+1

Sent from my SM-G920T using Tapatalk

M20B29 w/ Triple Webers into my '71 2002

Collapse

X

-

Hey, thank you! Glad to see you are still alive, I sincerely hope all is well with you.

Yeah.... thanks photo bucket. I'm going to have to transfer the older pictures to flickr in the next month.

-------------------------------

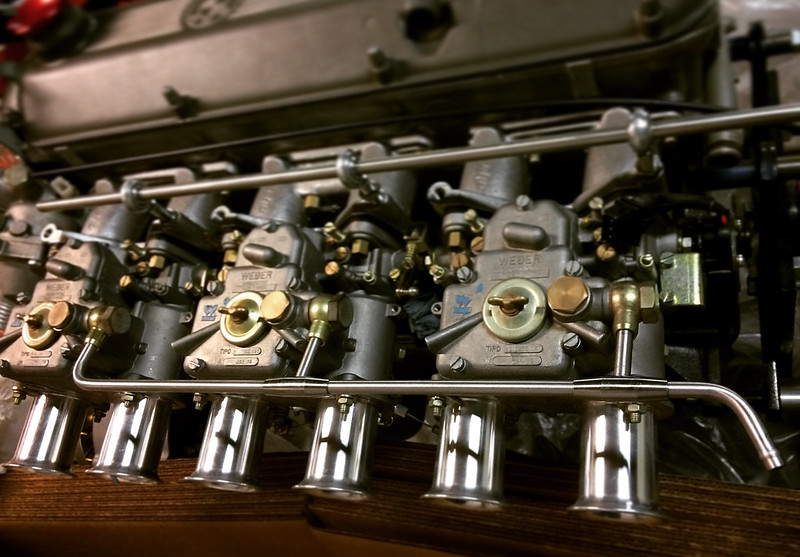

Last thing for the intake system is the fuel rail. I've been making fuel rails for the M10 for a bit now (see here https://www.bmw2002faq.com/forums/to...er-sidedrafts/), but am now playing around with M20 options.

Here's the first version mocked up for a friend. The next option I'm playing around with will have the rail mounted to where the heir-joint linkage would have gone with rubber lines going to each carb. It will be a more refined version of what you can find on some Datsun Z-cars. Inspiration is also coming from the old Aston Martin and Ferrari systems.

On the bodywork side, I've knocked out the floor drains. Seam sealing where needed. Will be laying down epoxy primed shortly after thanksgiving.Leave a comment:

-

Bad ass as always Andrew! Happy I checked back in again. Its getting close.Leave a comment:

-

Wow!! Nice andrew. I need to give some TLC to my body. But want to get it running first. Then will pull everything back apart and paint. Great work! Can't wait to see it with paint

Sent from my iPhone using TapatalkLeave a comment:

-

-

On the stuff stuck to the tunnel, I just used a scraper. No heat. The floor pans needed that bit of heat. Also, last night I cleaned up the residue with gas followed by the acetone via your suggestion (holy cow that acetone cleans the gas right up).Leaves an undesirable residue for paint prep which acetone fixes, but ~$2.8x/gal local gas prices vs ~$16/gal for acetone/lacquer thinner is a no brainer.

EDIT: ...and I meant the most recent removal. Noticed the scrape marks, freezing it tends to leave a honeycomb pattern.

-------------------------------------------------------------

OK, well we had Fabrication Day #2.

Fender rust is now repaired (inner pillar mount sections on both sides and that piece on the upper shelf of the passenger side fender.

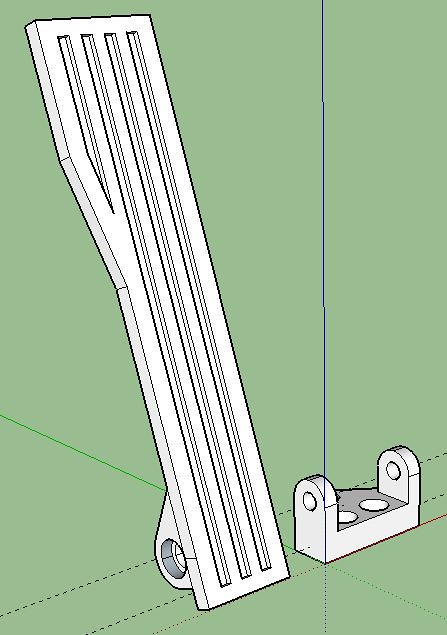

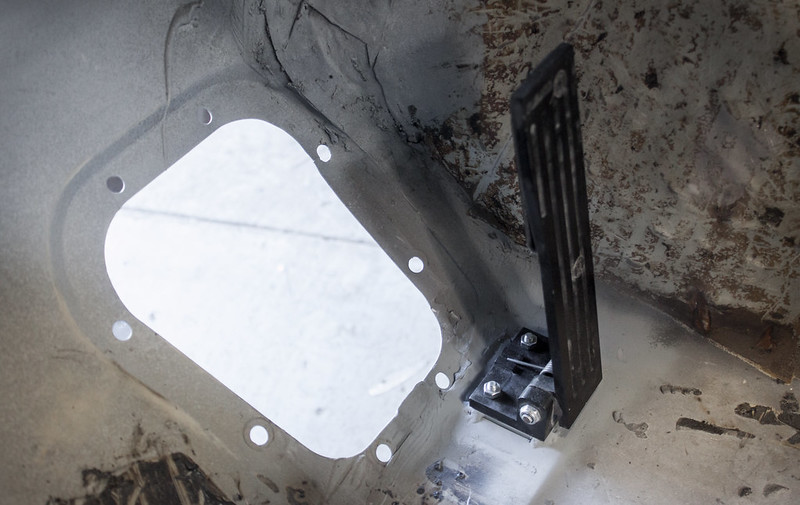

In the inside the stock "accelerator nubs bracket" was ground off and the IE pedal reinforcement plate welded on. It has been so fun to go from dreams to reality.

With the fabrication work on the fenders finished, the fenders were lines up and welded back in place. We then rolled the chassis back over to Maestro for a little more bodywork.

Maestro, the man himself. By all accounts, an artist.

The chassis is now %95 ready for paint. The following projects still remain.

1) cut hole for oil cooler

2) weld in a reinforcement brace at the front.

3) clean up the underbody, wheel wells, and spray on Wurth underbody coating.

Last edited by SkiFree; 10-14-2017, 09:19 PM.

Last edited by SkiFree; 10-14-2017, 09:19 PM.Leave a comment:

-

Leaves an undesirable residue for paint prep which acetone fixes, but ~$2.8x/gal local gas prices vs ~$16/gal for acetone/lacquer thinner is a no brainer.

EDIT: ...and I meant the most recent removal. Noticed the scrape marks, freezing it tends to leave a honeycomb pattern.Leave a comment:

-

Yep. I did the bulk of it with dry ice before media blasting, got the last bit of it with a torch (heat gun would have been better).What did you use to remove the tar?

I have used both the dry ice and heat methods. The dry ice does a nicer job, but found you must be very patient and let the tar really freeze. Heat makes it come up quick, but things get sticky. Plain old gasoline is the cheapest method to removing glue in my experiences.

As you say, gas works great! Jesus taught me that trick a few days ago. Got it in a spray bottle and it works like a charm.Leave a comment:

-

What did you use to remove the tar?

I have used both the dry ice and heat methods. The dry ice does a nicer job, but found you must be very patient and let the tar really freeze. Heat makes it come up quick, but things get sticky. Plain old gasoline is the cheapest method to removing glue in my experiences.Leave a comment:

-

I'd like to keep it with the factory side exit look, but a cool vintage Ansa double-tip would be tempting. The pumpkin should get driven, it will be living in Texas once finished.

Yesterday evening I removed the remaining factory tar. Should have done this sooner obviously. Spraying/wiping a little solvent throughout the cabin this afternoon will clear up any remaining tar/glue smears.

Leave a comment:

-

Leave a comment: