Northern's Sterlingsilber M52 Turbo 325is

Collapse

X

-

yeah there's a guy i follow on ig "bzdrifts" who had wastegate boost creep issues as well and had a tial flange welded directly to the exhaust housing. it turned out really great fitment wise imho and it fixed all the issues. its not very far down on his profile, oh and he kept a screamer pipe if thats the route you want to go! -

I talked to pazi88 and Armen Hovh who have done low boost cars on 44mm or smaller gates, so I decided to forgo the $800 wastegate upgrade and attempt to dodge the fitment issues.

I still need to choose a flex section between the WG and downpipe, just need to measure the exhaust tubing I have first.

Hopefully this is all I need to mount the WG to the turbine housing and recirc into the exhaust. I'll miss the screamer pipe, but oh well.

1 PhotoLast edited by Northern; 06-06-2021, 07:21 PM.Leave a comment:

-

Kind of a ramble:

Found some deserted roads to do some pulls the other evening, and since my EBC is currently a glorified boost gauge, I raised the boost cut threshold on it so I could see how much boost I'm making.

I let off at 14psi, so that explains why the car feels so fast...

12psi is probably the semi-sketchy limit for pump gas, and I'm really trying to target 10

I think the overboosting is a combination of two issues:

Rapidspool manifold wastegate priority.

I don't blame Otis because there's nowhere else for it to go, the entrance from the collector is teardrop shaped into the WG tube, and the tube itself is oversized.

I think it works fine for like 16+ psi, but can't bypass enough exhaust to go significantly lower than that.

Wastegate maybe too small to hold such a low target. 60mm WG would be almost 2x the xsection of a 44mm, but they are huge and expensive.

So tl;dr, I need to improve the WG priority somehow, and maybe switch to a larger WG?

The only way I see this happening is to cap the existing 44mm flange and weld the new one on the turbine housing + recirc into the downpipe.

Re: Idle stuff. Two things:

1. Had a few people mention some sort of crank acceleration table that isn't defined in the romraider defs. Forgive me but I'm a bit skeptical.

2. All my Idle control valve tables and Idle speed regulation tables were from the M3 (41.2) flash, not the 328i (41.1) flash (20 tables were different). Not sure if this is an artifact from me converting so long ago when a bunch of tables weren't defined or what. I thought I was pretty thorough, but it was ~5 years ago and the romraider definitions have come a long way.

I changed the ICV/ISR tables for now, we'll see if it improves the ~2000RPM starting idle hang or the weird oscillation at idle at >90degC.Last edited by Northern; 06-06-2021, 07:30 PM.Leave a comment:

-

Following this. I have the same funky idle ~1900 RPM on my M52 swap w/S52 cams and a Markert tune. Reset adaptions and it is fine for a period of time...Leave a comment:

-

I already cleaned up and modified an M52 TB by filling in the recess for the seal with epoxy, and I just bought the S52 throttle cable that supposedly works with it.

No idea if there's a cable that works with the e30 cruise module and M52 TB, I saw a guy who retrofitted the e30 cruise end onto an M52 cable, and someone who mentioned M42/M44 cables.

Assuming I can fix it with tables/tune, I can always throw that TB on my 4dr, which doesn't have cruise anyway.Leave a comment:

-

I only noticed the s52/m52 table snafu while I was writing that post, so I need to take a bit and try to see what the end values look like.

I went for a quick drive around the block on the new diff this evening. I had the windows up and everything off and I think it made more gear noise than my old diff? (solid bushings in the rear)

I did a quick drive to drop off some tools and with the windows down, I don't hear anything so maybe I'm just being paranoid.

I must be losing it because somehow the new taller diff feels sportier than the short gearing before?

I can't really explain it, but the gears don't feel long and I expected more of a change - maybe to regret it because I thought the 2.93 could be too tall?

In any case, I really like it, but I think my axles really need to be replaced. They have a lot of play and one started to make a clunk/ping noise.

Who knows, I might get a job soon and be able to afford to do things in other than the most jank ways lolLeave a comment:

-

TPS Adaptions seem okay to me, I recall mine being around that.s2.93 LSD went together fine, didn't check lockup because I don't have the tools, and what am I really going to do if it is off anyway.

Can't really check backlash or carrier bearing drag so I yolo'd both of them after a few hours messing with shims.

I'm fairly concerned about the condition of the pinion bearings because they don't feel the best, but I was too lazy to do anything about them so I slammed it all in the car and I'm hoping for the best. Should be very obvious if they're pooched with the solid subframe/diff bushings.

While the diff was off, I figured I was already halfway to having access to the brake hoses above the subframe, so I swapped the original hoses for the BMA Stainless hoses I bought a few years back. Absolute cock of a job, no idea why BMW didn't just put them like 0.5" further forward...

Tuning escapades:

Car looked like it was running like 1 pt richer than last year, but it was just the LC-1 losing calibration. Leaning toward replacement this/next year with something newer.

Trying to resolve a few weird issues:

Car might have weird TPS adaptations (12.53 - 13.06% is where it seems to stabilize - I have seen this range of adapts in logs from others though?)

Car idles ~2000 RPM on start unless I tap the gas pedal, or TPS adapts are reset.

Car goes quite lean on tip-in. - I've tried to add fuel to the main fuel table as a first step.

Possible causes:

M50 Throttle body instead of M52 (maybe TPS is angled differently on the shaft?) - Currently cleaning up an M52 TB and have an OBD2 throttle cable on order to test.

S52 Enrichment tables instead of M52, since they are quite different. - 100% an oversight, probably from when I switched to the S52 software years back.

My main theory about this is that something has to work because turbo/maf/modded software aside, nothing has changed off boost.

I ran M50 throttle body with M50 manifold without any issues, car idled fine.Leave a comment:

-

s2.93 LSD went together fine, didn't check lockup because I don't have the tools, and what am I really going to do if it is off anyway.

Can't really check backlash or carrier bearing drag so I yolo'd both of them after a few hours messing with shims.

I'm fairly concerned about the condition of the pinion bearings because they don't feel the best, but I was too lazy to do anything about them so I slammed it all in the car and I'm hoping for the best. Should be very obvious if they're pooched with the solid subframe/diff bushings.

While the diff was off, I figured I was already halfway to having access to the brake hoses above the subframe, so I swapped the original hoses for the BMA Stainless hoses I bought a few years back. Absolute cock of a job, no idea why BMW didn't just put them like 0.5" further forward...

Tuning escapades:

Car looked like it was running like 1 pt richer than last year, but it was just the LC-1 losing calibration. Leaning toward replacement this/next year with something newer.

Trying to resolve a few weird issues:

Car might have weird TPS adaptations (12.53 - 13.06% is where it seems to stabilize - I have seen this range of adapts in logs from others though?)

Car idles ~2000 RPM on start unless I tap the gas pedal, or TPS adapts are reset.

Car goes quite lean on tip-in. - I've tried to add fuel to the main fuel table as a first step.

Possible causes:

M50 Throttle body instead of M52 (maybe TPS is angled differently on the shaft?) - Currently cleaning up an M52 TB and have an OBD2 throttle cable on order to test.

S52 Enrichment tables instead of M52, since they are quite different. - 100% an oversight, probably from when I switched to the S52 software years back.

My main theory about this is that something has to work because turbo/maf/modded software aside, nothing has changed off boost.

Leave a comment:

-

Also, disregard the random chunks of motorcycle clutch in 2 pics of that post...

Kind of an off-topic post:

CBR is fully fixed. Chain, spockets, Stainless front brake lines, Front master cyl rebuild, and new battery (well, I still have new bar grips to install... but don't worry about it)

I didn't ride it this year yet, but it started up nicely.

Video (I think it only plays on flickr. R3v handles this weird so I guess Right click and open in new tab):

My friend Iain was storing a CBR929RR at my place for the winter, we started picking at it.

It had a few issues, but we cleaned the carbs, bypassed the broken knockoff fuel pump/fuel filter and put fresh gas in it, so it does have gas, just no spark.

Coils are getting +12V but there's still no spark. Either something wrong with both coils, the CDI brain, or the VR crank sensor.

Honestly this bike blows my mind because it somehow all just runs from a crank sensor. No cam, TPS, or anything else.

I bought a Link E36X G4X from a member of this forum.

This will not go on this car, since I'm very happy with how MS41 is performing with the 41.3 beta flash, and I already have an EBC for boost control

I don't know if it will go on my 4-dr car this year, because I want to test Alpha-N, Speed Density emulation, and a bunch of other features of the MS41.3 flash, but I will find somewhere to use it eventually.

Also because I've found myself bringing this up a few times recently, here's a pic of a 413 DME (Top) vs a MS41 (Bottom) to show the difference in the connector.

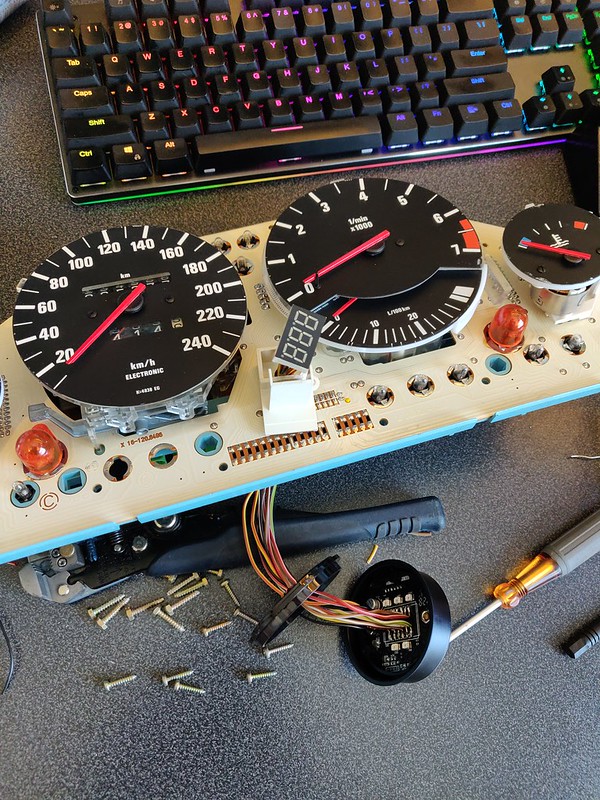

Lastly a teaser pic.

Leave a comment:

-

Dash seems to be completely working now, no tach dropout or jumpy coolant gauge.

I also really like having the AFR in the cluster like this.

I've been trying scrape together a 2.93 LSD forever. I think it's 6 years since the swap now.

I have gathered:

e36 328i Ring & Pinion

e30 s3.73 case & LSD guts (could interchange LSD guts/spider gears with the 2.93 but the carrier and cap are a different offset)

s2.79 LSD carrier + Ring & Pinion

Tacingdiffs cap + 4 clutch kit

Timken Pinion Bearings

SKF Carrier bearings

BMW diff seal kit

2 pinion crush sleeves

I started to take the e36 gears out to more or less build a diff from scratch, but I realized there are a few problems with my plan:

The "clean" e30 Diff case I have is rusty on the inside

Most likely going to need to mess with pinion shims, which means installing/removing the pinion a few times, probably ordering a few sets of shims and more crush sleeves.

Sure installing/removing the pinion is *possible* without a press, but it involves heat and BFH so I imagine the bearing wouldn't enjoy that very much

I also have an e30 2.93 open diff that wouldn't need nearly as much work since the pinion is already installed and all.

Case is grubby, but I popped it apart and it was alright inside.

The e30/e36 final drive TIS is out there on the internet, so I just followed those instructions, although the LSD stackup instructions are a little murky and it's lacking some torque specs.

Other than some confusion about how they chose to say some weird shit instead of "convex up" with their Belleville washer instructions, it was smooth sailing to install the racing diffs clutch/plate upgrade and their carrier cap.

FWIW, the spacer plate (or "spacer plates" in this diff, likely because the discs were robbed for my current diff and it looks like they fired a )

I didn't have any clearance issues like some people so I didn't need to machine the cap.

Unfortunately Rockauto has some wrong bearings listed (possibly for 168mm diff?) that of course I bought, so now I'm waiting on the correct ones.

The correct carrier bearings and races for an E30 188mm medium case are:The ones that came off the diff were SKF bearings, just for anyone wondering.TIMKEN LM503349A (2) TIMKEN LM503310 (2)

The Pinion bearings/Races I ordered are:Seem to be correct just based on part number. What came out were FAG bearings.TIMKEN HM88510 1 TIMKEN HM89410 1 TIMKEN HM88542 1 TIMKEN HM89449

Here is the s2.79 (missing clutches/plates) that I need to rob the LSD Carrier from:

Popped the tone wheel off with a chisel.

Give it a whack, rotate, repeat until it starts to come off, then just pry and it pops off

Bottom out a brass drift in the bolt holes and you can give it a few taps and it should start coming loose.

Tada

Same thing with the E30 open 2.93 (Probably will use this someday, so I'm wrapping both gearsets up for another time.

Comparison of 188mm diff pinions: 2.79 vs a 3.73. Huge size (and strength) difference between the two.

Random disassembly + 3 hours of wire-wheeling + rust converter + paint:

Yeah I just brushed on two thick coats of Tremclad. We'll see how that works, my guess is not well, but better than if I had tried to spray it as quickly as I brushed it.

Since the s2.79 had been cannibalized for another 4-clutch diff, I needed clutches/dog ear plates.

On a normal e30 LSD, you would remove the spacer plate to fit a third clutch/plate, and machine the carrier cap by ~2mm to fit the 4th clutch.

Since I needed to buy the clutches/plates anyway, it wasn't that much more to tack on a billet carrier cap to my racing diffs order.

pazi88 runs this exact same setup, and I think we bought our setups only a month or two apart.

When he installed his, he found that his carrier cap needed more machined off it to hit the 0.1-0.4mm spec in the TIS.

Racingdiffs said they corrected the issue after he and others ran into this problem, but I was convinced I would have the same issue.

Turns out mine was fine, with just a hair under the 0.4mm clearance spec.

One thing to note about the racingdiffs set is that I needed to file one spot on the inner spline of the clutch discs. If you try to place it over the spline on the ramp piece, it catches on a burr/defect from how they're cut.

ignoring the tiny washers, my plate stackup (in the orientation they are dropped into the carrier) was:

Bellville Washer (Convex Up)

Dog plate

Clutch disc

Dog plate

Clutch disc

[spider gear/ramp assembly]

Clutch disc

Dog plate

Clutch disc

Dog plate

Bellville washer (Convex Down)

I'm still cleaning up this case. Need to install the ring gear/tone ring/bearings and mess with the shims for lash.Leave a comment:

-

Small update.

Same 52lb injectors, new fuel rail setup:

Rust free M50 rail from California

Injector hats from ebay, (clips included, also adds a filter)

Gates 225psi hose

Here's the stupid pit that caused a month of pain swapping O-rings and fuel rail adapters around, then like $300 in parts to swap rails.

Maybe I'll weld up the pit to use this rail again, maybe I won't.

Copied Panici and desoldered/extended the 7segment from the Innovate LC-1.

( I gave up on the APSX G1 since it needed a serial input that is different than their documentation and they weren't willing to help.)

Fingers crossed that it all works.

I originally pulled it to change the SI batteries because the tach kept dying, and hopefully fixed the coolant temp wiggle by cleaning the ground.

(Edit from the future: I went for an hour drive today and it all seems to work. All the issues mentioned are gone so far. The AFR gauge also seems to be happy in its new home.)

While I was messing with the cluster, my clear windscreen for the CBR showed up (a full month earlier than expected too) so I threw that on and now I'm just waiting on a new rear sprocket.

Last edited by Northern; 05-09-2021, 03:33 PM.

Last edited by Northern; 05-09-2021, 03:33 PM.Leave a comment:

-

The whole MAP sensor ground issue was just weird because a lot of people reported that it worked for them, and only when I mentioned that mine didn't work did a few others start poking out of the woodwork with the same issueLeave a comment:

-

There are like 3 or 4 local dyno shops, but I'd want to tune it myself either way

The logging isn't bad with Romraider Logger, save three things:

You need to drag a laptop with you to datalog

It caps out at like 12Hz vs 100Hz on most standalones, or even 1000Hz on higher end or Link E36X.

MS41 doesn't have MAP, AFR, etc, so you have to either do without, feed them into your logging software (pain in the ass), or wire them into unused inputs in the ECU (there are only 4-5)

No onboard logging - Trying to rectify this with a logger.s module ( https://www.clown-shoe.com/single-po...-data-solution ) but mine is DOA and I've been slacking on returning it to the UK to get it replaced. Added bonus is that this gives 4 more 0-5V inputs to insert in the datalog.

Alternatively, there's an android app called ALDLdroid that lets you log via INPA USB cable on your phone, ba114 more or less pioneered getting that app working with MS41. Only issue with it for me is that the custom MS41.3 flash needs a different calibration file. I'm told Logger.S can output to ALDLdroid as well, but haven't verified this.

Here's an example of how it looks:

I didn't baffle the rear sump, just used the cut up stock baffle that came with the modded pan. I fill oil up to the dot above the full mark, but I do get typical lifter tick in autox so I don't think it helps as much as I'd like. Wish I did an S54 sump, really.

I drove the car to work for a year after the swap, did maybe 3-4 autox days, and have maybe put 10k (km) on the car with the IE 25mm bar. Haven't had any cracks yet, but have no idea how badly it flexes so I definitely want to weld a tab on each side next time I have a reason for the subframe to be off.Last edited by Northern; 05-06-2021, 10:01 AM.Leave a comment:

-

Are there any tuning shops local? I'd find just running something the local tuners know by the back of their hand saves a lot of headaches. Haltech seems best bang for the buck with a lot of local support.

Its cool to break into a factory DME, but at what cost.. Plus just nice to be able to log for debugging. I got out of those headaches, I mean cool when it all works. I guess a lot has changed in the last 5 years

Ill go Life Ecu in mine and just run an autosport on the firewall, then build an "Adapter" harness to the ECU, But the Deutsch HD connectors look good too.

Did you put in a baffle into your rear sump setup?

I have the S54 Arc Asylum pan setup on my US S50, I had no idea Tyler did standard E36 pan mod with that subframe.

Also, I have the 2 thick tabs off the subframe, I haven connected a bar yet, looks like id break them... Have you ran a big bar on your with much time on it?Leave a comment:

Leave a comment: