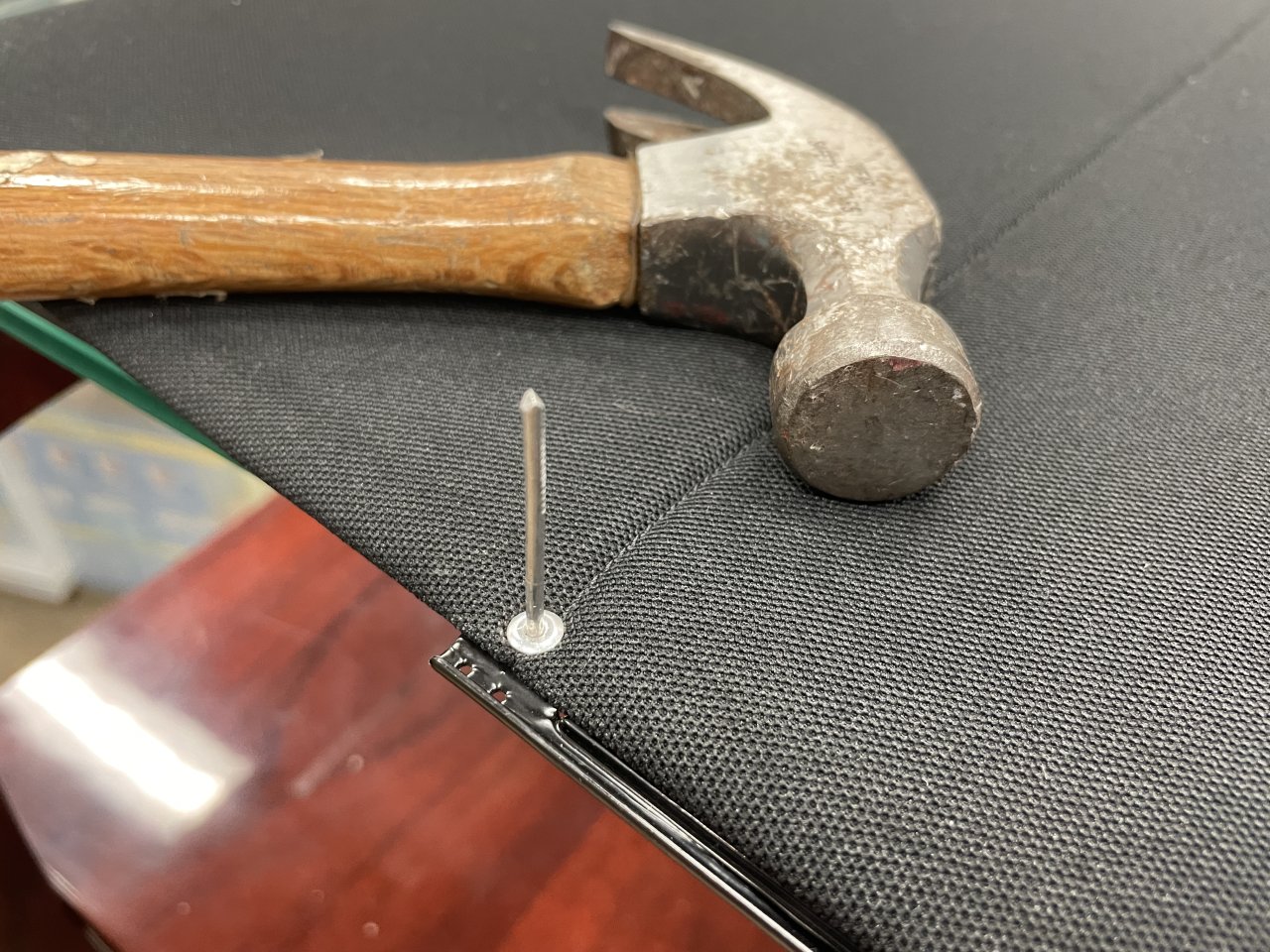

This new headliner really breathes some new life into the car, and honestly a lot of that "old BMW" smell is gone now. Maybe a big part of it is the decaying OEM vinyl headliner. This material is an actual woven textile, so it should also be a heck of a lot more durable than the thin textured vinyl stuff that was in there originally. Also, the little black clip thing in the upper corner of the rear window is just a little clamp to hold the ends of the headliner down until the window seal goes in. There is no real risk of it coming loose, but the shop put them in a few spots just to be safe so that the passing air while I was driving home would not mess with anything.

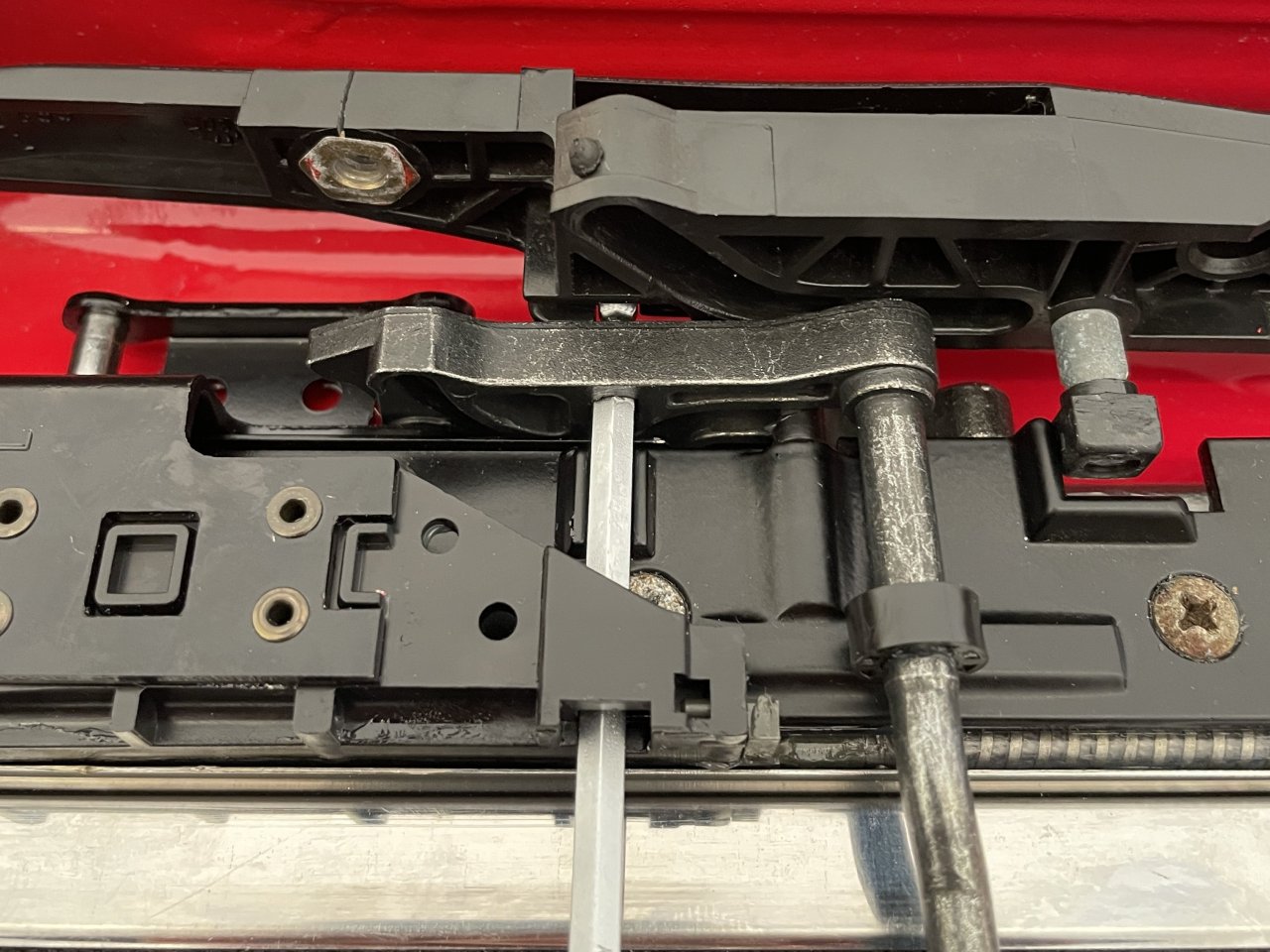

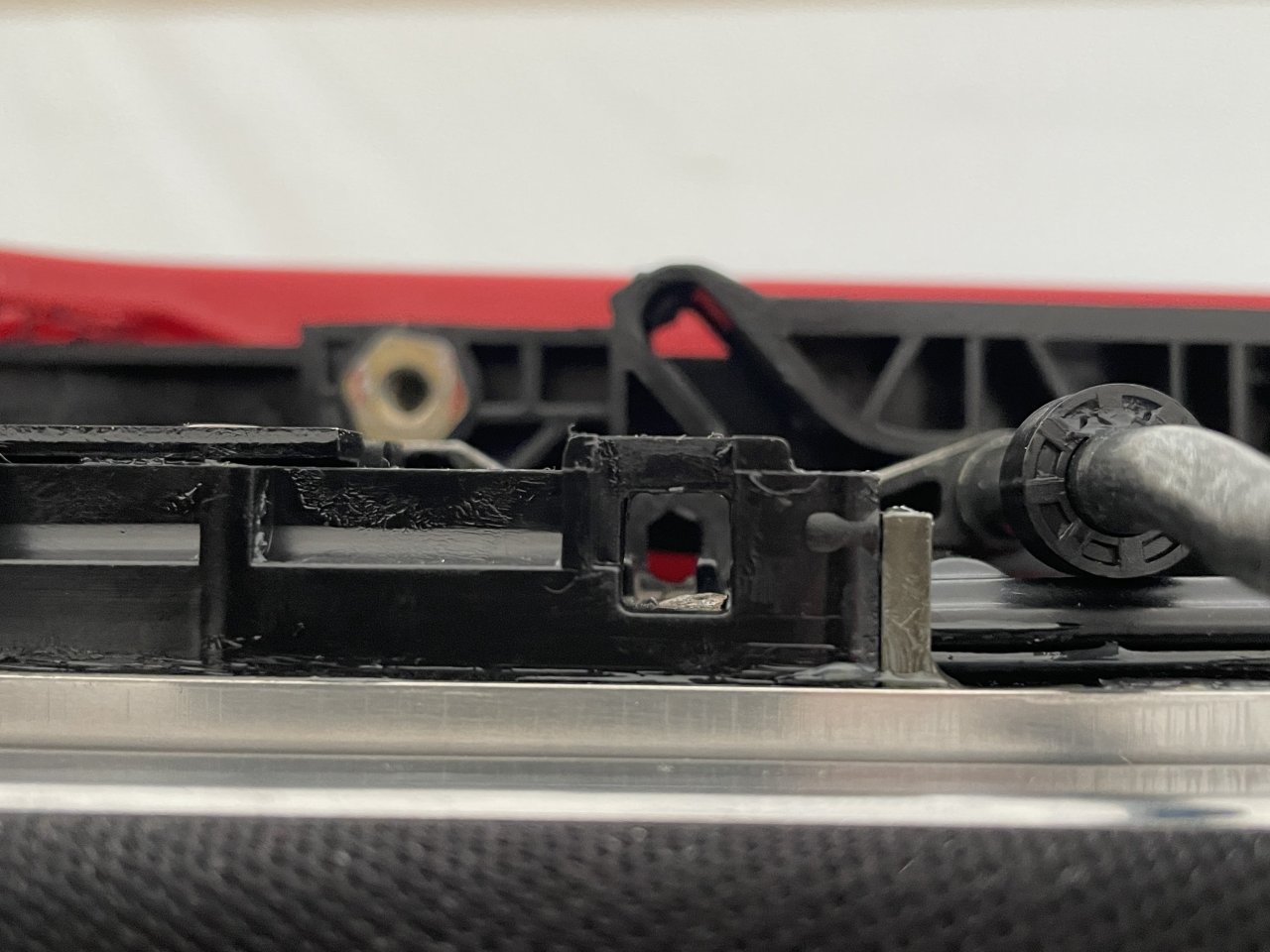

So, at this point I just need to call around to find a glass installer for the 4 fixed windows. From there, it is a matter of reassembling the sunroof mechanism, putting the interior back together, and doing a couple of little odds and ends. The end is in sight!

Now that I have the car back and have taken a good look at the workmanship, I can recommend this shop to others on here. They were professional, friendly, fast, and fairly priced (definitely not inexpensive, but they made every effort to come in under the quoted hours of labor and the quality of the work is exactly what I would have hoped for). It took them 1 week from drop-off to completion since they have about a dozen cars in the shop right now. Apparently a lot of BMW's of this era are coming through lately.

https://www.yelp.com/biz/wardell-aut...ps-santa-clara

The front upper console looks as good as new now. They were able to rewrap it with a single piece of textured vinyl, which is awesome since they had initially thought that they would need to sew together some pieces for the visor recesses. Thankfully, a little bit of heat and stretching got it all laid down securely! They did leave some overage in the places where it wraps onto the body, since I had said that I would be doing the final trimming and reassembly after the glass gets reinstalled (that is next on my list).

The A-pillar trim pieces also look nice and new. Same deal with the overage...I will trim it once it is installed.

My new sunroof headliner panel is looking really great.

I was impressed that the shop even put some tape over the door sills to protect my new paint from shoes while they were working on the car.

Much to my relief, the tight corners in the sunroof opening came out perfectly with no wrinkles or creases.

This new headliner really breathes some new life into the car, and honestly a lot of that "old BMW" smell is gone now. Maybe a big part of it is the decaying OEM vinyl headliner. This material is an actual woven textile, so it should also be a heck of a lot more durable than the thin textured vinyl stuff that was in there originally. Also, the little black clip thing in the upper corner of the rear window is just a little clamp to hold the ends of the headliner down until the window seal goes in. There is no real risk of it coming loose, but the shop put them in a few spots just to be safe so that the passing air while I was driving home would not mess with anything.

So, at this point I just need to call around to find a glass installer for the 4 fixed windows. From there, it is a matter of reassembling the sunroof mechanism, putting the interior back together, and doing a couple of little odds and ends. The end is in sight!

Comment