I like the Valve cover finish.

A Tale of Two 30s: Now with 100% More Boost!!!

Collapse

X

-

-

She lives! She runs! She boosts! She... overboosts.

Wastegate actuator clearly isn't opening at all. Finally started getting it street tuned and it was spiking in the 12-15psi range then getting shut down by the MS overboost protection that I (luckily) set. Kameron has said this is the correct wastegate vacuum line routing. I'm not entirely sure but need to play with it.

Which brings me to issue #2. AEM overnighted me a new wideband sensor that I got Friday afternoon. I tossed it in and everything was working exactly as it should. It worked Friday day/night and we did about 19 miles of tuning. I fire it up Sunday and the sensor craps out again. It started reading properly for about 10 seconds, then just climbed into off-the-charts lean and sits there. I'm pulling my hair out on this one. Too much heat that close to the turbo? Bad wiring?

Comment

-

Well, still waiting on the new wideband sensor. Doesn't look like AEM ended up getting it out last week so the car didn't do a whole lot of moving this weekend. I did confirm that my wastegate hose routing was wrong though and corrected it.

New plan for the wideband is to put it on its own switch. I've heard they are really susceptible to thermal shock from condensate droplets hitting the sensor when the car is first warming up. My car definitely condensates quite a bit so I'll just run a switch to it and flick it on after the car's been running for 10 seconds. Hopefully gives it a little added life.

Otherwise, she got a wash and an IS lip finally put on. Took a picture because she was lookin fancy. Bonus picture of the jetski I restored a few years ago that also got a wash and some new graphics put on. That was the first engine I built and what got me going down the whole project car road.

Comment

-

What was wrong with the routing for the wastegate? Cars lookin sweet, hopefully the new wideband does the trickComment

-

I had the pressure line from the charge piping going to the vent port on the wastegate actuator, instead of the diaphragm side. All fixed now.

Wideband showed up yesterday and I got to take her for a drive. Weirdly it worked fine for about 10 minutes then did the same off the charts lean thing it's been doing. I sat on the side of the road for 5 minutes just being pissed and trying to figure out how I was going to get back home. Fired it up again and it just started working perfectly again. No idea why but it worked perfectly the rest of the evening. I put about 50 miles on it with the autotune function running. By the end of the night I had it running well enough that I got a few great WOT pulls to redline at full boost. My AFR's are all looking good and I can confidently say that this car is a BLAST to drive.

Next up: I've decided I'm definitely going to put the wideband on a switch. I've been hearing that AEM's pre-programmed slow warm up to protect against thermal shock is really not very slow at all and could still be resulting in condensate hitting a fully warmed up sensor. I'm probably going to take another hard look at my wiring, though I'm pretty confident in it. I also confirmed alternator voltage was a steady 13.5 at idle and not spiking. Lastly, added a homemade copper heatsink to the sensor just for added peace of mind. I really want to be done with the whole wideband issue once and for all.Comment

-

Welp, this update begins with either really bad news or me being overly paranoid. Let's hope it's the latter...

I took the old girl to Euros by the Bay yesterday and was hanging out with my car, talking to people that were checking out the car, turbo setup, etc. when I noticed a guy take a picture of my car, and then of my engine, then just walk away. The guy was alone and not talking to anybody. I didn't really think too much about it until later I saw him walk up to another open hood car (LS-swapped older Benz) and snap a picture of its engine too. So basically now I'm panicked that he was in some way affiliated with CHP and my car is going to be on police record as having illegal mods. He definitely got my license plate in the picture, and just something about his behavior seemed off. I'm really hoping this isn't the beginning of the end. Either way, lesson is definitely learned that I need to keep my hood closed at shows with more than just my friends there.

In other bad news, my car cooked another wideband sensor yesterday too. AEM is deciding whether or not they're even going to give me another one. I'm finally calling uncle and moving my O2 bung further from the turbo in a last ditch hope that's my issue.Oh boy.

Now some good stuff! My little brother is a detailer and shampooed my carpets and polished up my junkyard hood as a favor. It all came out exceptional. I also got my cooling system very thoroughly flushed, then swapped in my new S54 radiator. I'm extremely happy to report that my car is running cool as a cucumber, even sitting in traffic on a hot day. So there's a major positive.

To-do's before dyno tuning next Monday:

- Verify base timing

- Install manual boost controller and adjust to 10psi

- Wideband sensor fiasco

- Track down my new oil leak, most likely from the new turbo oil lines

Comment

-

I asked my cop buddy and he told me I was completely crazy too haha. I guess he might've actually just liked my car and wanted pictures. Stranger things have happened.

Edit: A photographer for the show got a picture of our little lineup.

Last edited by the_eskimo_wonder; 09-11-2019, 04:35 PM.

Last edited by the_eskimo_wonder; 09-11-2019, 04:35 PM.Comment

-

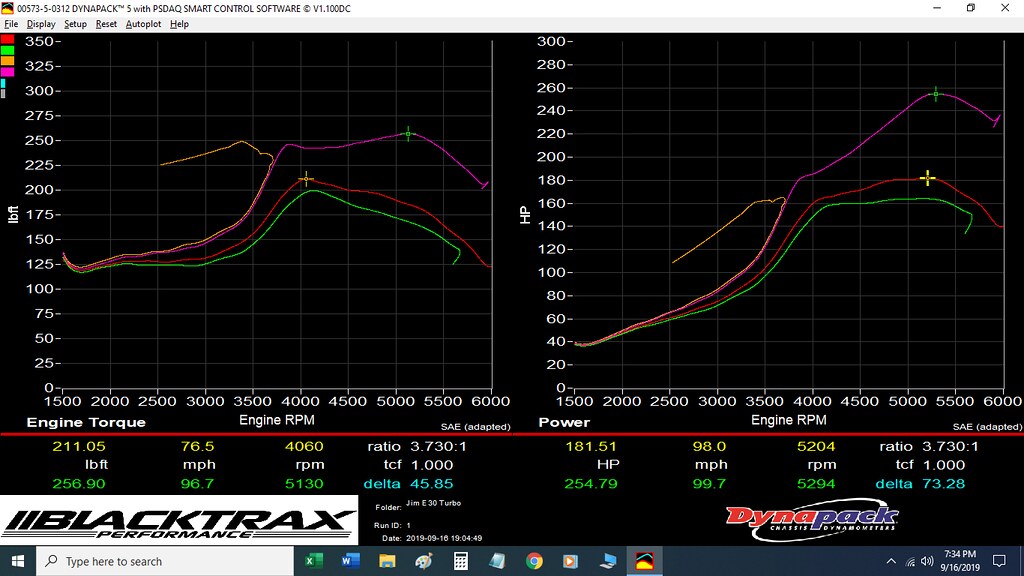

Had the moment of truth yesterday and got dyno tuned. First good thing is the engine didn't blow up. Aside from what looks like an oil drip from the back of the oil pan, it did very well, stayed cool,etc.

Unfortunately (and kinda fortunately) this thing is such a beast that there's no chance the stock clutch I put in there was going to hold... It started letting go right around 260 ft-lb of torque. The tuner managed to feather the throttle enough to get me a full run and a HP number, but ultimately wasn't able to finish. We didn't even get to turning up the boost (though it was creeping a bit due to him pulling timing from the top end). So until I get a new clutch and he can finish my tuning, he set my redline to 4500 rpm. So basically I'm driving the beastliest eta EVER. I'm really happy with the tune quality though. It would've taken me forever to get to the point it's at now. Strong, stable idle and very responsive to every little throttle blip. Even with the 4500 rpm redline I was able to hang pretty close to my buddy's N55 335i doing some 5th gear freeway pulls.

So... now I need a DD-able, street friendly, OEM feeling clutch that can hold 325 wtq. Who's got the answer???

Comment

-

It's been a while without any updates and it's probably time to fix that. The car has been in my garage in pieces for a while. I originally got stopped by this...

That's a pressure plate bolt that sheared off in the flywheel with an extractor bit that sheared off in said bolt. The dremel slit was a last ditch effort to use a giant flathead in hoped of removing it. It failed and it went to the machine shop.

Luckily he managed to save it. He also found out that the flywheel was pretty out of spec. He fixed it up all goodlike and got it back. Pictured here with the clutch that tried its very best.

So finally got that back in and got a big boy clutch on. I opted to go with TCD's stage 1 kit which is Clutchmasters branded. He promised stock clutch feel with a holding capacity of 380 ft-lb. They come pretty highly reviewed. Interestingly enough, the pressure plate is a Sachs unit painted white. Hard to tell which it is, but I'm guessing its the 618 performance one.

I've got some more goodies in store, but here's the last one for today. This is a Wangan-rebuilt 3.46 with increased LSD lockup (or so I'm told). I'm incredibly grateful to Kronus for parting with this and I'm really looking forward to giving this car a little longer legs. I think with the amount of power I now have it's going to be a nice all around ratio. It might just be because my 8-speed 6.2 powered truck cruises on the freeway at 1400 rpm, but I wasn't happy cruising this at 65-70 at 3000.

I also ran some numbers and with the 3.46 my 3rd gear pull from 3000 to 6500 will be 45-95mph which will just be downright vicious (and probably terrifying). It's time to get wild.

Last edited by the_eskimo_wonder; 11-06-2019, 04:53 PM.

Last edited by the_eskimo_wonder; 11-06-2019, 04:53 PM.Comment

-

Very cool! I think you're on the right track with the 3.46; 3.73 is too short for any boosted E30. You may even find you want a 3.25 (personally I'm running a 2.93 in my turbo M30)

Your wideband issue is very strange. My understanding is that 12-18" away from your exhaust housing is just about perfect, and as long as it's mounted above the "halfway" line, i.e. the senor points out semi-vertically and not sideways/upside down, you should be OK. I wonder if there is an electrical issue sending voltage spikes to the sensor or controller, causing failure?

I feel your clutch pain too. No BMW OEM clutch from this era can hold up to anything more than ~280ft-lbs. I'm currently running E28 M5 FW/Clutch/PP and have had to stop at 6psi/~300tq because that's all she'll hold. 6.3.6

Comment

-

So far my wideband issue has actually been solved. I did 2 things at the same time when I resolved it. First, I moved my bung back. It's now about 8-9 inches back from the turbo. At the same time AEM stopped sending me replacements so I had to get my own. When I received my Bosch unit I put it next to the ones they were sending me and realized they had been giving me unbranded sensors. I'm not sure which was the issue (maybe both), but I'm seeing more stable AFR readings and my Bosch unit has been doing well so far.Very cool! I think you're on the right track with the 3.46; 3.73 is too short for any boosted E30. You may even find you want a 3.25 (personally I'm running a 2.93 in my turbo M30)

Your wideband issue is very strange. My understanding is that 12-18" away from your exhaust housing is just about perfect, and as long as it's mounted above the "halfway" line, i.e. the senor points out semi-vertically and not sideways/upside down, you should be OK. I wonder if there is an electrical issue sending voltage spikes to the sensor or controller, causing failure?

I feel your clutch pain too. No BMW OEM clutch from this era can hold up to anything more than ~280ft-lbs. I'm currently running E28 M5 FW/Clutch/PP and have had to stop at 6psi/~300tq because that's all she'll hold. 6.3.6

Thanks for the info on the E28 M5 setup. I was looking into that but realized I'd probably max it out lower than I wanted to be. Seeing as I just had to spend $160 on getting my flywheel usable, if I was doing it again I would probably go that route but with a decently beefy Clutchmasters setup. Oh well.Comment

-

Your wideband placement is actually fine. I have 3 dsms and my evo that have all been running sensors in the o2 housing factory location which is literally 3" from the exhaust wheel. That's where we always run them and I run them there in customer cars all the time. Going on 5+ years in my personal cars. My boosted LS truck is literally in the exact same location as yours. Those cheap sensors just suck, look up the o2 heat sink bungs they sell now, they help big time too.

Nice setup though!Comment

-

It's been super duper crunch time this last week. My girlfriend has been abroad since the 1st and is back on the 15th. Naturally I decided to set my next dyno day for the 15th and have pretty much been doing a complete overhaul of the car getting it ready.

I was unhappy with my shifter and transmission feel on my previous setup, so I picked up a semi-rebuilt trans from a guy in my local FB group. I was also having some issues with play from my Garagistic DSSR. After a few minutes on the phone with them, we had an exchange going on and the replacement they sent me is a perfect fit. I'm really such a fan of that company. They do awesome stuff and are great to work with.

So the rebuilt trans, driveshaft, shift linkage, and diff all went in over the weekend and Monday night. Fresh Redline MTL in the trans and Royal Purple 75W-140 in the diff, new OEM rubber trans mounts, poly diff bushing, driveshaft compression sleeve, all the little bits and pieces. Oh and I did the front brake pads, rotors, and lines to match the back along with a full system flush. Lame picture for proof.

No post would be complete without some goodies. Received and installed a Tial Q50 blow off valve after lots of back and forth on which one I wanted to go with. Glad I chose the Tial. The quality is incredible, just look at the presentation of the packaging. Even the v-band clamp they provide is machined from a single piece of aluminum. Insane. Excited to hear the PSHH noises.

Aaaaand lastly... I went back through the logs from my last dyno session. The tuner had pointed out that I was getting some boost creep and it turns out it was worse than I expected. In one of the logs he was loading it at 50% throttle and boost was climbing to 12 psi by 4000 rpm. This is on an 8psi internal wastegate. I plan to tune it in the 12-14 psi range depending on how much power it makes and how the clutch does with it so I was concerned about the creep going too high.

Well, it turns out that this is common on cheap unbranded turbos. A little googling and I realized I had to port my wastegate opening. Not a small task and not one I wanted to take on 3 days before the dyno appointment but I didn't have a choice. Took the turbo out fo the car and popped off the turbine housing. You can see in the picture where the wastegate flapper covers and how much smaller the port is than the flapper. Using a Dremel with a carbide cutting bit followed by a sanding wheel bit to lay down the final polish I managed to open the hole up a few mm. The biggest change though is how much I was able to open up the back of the port from a very poor right angle shape to a nice radius that should promote a lot more flow. Of course I polished the surface up as smooth as I could. I was also able to cut a bit of material away from the flange that bolts to the back of the housing. The wastegate opening is limited by this piece (opens until it's sitting against it), so my machining there should give it an extra 2ish mm of opening. Hopefully this is able to keep my boost creep levels a little more under control.

Naturally I was so tired after hours of grinding that I forgot to take pictures of my final product and it's back in the car now so you guys will just have to imagine it.

Tonight I need to finish the overhaul of my vacuum lines and hopefully get it out of the garage for a quick test drive tomorrow.

Last edited by the_eskimo_wonder; 11-13-2019, 11:19 AM.

Last edited by the_eskimo_wonder; 11-13-2019, 11:19 AM.Comment

-

Hi kids, did ya miss me? I got all kinds of fun updates for you today!

Let's start off with the important thing... dyno day round 2! Click for spooly boi sounds:

IMG_0098

IMG_0098

She made..... not enough power. Sounds nice though (you hear that whip crack blow off? Mmmmm tasty). You can see on the graph with all the runs that my torque is just not doing what it's supposed to do. I was having some boost taper with my Hallman boost controller but the bottom line is on wastegate pressure so I clearly can't blame it all on that. Basically it sounds like either my turbo sucks (ha) and isn't providing the volume or (hopefully) my ignition system is the weak link and can't keep up at higher RPMs. There's no evidence of any actual spark blowout but I've really got my fingers crossed that it's weak spark from the old stock ignition system.

Final cleaned up dyno graph is from the last run. Peaking at 14.5 psi and tapering down to about 12-13. Hallman boost controller light spring is to blame for the taper I believe. It was fully maxed out at the end.

Now the less fun part... The rebuilt trans that I swapped in ended up just not going into first gear at all from a stop. Clutch in, put it in gear, and just grinds. Could start from second no problem so was using that. Also found that if I put her in first while rolling to a stop it went in fine so drove like that for a bit, then swapped it out for another trans my buddy grabbed me.

Car was driving ok at that point. I started driving it around a lot. I had a couple overboost issues when I would really get on it so I turned the boost controller down to about 12 and have been running it there. The car is truly a blast to drive. Fast, fun, makes all the right noises. It's far from perfect but it's back to being a driving project which is always more fun that on jackstands in the garage.

Like I mentioned in my last post, I cleaned up and rerouted the engine bay vacuum lines. I also have more dedicated lines running to the different items that need vacuum for better sensing and control. Engine bay is looking decent. It will be getting some more love soon enough. I plan to do a bit of a tuck/shave, paint it in satin black, and use an M3 firewall cover to hide those wires. I've decided it's time to start elevating the level of this build. It started out as a shitbox and it's time to make it something people would pay 5 digits for. Engine bay:

Well, then disaster strikes again. The trans that I just put into the car started really not liking going into any gear from a stop. Shifted fine driving around and fell into first when rolling to a stop. This is the 4th transmission that's been in the car under my ownership (including the automatic it came with). I was not stoked and dreading the idea of changing another transmission. Decided it was worth replacing the clutch master and slave cylinders again first. The master was a used but good condition unit pulled from another car and the slave was a new unit I snagged from a parts store when I blew the seal on the OEM one I was installing during the manual swap. I replaced the master and bled the system and ended up with a mushy pedal. So... out comes the basically brand new parts store slave. 10 points to anyone that can spot the problem...

Don't buy parts store parts kids.

While I was doing all that I decided to toss in the new E32 750il brake master cylinder because might as well while I'm in there. Wasn't too happy with my pedal feeling a bit soft and requiring a lot of pedal travel when compared to the other vehicles I drive. Yes, I do understand that this is not an upgrade to actual braking system itself, just a change in pedal feel. I also can confirm that my system is fully bled with fresh fluid. So a nice and clean brake master went in, along with a cleaned up brake fluid reservoir. Side by side on the 2 masters.

Comment

Comment