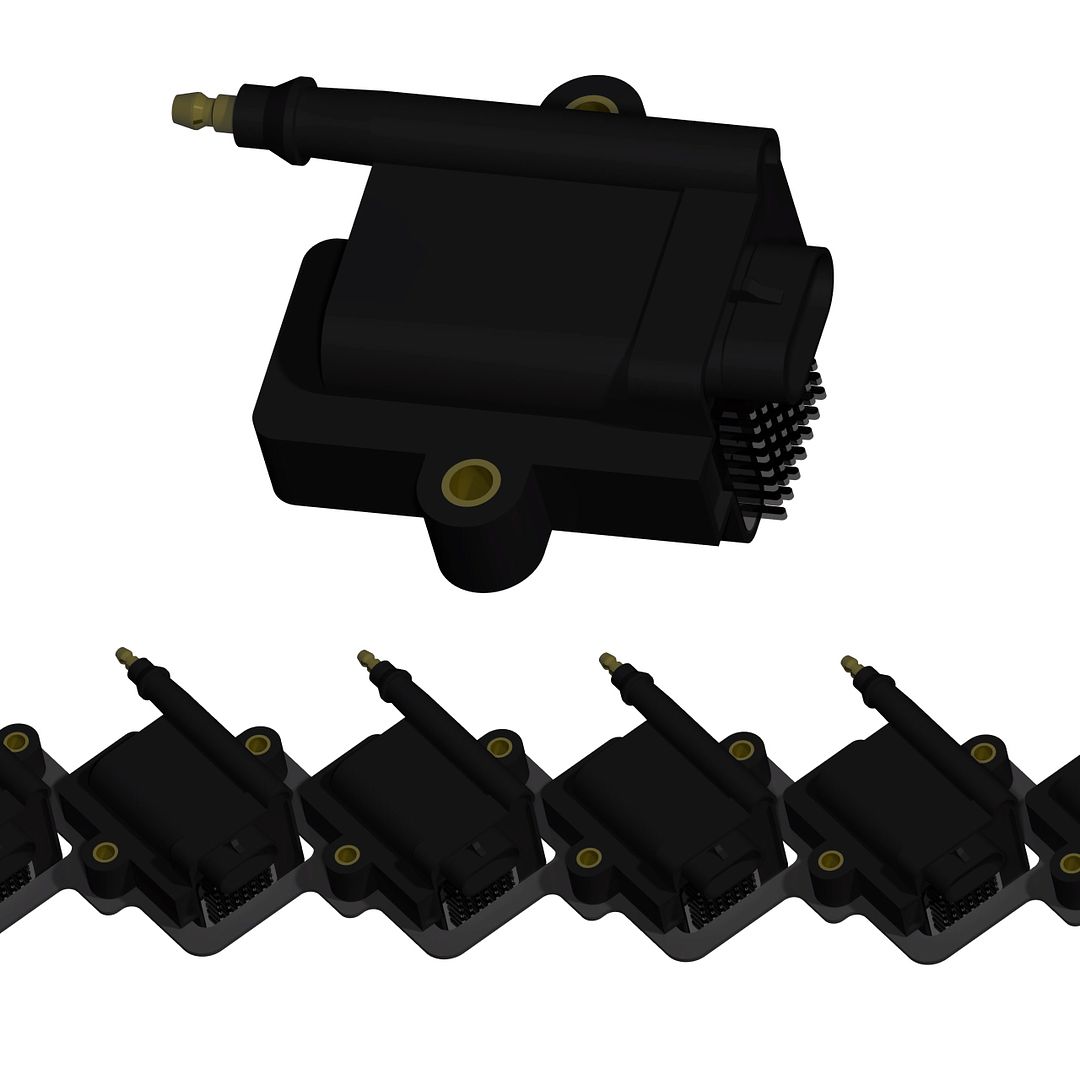

One thing I wasn't thinking about earlier is that my engine is located "underneath the windshield" and the height of the coil pack with vertical mounting is around 95mm, my engine is tilted +10deg more upright.. Not too much space available there neither

Need to measure..

Need to measure..George:

Volume of the plenum (as well as runner length and diameter) is always a compromise, unless it's some kind of a complicated variable type. Smaller volume gives a better response, but bigger will allow the best peak power.

About the upper limit, I think you can't make "too big" and lose peak performance, but you'll sure notice more lag and weakened throttle response.

I wish free valve system would become more common in near future.. Hmm, a free valve M30 ;D Check out Koenigsegg talking about their system on Youtube.

Leave a comment: