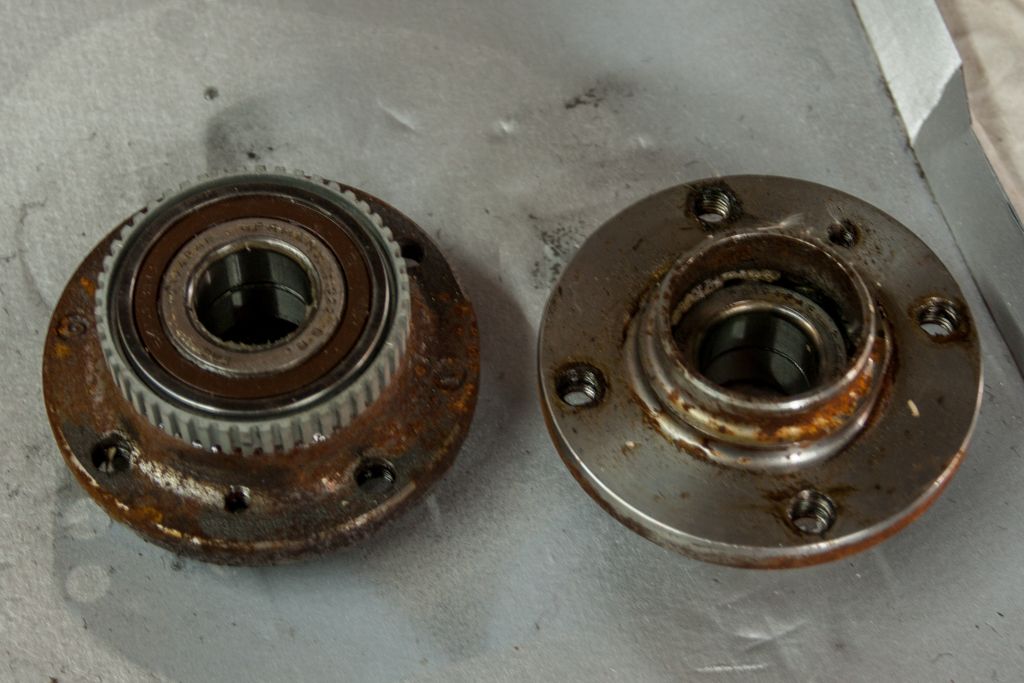

The zinc plating isnt to bad, once it works. I pretty much derust anything first, then leave it in some de-greaser and de rust again if bits were missing, then I leave it in the de-greaser that came with the kit for as long as possible, 2mins acid pickle and straight into the zinc tank after a quick rinse. That takes up to an hr depending on how much zinc you want, the gold/yellow colour takes 30seconds and I dry it with a hair dryer then.

The seats are great, love them :D

The seats are great, love them :D

Comment